Академический Документы

Профессиональный Документы

Культура Документы

Mech Preservation Procedure

Загружено:

mikehung123Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Mech Preservation Procedure

Загружено:

mikehung123Авторское право:

Доступные форматы

PECIKO FIELD DEVELOPMENT PROJECT PHASE 5

MECHANICAL PRESERVATION

PROCEDURE

CLASS 1

03

10 Dec 08

JI

TY

MD

As Built

02

4 Feb 08

JI

TY

MD

APPROVED FOR CONSTRUCTION

01

03 Jan 08

JI

TY

MD

CPY comments incorporated,

ISSUED FOR APPROVAL

00

27-Nov-07

JI

TY

MD

ISSUED FOR COMMENTS

DATE

BY

CHECK

APPR

APPR

REV

DESCRIPTION

CONTRACTOR

SUBCONTRACTOR

SPEC

REPS

COMPANY

APPROVAL

STATUS CODE : A = Issued for comments B = Issued for approval C = Approved D = As Built

PECIKO FIELD DEVELOPMENT PROJECTPHASE 5

CONTRACT PCK5 / EPSCI

Document Number

PT NISCONI

Rev

Status

03

ID-PK5-PF-NSB-0811020

Document Type

Discipline

PRC

PJM

This document is the property of COMPANY. It must not be stored, reproduced or disclosed to others without written authorization from the COMPANY.

PT NIPPON STEEL BATAM

Doc. Title :

PT. NISCONI

MECHANICAL PRESERVATION PROCEDURE

Doc. Type

PRC

Discipline

Page 2 of 9

PJM

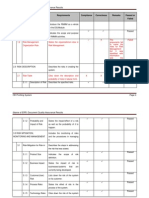

TABULATION OF REVISED PAGES

REVISIONS

SHEET

00

01

02

03

04

05

06

07

41

42

43

44

45

46

47

REVISIONS

SHEET

48

49

10

50

11

51

12

52

13

53

14

54

15

55

16

56

17

57

18

58

19

59

20

60

21

61

22

62

23

63

24

64

25

65

26

66

27

67

28

68

29

69

30

70

31

71

32

72

33

73

34

74

35

75

36

76

37

77

38

78

39

79

40

80

PECIKO FIELD DEVELOPMENT PROJECT PHASE 5

CONTRACT PCK5 / EPSCI

Doc. No : ID-PK5-PF-NSB-0811020

Rev.

: 03

Status: D

Date

: 10 Dec 08

This document is the property of COMPANY. It must not be stored, reproduced or disclosed to others without written authorization from the COMPANY.

PT NIPPON STEEL BATAM

Doc. Title :

PT. NISCONI

MECHANICAL PRESERVATION PROCEDURE

Doc. Type

PRC

Discipline

PJM

Page 3 of 9

MECHANICAL PRESERVATION PROCEDURE

TABLE OF CONTENTS

1.0 PURPOSE

2.0 SCOPE

3.0 DEFINITIONS

4.0 REFERENCE DOCUMENTS

5.0 RESPONSIBILITIES

6.0 PROCEDURE

7.0 GENERAL STATEMENT

8.0 ATTACHMENTS

PECIKO FIELD DEVELOPMENT PROJECT PHASE 5

CONTRACT PCK5 / EPSCI

Doc. No : ID-PK5-PF-NSB-0811020

Rev.

: 03

Status: D

Date

: 10 Dec 08

This document is the property of COMPANY. It must not be stored, reproduced or disclosed to others without written authorization from the COMPANY.

PT NIPPON STEEL BATAM

Doc. Title :

PT. NISCONI

MECHANICAL PRESERVATION PROCEDURE

Doc. Type

PRC

Discipline

PJM

Page 4 of 9

1.0 PURPOSE

This Procedure is to ensure that the project equipment are preserved and maintained its integrity in

accordance to project specifications and vendor requirement.

