Академический Документы

Профессиональный Документы

Культура Документы

Well Level

Загружено:

isabel_93_20110 оценок0% нашли этот документ полезным (0 голосов)

18 просмотров2 страницыreserva 3hfgtfg

Оригинальное название

Well Level[1]

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документreserva 3hfgtfg

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

18 просмотров2 страницыWell Level

Загружено:

isabel_93_2011reserva 3hfgtfg

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

Well Level

The well level will be the last one of the proposed methodical

approach. Specific and detailed actions should arise at the end

of it.

Within the key patterns selected, check that producers are

pumped off. If they are not, then this should be the first

opportunity to investigate before any additional drilling or

workover is performed.

It is recommended to follow injector well performance to assess plugging or fracturing of wells with rate and

wellhead pressure versus time. Additionally, use of the Hall plot to evaluate injectivity changes is

recommended, especially if changes in the water injection quality occur.

10

Well test frequency should be reviewed and prioritized

according to the knowledge gained from this multi-phased

process, such as patterns where workovers took place or where

water injection rates were modified. The team must have

confidence in these measurements, since capital expenditures

will result from them.

Figure 15 shows a producer type plot. Waterflood response

is observed when GOR decreases followed through time by

total liquid increase and then a gradually increasing water cut.

Figure 16 shows Hall plot behavior of two wells, one with

no change in injectivity and one with a drastic change that

helped the team identify a problem well with corroded casing

and out-of-zone injection.

Optimizing a Waterflood Using the Recommended

Practices

The following example from a portion of El Trapial field

shows the results that can be achieved by implementing a

good surveillance and monitoring program as described in this

paper.

The large drilling activity that took place in the field

between the years 2000 and 2003 triggered inefficiencies in

availability of the water treatment capacity, water-injection

distribution system, and electrical power supply. As a result,

some parts of the field observed steep oil declines from the

base production. Yearly nominal decline rates of as high as

33% were measured.

A pilot was set up with the objective of evaluating the

benefits of performing a more focused integrated water

injection management. An area was selected taking into

account the following criteria: low VRR, representative area

of the field, confined area, existence of spare facility capacity,

availability to increase water injection, and feasibility to

improve electrical supply conditions. Figure 17 shows the

location and pattern configuration of the pilot area.

The location of the pilot is in the central part of the main

block, where GOR, Wcut, and pressure maps along with Evol

calculations at a field level indicated room for improvement.

Block and pattern analyses were first performed in the

area, resulting in several action items. The amount of work

that was performed in the four inverted seven-spot patterns

consisted of remedial workovers in the injectors to assure that

water was going in all layers, increasing wellhead pressure in

the injection wells and ensuring that the pumped off

conditions were achieved in producers. Additionally, a

dedicated crew was assigned to the area and the highest

priority concerning energy supply was given to the area to

assure minimum power shortages.

Well test frequency was critical to assess the results of the

pilot, thus one test per week was performed in all wells. Both

producers and injectors were included in the plan.

As a result of the described work, Figure 18 shows that the

VRR ratio was increased to the desired value, total liquid

production rate increased, and the nominal oil decline rate

changed from 33% to 18% per year in a matter of about six

months.

Вам также может понравиться

- Sewage Disposal System Treatment and Recycling - Group 1Документ17 страницSewage Disposal System Treatment and Recycling - Group 1Rosevie Mae EnriqueОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- 100 Test Aarogya 2.0:: Mrs - Nisha KatouriaДокумент18 страниц100 Test Aarogya 2.0:: Mrs - Nisha KatouriaNisha KathuriaОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Bible Secrets of Moses and Solomon Vol2Документ40 страницBible Secrets of Moses and Solomon Vol2jamjam_9567885389% (80)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Ownership Data: InstallationДокумент2 страницыOwnership Data: InstallationRoshin99Оценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Assignment Schumpeter CaseДокумент1 страницаAssignment Schumpeter CaseValentin Is0% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- All About Drilling RIGДокумент5 страницAll About Drilling RIGSaroop JosephОценок пока нет

