Академический Документы

Профессиональный Документы

Культура Документы

Kerala Report

Загружено:

dpnairАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Kerala Report

Загружено:

dpnairАвторское право:

Доступные форматы

State Level Resources to Promote the Growth of Manufacturing in Kerala

State Level Actions

to

Promote Growth of Manufacturing

(Resources and Capability Review)

Kerala

Prepared for

National Manufacturing Competitiveness Council

CENTRE FOR RESEARCH, PLANNING & ACTION

July, 2012

State Level Resources to Promote the Growth of Manufacturing in Kerala

Though all care has been taken as to authenticity of various data

sources and accuracy of various presentations responsibility for any

errors that may remain as well as for opinions expressed lies with

Centre for Research, Planning & Action, New Delhi the agency that

carried out this study on behalf of NMCC.

State Level Resources to Promote the Growth of Manufacturing in Kerala

Table of Contents

Table of Contents .............................................................................................................. 3

List of Tables ..................................................................................................................... 4

List of Figures .................................................................................................................... 5

List of Annexure................................................................................................................ 5

1.

State Profile ................................................................................................................ 6

2.

Land for Industrial Purpose ................................................................................... 11

3.

Basic Infrastructure ................................................................................................ 16

4.

Profile of Logistics ................................................................................................... 18

5.

Trends of Industrial Production ............................................................................ 24

6.

Profile of Existing Industries .................................................................................. 31

7.

Raw Materials .......................................................................................................... 34

8.

Skill Profile of Manpower ....................................................................................... 35

9.

Profile of Business Environment ............................................................................ 41

10. Incentives and Schemes........................................................................................... 50

11. Conclusions and Core / Thrust Areas.................................................................... 52

State Level Resources to Promote the Growth of Manufacturing in Kerala

List of Tables

1.1: Administrative Units in Kerala ................................................................................ 8

1.2: Districts of Kerala & Areas ...................................................................................... 8

1.3: Key Demographics of Kerala.................................................................................... 9

1.4: Share & Growth Rate of Manufacturing Sector in Kerala GSDP (Current

Prices) ............................................................................................................................... 10

2.1: Land Use Pattern in Kerala .................................................................................... 11

2.2: District-wise Waste Land in Kerala ....................................................................... 12

2.3: Industrial Parks of Kerala Industrial Infrastructure Corporation (KINFRA) 14

2.4: Major Industrial Estates District Wise ............................................................... 14

2.5: Kerala SIDCO Industrial Parks in Kerala District Wise ................................. 15

3.1: Total Generation Capacity in Kerala .................................................................... 16

4.1: Ports in Kerala ......................................................................................................... 18

4.2: Road Network in Kerala ......................................................................................... 19

4.3: Communications Snapshot of Kerala .................................................................... 23

5.1: Key Industries in Kerala ......................................................................................... 24

5.2: District-wise Distribution of Operating Factories ................................................ 24

5.3: Industrial Clusters in Kerala .................................................................................. 25

5.4: Time-Series Data Showing Growth in Past 5 Years in Kerala ............................ 28

5.5: Gross Capital Formation for the State of Kerala ................................................. 29

6.1: Number of SME Units Operating in Kerala (Mar, 2011) .................................... 31

6.2: MSME Clusters in Kerala ...................................................................................... 32

6.3: Sanctioned MSME Clusters under MSE-CDP Scheme in Kerala (As on

30.6.2011) ......................................................................................................................... 32

7.1: Mineral Production in Kerala (2009-10) ............................................................... 34

8.1: Technical Education Institutions in Kerala (2010) ............................................... 36

8.3: Percentage Share of Professional & Technical Work Seekers in Kerala ........... 38

8.4: Labor Strikes Over the Year in Kerala ................................................................. 39

8.5: Company Lockouts over the Years in Kerala ....................................................... 39

9.1: Single Window Clearance Process in Kerala ........................................................ 42

9.2: No. of Applications Cleared/Disposed Since Inception ........................................ 42

State Level Resources to Promote the Growth of Manufacturing in Kerala

9.2 Special Agencies to Facilitate Industrialization ..................................................... 43

9.2: SWOT Analysis of Kerala Industrial Environment ............................................. 48

10.1: Project Lending Pre-requisites for KSIDC Financing ....................................... 51

List of Figures

Figure 1.1: Map of India Showing the Location of Kerala ........................................... 7

Figure 1.2: Sector Contribution to Kerala GSDP ........................................................ 10

Figure 3.1 Road Network of Kerala .............................................................................. 17

Figure 4.1: Railway Network in Kerala ........................................................................ 21

Figure 4.2: Airports in Kerala ....................................................................................... 22

Figure 6.1: Industry-wise State Public Sector Units in Kerala ................................... 33

List of Annexure

Annexure 1: Industry-wise Contribution to GSDP and Growth Rates ..................... 54

Annexure 2: Industrial Land with Directorate of Industries ..................................... 55

Annexure 3: Mini Industrial Estates in Kerala: District Wise ................................... 56

Annexure 4: Mineral Resources & Availability in Kerala .......................................... 57

Annexure 5: Ratio of the State on Key Characteristics of Overall and in

Manufacturing sector for India and Kerala ................................................................. 58

Annexure 6: Distribution of factories by employment in overall and manufacturing

sector in Kerala ............................................................................................................... 59

Annexure 7: Estimate of selected characteristics of factory sector by 3-digit industry

group (NIC-2008) for Kerala ......................................................................................... 60

Annexure 8: Engineering Colleges Intake in Kerala (2010-11) .................................. 63

Annexure 9: Trade Wise Intake in Polytechnics in Kerala (2010-11)........................ 64

Annexure 10: Select Manufacturing Sector Wages Rates in Kerala ......................... 65

Annexure 11: Cost of Doing Business in Kerala .......................................................... 68

State Level Resources to Promote the Growth of Manufacturing in Kerala

1.

State Profile

1.1

Introduction

1.1.1

The State has seen an average industrial growth rate of 10.56 percent at constant

prices in the last 5 years. The contributions of manufacturing sector to GSDP at constant

and current prices are 9.26 per cent and 9.33 per cent respectively during 2009-10. Some

of the key industries in the state include Handlooms & Power-looms, Rubber / Bamboo /

Coir Based Industries, Food Processing, etc.

1.1.2

The State Government has provided special support to MSMEs due to its high

employment and economic growth potential. This sector contributes greatly towards

domestic needs, export marketing and foreign exchange earnings by producing varieties

of products ranging from traditional to high tech. As on March 2010, there were about

213740 SSI/MSME units registered with a total investment of Rs. 731212.13 and direct

employment generation of 8, 31,847. Majority of the SME units operate in the Wood

Based, Food Products, Readymade Garments and General Engineering sectors.

1.1.3

For more information visit:

http://www.kerala.gov.in

http://www.ksidc.org

http://www.keralasidco.com

http://www.ibef.org/states/kerala.aspx

1.2 Location and Area

1.2.1

Kerala is located along the coastline, to the extreme south west of the Indian

peninsula, flanked by the Arabian Sea on the west and the mountains of the Western

Ghats on the east. The total area of the state is 38,863 sq km and encompasses 1.18 per

cent total land of India.

State Level Resources to Promote the Growth of Manufacturing in Kerala

Figure 1.1: Map of India Showing the Location of Kerala

The nature of the terrain and its physical features, divides an east west cross section of

the state into three distinct regions- hills and valleys with an average elevation of 1500

meters, midland and plains and the coastal region. Western Ghats is the origination of

about 44 rivers that flow in the state, 41 of which flow towards west into Arabian Sea and

3 are tributaries of River Cauvery. In the Midland Plains of central region, the hills have

slightly steep with wide valleys allowing agriculture. The Coastal Belt strip is

comparatively plain with extensive paddy fields, thick groves of coconut trees and

backwaters, interconnected with canals and rivers.

