Академический Документы

Профессиональный Документы

Культура Документы

OT HowTo f02

Загружено:

iwancoc15Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

OT HowTo f02

Загружено:

iwancoc15Авторское право:

Доступные форматы

Tear Here

How To Begin a

Fire Hydrant

Operation and

Maintenance Program

Story and photos by Larry Rader,

NDWC Environmental Consultant

The single most important thing about having fire hydrants is

that they advertise Fire Protection! Communities expect that at

a moments notice, day or night, in any weather, the hydrant will

supply sufficient water to extinguish a fire.

Fire hydrants come in two basic categories: wetbarrel and dry-barrel. Manufacturers intend wet-barrel hydrants to be used only in climates where the

temperature never drops below 32 degrees

because they are always charged with water. Drybarrel hydrants automatically drain after the water

is turned off and are much more widely used for

obvious reasons.

When the fire fighters eventually put the fire out,

they drove a tapered wooden plug into the hole in

the pipe wall and marked the location of the hole

with the fireplug. Later, when cast iron became

the material of choice for water lines, it became

harder to bore the hole. However, water systems

installed tees with wooden plugs at convenient locations and the wooden fireplug continued for several

more years.

Each manufacturer of dry-barrel hydrants has its

own method of operation, but the basics are similar. These hydrants are pressurized and drain

through a main valve in the base. When the main

valve is opened, the barrel is pressurized. When

the main valve is closed, the barrel drains. The

main valve is located below the normal frost line to

protect the hydrant from freezing, allowing the drybarrel hydrant to be used almost anywhere.

The hydrants evolution included a standpipe that

fire fighters shoved into the tee after they removed

the fireplug. It conveyed water above ground to a

hose connection and a ball valve, and it finally

made the wooden plug obsolete. It also became the

forerunner of the dry-barrel compression hydrant.

Compression Type: In this type of hydrant, the main

valve moves jointly on a vertical axis against a seat

located in the hydrant base. The valve moves against

the seat to close and away from the seat to open. A

vertical stem moves up or down when the operating

nut is rotated. The valve may be located below the

seat and opens against the pressure or above the

seat and opens with the pressure. (See Figure 1 on

page 3.)

In addition, communities may use fire hydrants for

things other than putting out fires. In the summer

2002 issue of On Tap, I addressed using of

hydrants for distribution line flushing. But, the primary reason you install and maintain fire hydrants

is to provide your customers with fire protection for

their homes and businesses.

Other types of dry-barrel hydrants include slide

gate and toggle, which describes the mechanics

that open and close them, and flush hydrants,

one

OF FOUR

Hydrant Types and How They Work

Around the time of the American Revolution, several communities in the U.S. built water distribution

systems. These early systems used main lines that

workers built using bored-out logs, which they fitted together then buried. When fire fighters needed water, they uncovered the wooden line and

bored a hole in the pipe wall. They used the water

that collected around the pipe for fighting the fire.

PAGE

Tear Here

A Short Hydrant History

Inspect Hydrants Regularly

which are installed in a pit and have nothing projecting above ground.

The method of allowing the hydrant to drain when

closed is equally as important as the method of

charging it. Most dry-barrel designs use weep holes,

or drains, located at the bottom of the hydrant and

below ground level. As the hydrant is turned on,

seals are manipulated to close the weep holes, keeping water from being forced out under pressure. As

the hydrant is closed, the seals are manipulated

away from the weep holes, and the barrel drains.

Each hydrant manufacturer has its own design for

almost every operation. The more brands, series, and

designs you have in your system, the more complicated your operation and maintenance (O&M) program

will become, and the more repair parts and specialized tools you will need to stock. So keep it simple,

find a style, brand, or model you like and stick with

it.

1. Loosen the hold-down nut.

Operation and Maintenance

Like any other piece of equipment, if you dont operate and maintain your fire hydrants properly, they

wont work when you need them most.

Operation: Under normal conditions, the water in

your distribution system moves at a fairly constant

rate and pressure. Opening a hydrant too quickly

could create negative pressure and set up a dangerous backflow situation. Closing a hydrant too quickly

can cause water hammer, which is very destructive to

lines and equipment. Water hammer is sort of like

running headlong into a brick wall. You will immediately wish you had slowed down more gradually.

