Академический Документы

Профессиональный Документы

Культура Документы

Process Control: WWW - Control-Systems-Principles - Co.uk. CE117 Process Control

Загружено:

Sharifah Zulaikha BenYahyaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Process Control: WWW - Control-Systems-Principles - Co.uk. CE117 Process Control

Загружено:

Sharifah Zulaikha BenYahyaАвторское право:

Доступные форматы

www.control-systems-principles.co.uk.

CE117 Process Control

PROCESS CONTROL

Peter Wellstead, www.control-systems-principles.co.uk

ABSTRACT: This is one of a series of white papers prepared by Control Systems

Principles to explain control problems and techniques that are often encountered in

industry. They describe what makes a particular type of system important and how it is

dealt with using feedback control. The white papers are background for the laboratory

models of real systems that Control Systems Principles has designed for training in control

techniques. This one is about control in the process industries as explained by our Process

Trainer System. Like most of our designs the Process Trainer is manufactured and

distributed by a partner company under licence. Details of the Process Trainer System can

be found at: www.tecquipment.com/Control/Process-Control/CE117.aspx.

1. Why is Process Control Important?

Process control is arguably the largest area of control engineering application. It is used in the

manufacturing, infrastructure and service industries, and these are grouped under the common

heading: the process industries. Most of the things that we use or do are associated with a

process of some form. For example, if you print this page on to paper, then you are

immediately using two process industry products: for the paper, the papermaking industries,

and for the ink, the chemical process industries. Other typical products of process industries are:

metals, textiles, rubber, polymers, paint, food and drinks, pharmaceuticals and chemicals of all

kinds. Of particular importance are the process industries that extract, process and distribute

natural resources: such as petrochemicals, gas, minerals and electricity.

Process control began as manufacturing and supply became industrialized and there was a need

for accuracy and repeatability. Before this, manufacturing and services were done to individual

requirements using traditional methods. The key transition came with the move to mechanization

and automation. So, for example, papermaking went from producing paper one sheet at a time

and to individual demands, to a continuous process in which pulp and water entered a machine

and standard finished paper flowed continuously from the process1. Metal production followed

a similar route, as did the manufacture and treatment of chemicals, and the petrochemical

industries. As cities grew, the infrastructure, the flow of information, the supply of goods and

services, have become organized along process lines. And all need process control in order to

function reliably

2. Standard Process Control Systems

2.1 Transducers and transmitters.

The need for accuracy and automation led to the development of measuring devices that could

continuously monitor process variables. Key things that need to be measured in a process system

are: (i) level (usually fluid level in vessels); (ii) pressure (liquid or gas); (iii) flow rate through a

pipe or channel and, (iv) the temperature. The devices that measure these variables are usually

called transducers, but because a process variable transducer can be a long way from the control

unit or control room, the measured variable must be transmitted to where it is needed for

monitoring or regulation. For this reason, we often talk of transmitters e.g. a device that

measures a process variable; converts the measurement into an electrical signal, and transmits it

to where it is used for control.

See the continuous manufacture of paper by typing fourdrinier paper making in your search engine.

1

www.control-systems-principles.co.uk.

CE117 Process Control

Level, pressure, temperature and flow transducers link naturally to the most common control

systems requirements:

(i)

Regulating the amount of material in a reservoir at a constant level as the demand

downstream in the process varies with production rate;

(ii)

Keeping the flow rate through a pipe at a constant level and loads and supplies

changes;

(iii) Maintaining the pressure at which material is treated in a vessel during a process;

(iv)

And controlling the temperature in a process vessel during a chemical reaction.

2.2. Process Regulation.

Regulation at a constant desired value - the

set point - is a hallmark of process control

systems. Sometimes set points are subject to

change by a higher level of control system or

human operator, but usually they stay

constant. Often controlled variables (like,

level, pressure and temperature) interact with

each other and it is necessary to regulate

several related variables simultaneously. As

an example, consider the process vessel

system shown in Figure 1.

fluid in

stirrer

Ti , wi

V

Q

Heat exchanger

This diagram represents a typical form of

industrial process and is the type of system

fluid out

represented in the Process Trainer. It consists

of a vessel with fluid flowing in and out,

plus a heat exchanger mounted inside vessel

T, w

so that it can change the temperature. To

ensure that every thing in the tank is well

Figure 1: A basic process system

mixed, and all parts are at the same

temperature, there is usually a stirring device or agitator in the tank. This is particularly

important in chemical reactions and for this reason the system in Figure 1 is often referred to as

a stirred-tank reactor.

