Академический Документы

Профессиональный Документы

Культура Документы

Us 4106436

Загружено:

RodrigoPomaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Us 4106436

Загружено:

RodrigoPomaАвторское право:

Доступные форматы

1 5i States

1611i [19]

Booker

[54] APPARATUS FOR DISPENSING A COATING

OF LIQUID ON AN ELEVATED CABLE OR

[57]

[76] Inventor: ifslie Lb]i(lmk;;1304 Old Mill Rd"

Aug. 15, 1978

ABSTRACT

liquid insulated coating material on a telephone cable or

the like adapted to be supported on and traversed over

an elevated supporting cable to which the coaxial cable

[22] Flled

[51]

[45]

A self-propelled apparatus for uniformly dispensing a

[21] Appl. No.: 717,982

.

4,106,436

Primary Examiner-Louis K. Rimrodt

Attorney, Agent, or Firm-Robert M. Hessin

THE LIKE

Core

[11]

Aug 26 1976

is secured. The apparatus includes a gasoline engine as

Int. CLZ .............................................. .. B05C 5/02

a primary power source drivingly connected to a posi

[52] US. Cl. ................................... .. 118/307; 118/421

[58] Field of Search ............. .. 118/ 307, 208, 421, 323,

118/4, 7; 184/3, 15 R

tive displacement hydraulic pump which provides pres

surized liquid coating material to both a reversible hy

draulic drive motor and a spray head. A hydraulic con

[56]

References Cited

trol system is disclosed for adjusting and controlling the

US- PATENT DOCUMENTS

operation of the apparatus. Manual spray means is fur

ther provided to facilitate the dispensing of liquid coat

2,264,048

11/1941

McMahon et al. ................ .. 118/307

2,858,555

11/1958

Medovick ...................... .. 118/208 X

3,662,707

5/1972

Dreve ............................ .. 118/307 X

"1g matenal 0111116 cable

18 Claims, 8 Drawing Figures

38

40

44

T\

?/4

48

I84

l\

m2

\ \ _//

40

/75

/7@

m5

1a?

(\

/

\y/

//

Q00 9,

\~>

/56

,/ /

a4 /40

5'2

-- | M2 I

i_ __

2?

22

I64 I

I

__

7e

52

80

88/

54

92

21

90 ii 7

e141

66

eaA60

74

'

Z0

F 7

/<5

/ M2

ma

\\ / ////

;

2

2/0

20a

lu-_'-

A56

72

75

/@a~>/

02

l24

/2 /4

204 205

x52

\ 45

122

52

/ /0

_ ._ w

56

if 50

l?@

US Patent

Aug. 15,1978

5%

40

\

42

48

2/4

26

Sheet2of3 I

40

4,106,436

55 / /0

US Patent

Aug. 15,1978

Sheet3 of 3

4,106,436

4, 106,436

ll

APPARATUS FOR DISPENSING A COATING OF

LIQUID ON AN ELEVATED CABLE OR THE LIKE

and nozzle means carried by the frame and communi

BACKGROUND OF THE INVENTION

1. Field of the Invention

ment of the apparatus therealong. The apparatus further

includes liquid supply means carried by the frame for

providing a quantity of liquid under elevated pressure,

cating with the liquid supply means for receiving liquid

therefrom and directing liquid onto a cable. The appara

tus also includes drive means carried by the frame and

operatively connected to the support means for propel

ling the apparatus along the cable upon which it is sup

-_

This invention relates generally to improvement in

the coating of cables, and more particularly, but not by

way of limitation, to an improved apparatus for apply

ing a liquid coating material to the exterior of an electri

ported.

cal coaxial cable or the like.

An advantage of the invention is the provision of the

apparatus which provides increased efficiency in the

2. Description of the Prior Art

In the telephone industry it has become common

place to periodically apply a liquid coating material to

the exterior of old telephone cables to maintain or im

prove the water resistant insulation characteristics of

these cables. Conventional telephone coaxial cables are

sheathed with lead to provide protection for the indi

maintaining of telephone cables or the like.

Another advantage of the present invention resides in

the provision of a self-propelled apparatus for dispens

ing a coating of liquid on a telephone cable or the like

supported above the ground which is unaffected by

terrain features beneath the cable.

A further advantage of the present invention resides

in the provision of an apparatus which minimizes the

vidual electrical conductors disposed therein. Through

long periods of exposure to the elements and through

the attack by squirrels, the lead sheathing often is af

possibility of overspraying liquid coating material onto

flicted with cracks or holes therein which permits the

adjacent foliage and structures during the coating of a

entrance of moisture into the coaxial cable which, in

length of telephone cable or the like.

turn, causes shorting among the individual electrical

A still further advantage of the present invention

conductors therein. Microscopic cracks form in the lead 25 resides in the provision of an apparatus for dispensing

sheathing through prolonged exposure of the cable to

coating liquid on a telephone cable or the like supported

the elements. Much larger holes in the lead sheathing

above the ground which employs the liquid coating

can be attributed to the knawing of squirrels on the lead

material as the hydraulic ?uid in the drive mechanism of

sheathing.

the apparatus.