2. Remove the hold-down nut.

3. Loosen the operating nut.

Dry-barrel hydrants should always be opened fully

because the drain mechanism operates with the main

valve. A partially opened hydrant can cause water to

be forced out through the drains and cause erosion

around the base of the hydrant.

OF FOUR

However, tightening the caps too soon can trap

water in the barrel and set up the possibility of freezing. As a matter of fact, because hydrants need a

supply of air to drain properly, a good way to check

the drain is to place your hand over an open nozzle

PAGE

two

Use a tarp to keep parts clean and

from being lost in the mud.

4. Remove the operating nut.

5. Remove the bonnet.

after the hydrant is turned off. As the water drains it

creates a vacuum that can be felt at the nozzle. So

remember: never tighten the caps until the hydrant

finishes draining. And never, ever operate a fire

hydrant with any wrench other than the one

designed for that particular hydrant.

Inspection: The American Water Works Association

(AWWA) recommends all hydrants be inspected

regularly, at least once a year. In freezing weather,

dry-barrel hydrants may need to be inspected in

spring and fall. But for the most part, much of

hydrant inspection is visual and common sense. For

example:

6. Use the manufacturers seat

wrench to unscrew the seat ring.

7. Lift out the entire valve, seat, and

stem assembly.

Dry Barrel Compression Type Hydrant

1. Make sure the hydrant, including all valves and

nozzles, is accessible with no obstructions.

2. Check with a listening device for main valve

leaks.

3. Use a chalked cord or plumb bob to check for

water standing in the barrel.

4. Loosen the cap and open the hydrant a few turns

to allow air to vent, and then tighten the cap and

open the hydrant fully. All caps must be tight at

this point.

1. operating nut

2. hold-down nut

3. top cap

4. top gasket

5. nozzel cap gasket

6. O-ring

7. nozzel cap

8. upper stem

9. body gasket

10. flange lock ring

11. valve seat

12. drain hole lining

13. drain valve

5. Make sure the hydrant is turned on fully and

check for any leaks around the operating stem,

nozzles, any seals or packing, and at the flanges.

Replace the O-rings if necessary.

6. Partially close the hydrant until the drains open

and flush the drains for a few seconds under pressure.

7. Exercise the watch valve and leave it open.

8. Perform hydrant inspection during line flushing

and flow testing, which were discussed in the

summer 2002 issue of On Tap.

9. And last, but certainly not least, if during the

inspection you discover a hydrant that is not

working or has major problems, tag it, notify the

fire department immediately, and make preparations to fix the problem.

Note: Each time you remove a hydrants parts, pay

special attention to all seals and threads, and note

any wear. Most manufacturers recommend that

these parts be lubricated before putting the hydrant

back together to ensure its smooth operation.

General Maintenance and Repairs

Source: www.clowcanada.com

three

OF FOUR

Figure 1

PAGE

Because of the many different brands and models,

always refer to the manufacturers literature for maintenance items and repair procedures. The manufacturer, or its representative, also can tell you what

tools are necessary to perform repairs, such as

removing the main valve stem or maintaining other

parts of the hydrant. Hydrant repair requires specialized tools. Do not start a project without them.

Valve stem with a safety stem coupling (A).

This coupling, along with the safety flange and

safety bolts & nuts (B), allow the hydrant to be

broken off, as in a car accident, without causing

the valve to be disturbed and water escaping.

What to Stock

Most manufacturers package repair parts in repair

kits, including all of the parts necessary to make a

certain repair. However, because I dont know your

system, Im not going to pretend I know what to tell

you to keep on the shelf. For instance, if you are located close to a distributor who sells and stocks parts for

your hydrants, you may want to stock very little yourself. In case you arent lucky enough to live close to a

distributor, you at least should have, traffic repair kits,

if you have hydrants with this breakaway feature, a

seals and O-ring kit or two, and a couple of seats.