The set-up shown in Figure 1 is the basis of many chemical process systems where reactions

take place in a reaction vessel, or systems where fluid is either stored or stabilized to a certain

temperature and flow rate. To make sure the system works in an optimal way, the total volume

of fluid in the tank V and the reaction temperature T are controlled to be constant. The

temperature in the vessel can be changed by a heat exchanger which supplies an input heat flow

rate Q, while the fluid input to the system is at temperature Ti and mass flow rate wi. The outflow

temperature is T and mass outflow rate w.

In general, the process control aim is to regulate both the vessel temperature T and the volume of

fluid V in the vessel at a desired level. The control variables are the fluid input flow rate, the

outflow rate and the heat input to the heater. For this set-up most commonly encountered

control tasks are:

www.control-systems-principles.co.uk.

CE117 Process Control

1. Level control. Here the task is to control the volume of fluid in the vessel, usually by

manipulating the inflow to the vessel, without regard to the temperature.

2. Temperature control. Here the task is only to control the temperature in the vessel,

without regards to the precise volume of fluid.

For both these control tasks, a three-term controller is normally used (see our white paper:

http://www.control-systems-principles.co.uk/whitepapers/three-term-control.pdf for details of

this technique). And usually a suitably tuned Proportional plus Integral (P, I) controller is

sufficient.

However, the situation can be more

complex, because changing one of the

Flow

control variables will change both of the

Controller

system outputs. Thus if the inflow

temperature is lower that the tank

FC

temperature, then an increase in wi will

tend to decrease the tank temperature.

Since both outputs must be held constant,

FT Flow

the two control systems can interact with

Transmitter

each other. In this case an extra control

mechanism is used to compensate for the

Flow

interaction between the two control

actuator

loops.

fluid flow , w

Figure 2: Flow control loop

3. Standard Process Control Loops

3.1 Flow control loop

The flow rate of material into the vessel,

wi , can vary as the supply system

changes. To allow for this a flow control

loop is sometimes used. These can be

part of a flow actuator or a separate

control system. In either case, the

schematic layout is shown in Figure 2.

Here the flow transmitter measures the

flow, sends it to the flow controller

which then changes the flow actuator. In

practice the flow actuator is usually

either a pump taking material from a

reservoir or a motorised valve in a

material feed line.

3.2. Level control loop

To control the volume of material in a

tank, it is common to use either a

pressure or a level transducer as the

controlled variable, and to transmit this

signal back to a level controller. The

Level Controller

LC

FCL

Flow Control

Loop

Process vessel

(stirred tank)

LT

Level

Transmitter

fluid out

Figure 3: Level control loop

www.control-systems-principles.co.uk.

CE117 Process Control

actuation signal from the level controller is used as the set point for the flow control loop. This is

shown in Figure 3, where the level control loop consists of the Level Transmitter, the Level

Controller and the Flow Control Loop.

This is an example of cascade control, where the set point to an inner loop (flow control) is

derived from the output of the controller in an outer loop (level control). In this cascade system,

the flow control loop is the slave loop and the outer level control loop is the master loop.

Note that not all systems have a local control flow loop. If control is sufficiently good with just

the level controller then the extra cost of a flow controller and flow transmitter is not justified.

However, the inner loop control gives more flexibility in controller design. It is, in a way, the

process control equivalent to the state feedback discussed in the ball and beam white paper.2

Local control of actuators can also help if the actuation process is significantly non-linear with

dead-zone, saturation or rate limiting. These non-linearities are demonstrated in the Servo

Trainer and the Engine Speed Control Systems.3 The message in all this discussion is that a

higher quality of control can be obtained with inner loop cascade control Thus, if there is no

economic argument against, then do it.

3.3 Temperature Control Loop

The structure of the temperature loop for a

basic process system is shown in Figure 4. A

temperature transmitter sends the temperature

signal to the temperature controller where it is

used to regulate the heat in to the heat

exchanger so that the vessel temperature is

held at the set point temperature for the

process. In a chemical reactor the heat

exchanger may also be designed to have a

cooling effect if the reaction is exothermic and

therefore releases heat. Reactions should be

maintained at specific temperatures to ensure a

correct reaction rate and reaction products.