A yet further advantage of the present invention

resides in the provision of apparatus for uniformly dis

In view of this deterioration that appears in the lead

sheathing of telephone cables, it has become economi

cally feasible to periodically apply an insulating coating

pensing a coating of liquid on a telephone cable or the

like supported above the ground which is light in

weight, economical in construction and operation, and

simple to operate and maintain.

to the exterior of such cables rather than to replace

cables with newer, better insulated cables. One such

technique which has gained widespread approval em

bodies the application of a liquid coating material called

Further objects and advantages of the present inven

Insalite which is manufactured and sold by Winton

Products Co., Inc. of Charlotte, North Carolina. Vari

tion will be evident from the following detailed descrip

tion when read in conjunction with the accompanying

ous techniques have been employed to apply this liquid

coating material to the exterior of telephone cables.

Most obviously, hand application has been employed to

drawings.

a limited degree in areas where it would be most disad

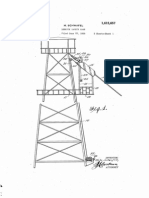

FIG. 1 is a front side elevation view of an apparatus

for dispensing a coating of liquid on an elevated cable or

vantageous for the liquid coating material to fall on

structures or foliage adjacent the work site. Another

technique embodies the manual application of the liquid

coating material by means of a roller sprayer having

BRIEF DESCRIPTION OF THE DRAWINGS

the like constructed in accordance with the present

45 invention and shown supported on a cable assembly to

be coated.

two or more spray nozzles which can be manipulated

FIG. 2 is a top plan view of the apparatus of FIG. 1.

and propelled manually from the ground to traverse

FIG. 3 is a rear side elevation view of the apparatus

of FIG. 1.

FIG. 4 is a left end elevation view of the apparatus of

FIG. 1.

along the cable by means of a conventional utility stick.

Pressurized liquid coating material is provided to the

spray head through a conduit connected to a pressure

tank on the operators back at the ground level. More

recently, an engine-powered pump has been utilized on

the ground to provide pressurized liquid coating mate

FIG. 5 is a right end elevation view of the apparatus

of FIG. 1.

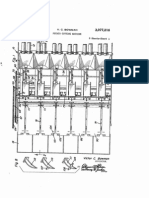

FIG. 6 is a schematic diagram of the hydraulic system

rial to the spray head being manipulated along the ca 55 of the present invention.

ble.

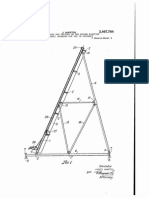

FIG. 7 is a partial cross-sectional view taken along

In contrast, the apparatus of the present invention

line 77 of FIG. 1.

overcomes all the disadvantages of the prior art appara

FIG. 8 is an enlarged partial cross-sectional view

tus and techniques and permits the economical, uniform

taken along line 8-8 of FIG. 2.

and neat application of liquid coating material to the 60

exterior of telephone cables or other elevated cables

DESCRIPTION OF A PREFERRED

EMBODIMENT

without manual manipulation and propulsion of the

apparatus during traverses along the cable.

Referring now to the drawings, an apparatus for

The present invention contemplates an apparatus for

dispensing a coating of liquid on a telephone cable or

dispensing a coating of liquid on a telephone cable or 65 the like in accordance with the present invention is

the like supported above the ground which apparatus

generally designated by the reference character 10. The

includes a frame, and support means carried on the

apparatus 10 is illustrated in FIGS. 1-5 suspended on a

frame for supporting the apparatus on a cable for move

cable assembly 12. The cable assembly 12 typically

4,106,436

and 44 and the sprockets 54, 46 and 42. A suitable form

comprises a supporting cable 14, a sheathed insulated

coaxial cable 16, typically carrying a plurality of indi

of hydraulic motor 50 is a positive displacement, sliding

vidual electrical conductors, and means 18 for mutually

engaging the support cable 14 and the coaxial cable 16

in parallel relation along their length. Such means may

suitably comprise one or more spirally wrapped wires

mutually encompassing the supporting cable 14 and the

vane type motor. Such motors are frequently utilized as

drive motors in conventional air impact wrenches.

A single cylinder, two cycle gasoline engine 66 is

mounted on the frame 20 adjacent the horizontally

extending member 30. An engine suitable for this appli

coaxial cable 16, or a plurality of longitudinally spaced

cation has a displacement of 1.9 cubic inches and a

hanger members, each suitably formed of wire or other

maximum power output of 1.5 horsepower. A 1 inch

pitch sprocket 68 is drivingly secured to the power

output shaft 70 of the engine 66. A gasoline tank 72 is

suitable material, supporting the coaxial cable 16 be

neath the supporting cable 14.

