Академический Документы

Профессиональный Документы

Культура Документы

US Patent for Cutting Food Products Machine

Загружено:

RodrigoPoma0 оценок0% нашли этот документ полезным (0 голосов)

22 просмотров4 страницыThis patent document describes a machine for cutting food products such as vegetables. The machine includes a frame, hopper, cutting plate, ejection plate below the cutting plate, and means for driving the cutting and ejection plates in rotation. The key aspects of the machine are that the ejection plate rotates in the opposite direction of the cutting plate and at a higher speed to prevent clogging. The machine can produce sliced or diced vegetables and includes additional cutting means to further cut slices into sticks.

Исходное описание:

maquina

Оригинальное название

Us 4821616

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis patent document describes a machine for cutting food products such as vegetables. The machine includes a frame, hopper, cutting plate, ejection plate below the cutting plate, and means for driving the cutting and ejection plates in rotation. The key aspects of the machine are that the ejection plate rotates in the opposite direction of the cutting plate and at a higher speed to prevent clogging. The machine can produce sliced or diced vegetables and includes additional cutting means to further cut slices into sticks.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

22 просмотров4 страницыUS Patent for Cutting Food Products Machine

Загружено:

RodrigoPomaThis patent document describes a machine for cutting food products such as vegetables. The machine includes a frame, hopper, cutting plate, ejection plate below the cutting plate, and means for driving the cutting and ejection plates in rotation. The key aspects of the machine are that the ejection plate rotates in the opposite direction of the cutting plate and at a higher speed to prevent clogging. The machine can produce sliced or diced vegetables and includes additional cutting means to further cut slices into sticks.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 4

United States Patent _[191

[11] Patent Number:

4,821,616

Mayeux et al.

[45] Date of Patent:

Apr. 18, 1989

U.S. Patent

Apr. 18, 1989

4,821,616

4,821,616

MACHINE FOR CU'I'I'ING FOOD PRODUCTS

SUCH AS IN PARTICULAR VEGETABLES

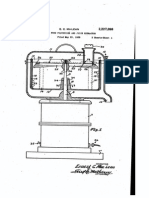

The present invention relates to a machine for cutting

food products, such as in particular vegetables.

More particularly, the invention concerns a machine

of the type comprising a frame supporting a hopper for

charging the products, a cutting plate, an ejection plate

for ejecting the cut products located below the cutting

plate, and means for driving the cutting plate and ejec

tion plate in rotation.

A number of machines of this type are already known

in the art, but they have drawbacks, in particular as

concerns the risks of degradation of the products owing

to a packing of the latter in certain parts of the ma

chines, risks of the blocking of the rotating component

parts, the regularity of the automatic feeding of the

products to the cutting element, and finally the mainte

nance of the products during the cutting thereof.

the ejection plate 6a or 6b. These connections are of

known type and will not be described in detail.

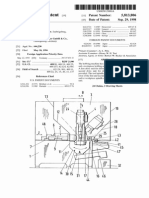

The other ends of said shafts are connected to driving

means 13 through respective gear means 14. These gear

means comprise a number of planet gears cooperative

with sun gears driven in rotation by the driving means

13. The gear means are so designed that the feed screw

and the ejection plate are driven in rotation in a direc

tion opposed to that of the cutting plate. Further, the

ejection plate is driven at a speed of rotation which is

higher than that of the cutting plate which has a speed

of rotation higher than that of the feed screw so as to

avoid any packing of the product.

As the gear means are of known type and do not

present any particular difficulty in their use, they will

not be described in more detail.

The driving means comprise a single motor, for ex

ample an electric motor, which permits, in the event of

a problem, the stopping of the rotation of all the rotat

20

ing component parts at the same time.

An object of the invention is therefore to overcome

Further, a deformable abutment element 15, such as a

these problems, by providing a machine whose struc

flexible strip, is disposed in the hopper above the cutting

ture is simple, reliable and of low price, while permit

plate for the purpose of orienting the products in the

ting an increase in the rate of treatment of the products

hopper and facilitating their entry into the feed screw.

25

for an improved quality.