1.3 Administrative Units

1.3.1

The State of Kerala is divided into 14 Districts. Following are the administrative

units in Kerala.

State Level Resources to Promote the Growth of Manufacturing in Kerala

1.1: Administrative Units in Kerala

Districts

Revenue Divisions

District Panchayats

Taluks

CD Blocks

Revenue Villages

Gram Panchayats

Corporations

Municipalities

Region

North Kerala

Central Kerala

South Kerala

1.2: Districts of Kerala & Areas

Districts

Kannur

Kasaragod

Kozhikode

Malappuram

Wayanad

Ernakulam

Idukki

Palakkad

Thrissur

Alappuzha

Kollam

Kottayam

Panthanamthitta

Thiruvanthapuram

14

21

14

63

152

1453

978

5

60

Area (Sq.Kms)

(Sq.

kms)

2966

1992

2345

3550

2131

2931

4479

4480

3032

1414

2498

2203

2462

2192

1.4 Demographic Information

1.4.1

The state has high density of population and the number of females per males is

the highest in the country. Table 1.3 lists the key demographics of the state.

State Level Resources to Promote the Growth of Manufacturing in Kerala

Population

1.3: Key Demographics of Kerala

3,33,87,677

Male

1,60,21,290

Females

1,73,66,387

Sex Ratio

1,084

Population Density (Per Sq.Kms)

859

Literacy Rate

93.91%

Male

96.02%

Females

91.98%

Source: Census 2011

1.5 Economy of the State

1.5.1 The States economy is predominantly agrarian in nature. The Gross State Domestic

Product (GSDP) at factor cost at constant (2004-05) prices has been estimated to be

181289.12 crores for the year 2009-10, registering a growth of 9.73% over the previous

year. At current prices the GSDP is estimated to be 230315.55 crores during 2009-10,

registering a growth rate of 14.57% over the previous year.

1.5.2 The per capita State Income is estimated to be Rs. 52,984 as compared to national

income of Rs. 38,155 for 2009-10 at constant (2004-05) prices.

1.5.3 The contribution of primary sector has been decreasing and tertiary sector has been

increasing over the years, with the secondary sector remaining almost stagnant. Majority

of the economic growth in the State is due the growth in the tertiary sector. Table 1.4

lists the contribution of the three key sectors to the State GSDP.

State Level Resources to Promote the Growth of Manufacturing in Kerala

Figure 1.2: Sector Contribution to Kerala GSDP

Constant (2004-05) Prices

Current Prices

1.5.4 Annexure: I gives details on Industry-wise contribution of State GDP. Table 1.5

specifically highlights the contribution of Manufacturing Sector to the State GDP. From

the data we see that the share of Manufacturing Sector has been increasing and is also

showing higher growth rates year-on-year.

1.4: Share & Growth Rate of Manufacturing Sector in Kerala GSDP (Current

Prices)

Sector

2007-08

Growth

2008-09 Growth

2009-10 Growth

Manufacturing

15082.23

Rate (%)

8.61

Rate (%)

17865.66 8.89

Rate (%)

21477.11 9.33

Registered

6437.81

3.68

7712.89

9464.67

Unregistered

8644.42

4.94

10152.77 5.05

3.84

4.11

12012.44 5.22

Source: Economic Review 2010

1.5.5 In terms of Human Development Index and life standard of the people, Kerala is

much ahead of the most other states in India, and in fact in certain development indices, it

is on a par with some of the developed countries. This peculiar paradox often termed as

the KERALA PHENOMENON or Kerala model of development by experts, which is

mainly owing to the performance of the State in the Service Sector.

Visit: www.kerala.gov.in

10

State Level Resources to Promote the Growth of Manufacturing in Kerala

2.

Land for Industrial Purpose

Land is one of the most invaluable resources as far as state of Kerala is concerned. The

state with its dense population, is finding it difficult to satisfy the land needs of even the

most deserving categories and development initiatives.

2.1 Non-Agricultural Land

2.1.1 Kerala has a diverse land use and cropping pattern. The land reforms introduced in

the State brought in radical and comprehensive institutional changes leading to drastic

transformation in the land holding pattern and a shift in the land use pattern.

2.1.2 Agriculture is still the dominant land use type accounting for over 55% of the

geographical area followed by forest land (including degraded forest) of 28%, with only

11% under non-agricultural use. Land under non-agricultural use was 9 percent in 199900 and has increased to 9.68 per cent in 2008-09 and it slightly declined to 9.31 percent

in 2009-10. The area under cultivable waste increased by 1821 hectares, while barren and

uncultivated land declined by 7019 ha. Table 2.1 shows the land use pattern in Kerala.

2.1: Land Use Pattern in Kerala

Classification of Land

2009-10

2008-09

Hectares Percentage Hectares Percentage

Total Geographical Area

3886287 100

Forest Cover

1081509 28

Land for Non-Agricultures Uses

361695

9

Barren and Uncultivated Land

17912

0.50

Permanent Pastures and Grazing Land 96

Land under Miscellaneous Tree Crops 4423

0.10

Cultivable Land

98014

3

Fallow other than current fallow

45374

1

Current Fallow

76945

2

Net Area Sown

2180679 56

Area Sown more than once

488026

13

Total Cropped Area

2668705 69

Source: Directorate of Economics & Statistics, Govt. of Kerala

3886287

1081509

376155

24931

229

6602

96193

45955

67759

2088955

605988

2694943

100

28

10

1

0

0

2

1

2

54

16

69

11

State Level Resources to Promote the Growth of Manufacturing in Kerala

2.2 Waste Land

2.2.1

As per the data available with Department of Land Resource, the total waste land

available in Kerala is 2458.7 hectares.

2.2.2

Table 2.2 shows the district wise waste land in the state.

2.2: District-wise Waste Land in Kerala

District

Waste Land (Hectares)

Alappuzha

1.32

Kannur

201.24

Ernakulam

103.95

Idukki

449.57

Kasaragod

322.54

Kollam

45.77

Kottayam

120.5

Kozhikode

92.76

Malappuram

203.16

Palghat

457.86

Panthanamthitta

111.36

Thiruvananthapuram

182.99

Thrissur

80.72

Wayanad

84.96

Source: Department of Land Resources, Ministry of Rural Development, GoI

2.3 Industrial Land Bank

2.3.1 Availability of developed Industrial area

2.3.1.1 A major challenge for industrial development in the State is the non-availability

of adequate land. The State Government is in the process of acquiring land at strategic

locations of the state for orderly development of industries. Such lands will be kept as

land bank for future industrial and infrastructure requirements.

2.3.1.2 In its Industrial Policy 2007, the Government has encouraged recognizing leasing

of land for industrial and commercial purpose as equity participation by the landowners.

A Fast Track Mechanism is also being devised for transparency in land acquisition and its

12

State Level Resources to Promote the Growth of Manufacturing in Kerala

utilization for the development of infrastructure through Public Private Partnerships, and

to address the address the concerns of the landowners through a time-bound

implementation of attractive rehabilitation schemes.

2.3.1.3 To avoid the situation of non-availability of land for future expansion /

implementation of latter phases of project, the developer will be allowed a call option

on buying adjacent land in future by remitting an annual premium to the Government for

a fixed period. The appropriate market value of the land will be provided to the

landowner.

2.3.1.4 The Government is also making provisions for the conversion of Industrial land

/plots into Industrial Parks / Commercial Estates, in cases where the established industry

remained in production for at least 5 years. Any industry, which commenced production,

but has been closed due to Court Order / Government Order / declared sick by BIFR, will

also be considered for conversion, in relaxation of the condition of being in production

for 5 years.

2.3.1.5 Existing DA, DP, IE, Growth Centers etc. are being modernized, expanded and

upgraded to meet the requirements of the industry. Any unused land / unused

infrastructure facility already allotted will be resumed and reallocated for starting new

units. Distribution of Pattayam for DA / DP plots will be done on a fast track basis.