?xedly secured by means of a bracket 74 to the horizon

The apparatus 10 comprises a rigid frame 20 compris

tally extending member 32 on the frame 20. A gasoline

ing a pair of horizontally spaced vertical members 22

line 76 is connected at one end 78 thereof to the tank 72

and 24 interconnected by a horizontally aligned top

member 26 and a horizontally aligned bottom member 15 and is connected at the opposite end 80 thereof to the

carburetor 82 of the engine 66. A suitable sheet metal

28. The frame 20 further includes a pair of horizontally

shroud 84 extends outwardly over the carburetor 82 to

protect it from the entrance of foreign matter during

from the vertical member 22 and the vertical member 24

operation of the apparatus 10.

at their junctures with the bottom member 28. A second

A positive displacement, rotary gear pump 86 is

bottom member 34 interconnects the outer ends of the 20

mounted on the frame 20 adjacent the engine 66. A

horizontally extending members 30 and 32 and is posi

extending members 30 and 32 extending respectively

tioned in parallel alignment with the bottom member

28. The various members of the frame 20 may be suit

ably constructed of % inch to % inch square steel tubing

with the various members mutually interconnected by

welding.

25

?-inch pitch sprocket 88 is drivingly secured to the

power input shaft 90 of the pump 86. The sprocket 88

and the sprocket 68 on the engine 66 are drivingly inter

connected by means of a i-inch pitch drive chain 92.

The pump 86 preferably includes a pressure relief valve

A pair of wheels 36 and 38 are journaled on the frame

20 about mutually parallel, horizontal axes. The axis of

the wheel 36 preferably intersects the frame 20 at the

juncture between the vertical member 22 and the top

member 26 while the axis of the wheel 38 preferably

intersects the frame 20 at the juncture between the

vertical member 24 at the top member 26. The wheels

36 and 38 are substantially of identical construction and

each includes a hub 40 upon which a sprocket 42 is 35

94 mounted integrally in the pump housing. The

sprocket 88 preferably includes 48 teeth formed on the

periphery thereof while the sprocket 68 of the engine 66

preferably includes 12 teeth formed on the periphery

?xedly secured. The two sprockets 42 are mutually

protection for the tank against solvent action during

cleaning. The tank is approximately 10 inches in length,

interconnected by a drive chain 44. The drive chain 44

and the sprockets 42 preferably have a i inch pitch with

the sprockets 42 having the same number of teeth, pref

erably 36. A second sprocket 26 is ?xedly secured to the

hub 40 of the wheel 38. The sprocket 46 also preferably

has a 1% inch pitch with 60 teeth formed thereon.

The rolling surface 48 of each of the wheels 36 and 38

is preferably formed of rubber or a suitable synthetic

thereof.

A liquid storage tank 96 is mounted on the bottom

members 28 and 34 of the frame 20 intermediate the

vertical members 22 and 24. The tank 96 is preferably

constructed of stainless steel sheet metal to provide

11 inches in width and 6 inches in height. The tank

provides a nominal storage capacity of approximately

2.5 gallons. An internally threaded aperture 98 is pro

vided in the top panel 100 of the tank 96 to provide

access to the interior of the tank to fill the tank with

liquid coating material. A ?lter assembly 102 having

external threads 104 formed thereon is threadedly se

resinous material. The rolling surface 48 preferably has 45 curable within the internally threaded aperture 98, as

best shown in FIG. 8. The ?lter assembly 102 includes

a rolling circumference of approximately 19 inches and

a downwardly extending, cylindrically shaped ?lter

is concave in cross-section to facilitate the rolling of the

member 106 which extends within the con?nes of the

wheels 36 and 38 along the supporting cable 14 of the

tank 96. The ?lter member 106 is closed at its bottom

cable assembly 12, as best shown in FIGS. 4 and 5.

A reversible hydraulic motor 50 is pivotally secured 50 end 108 and includes a plurality of ?lter slits 109 which

to the vertical member 24 of the frame 20 as shown at

extend through the cylindrical wall thereof. The upper

end portion 110 of the ?lter assembly 102 is provided

with an outwardly extending annular ?ange 112 which

52. A sprocket 54 is drivingly secured to the power

output shaft 56 of the motor 50. The sprocket 54 prefer

ably has a 1} inch pitch with six teeth formed thereon. A

drive chain 58 drivingly interconnects the sprocket 54

and the sprocket 46. A threaded bolt 60 is threadedly

secured through an internally threaded nut 62 which is

bears against a resilient annular seal 114, formed of an

elastomeric or synthetic resinous material, which is

bolt 60 relative to the nut 62 causes a resulting rotation

extending spokes 120. The spokes 120 permit the pas

disposed about the outer periphery of the ?lter assembly

102 between the threads 104 and the ?ange 112. A han

dle 116, comprising a pair of outwardly extending

?xedly secured to the vertical member 24. The outer

wings 118 is secured to the upper end portion 110 of the

end 64 of the bolt 60 abuttingly engages the hydraulic

motor 50. It will be seen that rotation of the threaded 60 ?lter assembly 102 by means of three radially outwardly

sage of liquid coating material therepast to freely enter

of the hydraulic motor 50 about the pivot connection 52

the tank 96 through the ?lter member 106.

thereby permitting the desired tension to be applied to

A catch pan 122 is disposed above the tank 96 and

the drive chain 58.