When possible, it is always better to have the manufacturers representative advise you as to the correct

stock of repair parts, grease, oil, or anything else

you may need. A particular repair item that most of

us never seem to have is an extension kit, which is

used to raise a hydrant after the ground around it

has been raised. No one would consider a hydrant

accessible if its nozzles were resting on the ground.

Recordkeeping

Dismantle the main valve, upper valve plate, and seat ring.

As the hydrant is closed, the

upper valve plate slides up and

uncovers the weep holes, allowing the hydrant to drain.

As the main valve is forced away

from the seat ring, the upper

valve plate moves down to seal

off the drain.

A good O&M program is only as good as the

records you keep. Start by assigning a number to

each hydrant. And, if you have a distribution map

of your system, note the location of each hydrant by

number. In addition, the record for each hydrant

should include all pertinent information, such as

location, make and model, size and number of nozzles, thread type, flow rates, size and material of

the main line, and maintenance history. A great

source for all sorts of recordkeeping forms relating

to hydrant O&M is in the AWWA Manual of Water

Supply Practices, Installation, Field Testing and

Maintenance of Fire Hydrants. Not only is this publication a good source of recordkeeping forms, it

also is one of the most comprehensive guides to fire

hydrant O&M. I have worn out more than one copy

and highly recommend it.

OF FOUR

Larry Rader has more than 25 years in

the water and wastewater industry.

When he isnt working on water and

wastewater problems, he likes to play

his banjo with an Old Time music

group in his hometown of Beverly, West Virginia. If

you have a question for Rader, he can be reached

through e-mail at lrader@meer.net.

National Drinking

Water Clearinghouse

West Virginia University

P.O. Box 6064

Morgantown, WV 26506

PAGE

four

Install the safety flange O-ring.

National Environmental Services Center

An Equal Opportunity/Affirmative Action Institution

Вам также может понравиться

- Nfpa 291 Hyd - Test PDFДокумент11 страницNfpa 291 Hyd - Test PDFJeff D. Agustin100% (1)

- Popular Mechanics: How to Fix Anything: Essential Home Repairs Anyone Can DoОт EverandPopular Mechanics: How to Fix Anything: Essential Home Repairs Anyone Can DoРейтинг: 4 из 5 звезд4/5 (2)

- Fire Hydrant SpecsДокумент14 страницFire Hydrant SpecsGie Mak100% (2)

- Ultimate Guide: Plumbing, Updated 5th EditionОт EverandUltimate Guide: Plumbing, Updated 5th EditionРейтинг: 4 из 5 звезд4/5 (3)

- Storage Checklists: Short-Term Storage (Less Than 60 Days)Документ7 страницStorage Checklists: Short-Term Storage (Less Than 60 Days)Karatebird100% (2)

- Confidence Testing For Fire Hydrants: A Guide To The Maintenance, Testing, and Marking of Private Fire HydrantsДокумент13 страницConfidence Testing For Fire Hydrants: A Guide To The Maintenance, Testing, and Marking of Private Fire HydrantsImdad PeshimamОценок пока нет

- Wrap Up For Winter MoДокумент6 страницWrap Up For Winter MoblackestsheepОценок пока нет

- Portable Gasoline Trash Pump: Model 761204 2" Intake/Outlet 7HP Mode L 761205 4" Intake/Outlet 14HPДокумент15 страницPortable Gasoline Trash Pump: Model 761204 2" Intake/Outlet 7HP Mode L 761205 4" Intake/Outlet 14HPtubjackieОценок пока нет

- Solvent Use in Freeze DryersДокумент5 страницSolvent Use in Freeze DryersTeviОценок пока нет

- Fire Hydrant - WikipediaДокумент9 страницFire Hydrant - WikipediaVaibhav SawantОценок пока нет

- Orbit Article Molecular Sieve Dehydration Switching ValvesДокумент12 страницOrbit Article Molecular Sieve Dehydration Switching ValvesPasquale Sessa0% (1)

- Mod 3Документ26 страницMod 3Sahil KumarОценок пока нет

- 10 Things Not To Do When Your Hydraulic Fitting LeaksДокумент4 страницы10 Things Not To Do When Your Hydraulic Fitting LeaksJosh WhiteОценок пока нет