SIDCO plots will be allotted expeditiously. Industrial plots will not be utilized for non

industrial purposes and speculation of land will not be allowed. Annexure 2 provides the

details on the land available in the Industrial Estates being developed by the Directorate

of Industries.

2.3.1.6 Kerala Industrial Infrastructure Corporation (KINFRA) is another agency

responsible for the development of industrial land. Table 2.3 gives details on the land

available in KINFRA Industrial Parks. KINFRA is currently developing the following

new parks,

Kera Park Thrissur

13

State Level Resources to Promote the Growth of Manufacturing in Kerala

KINFRA Spices Park Idukki

KINFRA Rubber Park Panthanamthitta

Visit: www.kinfra.org

2.3: Industrial Parks of Kerala Industrial Infrastructure Corporation (KINFRA)

District

Thiruvananthapuram

Name of Industrial Park

KINFRA International Apparel Park

Available Land (Acres)

5.05

Panthanamthitta

KINFRA

Park,

Adoor

Food Processing / General

KINFRA Park, Kunnamthanam Land

Built up space

KINFRA Park, Mazhuvannur Food Zone

28.10

Panthanamthitta

Ernakulam

Malappuram

2.00

8500 sq.ft

2.80

Palakkad

KINFRA Food Processing Park, Kakkancherry

Special Economic Zone

KINFRA Industrial & Textile Park, Kanjikode

15.00

90.00

Wayanad

KINFRA Park, Kalpetta (Undeveloped land)

12.00

Kannur

KINFRA Park, Thalaserry

3.75

Kannur

KINFRA Textile Centre, Nadukani

57.85

Kasaragod

KINFRA Park, Seethangoli

1.00

Source: Kerala Industrial Infrastructure Corporation

2.3.1.7 Kerala Small Industries Development Corporation (SIDCO) is the agency

responsible for developing industrial estates for Micro & Small Enterprises. At present

there are 19 Development Area/Plot, 17 Major Industrial Estates, 3 Functional Estates

and 111 Mini Industrial Estates in the Co-operative and SIDCO series in the State.

Annexure III provides the details on land availability in Mini Industrial Estates. Table 2.4

gives district wise available land in Major Industrial Estates of Kerala SIDCO.

2.4: Major Industrial Estates District Wise

District

Industrial

Estate

Total

Land

Available

Land

District

Industrial

Estate

Total

Land

Available

Land

Alappuzha

Kollakadavu

19.15315

50 cents

Kottayam

Ettumanoor

30.31

55 cents

Alappuzha

Cherthala

8.94

20 cents

Kozhikode

West Hill

12.44

Nil

Ernakulam

Palluruthy

1.86

Nil

Malappuram

Manjeri

4.99

Nil

Ernakulam

Mudickal

4.6215

Nil

Palakkad

Karakkad

10.96

4 cents

Kannur

Palayad

8.42

Nil

Palakkad

Olavakkode

21.93

2.98 acre

Kasaragod

Kasaragod

16.84

26.0343

Pappanam

code

Kallettum

Nil

Umayanalloor

Thiruvanan

thapuram

Thrissur

18.5327

Kollam

39.81

cents

15

cents

Nil

Kollam

Karunaga

ppally

Changana

cherry

8.63

35 cents

Thrissur

Ollur

29.5625

Nil

14.22

Nil

Kottayam

Source: Kerala Small Industries Development Corporation (KSIDCO)

14

State Level Resources to Promote the Growth of Manufacturing in Kerala

Visit: www.keralasidco.com

2.3.1.8 Kerala SIDCO has established an Industrial Park in every constituency in charge a

separate Industrial Parks division. Table 2.5 provides details on the land available in the

industrial parks.

2.5: Kerala SIDCO Industrial Parks in Kerala District Wise

Name of Project

Total Area

Allocable Area (Acres)

(Acres)

Area

Allotted

Available

(Acres)

(Acres)

Athani

11.81

7.07

6.94

0.13

Chelakkara

5.0251

4.2

Fully Allotted

Angamali

15.39

13.47

12.2067

1.2633

Moodadi

3.7778

3.0373

Fully Allotted

Shoranur

5.0104

3.8793

Fully Allotted

Thiruvarpu

1.34

1.0295

Fully Allotted

Kunnamthanam

1.5(3.5 Acres handed Under

over to CWC)

Area

1.5

Progress

Source: Kerala Small Industries Development Corporation (KSIDCO)

2.3.1.9 The major hurdle which comes in the way of the industrial development in the

state has been the inadequate infrastructure facilities. The Government intends to give

topmost priority to develop world-class infrastructure facilities to attract massive

investments in manufacturing and service sectors. The Government has evolved special

schemes to build up such facilities to convert the State into an investment friendly

destination. The initiatives include:

1. A proposed infrastructure company, Infrastructures Kerala Limited (INKEL), to

facilitate accelerated development of industrial infrastructure to attract massive

investment.

2. Develop major industrial water supply projects, power supply projects, sewerage

and effluent treatment plants etc., in industrial areas.

3. Ensure uninterrupted supply of quality power for industrial and commercial

purpose.

15

State Level Resources to Promote the Growth of Manufacturing in Kerala

3.

Basic Infrastructure

3.1 Power

3.1.1

Kerala is one among the few Indian states which have the lowest rates for

electricity for both domestic and commercial outfits. Kerala State Electricity Board is the

sole distributor of the electricity for the state of Kerala except for Thrissur Corporation

and Munnar where the distribution is managed by City Corporation and Tata Tea Ltd

respectively. There is a huge shortage of power from last few years and the State

Government is facing difficulties in providing sufficient power to the industries. Table

3.1 listes the current generation capacity in the state.

3.1: Total Generation Capacity in Kerala

Sr. No. Source

Generation Capacity (MW)

1

Hydro

1780 MW

2

Thermal

430 MW

3

Nuclear

0

4

New & Renewable

140 MW

Total

2350 MW

Source: Energy Statistics 2011, MOSPI, Govt. of India

3.2 Water Supply

3.2.1

Kerala has many important rivers that flow from north to south; Valapattanam

river (110 kms.), Chaliar (69 kms.), Kadalundipuzha (130 kms.), Bharathapuzha (209

kms.), Chalakudy river (130 kms.), Periyar (244 kms), Pamba (176 kms), Achancoil (128

kms.) and Kalladayar (121 kms.). Other than these, there are 35 more small rivers and

rivulets flowing down from the Ghats.

3.2.2

The average per capita supply of water in major cities is 150 to 200 liters per

capita day. There are 1,745 rural water supply schemes and 69 urban water supply

schemes. To ensure uninterrupted supply of industrial water, the State Government has

proposed to develop major water supply projects in industrial areas. The current tariffs

for industrial use of water is Rs25/- per 1000 liters with a minimum charge of Rs. 250/-.

16

State Level Resources to Promote the Growth of Manufacturing in Kerala

3.3 Roads

3.3.1

Roads are one of the basic modes of transportation system and also an important

priority sector of infrastructure. Systematic development of road is one of the important

pre-requisites for development and acceleration of growth in the economy. Among the

different modes of domestic transport systems, road transport carries more than 80

percent of the goods and passenger traffic. The network of roads, particularly from rural

to urban facilitates speedy movement of goods and services and ensures higher growth

trends, social integrity and well-being of the society. The productivity and efficiency of

road transport is directly linked with the availability and quality of road network.

3.3.2

Kerala has the highest road density among other Indian states and a well-

developed transport system operated by both public and private sector, thus enabling a

seamless movement of people and goods across the state.

3.3.3

Road density in the State is 417 Km/100 Sq.Km, which is far ahead of national

average of 100.39 Km/100 Sq.Km. The length of road per lakh population is 509.23 Km,

which is also much higher than the national average of 321.3 Km.

Figure 3.1 Road Network of Kerala

17

State Level Resources to Promote the Growth of Manufacturing in Kerala

4.