It will be seen from the foregoing that rotation of the 65 extends horizontally beyond the vertical members 22

output shaft 56 and the hydraulic motor 50, in either

and 24 of the frame 20 at the opposite ends 124 and 126

thereof. The catch pan 122 is preferably formed of stain

direction, will cause a corresponding, synchronized

rotation of the wheels 36 and 38 via the drive chains 58

less steel sheet metal in a funnel-shaped trough con?gu

4,106,436

ration with a circular aperture 128 formed in the medial

It will also be noted that a hook 190 is preferably

portion thereof at the juncture of the downwardly slop

secured to the top member 26 of the frame 20 upon

ing sides of the catch pan. As shown in FIG. 8, the ?lter

which the conduit 172 and hand operated spray nozzle

assembly 102 is introduced through the aperture 128 of

168 can be conveniently supported when not in use. The

the catch pan 122 when it is threadedly secured within 5 inlet port 192 of the gear pump 86 communicates with

the internally threaded aperture 98 of the liquid storage

tank 96. The annular seal 114 provides sealing engage

the liquid storage tank 96 via conduit 194.

A cable wiping assembly 196 is mounted on the appa

ment between the catch pan 122 adjacent the aperture

ratus 10 within the catch pan 122. The assembly 196

128 and the annular ?ange 112 of the ?lter assembly

includes a lower member 198 which is pivotally secured

102.

10 at its lower end to a bracket 200 mounted on the upper

The catch pan 122 is mounted directly to the frame 20

surface of the catch pan 122 adjacent the aperture 128.

to secure it in position as described above. The catch

pan 122 further includes an upwardly extending panel

130, also preferably formed of stainless steel sheet metal,

which is secured along the top member 26 and the verti

cal members 22 and 24 of the frame 20. Synthetic resin

ous, electrically non-conductive tip extensions 132 and

134 are mounted respectively on the opposite ends 124

The lower member 198 can be rigidly secured to the

bracket 200 in a predetermined position by means of a

threaded bolt and wing nut 202 interconnecting the

lower member 198 and the bracket 200. A cylindrically

shaped ferrule 204 is mounted on the upper end of the

lower member 198 via a coaxially aligned coil spring

206. The coil spring 206 permits the ferrule 204'to be

and 126 of the catch pan 122. The tip extensions provide

a considerable increase in overall length of the catch

pan beneath the cable assembly 12, and also provide

electrically non-conductive bumper surfaces on the

opposite ends of the catch pan.

A four-way hydraulic control valve 136 is mounted

de?ected from longitudinal alignment with the lower

position, which is that position illustrated in the draw

ings. Port 140 of the valve 136 is connected by conduit

coil spring 206.

It will be understood that the cable wiping assembly

member 198 when the ferrule 204 is acted upon by a

lateral force of predetermined magnitude. A brush 208

is carried by the ferrule 204 with the cylindrical handle

210 of the brush received within the ferrule 204. The

bristles 212 of the brush contact the lower portion of the

on the vertical member 24 of the frame 20. A suitable 25 coaxial cable 16 when the apparatus is properly ad

valve for this application is manufactured by Snap-Tite,

justed for use. By properly positioning the lower mem

Inc. of Union City, Pennsylvania. The valve is desig

ber 198 relative to the bracket 200, the bolt and wing

nated by Catalog No. P4230HUOD and is a three-posi

nut 202 can be mutually secured in such a manner as to

tion detent valve having an open center. The handle 138

provide a predetermined magnitude of force between

of the valve 136 rotates 45 to each side of the center

the bristles 212 and the cable 16 through the bias of the

196 is in position in FIG. 1 to wipe the cable 16 when

the apparatus 10 traverses the cable assembly 12 from

the valve 136 communicates with one port 152 of the 35 right to left as viewed therein. When the apparatus is to

reversible hydraulic motor 50 via conduit 154 and ?ow

move from left to right as viewed in FIG. 1, the cable

control valve 156 interposed in conduit 154. Port 158 of

wiping assembly 196 will be swung to the left about the

the valve 136 communicates with the other port 160 of

bracket 200 and the bristles 212 of the brush 208 will be

the reversible hydraulic motor 50 via coduit 162.

adjusted to contact the cable 16 at a point to the left of

Conduit 148 communicates with the liquid storage 40 the wheel 38.

tank 96 via conduit 164 and bypass valve 166 inter

The apparatus 10 further preferably includes a lifting

posed therein. Conduit 148 also communicates with a

eye or handle 214 which is ?xedly secured to the top

member 26 of the frame 20 intermediate the vertical

hand-operated spray nozzle 168, having a hand-con

142 to the output port 144 of the pump 86. Port 146 of

the valve 136 is connected to conduit 148. Port 150 of

members 22 and 24. In this position, the lifting eye 214

trolled valve 170 integrally formed therein, via conduit

172 and shut-off valve 174 interposed therein.

45 can be used to support the apparatus 10 when it is being

Conduit 148 further communicates with a spray noz

zle assembly 176 via conduit 178 and shut-off valve 180

interposed therein. The spray nozzle assembly 176 com

prises a bifurcated nozzle head 182 formed of tubular

material such as stainless steel tubing which is ?xedly

secured to a bracket 184. The bracket 184 is pivotally

secured to an outwardly extending shaft 186 which is

?xedly secured to the top member 26 of the frame 20.