2.0 SCOPE

Mechanical, electrical & instrumentation are included in this scope, once received in the Yard till sail away

of the project.

3.0 DEFINITIONS

COMPANY

TOTAL E & P INDONESIE

CONTRACTOR

PT NIPPON STEEL CONSTRUCTION INDONISIA

AFC

Approved for Construction

NSB

PT. Nippon Steel Batam Offshore Services

PMT

Project Management Team

OENG

Outfitting Engineering

QA / QC

Quality Assurance / Control

DISCIPLINE

A group of field of expertise

PCOM

Pre-commissioning

COM

Commissioning

SUBCONTRACTOR

A company selected and awarded by CONTRACTOR to perform a

certain Project Activity

SUPPLIER / VENDOR

A company selected and awarded by CONTRACTOR to supply a certain

Project goods

4.0 REFERENCE DOCUMENTS

ID-PK5-PF-NSB-0811048

Material Control, Handling, Preservation & Tracking

ID-PK5-PF-NSB-0811019

Mechanical / Pressure Vessel Installation Procedure

ID-PK5-PF-NST-3000001

Equipment list

ID-PK5-PF-NST-3006002

Material Handling Study report

ID-PK5-PF-NST-3003001

Equipment Data Sheet 20 Pig Launcher-1-R-1701 C

ID-PK5-PF-NST-3003002

Equipment Data Sheet Fuel gas Filters 1-F-17110 A/B

ID-PK5-PF-NST-3003003

Equipment Data Sheet Fuel gas Scrubber 1-V-17120

PECIKO FIELD DEVELOPMENT PROJECT PHASE 5

CONTRACT PCK5 / EPSCI

Doc. No : ID-PK5-PF-NSB-0811020

Rev.

: 03

Status: D

Date

: 10 Dec 08

This document is the property of COMPANY. It must not be stored, reproduced or disclosed to others without written authorization from the COMPANY.

PT NIPPON STEEL BATAM

Doc. Title :

PT. NISCONI

MECHANICAL PRESERVATION PROCEDURE

Doc. Type

PRC

Discipline

PJM

Page 5 of 9

ID-PK5-PF-NST-3003004

Equipment Data Sheet HP VENT TIP -1-VT-17150

ID-PK5-PF-NST-3003005

Equipment Data Sheet Disposal Tube -1-X-17450

ID-PK5-PF-NST-3003006

Equipment Data Sheet Crane Pedestal Diesel Tank -1-T-17710

ID-PK5-PF-NST-3003007

Equipment Data Sheet Diesel Oil Filter -1-F-17710

ID-PK5-PF-NST-3003008

Equipment Data Sheet Offloading pump -1-P-17050

ID-PK5-PF-NST-3003009

Equipment Data Sheet A/C mobile Diesel Generator-1-T-17050

D-PK5-PF-NST-3003015

Equipment Data Sheet Corrosion inhibitor storage Tank -1-T-17310

ID-PK5-PF-NST-3003018

Equipment Data Sheet MDEA storage Tank-1-T-17350

ID-PK5-PF-NST-3003020

Equipment Data Sheet Portable Methanol Injection Tank-1-T-17380

ID-PK5-PF-NST-3003018

Equipment Data Sheet MDEA storage Tank-1-T-17350

5.0 RESPONSIBILITIES

Fabrication Yard Manager

Responsible for implementation of this procedure.

Material Manager

Responsible for material & equipment control, handling,

preservation and tracking of equipment in accordance

with the procedure.

Store Supervisor

Responsible for equipment receipt, storage, preservation

(while in warehouse), issuance inventory & packaging.

Mechanical / Precom Engineer

Responsible for all the activities involves in Mechanical

equipment installation and preservation. Check if the

preservation of the equipment conforms with the

specification and vendor requirement, while stored in

warehouse and installed the wellhead platform.

Coordinate with Engineering (NISCONI) regarding the

vendor requirement for equipment preservation including

lubrications required.