Temperature

Transmitter

TT

Process vessel

(stirred tank)

TC

Heat exchanger

Temperature

Controller

Figure 4: Temperature control loop

If there is a flow control system associated with the vessel, and there are significant variations in

the temperature and the rate of in flow, then the temperature and level control systems will

interact significantly. There several control schemes for compensating for this interaction.

Feedforward control is the best known and simplest. We will use it as a way of introducing how

to handle interaction. Feedforward was developed as a way of compensating for changes in a

known disturbance to a process. So if we consider the temperature control to be the main control

loop, we will show how feedforward from a flow control system can help reduce disturbances in

temperature as the flow changes.

2

See the white paper: www.control-systems-principles.co.uk/whitepapers/ball-and-beam1.pdf

See the white paper: www.control-systems-principles.co.uk/whitepapers/engine-speed-control.pdf and

http://www.control-systems-principles.co.uk/whitepapers/servo-control-systems1.pdf

3

www.control-systems-principles.co.uk.

CE117 Process Control

3.3 Feed Forward Control

The main idea in feed forward control is to send information about a coming disturbance to a

control loop so that it can take compensatory action in good time. In Figure 5, this situation is

illustrated through the use of a feed forward loop that takes information about changes to the

level control and sends it through a feed forward controller to the Temperature Controller. Thus

if it is known that the feed of material or fluid is colder than the reaction vessel, then the feed

forward would be designed to increase the input to the heat exchanger in proportion to increases

in the inflow of feed material or fluid. This will compensate for the cooling action of the

increased in flow. For this to work effectively the systems needs to be well known, but even

approximate feed forward can reduce the impact of disturbances. In this case feedforward works

by introducing interaction between one feedback control loop and another. Other ways of doing

this exist and are explained in the Process Trainer manual.

Feed Forward Controller

FFC

LC

Feed forward

loop

FCL

Level control

loop

TT

Temperature

control

loop

Process vessel

(stirred tank)

LT

TC

Heat exchanger

Figure 5: Combined flow and temperature control

with flow feedforward loop

4. The Process Trainer

We have put these different aspects of a process control system in to a bench top system

(pictured on the next page). In this system a process vessel is heated by a heat exchanger while

the flows in and out of the vessel are actuated by sets of pumps and valves. In addition the vessel

can be sealed at the top so that it becomes pressurised. This lets us examine pressure control and

the kind of systems that use closed vessels to achieve particular process control objectives4.

Likewise the process fluid inlet temperature can be manipulated by a special cooling system; this

to adds a further dimension to the set of control problems that can be investigated and

demonstrated.

The pressurised head box of a paper making machine is an example of this form of system.

5

www.control-systems-principles.co.uk.

CE117 Process Control

Figure 6. The Process Trainer

5. A Final Word

We frequently get emails from students who are keen to learn more about control and get help

with their projects. However, we are sorry to say that we cannot answer general questions about

the contents of our white papers, unless we have a contract with your organisation.

6. Bibliography

History of Control and Control Industries: At Control Systems Principles we recommend the historical books of

Stuart Bennett. They are:

Bennett, S. A history of control engineering, 1800-1930, Peter Peregrinus Ltd, 1979

Bennett, S. A history of control engineering, 1930- 1955, Peter, Peregrinus Ltd, 1993

New books on process control are regularly published , but we still prefer the following book, authored by world

authorities in the field:

Seborg, DE, Mellichamp, DA, Edgar, TF and Doyle FJ, Process dynamics and control, Prentice Hall, 2003

Technology moves fast, and with the advent of mass computerization and automation, process control has become

integrated within plant -wide automation, system integration and business process design. This means that process

control systems are now part of the bigger task of optimizing and regulating entire enterprises. This area evolves

quickly and is specific to particular enterprises and process automation companies. Up-to-date material on this area

is rarely found in textbooks or taught courses. The best thing is to get practical laboratory experience and then relate

it to the literature and presentations of the companies that are driving innovation in process automation.