Profile of Logistics

4.1 Geographical Proximity to Ports

4.1.1

The State with a coastline of 590 kilometers has one Major port, 3 Intermediate

ports and 14 Minor Ports. Besides the Port of Kochi (a Major Port governed by Major

Port Trusts Act, 1963), there are 3 Intermediate and 14 Minor Ports in Kerala. Table 4.1

list all the ports operating in the state.

4.1: Ports in Kerala

Type

Locations

Major Port

Kochi

of Form Alappuzha, Kozhikkode

Intermediate Ports Top

Neendakara,

Minor Ports

Vizhinjam, Valiyathura, Thankasserry, Kayamkulam, Manakkodam,

Munambam,

Ponnani,

Beypore,

Vadakara,

Thalasserry,

Manjeswaram, Neeleswaram, Kannur, Azhikkal and Kasaragod

Source: Govt. of Kerala

4.1.2

The Major Port of Kochi is under the Ministry of Shipping, Government of India

while the intermediate and minor ports are under the administration of the Government of

Kerala. Most of the minor and intermediate ports in the State are seasonal in nature and

are underdeveloped. The Kochi Port, with container handling facility, is one of the most

modern international seaports in the country. It spreads over 827 hectares and has a water

frontage of 7.5 Km. An International Container Transshipment Terminal is being

developed at Vallarpadam in Kochi, completion of which would make the Kochi port a

major hub port in the Indian Ocean region.

4.1.3

The State Government has plans to provide a boost to coastal shipping with the

development of ports to ease the burden on the heavily congested highways in the State.

They have allowed private investment in Intermediate and Minor Ports from

1994.Government has also decided to develop a Deep Water Container Transshipment

Terminal at Vizhinjam in Thiruvananthapuram through PPP mode. The Terminal when

completed would be able to cater to container vessels up to 8000 TEUs in the initial

phase and 10000 to 12000 TEUs sizes in the subsequent phases.

18

State Level Resources to Promote the Growth of Manufacturing in Kerala

4.1.4

Canals link the lakes and backwaters to facilitate an uninterrupted inland water

navigation system from Thiruvananthapuram to Vadakara, a distance of 450 kms. The

Vembanadlake stretching from Alappuzha to Kochi is the biggest water body in the state

and is over 200 sq.kms. in area. Kuttanad in Alappuzha district alone has more than 20

per cent of India's total length of waterways. Waterways are successfully used for

commercial Inland Water Transport using locally-made crafts and passenger vessels. The

Inland waterways in Kerala including navigable portions of rivers area are about 1687

kms. The West Coast Canal also called National Waterway III stretching from Kovalam

in the South to Hosdurg in the North is being renovated for commercial transport.

4.2 Spread & Quality of Road Network

4.2.1

Kerala has the highest road density among other Indian states and a well-

developed transport system operated by both public and private sector, thus enabling a

seamless movement of people and goods across the state. Table 4.2 lists the length of

road network in the state.

4.2: Road Network in Kerala

Sr. No.

Type

1

National Highways

1542

2

State Highways

4655

3

Major District Roads

17117

Total

23314

Source: PWD, Govt. of Kerala

4.2.2

Length (Kms)

The State Government has established Roads and Development Corporation of

Kerala Ltd (RBDCK) on 23rd September 1999 for building and strengthening

infrastructure facilities for the overall development of the state. RBDCK is intended to

give a thrust for multifaceted growth in transport infrastructure by generating additional

resources through institutional finance, market borrowing and private participation.

4.2.3

The Kerala Road Fund Board has been set up by the Kerala State Public Works

Department to bring in greater private sector participation into developmental activities

like:

19

State Level Resources to Promote the Growth of Manufacturing in Kerala

Promoting Public Private Sector participation in Infrastructural projects

Funding Feasibility Studies for Innovative Road Projects

Constructing new roads wherever necessary

Implementing Road Safety Projects as are found essential for safe and smooth

movement of traffic

Funding Research related to maintenance and development of roads

Developing existing road network systems including upgrading roads maintained

by the PWD

Implementing futuristic projects like Rapid Transit Systems and Metro Rail

Projects in Cities

4.3 Spread & Quality of Rail Network

4.3.1

The Indian Railways has spread its impressive network in Kerala connecting the

state with all the major cities of the country. A number of long distance trains operate

from Kerala to these locations on a daily basis. The Railway division at

Thiruvananthapuram, Palakkad and Madurai (Tamil Nadu) jointly carry out transport

operations in Kerala. The railway network extends over 1148 route Kms in Kerala of

which 111.14 km are meter gauge. The total route length of Railways in

Thiruvananthapuram Division is 625.80 km.

20

State Level Resources to Promote the Growth of Manufacturing in Kerala

Figure 4.1: Railway Network in Kerala

4.4 Spread & Quality of Air Network

4.4.1

The state has three International Airports at Thiruvananthapuram, Kozhikode and

Kochi, of which the first two are owned by Govt. of India. The Cochin International

Airport is the first Greenfield airport in India setup on Public Private Partnership model.

21

State Level Resources to Promote the Growth of Manufacturing in Kerala

Figure 4.2: Airports in Kerala

Together, they have handled 45,715 international flights, carrying 4.9 million passengers

and 36,598 domestic flights carrying 1.9 million passengers in 2008-09.

4.4.2

Besides expansion of the existing airports, two more airports are about to come up

in the State, one at Kannur district and the other at Aranmula in Panthanamthitta district.

These airports will not only cater to the large overseas community of Keralites, but also

help the tourism sector of Kerala with more connectivity and easy flying across the state.

22

State Level Resources to Promote the Growth of Manufacturing in Kerala

4.5 Quality of Communication

4.5.1

Kerala has a tele-density of 80 per cent as compared to an all-India average of

52.7 per cent as of March 2010. The state has 1,242 automatic telephonic exchanges, of

which about 98% have Internet connectivity through the national Internet backbone.

According to estimates by the Telecom Regulatory Authority of India, Kerala had nearly

24.2 million wireless subscribers and 3.5 million wire-line subscribers as of March 2010.

Table 4.3 gives a snapshot of the communications in the state.

Visit: www.scribd.com/doc/54987552/kerala-190111

4.3: Communications Snapshot of Kerala

GSM cellular subscribers: 18,873,340

Internet/broadband subscribers: 1,059,800

Wireless subscribers: 24,194,621

Wire-line subscribers: 3,460,358

Post offices: 5,070

Telephone exchanges: 1,242

Source: Economic Review 2010

4.5.2

The state also has the highest penetration of optic fiber cable network in the

country and VSNL has an international communication gateway at Kochi with two highspeed submarine cable landings (SEA-ME-WE-3 and SAFE) offering 15Gbps bandwidth.

23

State Level Resources to Promote the Growth of Manufacturing in Kerala

5.

Trends of Industrial Production

The State has had an average Industrial growth rate of 10.56 at constant prices in the last

5 years. The contributions of manufacturing sector to GSDP at constant and current

prices are 9.26 per cent and 9.33 per cent respectively during 2009-10. Table 5.1 lists the

key industries in the state.

5.1: Key Industries in Kerala

Handlooms & Power-looms

Cashew

Rubber-based Industries

Beedi

Bamboo-based Industries

Mining

Coir-based Industries

Tourism

Khadi & Village Industries

Food Processing

Sericulture

Spices & Spice Extracts

Seafood & Marine Products

Table 5.2 gives the district wise distribution of operating factories from 2007 to 2009.

5.2: District-wise Distribution of Operating Factories

District

2007

2008

Thiruvananthapuram

988

989

Kollam

1827

1827

Panthanamthitta

2801

2823

Alappuzha

412

418

Kottayam

231

231

Idukki

1273

1273

Ernakulam

1508

1510

Thrissur

1039

1041

Palakkad

1948

1969

Malappuram

622

622

Wayanad

2063

2064

Kozhikode

2529

2547

Kannur

895

896

Kasaragod

118

118

Source: Economic Review 2010

2009

994

1820

2822

419

244

1274

1535

1036

1968

623

2065

2544

895

120

24

State Level Resources to Promote the Growth of Manufacturing in Kerala

5.1 Nature of Industries

Micro, small and medium enterprises (MSMEs) sector contributes significantly to the

manufacturing output, employment and exports of the country. It is estimated that in

terms of value, the sector accounts for about 45 percent of the manufacturing output and

provide employment about 66 million persons in over 29 million units throughout the

country. In fact, it provides the maximum opportunities for both self-employment and

jobs next only to agriculture sector.