As mentioned before, the machine according to the

The invention therefore provides a machine of the

invention, comprises two ejection zones 7 and 8 for the

type described hereinbefore, wherein said ejection plate

cut products constituted for example by two spouts

is driven in rotation in a direction opposed to the direc

disposed one above the other and adapted to be associ

tion of rotation of the cutting plate.

ated with product ejection plates of different forms, as

Advantageously, the ejection plate is driven at a

mentioned hereinbefore. The cutting means 9 are for

speed of rotation which is higher than that of the cut

example disposed in the upper spout in facing relation to

ting plate.

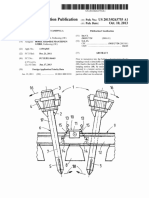

A better understanding of the invention will be had

from the following description which is given solely by

way of example with reference to the accompanying

drawing which represents a sectional view of machine

according to the invention.

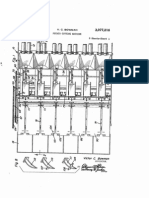

As can be seen in this FIGURE, a machine according

to the invention for cutting food products, such as in

particular vegetables, comprises a frame 1 on which is

pivotally mounted a hopper 2 for charging the products

in which may be disposed a rotary feed screw 3 for

urging the products against a cutting plate 4. This cut

ting plate is of known type and will not be described in

more detail.

This machine may be equipped with different cutting

means for obtaining, for example, small sticks of vegeta

bles or a macedoine of vegetables, and there have been

shown in the left part of this FIGURE a machine

equipped with a grate 5 permitting the obtainment of

macedoine and an ejection plate 6a for ejecting the

macedoine coming from the grate to a first ejection

zone 7.

In the right part of this FIGURE, a machine has been

shown which is equipped with an ejection plate 6b

which is different from the first-mentioned plate and

permits the ejection, for example of potatoes cut into

slices by the cutting plate, in the direction of a second

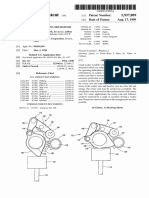

the ejection plate 6b for ejecting the products out into

slices. These cutting means 9 comprise a plurality of

discs fixed on a driving shaft connected to the driving

means 13 through gear means 14 of known type. These

discs are fixed on the shaft at a predetermined distance

from each other and are disposed parallel to the axis of

said spout, so as to determine the width of the cutting of

the products. These means permit, for example, the

cutting of slices of potatoes coming from the ejection

plate in the direction of the length, so as to produce

potatoe chips or French fried potatoes. Indeed, the

potatoes are urged against the cutting plate by the feed

screw 3, and the slices of potatoe fall onto the ejection

plate 6b. As the latter is driven in rotation, the slices of

potatoe are urged, under the effect of centrifugal force,

against the edge of the cutting chamber defined under

the cutting plate and are ejected in the direction of the

cutting means 9 disposed in the spout 8. These slices are

then cut into small sticks by these means 9.

Note that the gear means 16 driving the cutting

means 9 in rotation are so arranged as to drive the latter

at such speed of rotation that their output is higher than

the output of the cutting plate so as to avoid any pack

ing of the product in this region.

Furthermore, these gear means 16 and the gear means

14 are driven by a belt 17 which extends around rolling

surfaces of these gear means, and around the output

shaft of the electric motor 13.

The machine according to the invention may also be

equipped with a hopper which does not have a rotary

ejection zone 8, in which cutting means 9 are 'disposed

for producing the small sticks. These means will be

described in more detail hereinafter.

The machine according to the invention further coni

feed screw, the ejection plate being again driven in

prises three coaxial shafts 10, 11 and 12, disposed one

rotation in the direction opposed to that of the cutting

inside the other. One of the ends of the inner shaft 10 is 65 plate and at a higher speed. It will also be clear that

connected to the feed screw 3, one of the ends of the

intermediate shaft 11 is connected to the cutting plate 4,

and one of the ends of the outer shaft 12 is connected to

v although in the described embodiment the ejection

zones are constituted by two spouts disposed one above

the other, other embodiments are possible. Thus, for

4,821,616

example, the zones may be arranged facing each other

-necting opposite ends of said shafts to the driving

in the wall of the cutting chamber. -

means.