The bracket 184 canbe adjustably clamped to the shaft

186 by means of an internally threaded wing nut 188

which is threadedly secured to the externally threaded

outer end of the shaft 186. This construction permits the

nozzle head 182 of the spray nozzle assembly 176 to be

vertically adjusted relative to the frame 20 so that the

installed on and removed from a cable assembly 12 or

when it is being transported to and from the work site.

OPERATION

When it is desired to apply a liquid coating material

to the exterior of an insulated coaxial cable with the

apparatus 10, the apparatus is ?rst transported to the site

where the cable is located and the gasoline tank 72 is

?lled with the appropriate fuel for the engine 66. The

liquid storage tank 96 is ?lled with a suitable liquid

coating agent. One such liquid coating agent suitable for

coating insulated telephone cable, is manufactured and

sold by Winton Products Co., Inc. of Charlotte, North

Carolina and is sold under the trademark INSA

liquid streams emanating from the tips of the bifurcated 60 LITE. This product remains in liquid form until ex

posed to the air at which time the product proceeds to

nozzle head 182 properly impinge on the surface of the

coaxial cable 16 of the cable assembly 12. This feature is

harden to provide a suitable water-resistant seal on the

most advantageous when the apparatus 10 is to be alter

surface of the cable.

nately used on cable assemblies wherein the coaxial

It will be seen from the foregoing description of the

cable 16 is supported a distance below the supporting 65 structure of the apparatus 10 that the same liquid em

cable 14, and, in those situations where the coaxial cable

ployed to coat the cable is also employed in the appara

16 is secured directly to the support cable 14 by spiral

tus 10 to drive the apparatus 10 along the cable via the

wire interconnection as illustrated in the drawings at 18.

reversible hydraulic motor 50 and its chain and sprocket

4,106,436

quite suitable for this dual function. It is readily appar

ent that the utilization of the Insalite in this dual ca

only be swung to the left as viewed in FIG. 1, and

adjusted as described above, and the control valve 136

interconnection with the wheels 36 and 38. As men

tioned, as long as the Insalite is not exposed to the air

for any extended period, it remains in liquid form and is

adjusted to apply pressurized liquid coating material to

the port 160 of the reversible hydraulic motor 50 via

5 conduit 162.

pacity simpli?es the construction and maintenance of

the apparatus 10 and minimizes the weight of the appa

ratus which must be supported by the supporting cable

14.

The apparatus 10 is then lifted by suitable means and

the wheels 36 and 38 are positioned over the supporting

cable 14 as illustrated in the drawings. Since the appara

tus 10 weighs approximately 54 pounds dry, such hoist

The apparatus 10 can be conveniently stopped or

reversed at any point along its traverse of a length of

cable assembly 12 by engagement and manipulation of

the control handle 138 of the hydraulic control valve

136 from the ground by means of a conventional utility

stick as used in both the telephone and electric utility

industries.

The apparatus 10 provides important advantages in

the treating of telephone cables and the like which have

ing may be accomplished manually or through the em

ployment of a mechanical lifting device such as a light 15 been clearly lacking in the past. The apparatus 10 is

boom truck or the like.

eminently suited for treating cable assemblies which

The engine 76 is then started which, in turn, drives

the pump 86 to circulate the liquid through the system.

pass over dense underbrush, water or rough terrain

When it is desired to employ the apparatus 10 to manu

ally spray the Insalite liquid on the cable, such as in

those areas immediately adjacent the cable supporting

which would otherwise prevent the application of the

liquid coating material to the cable by personnel on the

ground. Further, employment of the catch pan 122 and

panel 130 minimizes the undesirable effects of over

spraying of the liquid coating material onto trees and

structures adjacent the cable assembly being treated.

poles, the valve 180 is shut off and the control valve 136

is positioned in its neutral or center position as shown in

At the end of a work day, the apparatus 10 can be

FIG. 6. Valve 174 is opened and valve 166 is suitably

adjusted to provide the desired pressure at the valve 170 25 conveniently cleaned and made ready for the next days

work by ?ushing the liquid coating material adhered

and the nozzle 168. The operator then employs the hand

thereto from the exterior of the apparatus by means of a

operated spray nozzle 168 to spray the Insalite on the

suitable solvent. This solvent can also be circulated

cable while controlling the spray with the hand oper

through the hydraulic system by the pump 86 to clean

ated valve 170. When this spraying operation is com

pleted, the valve 174 can be shut off to release the pres 30 the interior thereof.

It will be readily apparent to those skilled in the art of

sure on the conduit 172 and the valve 170. This conduit

172 can then be coiled and stored on the hook 190 of the

apparatus 10 as illustrated in FIG. 3.