5.3: Industrial Clusters in Kerala

District

Industries

Kannur

Handlooms, Power-looms, Beedi

Allepey

Coir Products

Idukki

Agriculture & Forest Based

Thiruvananthapuram

Handlooms, IT

Thrissur

Power-looms, Handlooms, Textile, Timber, Tile, Canning

Palakkad

Power-looms, Sericulture

Kollam

Minerals & Mining

Kozhikode

Rubber

Wayanad

Minerals & Mining

Kasaragod

Minerals & Mining

Kottayam

Rubber, Food Products, Engineering

Ernakulam

IT

Source: Directorate of Industries, Govt. of Kerala

5.1.1 Food Processing

Food processing industry has been recognized as a priority sector in Kerala due to its

potential for future growth and possibility of generating substantial employment. Kerala

Industrial Infrastructure Development Corporation (KINFRA) has been playing a pro

active role for the promotion of food processing industry in the State. KINFRA has set up

a number of food-theme based parks in the State. Being a priority sector, KINFRA has

also set up industrial parks to suit the specific needs of the food processing sector.

KINFRA Food Processing Park at Kakkancherry, Special Economic Zone (Food

Processing) at Kakkanchery, Food Processing Zone in KINFRA Small Industries Park,

25

State Level Resources to Promote the Growth of Manufacturing in Kerala

Mazhuvannur, KINFRA Food Processing Park at Adoor and Seafood Park India Private

Ltd at Aroor are the five Food Processing Industries parks already set up by KINFRA.

5.1.2 Handloom Industry

Handloom Industry is a major traditional industry of Kerala and this sector stands second

to the coir sector in providing employment to about 1.00 lakh persons. Handloom

industry in the State is mainly concentrated in Thiruvananthapuram and Kannur districts

and in some parts of Kozhikode, Palakkad, Thrissur, Ernakulam, Kollam and Kasaragod

districts.

The Handloom industry in Kerala is dominated by co-operative sector with 94% looms

and remaining 6% of handloom units owned by industrial entrepreneurs. The cooperative sector consists of both factory and cottage type societies. The largest number of

co-operative societies is in Thiruvananthapuram district, which accounts 53% of the total,

and the lowest in Wayanad and Panthanamthitta districts. The major products in

handloom sector of the State are dhothies, furnishing material, bed sheets, grey sarees and

lungi, which accounts for 67 percent of the total production in the industry. About 80.13

percent of the major handloom cloths are produced in the Southern region of the State

followed by the North (12 percent) and Central region (7.87 percent).

The overall production of handloom cloth by Handloom Industry of Kerala increased

from 20.20 million meters in 2008-09 to 23.95 million meters in 2009-10. The total value

of production also shows an increase from Rs. 146.38 crores in 2008-09 to Rs. 165.33

crores in 2009-10.

5.1.3 Coir Industry

Kerala accounts for 95 per cent of the total coir and coir products produced in India. The

coir industry provides employment to 383,000 workers. The Alappuzha district of Kerala

contributes around 90 per cent to the total coir produced in the state. The state has three

coir parks, two at Alappuzhaand one at Perumon, in Kollam. The Coir Co-operative

Marketing Federation (COIRFED) is the apex federation of around 819 coir cooperatives. USA is the largest importer of coir products from India, followed by the

European Union.

26

State Level Resources to Promote the Growth of Manufacturing in Kerala

5.1.4 Power-loom

Power-loom industry employs about 0.1 million people and ranks second among the

traditional industries of the state in terms of providing employment. The industry is

concentrated in the districts of Palakkad, Kozhikode, Thrissur, Ernakulam, Kollam and

Kasaragod. Around 94 per cent of the total number of looms is under the cooperative

sector, the rest being under industrial entrepreneurs. At the end of March 2009, there

were 676 registered primary handloom weavers co-operative societies (PHWCS),

consisting of 150 factory-type societies and 526 cottage-type societies. The overall

production of cloth in the co-operative sector of Kerala was 20.2 million meters in 200809, valued at US$ 32 million.

5.1.5 Electronics

The self-contained Electronics Technology Park at Technopark, Thiruvananthapuram,

has been instrumental in attracting global electronics manufacturers. The state has an

advantage of the availability of skilled and semi-skilled workers for the electronics

industry. Major companies operating in this sector include Traco Cable Company

Limited, Transformers & Electricals Kerala Limited and Kerala State Electronics

Development Corporation Limited.

5.2 Quantum of Output

5.2.1 Table 5.4 shows time series data series showing growth in past five years in Kerala

from 2003-2004 till 2008-2009.The No. of Factories, Value of Output, Net Value Added

shows a uneven trend. There was decrease in no. of Factories in 2006-2007 over previous

years and shown a marginal increase from 2007-2008 till 2008-2009.The Value of Output

shows a increasing trend from 2003-2004 till 2005-2006.Thereafter it declined and shown

a increasing trend during 2008-2009.The Net Value Added was highest during 20072008.It showed a decline during 2008-2009. Similar time series data based on several

characteristics is depicted in Annexure 7. Annexure 6 lists the distribution of factories

employment in overall and manufacturing sector in Kerala.

27

State Level Resources to Promote the Growth of Manufacturing in Kerala

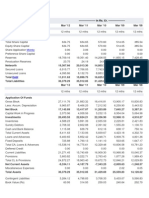

5.4: Time-Series Data Showing Growth in Past 5 Years in Kerala

Year

Characteristics

No. of Factories Value of Output

Net Value Added

2003-04

5491

3183189

409114

2004-05

5493

3611959

406601

AGR

0

13

-1

2004-05

5493

3611959

406601

2005-06

5643

4326786

446784

AGR

3

20

10

2005-06

5643

4326786

446784

2006-07

5554

5057943

355895

AGR

-2

17

-20

2006-07

5554

5057943

355895

2007-08

5584

5556577

592824

AGR

1

10

67

2007-08

5584

5556577

592824

2008-09

5868

7090489

770511

AGR

5

28

30

ACGR%

1.3

17.4

13.5

* Annual Growth Rate * Annual Compounded Growth Rate

Source: Annual Survey of Industries, Ministry of Statistics, Planning & Implementation,

GoI., 2003-2008

5.2.2 Gross Capital Formation (GCF) Gross capital formation had witnessed a huge

growth between 2003-04 and 2004-05 followed by sluggish growth between 2004-05 and

2005-06. The GCF had declined by about 30% between 2005-06 and 2006-07, followed

by another huge growth of 105%. Between the years 2007-08 and 2008-09, it declined by

56%. Table 5.5 lists the gross capital formation for the period between 2003-04 and

2008-09.

28

State Level Resources to Promote the Growth of Manufacturing in Kerala

5.5: Gross Capital Formation for the State of Kerala

Characteristics

Gross Capital Formation (Rs.)

2003-04

84491

2004-05

222346

AGR

163

2004-05

222346

2005-06

230537

AGR

4

2005-06

230537

2006-07

161708

AGR

-30

2006-07

161708

2007-08

330916

AGR

105

2007-08

330916

2008-09

146806

AGR

-56

ACGR%

12.00

* Annual Growth Rate * Annual Compounded Growth Rate

Source: Annual Survey of Industries, Ministry of Statistics, Planning & Implementation,

GoI., 2003-2008

5.3 Efficiency

5.3.1

Annexure 5 lists the ratio of key characteristics of efficiency of industry for

overall industry and in particular the manufacturing sector for India and Kerala. The fact

of the manufacturing sector not being a core sector of the State is evident in the ratio,

where the state is a lot lower on the characteristics.