The machine according to the invention may be part

of a more complete installation comprising for example

a potatoe peeling device and conveyor means between

the peeling device and the machine according to the

invention.

What is claimed is:

1. A machine for cutting food products such as in

7. A machine according to claim 1, wherein the driv

ing means comprise a single motor.

8. A machine according to claim 1, comprising a

deformable abutment element disposed in said hopper

above the cutting plate.

9. A machine according to claim 1, comprising two

zones for the ejection of the cut products adapted to be

particular vegetables, comprising a frame, a hopper for

charging the products carried by the frame, a cutting

plate, an ejection plate for ejecting the cut products and

disposed below the cutting plate, and driving means for

driving in rotation the cutting plate and the ejection

plate, said ejection plate being driven in rotation in a

associated with product ejection plates of different

forms.

10. A machine according to claim 9, wherein said

ejection zones are constituted by spouts disposed one

above the other.

direction opposed to the direction of rotation of the

cutting plate.

2. A machine according to claim 1, wherein the driv

ing means are arranged to drive the ejection plate in

rotation at a speed higher than the speed of the cutting 20

plate.

11. A machine according to claim 9, further compris

ing cutting means disposed in one of said ejection zones.

12. A machine according to claim 10, further com

prising cutting means disposed in an upper spout of said

spouts.

13. A machine according to claim 11, wherein said

cutting means comprise a drive shaft, gear means con

necting said drive shaft to the driving means, and a

3. A machine according to claim 1, further compris

ing a rotary feed screw disposed in said hopper.

4. A machine according to claim 3, further compris

plurality of discs fixed on said drive shaft, said discs

cutting plate.

longitudinal axis of said one ejection zone so as to deter

ing means for driving the feed screw in rotation in a 25 being fixed on said drive shaft at a predetermined dis

tance from one another and disposed to be parallel to a

direction opposed to the direction of rotation of the

mine the width of the cutting of the products.

5. A machine according to claim 4, said driving

14. A machine according to claim 12, wherein said

means for the feed screw being arranged to drive the

feed screw at a speed of rotation which is lower than the 30 cutting means comprise a drive shaft, gear means con

necting said drive shaft to the driving means, and a

speed of rotation of the cutting plate.

plurality of discs fixed on said drive shaft, said discs

6. A machine according to claim 3, comprising three

being fixed on said drive shaft at a predetermined dis

coaxial shafts disposed one inside the other, an end of

tance from one another and disposed t0 be parallel to a

the inner shaft being connected to the feed screw, an

end of the intermediate shaft being connected to the 35 longitudinal axis of said upper ejection zone so as to

determine the width of the cutting of the products.

cutting plate, and an end of the outer shaft being con

Ik

*

i

Ik

*

nected to the ejection plate, respective gear means con

45

50

55

65

Вам также может понравиться

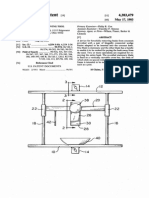

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANДокумент6 страницWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaОценок пока нет

- Jurnal Bubut FixsafasfasfДокумент6 страницJurnal Bubut FixsafasfasfAdiBimaSanjaya100% (1)

- United States Patent (19) : Miiller (45) Date of PatentДокумент8 страницUnited States Patent (19) : Miiller (45) Date of PatentRodrigoPomaОценок пока нет

- Variable displacement compressor hinge mechanismДокумент13 страницVariable displacement compressor hinge mechanismSelvaraji MuthuОценок пока нет

- Project ZДокумент31 страницаProject ZADITYAОценок пока нет

- LL-LLL'LL-FLL: 31, 1940. E. C. MmleanДокумент7 страницLL-LLL'LL-FLL: 31, 1940. E. C. MmleanKrozeОценок пока нет

- European Patent Application: 22.06.2011 Bulletin 2011/25 A01D 45/02Документ13 страницEuropean Patent Application: 22.06.2011 Bulletin 2011/25 A01D 45/02Lenti TiborОценок пока нет

- CN206118432 (U) EnglishДокумент4 страницыCN206118432 (U) EnglishGabriel PhilippiОценок пока нет