When it is now desired to cause the apparatus 10 to

applying liquid coating material to coaxial telephone

cables or the like to improve or maintain their water

resistance capabilities that the apparatus of the present

automatically dispense the Insalite liquid on the cable 35 invention provides clear and distinct advantages over

the methods and apparatus currently in use which re

16, the cable wiping assembly 196 is positioned as

quire the manual application of the liquid coating mate

shown in the drawings and described above, the valve

rial to the cable by means of a spray head manipulated

180 is opened and the control valve 136 is positioned

by an operator from the ground and supplied with pres

such that pressurized liquid is applied therethrough

through the open valve 156 and the conduit 154 to the 40 surized liquid coating material from a pump or pressur

ized container on the ground which must be moved

port 152 of the reversible hydraulic motor 50. The appa

ratus 10 will then move along the cable assembly 12 in

a direction from right to left as viewed in FIG. 1. The

along beneath the cable.

Changes may be made in the construction, combina

tion and arrangement of parts or elements as heretofore

ulation of the flow control valve 156. The spray pres 45 set forth in the speci?cation and shown in the drawings

without departing from the spirit and scope of the in

sure at the spray nozzle assembly 176 is adjusted by

vention as de?ned in the following claims.

manipulation of the by-pass valve 166.

What is claimed is:

As the apparatus 10 traverses the cable assembly 12

1. Apparatus for dispensing a coating of liquid on a

under its own power, the liquid coating material is uni

telephone cable or the like supported above the ground,

formly dispensed on the upper surface of the coaxial

comprising:

,

cable 16 of the cable assembly 12 by the spray nozzle

176, and excess liquid coating material is distributed on

a frame;

support means carried on said frame for supporting

the lower surface of the coaxial cable 16 by the trailing

said apparatus on a cable for movement of said

, bristles 212 of the brush 208. Excess liquid coating mate

apparatus therealong;

rial from the spray nozzle assembly 176 or dripping 55

liquid supply means carried by said frame for provid

from the cable assembly 12 falls downwardly into the

forward speed of the apparatus 10 is adjusted by manip

catch pan 122 and is directed thereby along its sloping

sides to and through the ?lter assembly 102 in the aper

tures 128 and 98 and into the liquid storage tank 96

through the ?lter member 106 for recirculation through

the system. This latter feature of the apparatus 10 maxi

mizes the ef?ciency of utilization of the liquid coating

material while minimizing the possible adverse effects

of spattering the liquid coating material on objects not

65

intended to be coated.

If it is desired to cause the apparatus 10 to move along

the cable assembly 12 in a direction from left to right as

viewed in FIG. 1, the cable wiping assembly 196 need

ing a quantity of liquid under elevated pressure;

nozzle means carried by said frame and communicat

ing with said liquid supply means for receiving

liquid therefrom and directing liquid onto a cable;

hydraulic motor drive means carried by said frame

and operatively connected to said support means

for propelling said apparatus along the cable upon

which it is supported;

conduit means for connecting said hydraulic motor to

said liquid supply means for conducting liquid be

tween said hydraulic motor and said liquid supply

means to drive said hydraulic motor; and

4,106,436

10

means drivingly connecting said hydraulic motor to

9. The apparatus as de?ned in claim 4 wherein said

said support means for transmitting power from

said hydraulic motor to said support means thereby

means operatively connecting said pump means and

said nozzle means is characterized further to include:

valve means interposed between said pump means

to propel said apparatus.

and said nozzle means for controlling the flow of

2. The apparatus as de?ned in claim 1 wherein said

nozzle means is characterized further to include:

liquid through said nozzle means.

a plurality of nozzles, each of said nozzles being ori

10. The apparatus as de?ned in claim 4 wherein said

ented to direct liquid therefrom onto a cable.

3. The apparatus as defined in claim 2 characterized

conduit means operatively connecting said hydraulic

drive motor and said pump means is characterized fur

ther to include:

further to include:

control valve means interposed between said pump

means carried by said frame for removing excess

means and said hydraulic drive motor for control

liquid from the cable.

4. Apparatus for applying a coating of liquid on a

telephone cable or the like supported above the ground,

comprising:

a frame;

ling the ?ow of liquid to said hydraulic drive motor

and causing said hydraulic drive motor to drive

15

wheel means journaled on said frame for supporting

said apparatus on a cable for movement of said

apparatus therealong;

pump means carried on said frame for pumping liquid

said wheel means in one direction to move said

apparatus in a corresponding direction along the

cable upon which it is supported and, alternately,

causing said hydraulic drive motor to drive said

wheel means in a second direction to move said

20

therethrough;

pump drive means operatively connected to said

pump means for driving said pump means;

means operatively connected to said pump means for

providing liquid to said pump means to be pumped

therethrough;

nozzle means carried on said frame for directing liq

uid therethrough onto a cable;

means operatively connecting said pump means and

said nozzle means for conducting liquid pumped

from said pump means to said nozzle means;

a hydraulic drive motor;

means for drivingly connecting said hydraulic drive

motor to said wheel means to move said apparatus

along the cable upon which it is supported; and

conduit means operatively connecting said hydraulic

apparatus in a corresponding opposite direction

along the cable.