Вам также может понравиться

- AssignmentДокумент28 страницAssignmentfaisal58650Оценок пока нет

- Process Control: University of Rizal SystemДокумент21 страницаProcess Control: University of Rizal SystemJMОценок пока нет

- 11process Control Fundamentals PDFДокумент59 страниц11process Control Fundamentals PDFshubhamОценок пока нет

- Diagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceОт EverandDiagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceОценок пока нет

- Chemical Enginineering Fourth YearДокумент68 страницChemical Enginineering Fourth YearHabib NuredinОценок пока нет

- ADPC Module 1Документ23 страницыADPC Module 1Asif MohammedОценок пока нет

- Process Control EnggДокумент27 страницProcess Control EnggAnonymous gUjimJKОценок пока нет

- ECNG3004 Control System ApplicationsДокумент7 страницECNG3004 Control System ApplicationsMarlon BoucaudОценок пока нет

- Process Control Unit 1Документ16 страницProcess Control Unit 1Carn JosephОценок пока нет

- Control System Mini ProjectДокумент14 страницControl System Mini ProjectMuhammad Al-baihaqiОценок пока нет

- Lectures Process ControlДокумент98 страницLectures Process Controlrizzagorospe100% (1)

- Process Control PCT301T ProjectДокумент29 страницProcess Control PCT301T ProjecterickamitzОценок пока нет

- Basic Elements of Generalized Process ControlДокумент11 страницBasic Elements of Generalized Process ControlMourougapragash SubramanianОценок пока нет

- Introduction To Process InstrumentationДокумент15 страницIntroduction To Process Instrumentationtaufikrezza85Оценок пока нет

- Basics of Control EngineeringДокумент3 страницыBasics of Control Engineeringbrian qlpОценок пока нет

- College of Engineering Education Matina, Davao CityДокумент8 страницCollege of Engineering Education Matina, Davao CityGrazel MDОценок пока нет

- 1815 03 PDFДокумент29 страниц1815 03 PDFsiamak001Оценок пока нет

- Process Control Elements in The LoopДокумент13 страницProcess Control Elements in The LoopTimothy LeonardОценок пока нет

- Process Instrumentation, Dynamics and ControlДокумент23 страницыProcess Instrumentation, Dynamics and ControlLavanya ManoharanОценок пока нет

- Control SystemДокумент183 страницыControl Systemsantoshgowda8Оценок пока нет

- Industrial Process ControlДокумент111 страницIndustrial Process ControlNazif Jaafar86% (7)

- UC 9 Level IVДокумент35 страницUC 9 Level IVGizaw TadesseОценок пока нет

- Control System NotesДокумент179 страницControl System NotesChandrashekarОценок пока нет

- اخررررر تعديلДокумент10 страницاخررررر تعديلAhmed nawfalОценок пока нет

- 2023 PCI360S Introductory ConceptsДокумент19 страниц2023 PCI360S Introductory ConceptsSifanele PotwanaОценок пока нет

- Control Systems and Task of Control Engineers 1.1 Introduction To Control EngineeringДокумент7 страницControl Systems and Task of Control Engineers 1.1 Introduction To Control EngineeringMagarsaa Qana'iiОценок пока нет

- Beyond The ClassroomДокумент8 страницBeyond The Classroomابوالحروف العربي ابوالحروفОценок пока нет

- Lecture 1.0Документ7 страницLecture 1.0Nischal chandraОценок пока нет

- Process ControlДокумент37 страницProcess ControlSaad2222Оценок пока нет

- Lesson 1Документ18 страницLesson 1Paul Simon NacisОценок пока нет

- Topic 2.0 Introduction To Process Control DynamicsДокумент16 страницTopic 2.0 Introduction To Process Control DynamicsByron MawoyoОценок пока нет

- Automatic Controls 1 - Basics (GCM - 08) PDFДокумент74 страницыAutomatic Controls 1 - Basics (GCM - 08) PDFMostafa AgamyОценок пока нет

- Adcontrol ReviewerДокумент28 страницAdcontrol Reviewerjezreel gamboaОценок пока нет

- Designing of Fuzzy Logic Controller For Liquid Level ControllingДокумент10 страницDesigning of Fuzzy Logic Controller For Liquid Level ControllingSkr KhanОценок пока нет

- Why Do We Need Process ControlДокумент6 страницWhy Do We Need Process ControlSebastien PaulОценок пока нет

- Chapter - One (1) ControlДокумент7 страницChapter - One (1) Controlmesfin snowОценок пока нет