- Us1955360 PDFДокумент8 страницUs1955360 PDFRodrigoPomaОценок пока нет

- Title - Wood Chipper ConstructionДокумент4 страницыTitle - Wood Chipper Constructionمحمد عبدالدايمОценок пока нет

- Copying LatheДокумент4 страницыCopying LatheGustavoОценок пока нет

- Another Corn Dog Machine PatentДокумент14 страницAnother Corn Dog Machine PatentMinnesota Public RadioОценок пока нет

- EP 1 262 663 A2 Rotor for Variable Displacement Swash Plate CompressorДокумент16 страницEP 1 262 663 A2 Rotor for Variable Displacement Swash Plate CompressorSelvaraji MuthuОценок пока нет

- United States Patent 1191Документ13 страницUnited States Patent 1191ddeeff715Оценок пока нет

- June 23, 1925.: F . I: ZacherДокумент3 страницыJune 23, 1925.: F . I: ZachershamsОценок пока нет

- Powder Filling Machine PatentДокумент11 страницPowder Filling Machine PatentDaniel VelasquezОценок пока нет

- US2481440 AyamДокумент11 страницUS2481440 AyamOm FaОценок пока нет

- United States Patent (191: Andersen Et A1Документ5 страницUnited States Patent (191: Andersen Et A1khoagleОценок пока нет

- Bag cutting mechanism for adjustable bag lengthДокумент3 страницыBag cutting mechanism for adjustable bag lengthJhonnatan E Avendaño Florez100% (1)

- Multi-Purpose Oscillating Sifter MachineДокумент4 страницыMulti-Purpose Oscillating Sifter MachineSantos JustinОценок пока нет

- Raschel Machine With Stitch Comb and Knock-Over BarДокумент6 страницRaschel Machine With Stitch Comb and Knock-Over Barntd1011Оценок пока нет

- United States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoДокумент7 страницUnited States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDanister GladwinОценок пока нет

- SL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296Документ7 страницSL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296lucasmosnaОценок пока нет

- Us 4207797Документ7 страницUs 4207797fghdfjerОценок пока нет

- BALER FOR TYING ROUND BALE USING TWINEДокумент16 страницBALER FOR TYING ROUND BALE USING TWINEN. P. JAGANОценок пока нет

- US2126921Документ5 страницUS2126921Jhonnatan E Avendaño Florez100% (1)

- Us 4023499Документ4 страницыUs 4023499ererОценок пока нет

- Ulllted States Patent (19) (11) Patent Number: 5,937,809Документ15 страницUlllted States Patent (19) (11) Patent Number: 5,937,809LazarОценок пока нет

- Tamping Method With 4 Hand TamperДокумент3 страницыTamping Method With 4 Hand TamperjasonОценок пока нет

- Rig-E???': Gill!Документ6 страницRig-E???': Gill!luiscremaschiОценок пока нет

- Tip Brake Mechanism Slows Wind Turbine Blade RotationДокумент11 страницTip Brake Mechanism Slows Wind Turbine Blade RotationRubén Gutiérrez AmoОценок пока нет

- Coco Inven PDFДокумент4 страницыCoco Inven PDFsushil-funОценок пока нет

- Patent Brake System for DrawworksДокумент9 страницPatent Brake System for DrawworksardserОценок пока нет

- Qiang Yin, Feiyu Zhao and Guoquan Zhang: Design of The Key Device of Automatic Production Line of Alkaline NoodleДокумент8 страницQiang Yin, Feiyu Zhao and Guoquan Zhang: Design of The Key Device of Automatic Production Line of Alkaline NoodleTrà Hữu HạnhОценок пока нет

- Us1223254 PDFДокумент7 страницUs1223254 PDFRodrigoPomaОценок пока нет

- Us 5791053Документ6 страницUs 5791053James LindonОценок пока нет

- US2009857 FORMADOR SOBRES PotdevinДокумент3 страницыUS2009857 FORMADOR SOBRES PotdevinJhonnatan E Avendaño FlorezОценок пока нет

- United States Patent: (12) (10) Patent N0.: US 7,377,754 B2Документ23 страницыUnited States Patent: (12) (10) Patent N0.: US 7,377,754 B2Selvaraji MuthuОценок пока нет