5.4 Constraints

5.4.1 Availability of Land Due the high density of population, there is a shortage of

industrial space in the state. Most of the industrial parks and estates have already been

fully allotted and the State Government is in the process of acquiring new land for

development. Until then there could be no major expansion of the industry in the state.

29

State Level Resources to Promote the Growth of Manufacturing in Kerala

5.4.2 Infrastructure The State is also facing the issues of inadequate and

underdevelopment infrastructure, particularly in Power and Logistics sectors. The State

Government has plans to develop rivers and backwaters to establish an Inland Waterways

System and ease the traffic on the road network.

5.4.3 Power Shortage The State is currently facing a huge shortage of power supply and

there have been constant power-cuts for industries. Due the lack of available land for

power projects and environmental concerns, there could be no new power projects be

established in the State.

5.4.4 Environmental Issues The State has a huge green cover and there have been issues

for developing factories which release pollutants. The current regulations also delays the

process of environmental permits for new units.

5.4.5 Greater Focus on Less Labor Intensive Jobs Over the years the service industry in

the state has developed immensely attracting manpower from the state. This has led to a

shortage of skilled manpower for labor intensive manufacturing jobs.

5.4.6 Raw Material Shortage Rubber-based Industries are prominent in the State and

currently there is a shortage of the raw material due to issues such as small landholding of

rubber plantations etc

30

State Level Resources to Promote the Growth of Manufacturing in Kerala

6.

Profile of Existing Industries

6.1 SMEs

6.1.1 Micro, small and medium enterprises (MSMEs) sector contributes significantly to

the manufacturing output, employment and exports of the country. In Kerala, the State

Government has provided special support to MSMEs due to its high employment and

economic growth potential. This sector contributes greatly towards domestic needs,

export marketing and foreign exchange earnings by producing variety of products

ranging from traditional to high tech. Though the volume of production of MSME sector

is very large, the quality of production, diversification of products, energy consumption

and environmental effects has always been a concern.

6.1.2 As of March 2010, there were about 213740 SSI/MSME units registered in the

state. The total investment in the tune of Rs. 731212.13 lakhs, the total number of

employment generated is 831847 and value of goods and services produced is Rs.

1545949 lakh. Table 6.1 lists number of SME units operating in the state based on

industry type. Table 6.2 lists the key MSME Clusters operating in Kerala.

6.1: Number of SME Units Operating in Kerala (Mar, 2011)

Industry

No. of Units Industry

No. of Units

Type

Operating

Type

Operating

Wood Based

1057

Mobile Phone Repairing

97

Food Products

1619

Rexin Products

185

Readymade Garments

1553

Wax Candles

79

Cement Products

766

PVC Products

133

General Engineering

1821

Mineral Water

31

Software Development

504

Paper Products

175

Marine Products

26

Printing

324

Rubber Products

143

Miscellaneous

3235

Products/Services

Fiber Glass Products

30

Total

11778

Source: Directorate of Industries, Govt. of Kerala

31

State Level Resources to Promote the Growth of Manufacturing in Kerala

6.2: MSME Clusters in Kerala

District

Location

Product

District

Alappuzha

Alappuzha

Coir & Coir Kollam

Ernakulam

Ernakulam

Rubber

Kottayam

Ernakulam

Ernakulam

PowerMalappuram

Ernakulam

Kochi

Sea Food Palakkad

Kannur

Kannur

PowerSource: MSME Institute, Thrissur

Location

Kollam

Kottayam

Malappuram

Palakkad

-

Product

Coir &

Rubber

PowerPower-

6.1.3 The Kerala Bureau of Industrial Promotion (K-BIP) is coordinating the Cluster

Development activities throughout the State in association with Directorate of Industries

and Commerce. It coordinates the implementation of setting up of Common Facility

Centers (CFCs) in clusters as per MSMEEDP scheme of Government of India. Table

below provides details on clusters that have been sanctioned under this scheme. Table 6.3

lists the sanctioned MSME clusters under the MSE-CDP Scheme in Kerala.

Visit: www.kerala.gov.in

6.3: Sanctioned MSME Clusters under MSE-CDP Scheme in Kerala (As on

30.6.2011)

Name of Cluster

Location

Total Investment

(Rs. Lakhs)

Rubber Cluster

Plastic Cluster

Plywood Manufacturers

Terra Tile Cluster

Furniture Cluster

Rice Millers Cluster

Wood Cluster

General Engineering Cluster

Changanacherry, Kottayam

Aluva, Ernakulam

Perumbavoor, Ernakulam

Thrissur

Ernakulam

Kalady, Ernakulam

Malappuram

Malappuram

266.54

490

417.23

499.3

496.58

713.4

238.9

315.01

Ethnic Food Processing Cluster

Pala, Kottayam

454.86

Printers Clusters

Ernakulam

Nature Fiber& Allied Products Vaikkom, Kottayam

Cluster

253

485

Source: Directorate of Industries, Govt. of Kerala

6.1.4 There were further proposals submitted by the State Government to Central

Government for developing the following clusters,

32

State Level Resources to Promote the Growth of Manufacturing in Kerala

1. Wood Cluster at Chadayamangalam, Kollam

2. Wood Furniture Cluster at Kannur

3. Agriculture Implements Cluster at Shoranur, Palakkad

4. Offset Printers Cluster at Kannur

5. Toys Cluster at Kottayam

6. Garments Cluster at Kollam

6.2

Large Industries

6.2.1 There are 63 State Public Sector Units (SPSUs) under the Industries Department out

of which, 17 have remained closed for long periods. Five are welfare corporations and

four are developmental agencies. Thirty seven companies are directly engaged in

manufacturing activities. Table 6.4 gives a break up of SPSUs based on type of industry.

Figure 6.1: Industry-wise State Public Sector Units in Kerala

Source: Economic Review 2010

The PSUs have been showing a trend of growth, both in respect of turnover and profit,

compared to the performance during the preceding years. It is observed from the

performance of 37 PSUs, only 5 units are functioning in losses and it is mainly seen in

the co-operative sector.

33

State Level Resources to Promote the Growth of Manufacturing in Kerala

7.

Raw Materials

7.1 Description

7.1.1 The State is endowed with a variety of mineral resources; however they are not

available in plentiful amounts. There are occurrences/deposits of minerals such as Heavy

Mineral Sands ( Ilmenite, Rutile, Zircon, Monazite, Sillimanite), Gold, Iron ore, Bauxite,

Graphite, China Clay, Fire Clay, Tile and Brick Clay, Silica Sand, Lignite, Limestone,

Limeshell, Dimension Stone (Granite), Gemstones, Magnesite, Steatite etc. Mining

activities are largely confined to few minerals such as Heavy Mineral Sands, China Clay

and to a lesser extent Limestone/Limeshell, Silica Sand and Granite. Heavy mineral sand

and China Clay contribute more than 90% of the total value of mineral production in the

State. Table 7.1 listed the mineral production in Kerala for 2009-10.

7.1.2 There are extensive deposits of white clay and commercially valuable deposits of

graphite, lignite (brown coal), limestone, and mica in Kerala. Iron ore has been found at

Calicut. Kerala's monazite, magnetite, sillimanite, and zircon deposits are largely

undeveloped. Apart from this the beach sand of Kerala is rich in radioactive elements.

Although it has been proved that there are deposits of gold at some places of Wayanad,

Kozhikode and Malappuram districts, mining is yet to start. Neendakara, Chavara and

Kayamkulam regions have ample deposits of illuminate, magnetite, zircon etc. Kerala

State Mineral Development Corporation and the Mining and Geology Department play

the lead role in mining and research. Annexure 4 lists the location and mineral reserves.