- Lecture 1Документ26 страницLecture 1ahmedelebyaryОценок пока нет

- Unit 1 - Introduction: PretestДокумент18 страницUnit 1 - Introduction: Pretestariel mentawanОценок пока нет

- Day 10 King SaudДокумент9 страницDay 10 King SaudSri NurОценок пока нет

- Processcontrol 170515171334Документ13 страницProcesscontrol 170515171334Coral Del Mar100% (1)

- Introduction To Control: The ProcessДокумент7 страницIntroduction To Control: The ProcessshajiОценок пока нет

- Process ControlДокумент9 страницProcess ControlRajalakshmi VengadasamyОценок пока нет

- My Notes ctlp2009 Rev 20220918Документ138 страницMy Notes ctlp2009 Rev 20220918Keegan PaulОценок пока нет

- Basic Process ControlДокумент38 страницBasic Process ControlBoris bryan AletanuОценок пока нет

- Level Flow Plant ControlДокумент9 страницLevel Flow Plant ControlAmanina HakimОценок пока нет

- Experiment No. 04: DR D Y Patil School of Engineering & TechnologyДокумент4 страницыExperiment No. 04: DR D Y Patil School of Engineering & Technologypradnya sadigaleОценок пока нет

- EI2352 - Process Control - 2 Marks With AnswersДокумент19 страницEI2352 - Process Control - 2 Marks With Answersnagarajansamayans100% (1)

- Heat Exchanger & Furnace Operations and ControlsДокумент6 страницHeat Exchanger & Furnace Operations and Controlsnilesh_092Оценок пока нет

- Paper Multivariable Tank 0405131Документ17 страницPaper Multivariable Tank 0405131Vaghela ChintanОценок пока нет

- The Level Control of The Boiler Drum: Chenhui HeДокумент32 страницыThe Level Control of The Boiler Drum: Chenhui Hebeymar_5631Оценок пока нет

- PROCON Student ManualДокумент48 страницPROCON Student ManualPaul100% (1)

- Process ControlДокумент39 страницProcess ControlMonty KushwahaОценок пока нет

- Fundamentals of Controls System Group 1Документ17 страницFundamentals of Controls System Group 1Louie CamposОценок пока нет

- Topic 2.0. Introduction To Process ControlpptxДокумент48 страницTopic 2.0. Introduction To Process ControlpptxProsper ChimukaОценок пока нет

- Distillation Column Control DesignДокумент22 страницыDistillation Column Control DesignAnand Dudheliya0% (1)

- Strategy For DistillationColumn ControlДокумент529 страницStrategy For DistillationColumn ControlLisandro Mangini100% (2)

- Intro Theory Level FlowДокумент5 страницIntro Theory Level FlowAzura BahrudinОценок пока нет

- Student CHAPT 2Документ46 страницStudent CHAPT 2Sharifah Zulaikha BenYahyaОценок пока нет

- Student CHAPTER 6Документ24 страницыStudent CHAPTER 6Sharifah Zulaikha BenYahyaОценок пока нет

- 112student - CHAPTER 4Документ39 страниц112student - CHAPTER 4Sharifah Zulaikha BenYahyaОценок пока нет

- 2student - CHAPTER 5Документ21 страница2student - CHAPTER 5Sharifah Zulaikha BenYahyaОценок пока нет

- Palm Based Oleochemicals-CosmeticsДокумент34 страницыPalm Based Oleochemicals-CosmeticsSharifah Zulaikha BenYahyaОценок пока нет

- Infection PreventionДокумент10 страницInfection PreventionSharifah Zulaikha BenYahyaОценок пока нет

- Example Problem: ViscosityДокумент3 страницыExample Problem: ViscosityRaoof AlabsiОценок пока нет

- BernoulliДокумент19 страницBernoullimiam22Оценок пока нет

- Reactions of HydrocarbonsДокумент6 страницReactions of HydrocarbonsSharifah Zulaikha BenYahyaОценок пока нет

- Classification Tests For HydrocarbonsДокумент8 страницClassification Tests For HydrocarbonsAnna Donato60% (5)

- ENT300 Chapter 8Документ36 страницENT300 Chapter 8Sharifah Zulaikha BenYahyaОценок пока нет