11. The apparatus as de?ned in claim 4 wherein said

pump drive means is characterized further to include:

a pump drive motor carried on said frame and having

a power output shaft;

a power input shaft mounted on said pump means;

and

means for drivingly interconnecting the power out

put shaft of said pump drive motor and the power

input shaft of said pump means.

12. The apparatus as de?ned in claim 11 wherein said

pump drive motor is characterized further to include:

an internal combustion engine carried on said frame;

a fuel tank carried on said frame; and

a conduit interconnecting said fuel tank and said in

ternal combustion engine.

13. The apparatus as de?ned in claim 11 wherein said

drive motor and said pump means for conducting

means for drivingly interconnecting the power output

liquid pumped from said pump means to said hy

40 shaft of said pump drive motor and the power input

draulic drive motor.

shaft of said pump means is characterized further to

5. The apparatus as de?ned in claim 4 characterized

include:

further to include:

a drive sprocket secured to the power output shaft of

means carried by said frame for removing excess

said pump drive motor;

liquid from the cable upon which such liquid has

a driven sprocket secured to the power input shaft of

45

been directed by said nozzle means.

said power pump means; and

6. The apparatus as de?ned in claim 4 characterized

an endless drive chain mutually drivingly engaging

further to include:

said drive sprocket and said driven sprocket.

control means operatively connected to said wheel

14. Apparatus for applying liquid coating material to

drive means for causing said wheel drive means to

50 telephone cables or the like comprising:

drive said wheel means in one direction to move

a rigid frame having an upper portion, a lower por

said apparatus in a corresponding direction along

tion, a ?rst end and a second end;

the cable upon which it is supported and, alter

?rst and second wheel means journaled respectively

nately, for causing said wheel drive means to drive

on the upper portion of said frame adjacent the ?rst

said wheel means in a second direction to move 55

and second ends thereof for supporting said appa

said apparatus in a corresponding opposite direc

ratus on a cable for movement of said apparatus

tion along the cable.

therealong;

7. The apparatus as de?ned in claim 4 characterized

reservoir means carried on the lower portion of said

further to include:

frame for containing a quantity of liquid coating

means carried by said frame for catching excess liquid 60

material therein;

from said nozzle means and returning such excess

a pump carried on the lower portion of said frame,

liquid to said means for providing liquid to said

said pump having an inlet port and an outlet port;

pump means for reuse.

8. The apparatus as de?ned in claim 7 wherein said

means for catching excess liquid from said nozzle means 65

is characterized further to include:

?lter means for ?ltering said excess liquid prior to the

reuse thereof.

conduit means for conducting liquid coating material

from said reservoir means to the inlet port of said

Pump;

a control valve carried on said frame and having an

inlet port, a return port, a ?rst motor port and a

second motor port;

11

4,106,436

12

conduit means for conducting liquid coating material

said second wheel means comprises a second circular

from the outlet port of said pump to the inlet port

of said control valve;

a hydraulic drive motor carried on said frame, said

hydraulic drive motor having a forward port and a

wheel journaled on the upper portion of said frame

adjacent the second end thereof and having a cir

cumferential recess formed thereon sized and

shaped to engage the cable upon which said appa

ratus is supported for movement therealong.

reverse port;

16. The apparatus as de?ned in claim 15 wherein said

control valve is characterized further to include:

control lever means responsive to operating forces

drive means operatively connecting said hydraulic

drive motor and said ?rst and second wheel means

for driving said wheel means in response to said

hydraulic drive motor;

conduit means for conducting liquid coating material

between the first motor port of said control valve

and the forward port of said hydraulic drive motor;

conduit means for conducting liquid coating material

15

between the second motor port of said control

valve and the reverse port of said hydraulic drive

motor;

nozzle means carried on said frame for directing liq

uid coating material onto said cable;

20

conduit means for conducting liquid coating material

between the return port of said control valve and

said nozzle means;

primary drive motor means carried by said frame for

providing power to said pump; and

25

means operatively connecting said primary drive

control valve is characterized further to include:

control lever means responsive to operating forces

external thereto for alternately positioning said

control valve in a plurality of positions comprising:

a forward position communicating the inlet port

with the ?rst motor port and communicating the

second motor port with the return port;

a neutral position communicating the inlet port

with the return port and blocking the ?rst and

motor means and said pump for transmitting power

from said primary drive motor means to said pump.

15. The apparatus as de?ned in claim 14 wherein:

said ?rst wheel means comprises a ?rst circular wheel

second motor ports; and

a reverse position communicating the inlet port

with the second motor port and communicating

the ?rst motor port with the return port.

18. The apparatus as de?ned in claim 14 wherein said

hydraulic drive motor is characterized further as being

journaled on the upper portion of said frame adja

cent the ?rst end thereof and having a circumferen

tial recess formed thereon sized and shaped to en

gage the cable upon which said apparatus in sup

ported for movement therealong; and

external thereto for positioning said control valve

in a ?rst forward position communicating the inlet

port with the ?rst motor port and communicating

the second motor port with the return port, and,

alternately for positioning said control valve in a

reverse position communicating the inlet port with

the second motor port and communicating the ?rst

motor port with the return port.

17. The apparatus as de?ned in claim 15 wherin said

a sliding vane rotary motor.