- Common Causes of Refrigerant Leaks and How To Fix Them: Buyer's GuideДокумент6 страницCommon Causes of Refrigerant Leaks and How To Fix Them: Buyer's Guideali zalatОценок пока нет

- ICI SAFETY NEWSLETTER No 56Документ9 страницICI SAFETY NEWSLETTER No 56Иванов ИванОценок пока нет

- ICI SAFETY NEWSLETTER No 61 PDFДокумент6 страницICI SAFETY NEWSLETTER No 61 PDFИванов ИванОценок пока нет

- Popular Mechanics Repairing Cooling System LeaksДокумент4 страницыPopular Mechanics Repairing Cooling System LeaksAdriana OrtegaОценок пока нет

- 10 Things Not To Do When Your Hydraulic Fitting LeaksДокумент2 страницы10 Things Not To Do When Your Hydraulic Fitting LeaksEduardo CramerОценок пока нет

- American Top Loader Washing Machine + SerialДокумент67 страницAmerican Top Loader Washing Machine + SerialMandragora officinarum100% (1)

- 120 Volt Electric Single Ybss ManualДокумент17 страниц120 Volt Electric Single Ybss ManualSal TargarienОценок пока нет

- Installation Instructions: For Stacked Washers and DryersДокумент24 страницыInstallation Instructions: For Stacked Washers and DryersMircea FrantОценок пока нет

- API Plans That I Use.: Hot Water ApplicationsДокумент7 страницAPI Plans That I Use.: Hot Water ApplicationsSudip SardarОценок пока нет

- Drain Cleaning Protocol: by Emily Gutowski On Dec 03, 2020 02:25 PMДокумент6 страницDrain Cleaning Protocol: by Emily Gutowski On Dec 03, 2020 02:25 PMJOSEPH DIASОценок пока нет

- Handheld Steam Cleaner: Owner's GuideДокумент16 страницHandheld Steam Cleaner: Owner's GuideBen SzapiroОценок пока нет

- Kenmore Washer 11026904691Документ37 страницKenmore Washer 11026904691soonrapturedОценок пока нет

- Seal Plans That I UseДокумент9 страницSeal Plans That I Usedhanu_aquaОценок пока нет

- The Plumbing BasicsДокумент36 страницThe Plumbing BasicsDewmabel BaconawaОценок пока нет

- Muller CoДокумент12 страницMuller CoRamSalunkheОценок пока нет

- DWD Ld1411 ManualДокумент32 страницыDWD Ld1411 Manualsarvaanyaa100% (1)

- Manual TQC PDFДокумент13 страницManual TQC PDFKissmark Rivas MorenoОценок пока нет

- PR Ec Sio N: Owner'S GuideДокумент13 страницPR Ec Sio N: Owner'S GuideHencheal AtangaОценок пока нет

- DistillationДокумент8 страницDistillationRaz MahariОценок пока нет

- Catalog DEAIR HM 2022Документ20 страницCatalog DEAIR HM 2022Nguyễn Anh TuấnОценок пока нет

- Owner'S Manual: Foot Operated Faucet Control Valves For Commercial SinksДокумент13 страницOwner'S Manual: Foot Operated Faucet Control Valves For Commercial Sinksmember1000Оценок пока нет

- Collong System ReportДокумент19 страницCollong System ReportNiko EscuetaОценок пока нет

- 1 716554253262412976 PDFДокумент5 страниц1 716554253262412976 PDFAli YarahmadiОценок пока нет

- SOP SMB - 050.1 - Using A Rotory Evaporator DF NS 0614Документ4 страницыSOP SMB - 050.1 - Using A Rotory Evaporator DF NS 0614Kimia AsikОценок пока нет

- Bennett Read Hydro User GuideДокумент12 страницBennett Read Hydro User GuidePieter Steenkamp100% (1)

- DF NMK503WebInstallationManualДокумент6 страницDF NMK503WebInstallationManualJames LoewenОценок пока нет