- Chem Lab (Ii) 3Документ11 страницChem Lab (Ii) 3Nurul Hasanah88% (75)

- Concentric Tube Heat ExchangersДокумент12 страницConcentric Tube Heat ExchangersSharifah Zulaikha BenYahyaОценок пока нет

- By: Nevina Keskineva Chemistry Department, East Stroudsburg UniversityДокумент12 страницBy: Nevina Keskineva Chemistry Department, East Stroudsburg UniversitySharifah Zulaikha BenYahyaОценок пока нет

- Heat ExchangerДокумент18 страницHeat ExchangerNilesh GohelОценок пока нет

- Lab ReportДокумент16 страницLab ReportSharifah Zulaikha BenYahyaОценок пока нет

- Tools of Marketing CommunicationДокумент4 страницыTools of Marketing CommunicationSharifah Zulaikha BenYahyaОценок пока нет

- Concentric Tube Heat ExchangerДокумент10 страницConcentric Tube Heat ExchangerSharifah Zulaikha BenYahyaОценок пока нет

- Academic Sessions 2014-2015 UitmДокумент2 страницыAcademic Sessions 2014-2015 UitmsilentsioОценок пока нет

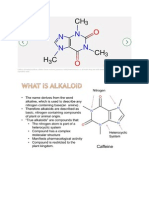

- Chemical Structure & Uses of CaffeineДокумент2 страницыChemical Structure & Uses of CaffeineSharifah Zulaikha BenYahyaОценок пока нет

- AutoCAD 2013 2D Tutorials by Kristen S. KurlandДокумент255 страницAutoCAD 2013 2D Tutorials by Kristen S. KurlandnotevaleОценок пока нет

- Article 4Документ14 страницArticle 4Sharifah Zulaikha BenYahya100% (1)

- Academic Sessions 2014-2015 UitmДокумент2 страницыAcademic Sessions 2014-2015 UitmsilentsioОценок пока нет

- Using JAXB For XML With Java - DZone JavaДокумент20 страницUsing JAXB For XML With Java - DZone JavajaehooОценок пока нет

- All-India rWnMYexДокумент89 страницAll-India rWnMYexketan kanameОценок пока нет

- NURS 366 Exam 1 Study Guide and RubricДокумент7 страницNURS 366 Exam 1 Study Guide and RubriccmpОценок пока нет

- STAG-4 QBOX, QNEXT, STAG-300 QMAX - Manual - Ver1 - 7 - 8 (30-09-2016) - EN PDFДокумент63 страницыSTAG-4 QBOX, QNEXT, STAG-300 QMAX - Manual - Ver1 - 7 - 8 (30-09-2016) - EN PDFIonut Dacian MihalachiОценок пока нет

- SBMPTN 2016 Kode 333Документ6 страницSBMPTN 2016 Kode 333Allisa MasithaОценок пока нет

- Wa0009.Документ14 страницWa0009.Pradeep SinghОценок пока нет

- Quanser Active Mass Damper UserManual PDFДокумент21 страницаQuanser Active Mass Damper UserManual PDFCHAVEZ MURGA ARTURO ALEJANDROОценок пока нет

- Eva Karene Romero (Auth.) - Film and Democracy in Paraguay-Palgrave Macmillan (2016)Документ178 страницEva Karene Romero (Auth.) - Film and Democracy in Paraguay-Palgrave Macmillan (2016)Gabriel O'HaraОценок пока нет

- Children's LiteratureДокумент13 страницChildren's Literaturerexson de villaОценок пока нет

- Asian Parliamentary DebateДокумент10 страницAsian Parliamentary Debateryn hanakuroОценок пока нет

- Klarna: Klarna A Company Valued To Be 5.5 Billion and 8 Most Valued Fintech Company in The WorldДокумент1 страницаKlarna: Klarna A Company Valued To Be 5.5 Billion and 8 Most Valued Fintech Company in The WorldChetan NarasannavarОценок пока нет

- ACA 122-My Academic Plan (MAP) Assignment: InstructionsДокумент5 страницACA 122-My Academic Plan (MAP) Assignment: Instructionsapi-557842510Оценок пока нет

- Cpar Q2 ReviewerДокумент2 страницыCpar Q2 ReviewerJaslor LavinaОценок пока нет

- HARRISON 1993 - The Soviet Economy and Relations With The United States and Britain, 1941-45Документ49 страницHARRISON 1993 - The Soviet Economy and Relations With The United States and Britain, 1941-45Floripondio19Оценок пока нет