Mechanical Supervisor

Coordinate with Mechanical Engineer regarding the

equipment preservation. Coordinate with other dept for

the implementation of this procedure.

Engineering (NISCONI)

Coordinate with vendor regarding the requirement for

preservation including lubrication / preservatives to be

used for preservation.

PECIKO FIELD DEVELOPMENT PROJECT PHASE 5

CONTRACT PCK5 / EPSCI

Doc. No : ID-PK5-PF-NSB-0811020

Rev.

: 03

Status: D

Date

: 10 Dec 08

This document is the property of COMPANY. It must not be stored, reproduced or disclosed to others without written authorization from the COMPANY.

PT NIPPON STEEL BATAM

Doc. Title :

PT. NISCONI

MECHANICAL PRESERVATION PROCEDURE

Doc. Type

PRC

Discipline

PJM

Page 6 of 9

6.0 PROCEDURE

1.) This procedure is the minimum requirement for equipment preservation in the Yard. Vendor

preservation requirement shall prevail once received from Engineering.

2.) Before the equipment is delivered in Yard, Engineer (NISCONI) shall advise the Yard on some precaution of storing and preserving the equipment. The same will apply if the equipment is supplied by

Client, the Yard shall be informed on the preservation requirement.

3.) Material / Equipment Receiving, Control, Handling, Preservation and Tracking shall be handled by

Warehouse Group as per Procedure ID-PK5-PF-NSB-0811048.

4.) Electrical and Instrument Panels original packing shall not be torn-out. Once torn-out these panels

shall be kept in an air-conditioned room. Vendor shall be consulted on the preservation requirement.

5.) Once equipment issued to the Yard, Mechanical / Precom Engineer and Mechanical supervisor shall

continue the preservation whether equipment is on lay-down area, installed on the deck till Precommissioning, Commissioning and until sail away.

6.) Once installed on the deck, the equipment shall be protected by plastic sheet over-layed by fire

retardant blanket or cover by plywood.

7.) Rotating equipment shall be internally protected by vendor with rust preventive oil. Periodic checking

shall be performed in the Yard once a week. Top up with the recommended preservative oil once

noticed it is in low level.

8.) As required by vendor, rotating equipment shaft shall be turned manually with minimum of two and

one-fourth revolutions in week interval. Care should be taken that the final position of the shaft after

turning is at least one quarter revolution from the point at which it was rotated. Oil levels shall be

checked at the time of rotation. A preservation log shall be kept to record those actions.

9.) Space heaters for motors or generators shall be energized upon advise by vendor, irrespective of the

location, i.e. warehouse, lay-down area or platform. These shall be energized using temporary power

supply until it is connected in MCC.

10.) All exposed machined surface shall be protected by grease or other preservative recommended by

vendor.

11.) Valve stems shall be greased to prevent from rusting.

12.) All junction box / panel cable entries that are not used (spares) shall be plugged with suitable material.

13.) Valve flanges must have a suitable cover installed on both openings to keep out foreign materials, dirt

rust etc.

14.) Glass material of instrument or equipment shall be covered with thick carton material or plywood to

avoid breakage.

PECIKO FIELD DEVELOPMENT PROJECT PHASE 5

CONTRACT PCK5 / EPSCI

Doc. No : ID-PK5-PF-NSB-0811020

Rev.

: 03

Status: D

Date

: 10 Dec 08

This document is the property of COMPANY. It must not be stored, reproduced or disclosed to others without written authorization from the COMPANY.

PT NIPPON STEEL BATAM

Doc. Title :

PT. NISCONI

MECHANICAL PRESERVATION PROCEDURE

Doc. Type

PRC

Discipline

PJM

Page 7 of 9

15.) Foods and drinks shall not be allowed on the platform so as not to attract rodents (i.e., mice, rats etc.)

Once these rodents are noticed in the platform, it must be terminated immediately to avoid damaging

cables inside the panels.