- Five Questions and Answers About Heat ExchangersДокумент4 страницыFive Questions and Answers About Heat ExchangersAatish ChandrawarОценок пока нет

- Jones Hydrant OM 8-21-09Документ6 страницJones Hydrant OM 8-21-09RktBatamОценок пока нет

- Manual Filtros Dynamic Series Rainbow Pentair InglesДокумент2 страницыManual Filtros Dynamic Series Rainbow Pentair InglesIrvin Enrique Solano SalvadorОценок пока нет

- Lab Rotary EvaporatorДокумент7 страницLab Rotary EvaporatorAnna Yunita SitompulОценок пока нет

- Sears Wet:Dry Vac L0901082Документ12 страницSears Wet:Dry Vac L0901082007003sОценок пока нет

- Rotary Evaporator Fact SheetДокумент3 страницыRotary Evaporator Fact SheetAbid ZiaОценок пока нет

- WALLACH LL100 TWO TRIGGER CRYOSURGICAL UNIT For N2O Instructions For UseДокумент8 страницWALLACH LL100 TWO TRIGGER CRYOSURGICAL UNIT For N2O Instructions For UsePierre Richard MompremierОценок пока нет

- Dehumidifier ManualДокумент32 страницыDehumidifier Manual42e9d4f7Оценок пока нет

- 16-Ton Air/Hydraulic Pipe Bender: Assembly and Operation InstructionsДокумент6 страниц16-Ton Air/Hydraulic Pipe Bender: Assembly and Operation InstructionsScotty ThomasОценок пока нет

- Operating Instructions: Century Fire Hydrant B-50-B18 HYDRANT B-50-B24 HYDRANTДокумент8 страницOperating Instructions: Century Fire Hydrant B-50-B18 HYDRANT B-50-B24 HYDRANTdavid messierОценок пока нет

- The Dual Seal ArrangementДокумент17 страницThe Dual Seal Arrangementnyuvaraj1981Оценок пока нет

- Great Care Goes Into Ensuring That Electrical Power Stays Inside Electric CablesДокумент9 страницGreat Care Goes Into Ensuring That Electrical Power Stays Inside Electric CablesJosh WhiteОценок пока нет

- Operation and Maintenance Manual H450 TREND 8-18-16Документ24 страницыOperation and Maintenance Manual H450 TREND 8-18-16Ferry SoebagioОценок пока нет

- Probationary Firefighters ManualДокумент45 страницProbationary Firefighters ManualHualy DelgadoОценок пока нет

- Pdfs SystemcontaminationДокумент4 страницыPdfs SystemcontaminationLuis Carlos Mayorga GarciaОценок пока нет

- Karcher b102 Plus Operation User S Manual 20Документ20 страницKarcher b102 Plus Operation User S Manual 20SALAH NETОценок пока нет

- Instructions ReportДокумент3 страницыInstructions Reportapi-610888717Оценок пока нет

- Strainer GuideДокумент26 страницStrainer Guidemudrijasm100% (1)

- Installation & Operation Manual: ContentДокумент3 страницыInstallation & Operation Manual: ContenthannusОценок пока нет

- Provide The Steps Required To Perform This Procedure.: 7. Step-By-Step Operating ProcedureДокумент3 страницыProvide The Steps Required To Perform This Procedure.: 7. Step-By-Step Operating Procedureazini amizaОценок пока нет

- List Konsignasi Ke DynagearДокумент3 страницыList Konsignasi Ke DynagearJohanes PangestuОценок пока нет

- S770 Hyd SJC V-1605Документ2 страницыS770 Hyd SJC V-1605Teknik MakinaОценок пока нет

- Sampling Conditioning SystemДокумент24 страницыSampling Conditioning System王祚Оценок пока нет

- Instruction Manual Book 1 PDFДокумент400 страницInstruction Manual Book 1 PDFRM HaroonОценок пока нет

- 8 Inch SS 50 HZ CatalogueДокумент12 страниц8 Inch SS 50 HZ CataloguewagayeОценок пока нет