- Wagner Iron Works v. Koehring Company, A Wisconsin Corporation, Wagner Iron Works v. Henry Manufacturing Company, Inc., 282 F.2d 317, 10th Cir. (1960)Документ10 страницWagner Iron Works v. Koehring Company, A Wisconsin Corporation, Wagner Iron Works v. Henry Manufacturing Company, Inc., 282 F.2d 317, 10th Cir. (1960)Scribd Government DocsОценок пока нет

- 1,138,232. Patented May 4, 1915,: 0, J, McgannДокумент3 страницы1,138,232. Patented May 4, 1915,: 0, J, McgannVyacheslavОценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2014/0021016 A1Документ14 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2014/0021016 A1Kalai SelvanОценок пока нет

- US2447117Документ6 страницUS2447117MahnooshОценок пока нет

- Sept. 23, 1969 C. P. Nanney Etal 3,458,436: Filed July 7. 1967Документ18 страницSept. 23, 1969 C. P. Nanney Etal 3,458,436: Filed July 7. 1967Catalin AlexandruОценок пока нет

- Dual Acting ShaperДокумент30 страницDual Acting ShaperAbhijeet NaikОценок пока нет

- Compressed Air MotorДокумент10 страницCompressed Air Motorjahson362Оценок пока нет

- Patented May 27, 1919.: S. H. GarstДокумент4 страницыPatented May 27, 1919.: S. H. GarstKrozeОценок пока нет

- Fabrication of Multi Nut Tighter or Remover Mechanical ProjectДокумент6 страницFabrication of Multi Nut Tighter or Remover Mechanical ProjectBhuvnesh MehtaОценок пока нет

- Horizontal Centrifuge for Separating Oil MudДокумент12 страницHorizontal Centrifuge for Separating Oil MudMurtaza ÇakaloğluОценок пока нет

- Improving lubrication oil drainage in outboard motorsДокумент6 страницImproving lubrication oil drainage in outboard motorsIsmael Arinas PellónОценок пока нет

- Shaft Mounting Device Measures and Controls Thrust LoadsДокумент7 страницShaft Mounting Device Measures and Controls Thrust LoadsNicandroGonzalesОценок пока нет

- Milliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaДокумент4 страницыMilliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaOscar Lora SiñaniОценок пока нет

- US shrimp-deheading machine patentДокумент6 страницUS shrimp-deheading machine patentPham LoiОценок пока нет

- Automatic roll changing system for metal rolling millsДокумент6 страницAutomatic roll changing system for metal rolling millsPooria1989Оценок пока нет

- Patente TrituradoraДокумент11 страницPatente TrituradoraDany ChimborazoОценок пока нет

- The Line Boring MachineДокумент8 страницThe Line Boring MachineJinky L. LavegaОценок пока нет

- Pedal-powered coconut graterДокумент12 страницPedal-powered coconut graterPrincess Diane Gravides0% (3)

- %WWMD%WM: J. H. Vanderslig-E. Flanging MachineДокумент4 страницы%WWMD%WM: J. H. Vanderslig-E. Flanging MachineOO G-sus OoОценок пока нет

- Method and Machine for Manufacturing Paperboard Tubes by Helical WindingДокумент8 страницMethod and Machine for Manufacturing Paperboard Tubes by Helical WindingUvxtalОценок пока нет

- Illustrated Catalogue of Cotton MachineryОт EverandIllustrated Catalogue of Cotton MachineryОценок пока нет

- United States Patent: Dreve, Jr. (45) May 16, 1972Документ6 страницUnited States Patent: Dreve, Jr. (45) May 16, 1972RodrigoPomaОценок пока нет

- Large Batch Hard Candy and LollipopsДокумент2 страницыLarge Batch Hard Candy and LollipopsRodrigoPomaОценок пока нет

- LM 7805 RegulatorДокумент12 страницLM 7805 RegulatorFadel BairuniОценок пока нет