16.) In all the preservation activities, Mechanical Engineer shall keep record and readily available if

required by Client for verification.

7.0 GENERAL STATEMENT

1. Equipment shall be protected keep clean throughout the duration of the project by means of

protective covers or regular maintenance routine.

2. Special care shall be taken to prevent damage to any mechanical equipment due to welding and

grinding or sand blasting is taken place nearby or other fabrication or installation works.

3. Equipment shall be preserved in accordance with manufacturers recommendation.

4. All equipment in preservation shall be located in a dedicated area far from blasting and painting area

and protected from direct exposure to sunlight.

8.0 Attachment

1.) Ex project preservation sample preservation record.

PECIKO FIELD DEVELOPMENT PROJECT PHASE 5

CONTRACT PCK5 / EPSCI

Doc. No : ID-PK5-PF-NSB-0811020

Rev.

: 03

Status: D

Date

: 10 Dec 08

This document is the property of COMPANY. It must not be stored, reproduced or disclosed to others without written authorization from the COMPANY.

PT NIPPON STEEL BATAM

Doc. Title :

PT. NISCONI

MECHANICAL PRESERVATION PROCEDURE

Doc. Type

PECIKO FIELD DEVELOPMENT PROJECT PHASE 5

CONTRACT PCK5 / EPSCI

PRC

Discipline

PJM

Page 8 of 9

Doc. No : ID-PK5-PF-NSB-0811020

Rev.

: 03

Status: D

Date

: 10 Dec 08

This document is the property of COMPANY. It must not be stored, reproduced or disclosed to others without written authorization from the COMPANY.

PT NIPPON STEEL BATAM

Doc. Title :

PT. NISCONI

MECHANICAL PRESERVATION PROCEDURE

Doc. Type

PECIKO FIELD DEVELOPMENT PROJECT PHASE 5

CONTRACT PCK5 / EPSCI

PRC

Discipline

PJM

Page 9 of 9

Doc. No : ID-PK5-PF-NSB-0811020

Rev.

: 03

Status: D

Date

: 10 Dec 08

This document is the property of COMPANY. It must not be stored, reproduced or disclosed to others without written authorization from the COMPANY.

Вам также может понравиться

- Preservation ProcedureДокумент9 страницPreservation ProcedureMuhammadPurnamaSugiriОценок пока нет

- Preservation Procedure For Rotating Equipment Rev 1Документ5 страницPreservation Procedure For Rotating Equipment Rev 1Murali D Murthy75% (4)

- Equipment Maintenance and Preservation ProcedureДокумент16 страницEquipment Maintenance and Preservation ProcedureMohamad Shafey100% (2)

- Preservation Procedure OverviewДокумент18 страницPreservation Procedure OverviewSreni Excel Macros100% (5)

- OISD Standard for Preserving Idle Mechanical EquipmentДокумент28 страницOISD Standard for Preserving Idle Mechanical EquipmentIrfa Garnadi100% (4)

- Mothballing of EquipmentДокумент7 страницMothballing of EquipmentMohammed Ashraf100% (1)

- Piping Reinstatement: Inspection Test Report Form NoДокумент2 страницыPiping Reinstatement: Inspection Test Report Form NoFrancisco75% (4)

- PreservationsДокумент23 страницыPreservationsShijumon KpОценок пока нет

- Mechanical Completion Documents Handling ProcedureДокумент7 страницMechanical Completion Documents Handling Procedureiwan100% (6)

- NORSOK Z-006 - PreservationДокумент20 страницNORSOK Z-006 - Preservationjoaocavti100% (4)

- Preservation Check Sheet PRODДокумент2 страницыPreservation Check Sheet PRODBảo Hạnh Phúc Bảo Hạnh PhúcОценок пока нет

- Asset Preservation MethodsДокумент10 страницAsset Preservation MethodsLuck Luqe67% (3)