- Chillers, Fcu'S & Ahu'S: Yasser El Kabany 35366866 010-9977779 35366266Документ31 страницаChillers, Fcu'S & Ahu'S: Yasser El Kabany 35366866 010-9977779 35366266mostafaabdelrazikОценок пока нет

- Wpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1Документ1 страницаWpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1Gabriel Alejandro Marino EstayОценок пока нет

- Mechanical Valves & Flexible Joints: Leading The Way in Piping NeedsДокумент40 страницMechanical Valves & Flexible Joints: Leading The Way in Piping NeedsTanveer AzizОценок пока нет

- ANSI HI 9-8-1998 Pump Intake DesignДокумент82 страницыANSI HI 9-8-1998 Pump Intake DesignPilar Ruiz Ramirez100% (1)

- P 143 MPR Apx IДокумент28 страницP 143 MPR Apx ILakshmanan VenkateswaranОценок пока нет

- 11-Fire Protection SystemДокумент11 страниц11-Fire Protection Systembianca_torres_8Оценок пока нет

- Ressure Test Procedure For Piping SystemДокумент5 страницRessure Test Procedure For Piping SystemKyaw Kyaw AungОценок пока нет

- Hydrostatic Testing ProceduresДокумент2 страницыHydrostatic Testing Proceduresomar sadiqОценок пока нет

- Component Operation: Section 3Документ82 страницыComponent Operation: Section 3Tú Xuân LươngОценок пока нет

- MS - 304 - Dated 09.02.2001Документ5 страницMS - 304 - Dated 09.02.2001sujaraghupsОценок пока нет

- Leakage Acceptance Rates Comparison Metal & Soft SEATED VALVES ISO 5208/API 598/API 6D/MSS SP-61/FCI 70-2Документ6 страницLeakage Acceptance Rates Comparison Metal & Soft SEATED VALVES ISO 5208/API 598/API 6D/MSS SP-61/FCI 70-2Wilson RinconОценок пока нет

- Enerpac Industrial Tools Catalog E330a en-AUДокумент428 страницEnerpac Industrial Tools Catalog E330a en-AURichard GrahamОценок пока нет

- Course Material - Standards Pertaining To ValvesДокумент11 страницCourse Material - Standards Pertaining To ValvesAhmed Abd El RahmanОценок пока нет

- Removable Cover Check Valves For Potable Water Pump StationsДокумент4 страницыRemovable Cover Check Valves For Potable Water Pump StationsOleg ShkolnikОценок пока нет

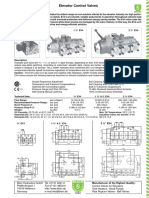

- Elevator Control Valves: EN ISO 9001Документ4 страницыElevator Control Valves: EN ISO 9001Bantu BantuОценок пока нет

- 0900766b815c34b4 PDFДокумент201 страница0900766b815c34b4 PDFJULIAN ANDRES ROJASОценок пока нет

- SCI Butterfly Valves - BFV0211 PDFДокумент6 страницSCI Butterfly Valves - BFV0211 PDFSalik ShabbirОценок пока нет

- Fire PUMPS T&C ChecklistДокумент6 страницFire PUMPS T&C ChecklistUmair BaBerОценок пока нет

- D1 620en PlungerpumpДокумент4 страницыD1 620en PlungerpumpAkhil JoseОценок пока нет

- New Microsoft Office Word DocumentДокумент9 страницNew Microsoft Office Word DocumentjaimonjoyОценок пока нет

- Factory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: DДокумент6 страницFactory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: Dbayu dewantoОценок пока нет

- Series 826YD Specification SheetДокумент2 страницыSeries 826YD Specification SheetFEBCOОценок пока нет

- Hydraulic CalculationsДокумент36 страницHydraulic CalculationsAhmed WazirОценок пока нет

- Site Development Foundation Plan: Goldwyn R. BariaДокумент1 страницаSite Development Foundation Plan: Goldwyn R. BariaMille Alfred AgaloosОценок пока нет

- Ata 36Документ52 страницыAta 36Geovanni Riquelme LooОценок пока нет

- Clean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeОт EverandClean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeРейтинг: 5 из 5 звезд5/5 (2)