- FiltrationДокумент77 страницFiltrationmeet2abhayОценок пока нет

- 2022 CA Security Assessment and Authorization StandardДокумент25 страниц2022 CA Security Assessment and Authorization StandardDonaldОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Business Ethics ANSWERSДокумент3 страницыBusiness Ethics ANSWERSMỹ HàОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- United States Patent: (45) Date of Patent: Sep - 8, 2020Документ14 страницUnited States Patent: (45) Date of Patent: Sep - 8, 2020M FОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Reco-Cool HD Premium-N 25% Antifreeze-Coolant v4 - MSDS - 230224 - 171528Документ7 страницReco-Cool HD Premium-N 25% Antifreeze-Coolant v4 - MSDS - 230224 - 171528Jon HermanОценок пока нет

- Introduction To IoT PDFДокумент94 страницыIntroduction To IoT PDFsolbahiaОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Understanding Building Construction Types - Firefighter Nation PDFДокумент3 страницыUnderstanding Building Construction Types - Firefighter Nation PDFRakeshОценок пока нет

- How To Be A Multi-Orgasmic Woman: Know Thyself (And Thy Orgasm Ability)Документ3 страницыHow To Be A Multi-Orgasmic Woman: Know Thyself (And Thy Orgasm Ability)ricardo_sotelo817652Оценок пока нет

- A Strategic Behaviour Guidance Tool in Paediatric Dentistry: 'Reframing' - An ExperienceДокумент3 страницыA Strategic Behaviour Guidance Tool in Paediatric Dentistry: 'Reframing' - An Experiencesilky groverОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- New Tenant Welcome LetterДокумент1 страницаNew Tenant Welcome Letterkristen uyemuraОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Auto Collision 1Документ2 страницыAuto Collision 1api-252290060Оценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Transgenic PlantsДокумент27 страницTransgenic Plantsqud86Оценок пока нет

- Resume - Shady Brook Assistant PrincipalДокумент1 страницаResume - Shady Brook Assistant Principalapi-359951158Оценок пока нет

- AGR. 376 - Meat Processing Technology: Beef Fabrication and Identification of Cuts Dr. Stanley F. Kelley Fall 2000Документ22 страницыAGR. 376 - Meat Processing Technology: Beef Fabrication and Identification of Cuts Dr. Stanley F. Kelley Fall 2000EugeniuОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- W - Paul Smith, William C. Compton and W - Beryl WestДокумент5 страницW - Paul Smith, William C. Compton and W - Beryl Westefarfan26Оценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- Pile Hammer Delmag d12-42Документ1 страницаPile Hammer Delmag d12-42Jorge Rosero QuevedoОценок пока нет

- Reference Texts - Textes de RéférenceДокумент7 страницReference Texts - Textes de RéférenceSid PatelОценок пока нет

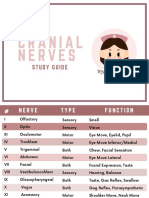

- Cranial NervesДокумент6 страницCranial Nervesvienny kayeОценок пока нет

- Legal Requirements For Starting A SME Business in Pakistan PDFДокумент12 страницLegal Requirements For Starting A SME Business in Pakistan PDFUsman AbbasОценок пока нет

- Chemical Bonding Assignment 2 AnswersДокумент5 страницChemical Bonding Assignment 2 AnswersdarylchenОценок пока нет

- Novilyn C. Pataray BSN - Ii: Assessment Diagnosi S Pathophysiolog Y Planning Interevention Rationale EvaluationДокумент1 страницаNovilyn C. Pataray BSN - Ii: Assessment Diagnosi S Pathophysiolog Y Planning Interevention Rationale EvaluationCharina AubreyОценок пока нет

- AcknowledgementДокумент2 страницыAcknowledgementSonali SinghОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- DVM Checklist PDFДокумент12 страницDVM Checklist PDFperlita elorinОценок пока нет

- Metrel D.D. - Class A Power Quality AnalysersДокумент7 страницMetrel D.D. - Class A Power Quality AnalysersMonster LifeОценок пока нет