- QIR-112-Static Equipment Preservation CardДокумент2 страницыQIR-112-Static Equipment Preservation CardSamer BayatiОценок пока нет

- Preservation Procedure ExampleДокумент18 страницPreservation Procedure Exampleshetty259641Оценок пока нет

- Nitrogen Purging PDFДокумент17 страницNitrogen Purging PDFgshdavid100% (2)

- Hydrostatic Test Procedure Site RevDДокумент23 страницыHydrostatic Test Procedure Site RevDBhavani Prasad100% (8)

- Nitrogen Purging ProcedureДокумент17 страницNitrogen Purging ProcedureTanver Ali100% (2)

- Flushing Procedure Final 11Документ4 страницыFlushing Procedure Final 11Hamada ELaraby50% (2)

- Procedure For Material PreservationДокумент7 страницProcedure For Material PreservationPugal100% (1)

- 02 MechanicalДокумент44 страницы02 MechanicalSigit Bintan100% (1)

- Itp TankДокумент4 страницыItp TankAmber Chavez100% (2)

- Drying of Pipelines Prior To Commissioning - CEPS A.SДокумент6 страницDrying of Pipelines Prior To Commissioning - CEPS A.Sim4uim4uim4uim4uОценок пока нет

- Kencana Infrastructure Quality Assurance ProcedureДокумент22 страницыKencana Infrastructure Quality Assurance Procedurenaseema1100% (9)

- ITP's and ITR's A Necessary - Monster - PDFДокумент5 страницITP's and ITR's A Necessary - Monster - PDFshastri85Оценок пока нет

- Inspection and Test Plan For Centrifugal PumpДокумент4 страницыInspection and Test Plan For Centrifugal PumpVinh Do Thanh100% (1)

- Donggi Senoro LNG Project: Inspection and Test Plan FOR Hot Oil Heater ErectionДокумент5 страницDonggi Senoro LNG Project: Inspection and Test Plan FOR Hot Oil Heater ErectionAlif Rahmat FebriantoОценок пока нет

- Preservation Storage For Reciprocating CompressorДокумент7 страницPreservation Storage For Reciprocating CompressorSubbarayan Saravanakumar100% (1)

- Valve Testing, Preservation & Installation DocumentsДокумент15 страницValve Testing, Preservation & Installation DocumentsGaurav KhamkarОценок пока нет

- Drying and Nitrogen ProcedureДокумент5 страницDrying and Nitrogen ProcedureAdaghara67% (3)

- FIELD INSPECTION PROCEDURESДокумент29 страницFIELD INSPECTION PROCEDURESsbmmla91% (22)

- How To Mothball and Decommission Industrial PlantsДокумент4 страницыHow To Mothball and Decommission Industrial Plantswholenumber100% (2)

- Flange Management Register: Dr. Concrete Building Material General Contracting & Trading FZEДокумент1 страницаFlange Management Register: Dr. Concrete Building Material General Contracting & Trading FZEsudeesh kumar100% (1)

- Air Blowing of 12" Ipp Line 178GN30004: Method Statement FORДокумент5 страницAir Blowing of 12" Ipp Line 178GN30004: Method Statement FORrvsreddysenaОценок пока нет

- Ione-Aa00-Pe-Cm-0003 System & Sub-System Subdivision - Rev. 2Документ50 страницIone-Aa00-Pe-Cm-0003 System & Sub-System Subdivision - Rev. 2YusufОценок пока нет

- Spare Part PhilosophyДокумент27 страницSpare Part Philosophyavaisharma50% (2)

- IOCL Static Equipment ITPДокумент12 страницIOCL Static Equipment ITPaamirapi100% (3)

- Inspection Test Plan - Piping FabricationДокумент5 страницInspection Test Plan - Piping Fabricationhassan_ndt80% (5)

- 16" Utue Ka-Ubit PP Gas Pipeline Nitrogen Purging ProcedureДокумент17 страниц16" Utue Ka-Ubit PP Gas Pipeline Nitrogen Purging ProcedureRichard Nwachukwu92% (12)