7.1: Mineral Production in Kerala (2009-10)

Mineral

Production (Tons)

Mineral

Production (Tons)

China Clay

947619.8

Quartz

1145

Ilmanite

162066.67

Graphite

820

Rutile

8226.71

GBS

9765296.19

Zircon

16002.89

GDS

1109.65

Sillimanite

7310.29

Laterite

1322706

Silica Sand

179758.6

Brick Clay

1201741.1

Limeshell/Sea shell

85395.36

Ordinary Sand

2679072.5

Lime stone

686549.04

River Sand

5248901.6

Bauxite/Laterite

110451.44

Source: Directorate of Mining & Geology

34

State Level Resources to Promote the Growth of Manufacturing in Kerala

8.

Skill Profile of Manpower

A long tradition of literacy and quality education has been the core strength of Kerala.

According to the 2011 census, Keralas literacy rate is 93.91%; well ahead of the national

average. With several reputed universities and technical institutions like engineering

colleges, institutes for information technology and management, research institutions, etc,

Kerala has the densest cluster of Science & Technology personnel in the country. The

large pool of educated and skilled human resource has substantial exposure to the best

practices of global business requirements thereby providing the state with the right

platform for social and economic growth.

Concerted effort is being made by the State Government for skill upgradation of work

force to match the world standards. The Government has plans for the formulation of a

scheme for capacity development of human resources for the next 20 years involving

premier institutes in the domain. A task force is being created to identify the skill sets

required for modern industries, setting up of finishing schools to meet the requirements

on the basis of the recommendations of the task force and establishing Management

Institutes for Micro Enterprise Development.

A number of factors are converging to create skills imbalance in the economy changing

age of the workforce, larger generation of young workers and available resources,

changing nature of jobs from agrarian to manufacturing to servicing, need for

investments in training vis--vis growth requirements, and insufficient workforce

planning, to name a few.

8.1 Database of Training Institutions

8.1.1 The education system in Kerala is well established with infrastructure ranging from

primary schools to colleges of higher education. The state has allowed the setting up of a

number of private colleges, especially engineering colleges to supplement the

government colleges.

35

State Level Resources to Promote the Growth of Manufacturing in Kerala

8.1.2 As of 2010 there are about 119 engineering colleges in the state with a total

sanctioned intake of 38009. Out of these engineering colleges, 105 (88.24%) are selffinancing colleges, 11 (9.24%) are government colleges and 3 (2.52%) are private aided

colleges. Kerala University has the largest number of engineering colleges affiliated to it.

During 2010, 35 self-financing engineering colleges are started in the state. Tables 8.1 list

the number of technical institutions in the state.

Institutions

Government

8.1: Technical Education Institutions in Kerala (2010)

Number Institutions

Engineering 9

Fine Arts Colleges

Number

3

Colleges

Private Aided Engineering 3

Government Technical High 39

College

Schools

Government

Polytechnic 36

Colleges

Government

Government

Commercial 17

Institutes

Women's 7

Tailoring and Garment Making 42

Polytechnic Colleges

Training Centers

Private Aided Polytechnic 6

Vocational Training Centers

Colleges

Source: Directorate of Technical Education

8.1.3 The Industrial Training Department is responsible for the functioning of Industrial

Training Institutes (ITIs) in the state. There are currently about 52 ITIs and a basic

training centre, with a total intake of 16503 students, of which 30% of the seats are

reserved for women candidates. Table 8.2 lists the district wise distribution of ITIs/ITCs

in the state.

Visit: www.det.kerala.gov.in/index.php

36

State Level Resources to Promote the Growth of Manufacturing in Kerala

8.2: District Wise Distribution of ITIs/ITCs in Kerala

District

No of Affiliated ITIs/ITCs

Total

Government

Private

General

Women

SCDD

General

Women

SCDD

Thiruvananthapuram 62

51

Kollam

53

48

Panthanamthitta

35

33

Alappuzha

49

45

Kottayam

35

31

Idukki

10

Ernakulam

57

55

Thrissur

42

34

Palakkad

17

14

Malappuram

16

11

Kozhikode

27

23

Wayanad

Kannur

29

26

Kasaragod

Total

445

19

25

389

Source: Department of Industrial Training, Govt. of Kerala

8.2 Availability of Technically Qualified Persons

8.2.1 The number of professional and technical work seekers in 2009 was 1.65 lakhs.

This number slightly decreased to 1.61 lakhs in June 2010. The share of employment

seekers with professional and technical qualifications is given in the table below and it is

seen that more than 90 percent of the technical and professional employment seekers are

ITI and Diploma holders in engineering. Table 8.3 lists the percentage work seekers in

the state.

37

State Level Resources to Promote the Growth of Manufacturing in Kerala

8.3: Percentage Share of Professional & Technical Work Seekers in Kerala

Educational Qualification

2007 (%)

2008 (%)

2009 (%)

2010 (%)

Medical Graduates

1.55

1.55

1.66

1.28

Engineering Graduates

5.1

5.54

6.51

4.74

Diploma Holders in Engineering

23.56

22.21

24.8

23.6

ITI Certified holders

68.93

69.84

66.23

69.89

Agricultural Graduates

0.47

0.455

0.4

0.25

Veterinary Graduates

0.39

0.402

0.41

0.23

Total

100

100

100

100

Source: Economic Review 2010

8.2.2 Analysis of the sector wise growth of employment in public and private

establishments in Kerala in March 2010 revealed that the highest employment is in the

community, social and personnel services 44.29%, followed by manufacturing 22.91%,

financing and business services 9.20%, Transport 8.32%, Agriculture 7.17%, Electricity,

Gas, Water, Sanitary services 2.63%, Construction 1.91% and the lowest employment is

in the mining and Quarrying 0.239%.

8.2.3 Engineering colleges in the state offer varied courses to suit the needs of the

growing industry. Annexure 8 and 9 provide details on course-wise student intake for

engineering and polytechnic colleges.

8.3 Labor Wage Rate

8.3.1

The State Labor Department has identified 83 categories of employment spanning

agriculture, manufacturing and service industries under the Minimum Wages Act, out of

which minimum wages are notified in 46 employments. Annexure 10 lists the minimum

wages for key manufacturing industries of the state.

38

State Level Resources to Promote the Growth of Manufacturing in Kerala

8.4 Attitude of Labor Towards Professional Work Culture

8.4.1

During 2009-10, 2352 industrial disputes were registered in the State. At the end

of the year, there were 5122 cases along with the pending disputes of previous year which

is less than 14.1% of previous year. A total of 2357 disputes were settled during the year

under review. Due to strike and lockout 39347 workers were affected which led to loss of

839788 man days. Table 8.4 and 8.5 lists the number of strikes and lockouts in the state

and the lost man-days.

8.4: Labor Strikes Over the Year in Kerala

2006

2007

2008

2009

Items

2005

Pending

Arose

Total

Man-day lost

1

10

11

3250553

0

6

6

86977

1

2

3

86746

0

22

22

394198

4

18

22

177494

2010

(As

on

30.9.10)

3

8

11

135502

Source: Economic Review 2010

8.5: Company Lockouts over the Years in Kerala

2005

2006

2007

2008

2009

Items

Pending

Arose

Total

Man-day

lost

27

4

31

1855429

23

6

29

1811755

27

0

27

1505370

4

5

9

758144

8

13

21

506606

2010 (As

on

30.9.10)

10

9

19

649439

Source: Economic Review 2010

8.5 Status of Labor Related to Legislation

8.5.1

The prominent role of the Labor Department is to maintain industrial peace and

harmony in Kerala. Enforcement of labor laws and implementation of labor welfare

schemes are pre requisites for maintaining the harmonious relation and creating

39

State Level Resources to Promote the Growth of Manufacturing in Kerala

conducive climate for sustained investment. Labor Department is responsible for the

enforcement of labor enactments, settlement of industrial disputes, administration of

various welfare measures, revising / fixing the minimum wages of employees,

implementation of social security and insurance schemes so as to safeguard the rights and

privileges of working class and thereby providing a labor friendly atmosphere in the

State. There are 30 labor enactments administered by the Department. 83 categories of

employment have been covered by the minimum wages Act, 1948 out of which minimum

wages are notified in 46 employments.