- Material Requirement Planning (MRP)Документ20 страницMaterial Requirement Planning (MRP)Faisal Ibn RezaОценок пока нет

- Network Monitoring & Forensics: Jim IrvingДокумент102 страницыNetwork Monitoring & Forensics: Jim IrvingKarel GoldmannОценок пока нет

- JLPT N2 Vocab - 04Документ345 страницJLPT N2 Vocab - 04raj_kumartОценок пока нет

- Schopenhauer and KantДокумент8 страницSchopenhauer and KantshawnОценок пока нет

- 2beloved Lizzo PDFДокумент1 страница2beloved Lizzo PDFAntwerpQueerChoir AQCОценок пока нет

- Conformity Observation Paper 1Документ5 страницConformity Observation Paper 1api-524267960Оценок пока нет

- Math 3140-004: Vector Calculus and PdesДокумент6 страницMath 3140-004: Vector Calculus and PdesNathan MonsonОценок пока нет

- Strength Exp 2 Brinell Hardness TestДокумент13 страницStrength Exp 2 Brinell Hardness Testhayder alaliОценок пока нет

- Unibertsitaterako Hautaproba Ingelesa EHU/UPVДокумент2 страницыUnibertsitaterako Hautaproba Ingelesa EHU/UPVdabidОценок пока нет

- Accaf3junwk3qa PDFДокумент13 страницAccaf3junwk3qa PDFTiny StarsОценок пока нет

- Fire Safety Management - Traditional Building Part#2Документ194 страницыFire Safety Management - Traditional Building Part#2Yoyon Haryono100% (1)

- Bed BathДокумент6 страницBed BathKristil ChavezОценок пока нет

- Federal Ombudsman of Pakistan Complaints Resolution Mechanism For Overseas PakistanisДокумент41 страницаFederal Ombudsman of Pakistan Complaints Resolution Mechanism For Overseas PakistanisWaseem KhanОценок пока нет

- 173544avaya Aura AES 7-0 JTAPI Programmers GuideДокумент88 страниц173544avaya Aura AES 7-0 JTAPI Programmers GuideAhmed SakrОценок пока нет

- Café Management System Full and Final ReportДокумент18 страницCafé Management System Full and Final ReportMuhammad Xalman Xhaw100% (3)

- Unleash Your Inner Millionaire: Achieve Wealth, Success, and Prosperity by Reprogramming Your Subconscious MindДокумент20 страницUnleash Your Inner Millionaire: Achieve Wealth, Success, and Prosperity by Reprogramming Your Subconscious MindMariana PopaОценок пока нет

- Mastering Drones - A Beginner's Guide To Start Making Money With DronesОт EverandMastering Drones - A Beginner's Guide To Start Making Money With DronesРейтинг: 2.5 из 5 звезд2.5/5 (3)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindОт EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindОценок пока нет

- Artificial Intelligence: From Medieval Robots to Neural NetworksОт EverandArtificial Intelligence: From Medieval Robots to Neural NetworksРейтинг: 4 из 5 звезд4/5 (3)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!От EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Рейтинг: 4 из 5 звезд4/5 (3)

- Dark Aeon: Transhumanism and the War Against HumanityОт EverandDark Aeon: Transhumanism and the War Against HumanityРейтинг: 5 из 5 звезд5/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureОт EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Create Profitable Side Hustles with Artificial IntelligenceОт EverandCreate Profitable Side Hustles with Artificial IntelligenceОценок пока нет

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.От EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Рейтинг: 4 из 5 звезд4/5 (5)

- In the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkОт EverandIn the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkРейтинг: 5 из 5 звезд5/5 (1)

- Evil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityОт EverandEvil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Arduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!От EverandArduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!Рейтинг: 3 из 5 звезд3/5 (1)

- How to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionОт EverandHow to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionРейтинг: 3.5 из 5 звезд3.5/5 (129)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsОт EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsОценок пока нет

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessОт EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessОценок пока нет

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceОт EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceРейтинг: 5 из 5 звезд5/5 (9)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationОт EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationРейтинг: 4.5 из 5 звезд4.5/5 (2)