- Grieg Spec Preservation InstructionsДокумент9 страницGrieg Spec Preservation InstructionsKARTHIGEYAN.RОценок пока нет

- Air Blowing ProcedureДокумент5 страницAir Blowing ProcedureArslan NisarОценок пока нет

- ITP For Storage TankДокумент6 страницITP For Storage Tankittiphon3194% (17)

- Preservation Inspection Check ListДокумент2 страницыPreservation Inspection Check ListZaini Achmad0% (2)

- Material Storage Handling and Preservation ProcedureДокумент24 страницыMaterial Storage Handling and Preservation ProcedureFerdie OS100% (7)

- Contract Inspection ProceduresДокумент6 страницContract Inspection ProceduresAndreas Schlager100% (2)

- Acid Cleaning ProcedureДокумент6 страницAcid Cleaning ProcedureMadhan RajОценок пока нет

- Boiler Inspection and Test PlanДокумент13 страницBoiler Inspection and Test Plandoley_pranab100% (3)

- 12 Procedure For Coating Wrapping Rev 01Документ6 страниц12 Procedure For Coating Wrapping Rev 01dnbinh100% (2)

- Vaccum Box Test Procedure For All TanksДокумент6 страницVaccum Box Test Procedure For All Tanksויליאם סן מרמיגיוסОценок пока нет

- Pre Comm ProcedureДокумент8 страницPre Comm ProcedurewahyuОценок пока нет

- 80 Marketing - QC-HSE Installtion Procedure Q-051-07-YMN Betara Rev AДокумент9 страниц80 Marketing - QC-HSE Installtion Procedure Q-051-07-YMN Betara Rev Agstketut100% (1)

- PSP-KPD-FAB-G6014 R3215 Mechanical Completion Procedure Rev A1Документ16 страницPSP-KPD-FAB-G6014 R3215 Mechanical Completion Procedure Rev A1Badri AbdullahОценок пока нет

- Mechanical Draft Cooling TowerДокумент54 страницыMechanical Draft Cooling Towerashish278367% (3)

- 22 Equipment Unloading, Storing, Installation and ErectionДокумент8 страниц22 Equipment Unloading, Storing, Installation and ErectionAkhilesh KumarОценок пока нет

- RFQ 002Документ11 страницRFQ 002John EricksonОценок пока нет

- Eis-Cms-Pk - 023-Replacement of Girth Gear Assembly For 03-Vr-2701abДокумент5 страницEis-Cms-Pk - 023-Replacement of Girth Gear Assembly For 03-Vr-2701abhastmishОценок пока нет

- Safety Plan For Erection Steel BuildingДокумент8 страницSafety Plan For Erection Steel Buildingari_prasОценок пока нет

- Ptg-tmy-yad2-In-rfq-019 Rev 0 RFQ For Wave Protection For Esv-Sdv & Fo JBДокумент15 страницPtg-tmy-yad2-In-rfq-019 Rev 0 RFQ For Wave Protection For Esv-Sdv & Fo JBAditya PranotoОценок пока нет

- EXW-P006-0000-CD-SHC-MT-00093 Method Statement For Waterproofing System Rev 1Документ43 страницыEXW-P006-0000-CD-SHC-MT-00093 Method Statement For Waterproofing System Rev 1Syed Umair HashmiОценок пока нет

- 036-Nitrogen Purging Procedure PDFДокумент13 страниц036-Nitrogen Purging Procedure PDFKöksal Patan78% (9)

- Method Statement for Anti-termite TreatmentДокумент6 страницMethod Statement for Anti-termite TreatmentJaime Manalili LandinginОценок пока нет

- 1ST Periodical Test Paper CSS 12Документ3 страницы1ST Periodical Test Paper CSS 12Ched Augustus AranОценок пока нет