- 1 ChuquisacaДокумент6 страниц1 ChuquisacaRodrigoPomaОценок пока нет

- Diagrama Bases 1Документ1 страницаDiagrama Bases 1RodrigoPomaОценок пока нет

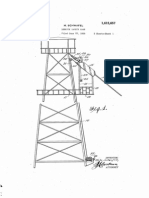

- M. Schwafel: Derrick Safety CageДокумент4 страницыM. Schwafel: Derrick Safety CageRodrigoPomaОценок пока нет

- Us 4106436Документ10 страницUs 4106436RodrigoPomaОценок пока нет

- Nov. 25, v1941. J, R, Mcmahon Eral 2,264,048: Apparatus For Applying Protective Coatings T0 SuspendedДокумент7 страницNov. 25, v1941. J, R, Mcmahon Eral 2,264,048: Apparatus For Applying Protective Coatings T0 SuspendedRodrigoPomaОценок пока нет

- United States Patent: Dreve, Jr. (45) May 16, 1972Документ6 страницUnited States Patent: Dreve, Jr. (45) May 16, 1972RodrigoPomaОценок пока нет

- United States Patent (19) : Grote Et A1Документ9 страницUnited States Patent (19) : Grote Et A1RodrigoPomaОценок пока нет

- Us2467764 PDFДокумент10 страницUs2467764 PDFRodrigoPomaОценок пока нет

- Us659197 PDFДокумент3 страницыUs659197 PDFRodrigoPomaОценок пока нет

- Us 2296645Документ4 страницыUs 2296645RodrigoPomaОценок пока нет

- June 16, 1964: C. R. Steele Disintegrator Having Downwardly Inclined Baffles Filed Nov. 17, 1960Документ6 страницJune 16, 1964: C. R. Steele Disintegrator Having Downwardly Inclined Baffles Filed Nov. 17, 1960RodrigoPomaОценок пока нет

- Us1223254 PDFДокумент7 страницUs1223254 PDFRodrigoPomaОценок пока нет

- Us1955360 PDFДокумент8 страницUs1955360 PDFRodrigoPomaОценок пока нет

- MXTVXVW PDFДокумент3 страницыMXTVXVW PDFRodrigoPomaОценок пока нет

- Measure cheese with this compact dispenserДокумент5 страницMeasure cheese with this compact dispenserRodrigoPomaОценок пока нет

- Us2678614 PDFДокумент6 страницUs2678614 PDFRodrigoPomaОценок пока нет

- Us4589264 PDFДокумент6 страницUs4589264 PDFRodrigoPomaОценок пока нет

- Musical Intelligence: Let's Cut It Off! I Guess You Are Out of TuneДокумент1 страницаMusical Intelligence: Let's Cut It Off! I Guess You Are Out of TuneHenry GutierrezОценок пока нет

- Datasheet UA741CPДокумент19 страницDatasheet UA741CPlcruz_86Оценок пока нет

- Cba The GPSДокумент7 страницCba The GPSRodrigoPomaОценок пока нет

- MikroДокумент5 страницMikroAmir Si KetengОценок пока нет

- A9 PDFДокумент25 страницA9 PDFRodrigoPomaОценок пока нет

- H. J. Smith: Potato Cutting Machine 28 Filed 00Документ3 страницыH. J. Smith: Potato Cutting Machine 28 Filed 00RodrigoPomaОценок пока нет

- Us116842 PDFДокумент6 страницUs116842 PDFRodrigoPomaОценок пока нет

- HYDRO VesselsДокумент5 страницHYDRO VesselsMarvinPatricioNarca0% (1)

- United States Air Force: Next Generation Ejection SeatДокумент2 страницыUnited States Air Force: Next Generation Ejection SeatChris EfstathiouОценок пока нет

- Slip and Crystallographic TexturesДокумент34 страницыSlip and Crystallographic TexturesSunkulp GoelОценок пока нет

- R07-HC3C20-AAP-MTS-CI-0005 (02) Method Statement of Site Mobilization at Island (Revised)Документ32 страницыR07-HC3C20-AAP-MTS-CI-0005 (02) Method Statement of Site Mobilization at Island (Revised)like saddamОценок пока нет

- MIT OCW Principles of Inorganic Chemistry II Lecture on Octahedral ML6 Sigma ComplexesДокумент7 страницMIT OCW Principles of Inorganic Chemistry II Lecture on Octahedral ML6 Sigma Complexessanskarid94Оценок пока нет