- Summary of Goodbye, Things: The New Japanese Minimalism by Fumio SasakiОт EverandSummary of Goodbye, Things: The New Japanese Minimalism by Fumio SasakiРейтинг: 4.5 из 5 звезд4.5/5 (5)

- The Martha Manual: How to Do (Almost) EverythingОт EverandThe Martha Manual: How to Do (Almost) EverythingРейтинг: 4 из 5 звезд4/5 (11)

- The Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterОт EverandThe Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterРейтинг: 4 из 5 звезд4/5 (467)

- The Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingОт EverandThe Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingРейтинг: 4 из 5 звезд4/5 (2997)

- Decluttering at the Speed of Life: Winning Your Never-Ending Battle with StuffОт EverandDecluttering at the Speed of Life: Winning Your Never-Ending Battle with StuffРейтинг: 4.5 из 5 звезд4.5/5 (578)

- Declutter Like a Mother: A Guilt-Free, No-Stress Way to Transform Your Home and Your LifeОт EverandDeclutter Like a Mother: A Guilt-Free, No-Stress Way to Transform Your Home and Your LifeРейтинг: 4.5 из 5 звезд4.5/5 (164)

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingОт EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingРейтинг: 4.5 из 5 звезд4.5/5 (847)

- Success at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.От EverandSuccess at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Рейтинг: 4 из 5 звезд4/5 (17)

- It's All Too Much: An Easy Plan for Living a Richer Life with Less StuffОт EverandIt's All Too Much: An Easy Plan for Living a Richer Life with Less StuffРейтинг: 4 из 5 звезд4/5 (232)

- Build Your Own Sheds & Outdoor Projects Manual, Fifth Edition: Over 200 Plans InsideОт EverandBuild Your Own Sheds & Outdoor Projects Manual, Fifth Edition: Over 200 Plans InsideРейтинг: 5 из 5 звезд5/5 (1)

- The Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyОт EverandThe Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyРейтинг: 4 из 5 звезд4/5 (278)

- Summary of KC Davis's How to Keep House While DrowningОт EverandSummary of KC Davis's How to Keep House While DrowningРейтинг: 5 из 5 звезд5/5 (1)

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingОт EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingРейтинг: 4.5 из 5 звезд4.5/5 (79)

- Let It Go: Downsizing Your Way to a Richer, Happier LifeОт EverandLet It Go: Downsizing Your Way to a Richer, Happier LifeРейтинг: 4.5 из 5 звезд4.5/5 (67)

- The Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyОт EverandThe Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyРейтинг: 4 из 5 звезд4/5 (40)

- How to Manage Your Home Without Losing Your Mind: Dealing with Your House's Dirty Little SecretsОт EverandHow to Manage Your Home Without Losing Your Mind: Dealing with Your House's Dirty Little SecretsРейтинг: 5 из 5 звезд5/5 (339)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresОт EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresРейтинг: 1 из 5 звезд1/5 (2)

- Building Outdoor Furniture: Classic Deck, Patio & Garden Projects That Will Last a LifetimeОт EverandBuilding Outdoor Furniture: Classic Deck, Patio & Garden Projects That Will Last a LifetimeОценок пока нет

- Martha Stewart's Organizing: The Manual for Bringing Order to Your Life, Home & RoutinesОт EverandMartha Stewart's Organizing: The Manual for Bringing Order to Your Life, Home & RoutinesРейтинг: 4 из 5 звезд4/5 (11)

- Mini Farming: Self-Sufficiency on 1/4 AcreОт EverandMini Farming: Self-Sufficiency on 1/4 AcreРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Kintsugi Wellness: The Japanese Art of Nourishing Mind, Body, and SpiritОт EverandKintsugi Wellness: The Japanese Art of Nourishing Mind, Body, and SpiritРейтинг: 4.5 из 5 звезд4.5/5 (3)

- How to Build a House: A Practical, Common-Sense Guide to Residential ConstructionОт EverandHow to Build a House: A Practical, Common-Sense Guide to Residential ConstructionРейтинг: 4 из 5 звезд4/5 (5)