- SGS MIN TP2003 10 Coal Quality Management PDFДокумент4 страницыSGS MIN TP2003 10 Coal Quality Management PDFDavid SimanungkalitОценок пока нет

- Analyze OOAD Models For Library Management SystemДокумент2 страницыAnalyze OOAD Models For Library Management SystemPradeepОценок пока нет

- Blessings InterviewДокумент329 страницBlessings Interviewsalihu_aliОценок пока нет

- How To Set Up A Pmo PDFДокумент18 страницHow To Set Up A Pmo PDFMona NabilОценок пока нет

- Method Statement For Plastering WorkДокумент15 страницMethod Statement For Plastering Workstrikersam100% (9)

- Quality Control in Production ManagementДокумент68 страницQuality Control in Production ManagementAtul Dwivedi100% (2)

- Agile Quality AssuranceДокумент269 страницAgile Quality Assurancevijaysudhakar100% (1)

- Quality Assurance PlanДокумент7 страницQuality Assurance PlanTomi KazuoОценок пока нет

- Ans: D: Software Quality Assurance MCQДокумент10 страницAns: D: Software Quality Assurance MCQRavishankar YadavОценок пока нет

- Various Dept of Vizag Steel Plant Particulars of OrganizationДокумент27 страницVarious Dept of Vizag Steel Plant Particulars of OrganizationSumanth VasistaОценок пока нет

- Field Sampling Procedures Manual 2005Документ574 страницыField Sampling Procedures Manual 2005BWB49Оценок пока нет

- Tashlie Ann Ramos NatadДокумент3 страницыTashlie Ann Ramos NatadJustin SantosОценок пока нет

- Quality Management and Control in ConstructionДокумент22 страницыQuality Management and Control in ConstructionjennyОценок пока нет

- Method Statement LV MV CablesДокумент14 страницMethod Statement LV MV CablesehteshamОценок пока нет

- Pembekalan TerbaruДокумент86 страницPembekalan TerbaruHaristika ChresnaОценок пока нет

- Unit 5Документ72 страницыUnit 5227r5a0522Оценок пока нет

- DuPont Welding Quality Manual SEOДокумент54 страницыDuPont Welding Quality Manual SEORodolfoMarínОценок пока нет

- Yamaha Motors Seminar InsightsДокумент27 страницYamaha Motors Seminar Insightsmaxsteelfireblade60% (5)

- SOP on Revised Grains Quality ControlДокумент8 страницSOP on Revised Grains Quality ControlPauline Caceres AbayaОценок пока нет

- Qa Document Rmmm-Ts HR Profiling SystemДокумент33 страницыQa Document Rmmm-Ts HR Profiling Systemapi-260228939Оценок пока нет

- Pipe Hangers and SupportДокумент120 страницPipe Hangers and Supportangel gabriel perez valdezОценок пока нет

- Capstone Manuscript TemplateДокумент52 страницыCapstone Manuscript TemplateFrancisco AssisiОценок пока нет

- WHO Male Latex CondomДокумент155 страницWHO Male Latex CondomjuancgoОценок пока нет

- ISACA CISA v2021-08-09 q147Документ36 страницISACA CISA v2021-08-09 q147Eubert Nkum MensahОценок пока нет

- 02-200 Principles and FundamentalsДокумент7 страниц02-200 Principles and FundamentalsTep PiОценок пока нет

- Steel Erection Method Statement-Exit.10 - Rev-01 (AutoRecovered)Документ106 страницSteel Erection Method Statement-Exit.10 - Rev-01 (AutoRecovered)Syed Mohammed ZakariaОценок пока нет

- Deviations and Non-Conformances SOPДокумент1 страницаDeviations and Non-Conformances SOPqmdocs33% (9)

- Project Execution Plan BTSДокумент28 страницProject Execution Plan BTSAnyanime WilliamsОценок пока нет

- SQA Lecture 1Документ55 страницSQA Lecture 1MuzammilAhmadKhanОценок пока нет