- Interior Latex Semi-Gloss GL64XX: PremiumДокумент2 страницыInterior Latex Semi-Gloss GL64XX: PremiumVenkatesh SridharanОценок пока нет

- Calcium Sulfate Crystallization in Phosphoric Acid PDFДокумент133 страницыCalcium Sulfate Crystallization in Phosphoric Acid PDFabderrahimnОценок пока нет

- Tivizen Iplug Greek GuideДокумент13 страницTivizen Iplug Greek GuideDenexoОценок пока нет

- Operating Manual Parts List: 1000Vmc (Siemens)Документ226 страницOperating Manual Parts List: 1000Vmc (Siemens)apodshОценок пока нет

- 2011 Equipment Packing InstructionsДокумент3 страницы2011 Equipment Packing InstructionsNidhi MurthyОценок пока нет

- G100-G102-Chassis-Manual #1Документ151 страницаG100-G102-Chassis-Manual #1Daihatsu Charade BanjarnegaraОценок пока нет

- Methode of Statement Lightning Protection & Earthing System Review 4Документ27 страницMethode of Statement Lightning Protection & Earthing System Review 4firman zakirОценок пока нет

- PLKKKДокумент36 страницPLKKKelecompinnОценок пока нет

- Bunker SiloДокумент3 страницыBunker SiloManju Civil PОценок пока нет

- BHEL - PresentationДокумент32 страницыBHEL - Presentationsenthil031277Оценок пока нет

- Manual E-Claw EngДокумент18 страницManual E-Claw Engshyampillai2007Оценок пока нет

- Especificaciones Discos de Embrague Transmision - Cat 140HДокумент6 страницEspecificaciones Discos de Embrague Transmision - Cat 140HSergio StockmansОценок пока нет

- Total Internal Reflection and Critical Angle VedioДокумент16 страницTotal Internal Reflection and Critical Angle VedioNor AzizahОценок пока нет

- 92v Parts List ViperДокумент194 страницы92v Parts List Viperreltih18Оценок пока нет

- Diesel Engine: Service Parts List ForДокумент49 страницDiesel Engine: Service Parts List ForIgnacio OsorioОценок пока нет

- Nabll Mix DesignДокумент29 страницNabll Mix DesignPIDCL WITH SUBUDHIОценок пока нет

- BPM Third Wave Smith Fingar Apr2003 PDFДокумент10 страницBPM Third Wave Smith Fingar Apr2003 PDFNadeem AzadОценок пока нет

- Part Ii - Particular Technical Specifications Chapter 13 - Permanent Access Bridge 13. PERMANENT ACCESS BRIDGE........................................................ 13-1Документ11 страницPart Ii - Particular Technical Specifications Chapter 13 - Permanent Access Bridge 13. PERMANENT ACCESS BRIDGE........................................................ 13-1Anonymous KHIyWRIWmaОценок пока нет

- Adf Interview Questions and AnsewrsДокумент85 страницAdf Interview Questions and Ansewrsleninbabus100% (2)

- Grade CalculatorДокумент1 страницаGrade CalculatorKHENN ALDIANOОценок пока нет

- MWD Log Quality & StandardsДокумент168 страницMWD Log Quality & StandardsHamed Sadeghi100% (1)

- 864 Wiring Schematic: S/N 518913001-14999 S/N 516812001-14999 S/N 517512001-14999 (Printed March 2001) V-0072Документ6 страниц864 Wiring Schematic: S/N 518913001-14999 S/N 516812001-14999 S/N 517512001-14999 (Printed March 2001) V-0072Ataa AssaadОценок пока нет

- DP TV Aver 15022 DriversДокумент94 страницыDP TV Aver 15022 DriversMohammed Tahver Farooqi QuadriОценок пока нет

- Tacloban Master Training Schedule (January-June 2012) For Web New FormatДокумент5 страницTacloban Master Training Schedule (January-June 2012) For Web New FormatFariq AdlawanОценок пока нет

- Genetic AlgorithmДокумент46 страницGenetic AlgorithmJerryОценок пока нет