8.6 Labor Regulations

8.6.1

Kerala is a model state for labor welfare measures. About 28 Labor Welfare Fund

Boards are functioning in Kerala under different departments. The State Government is

of the view that healthy labor relation and good work culture are the pre requisites for the

growth and sustenance of the industry. They have proposed to spearhead a massive

campaign to highlight the healthy labor relations and to remove the unfounded

perceptions.

The management will have the right to choose and deploy employees. However, local

workforce shall be engaged to the extent possible.

Government will take initiative in promoting a new management culture through regular

interaction with the industrialists and trade unions.

A reconciliation forum will be set up involving Departments of Labor, Industries and

Commerce, ensuring participation of trade unions for the effective redressal of labor

issues. Arbitration mechanism shall be implemented if industrial disputes arise, for

speedy decisions.

Public Sector Advisory Board and Fast Track Labor Courts will be constituted for Policy

making and dispute settlement.

40

State Level Resources to Promote the Growth of Manufacturing in Kerala

9.

Profile of Business Environment

9.1 Single Window System

9.1.1

Kerala is one of the first states in India to have legislation for statutory Single

Window Clearance. The Government of Kerala has introduced the Single Window

Clearance System from 1st June, 2000 for expediting the issue of various clearances for

new Industrial Projects. As per this system, a final clearance for all new projects, either

approval or rejection, is to be given within a specific period from the date of submission

of application; a statutory requirement under the Kerala State Single Window Clearance

Boards and Industrial Township Area Development Act 1999.

9.1.2

A State Level Board for aiding medium and large-scale industries has been

constituted in this regard, headed by the Chief Secretary, which shall issue clearances

within a timeframe of 45 days. Kerala State Industrial Development Corporation has been

designated as the Single Contact Point and the Convener of the State Board. The Board

has statutory powers to enforce its decisions.

9.1.3

In a similar manner, District Level Boards have been constituted for clearing

small scale industrial undertakings, with the District Collector as the Chairman and

General Manager, District Industries Centre as the Convener; the stipulated time frame

being 60 days.

9.1.4

Industrial Area Boards have also been set up in various industrial areas of the

state for the clearance of projects being set up in these areas. An officer not below the

rank of District Collector is the Chairman in each Board, with the Designated Authority

of the Industrial Area as Convener, to issue clearances within a period of 30 days

9.1.5

A composite application form has also been formulated, which the entrepreneur

needs to submit only at the designated contact points. With the introduction of the Single

Window Clearance System, setting up of Industrial projects in the State is expected to

41

State Level Resources to Promote the Growth of Manufacturing in Kerala

become a hassle free operation. Table 9.1 shows the Single Window Clearance process

and Table 9.2 lists the number of applications cleared/disposed since inception.

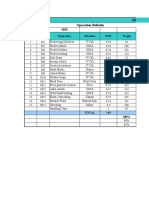

9.1: Single Window Clearance Process in Kerala

9.2: No. of Applications Cleared/Disposed Since Inception

Single Window Clearance Board Green Channel Counter

Received

Disposed

Received

Disposed

Thiruvananthapuram 18

14

4

4

Kollam

220

210

1202

1199

Panthanamthitta

206

180

878

871

Alappuzha

80

76

1162

1162

Kottayam

150

147

3318

3318

Idukki

0

0

0

0

Ernakulam

243

218

756

745

Thrissur

91

86

2630

2599

Palakkad

195

186

5136

5133

Malappuram

108

104

739

734

Kozhikode

173

167

3558

3558

Wayanad

2

2

250

250

Kannur

218

210

8464

8456

Kasaragod

21

21

2393

2393

Total

1725

1621

30490

30422

Source: Directorate of Industries, Govt. of Kerala

District

42

State Level Resources to Promote the Growth of Manufacturing in Kerala

9.2 Special Agencies to Facilitate Industrialization

9.2.1 Kerala State Industrial Development Corporation (KSIDC)

Kerala State Industrial Development Corporation Ltd. (KSIDC) is a wholly owned

company of Government of Kerala setup for the promotion and development of medium

and large scale units in the State. It acts as the nodal agency for foreign and domestic

investments in the state by providing comprehensive support for investors, besides

processing various incentive schemes and facilitating constant interaction between the

government and the industrial sector. The agency promoted more than 650 projects in the

State with an investment outlay of Rs.5155crores. Following are the key areas of focus

for the agency:

1. Identification of Investment Ideas

2. Translating ideas into concrete proposals

3. Feasibility Study, Project Evaluation

4. Financial Structuring, Loan Syndication

5. Assisting in Central and State Govt. Clearances

6. Development and Administration of Growth Centers

7. Industrial and Infrastructure development

On-Going Mega Projects

Life Sciences Park - KSIDC proposes to develop a Life Sciences Park at

Thiruvananthapuram. 260 acres of land in Veiloor Village have been identified for the

purpose and KSIDC is in the process of acquisition of this land for the project. The Life

Sciences Park, when functional, would be a geographic cluster of industry

(Biotechnology, Nanotechnology & Life Sciences), research institutions and sci-tech

academia. The Park would address the needs of the rapidly emerging life sciences

industry and is expected to attract investments, both domestic and foreign, in the related

areas.

Electronics Hub - KSIDC has initiated steps for setting up of an Electronic Hub at Kochi.

The proposed Electronic Hub would be developed in 330 acres of land, offering world

43

State Level Resources to Promote the Growth of Manufacturing in Kerala

class facilities for manufacturing, contract manufacturing, R&D and fabrication units in

the electronics sector. The Hub would house companies in the semiconductor and

electronic components sector, including their manufacture, research & development,

design, etc. The land acquisition procedure has been initiated.

Petro-Chemical Complex - The market survey conducted by KSIDC by engaging M/s.

Industrial Development Service Pvt. Ltd. (IDS), New Delhi has established scope for

setting up a project for manufacturing Propylene Oxide utilizing Propylene available with

BPCL-Kochi Refinery. In this context, KSIDC has developed a proposal for setting up a

Propylene-based petrochemical complex at Kochi. The estimated investment for setting

up the above project is Rs.1000Crore. KSIDC has prepared a pre-feasibility report for the

project and is looking for technology tie-up.

Titanium Sponge Project - Govt. of Kerala proposes to set up a Titanium Complex in

Kollam District consisting of a Titanium Sponge Plant of 10000 tons per annum capacity,

Titanium metal and downstream products. The proposed plant will be located adjacent to

the Kerala Minerals and Metals Ltd. (KMML), Chavara, a Govt. owned company

producing Titanium products. An extent of about 300 acres of land has been identified for

the project. KSIDC has commissioned a consultant to conduct techno-economic

feasibility of the project.

LNG Terminal - As the State's Promotional Agency, KSIDC has been instrumental to

facilitate establishment of the LNG Terminal at Kochi. The Terminal is being

implemented by M/s. Petronet LNG Ltd, a joint venture of ONGC, GAIL, IOC and

BPCL. Capacity of the LNG Re-gasification Terminal in the 1st phase is 2.5 Million

TPA, which will be enhanced to 5 Million TPA in the 2nd phase. The location is inside

the Cochin Port SEZ at Puthuvypeen, Kochi. The project aims to supply Regasified LNG

(R-LNG) to various customers in sectors like power, fertilizer, and industrial sector and

for City Gas Distribution (CGD) in the Southern States of Kerala, Tamil Nadu and

Karnataka, with the pipeline infrastructure is in place. The project, which has an

estimated cost of Rs.3,600Crores in the 1st phase has 3 major components, viz., Storage

Tanks, Marine Facility and Re-gasification Facility. 2 Nos. of Storage Tanks with a total

capacity of 5 Million TPA are under construction.