35

40

45

50

55

60

65

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Large Batch Hard Candy and LollipopsДокумент2 страницыLarge Batch Hard Candy and LollipopsRodrigoPomaОценок пока нет

- United States Patent: Dreve, Jr. (45) May 16, 1972Документ6 страницUnited States Patent: Dreve, Jr. (45) May 16, 1972RodrigoPomaОценок пока нет

- Nov. 25, v1941. J, R, Mcmahon Eral 2,264,048: Apparatus For Applying Protective Coatings T0 SuspendedДокумент7 страницNov. 25, v1941. J, R, Mcmahon Eral 2,264,048: Apparatus For Applying Protective Coatings T0 SuspendedRodrigoPomaОценок пока нет

- 1 ChuquisacaДокумент6 страниц1 ChuquisacaRodrigoPomaОценок пока нет

- M. Schwafel: Derrick Safety CageДокумент4 страницыM. Schwafel: Derrick Safety CageRodrigoPomaОценок пока нет

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANДокумент6 страницWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaОценок пока нет

- Us1223254 PDFДокумент7 страницUs1223254 PDFRodrigoPomaОценок пока нет

- Us4589264 PDFДокумент6 страницUs4589264 PDFRodrigoPomaОценок пока нет

- Us2467764 PDFДокумент10 страницUs2467764 PDFRodrigoPomaОценок пока нет

- June 16, 1964: C. R. Steele Disintegrator Having Downwardly Inclined Baffles Filed Nov. 17, 1960Документ6 страницJune 16, 1964: C. R. Steele Disintegrator Having Downwardly Inclined Baffles Filed Nov. 17, 1960RodrigoPomaОценок пока нет

- Us1955360 PDFДокумент8 страницUs1955360 PDFRodrigoPomaОценок пока нет

- United States Patent - (191: Mayeux Et AlДокумент4 страницыUnited States Patent - (191: Mayeux Et AlRodrigoPomaОценок пока нет

- United States Patent (19) : Grote Et A1Документ9 страницUnited States Patent (19) : Grote Et A1RodrigoPomaОценок пока нет

- Jan. 1, 1952 F, J, Uprighete 2,580,864: Ea 6-) "?? (0 JUPE/GHTДокумент5 страницJan. 1, 1952 F, J, Uprighete 2,580,864: Ea 6-) "?? (0 JUPE/GHTRodrigoPomaОценок пока нет

- United States Patent (19) : Miiller (45) Date of PatentДокумент8 страницUnited States Patent (19) : Miiller (45) Date of PatentRodrigoPomaОценок пока нет

- H. J. Smith: Potato Cutting Machine 28 Filed 00Документ3 страницыH. J. Smith: Potato Cutting Machine 28 Filed 00RodrigoPomaОценок пока нет

- Cba The GPSДокумент7 страницCba The GPSRodrigoPomaОценок пока нет

- United States Patent (191: (73) AssigneeДокумент6 страницUnited States Patent (191: (73) AssigneeRodrigoPomaОценок пока нет

- A Typical Day at The Office: Unit 2 Writing AssignmentДокумент1 страницаA Typical Day at The Office: Unit 2 Writing AssignmentRodrigoPomaОценок пока нет

- Habits and Routines: Unit Writing AssignmentДокумент1 страницаHabits and Routines: Unit Writing AssignmentRodrigoPomaОценок пока нет

- Past Activities: Unit 1 Writing AssignmentДокумент1 страницаPast Activities: Unit 1 Writing AssignmentRodrigoPomaОценок пока нет

- Notas Organica IДокумент6 страницNotas Organica IRodrigoPomaОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Evolution of Trademark Laws in IndiaДокумент13 страницEvolution of Trademark Laws in IndiaPrince JohnОценок пока нет

- Megger Torkel 840 Battery Load Tester Product Manual PDFДокумент58 страницMegger Torkel 840 Battery Load Tester Product Manual PDFMisdehRasmanОценок пока нет

- 1995 Schoemaker ScenarioPlanning ToolforStrategicThinking SloanManagementReviewДокумент17 страниц1995 Schoemaker ScenarioPlanning ToolforStrategicThinking SloanManagementReviewimmaculate79Оценок пока нет

- Manual Epson TX 121Документ36 страницManual Epson TX 121Adhoen BalaDewa Haqiqi0% (1)

- Soft Light Dimmer-Cd00003922Документ8 страницSoft Light Dimmer-Cd00003922Dan EsentherОценок пока нет

- Test Bank For Essentials of Pharmacology For Health Occupations 6th Edition WoodrowДокумент22 страницыTest Bank For Essentials of Pharmacology For Health Occupations 6th Edition Woodrowheadgearridden05e6rl100% (48)

- Nonprofit Organizational Samples User AgreementДокумент4 страницыNonprofit Organizational Samples User AgreementPriscilla NzessiОценок пока нет

- Colorwork Yoke Sweater m20426 Nub v1619034143967Документ6 страницColorwork Yoke Sweater m20426 Nub v1619034143967hello hiОценок пока нет

- Publius Vergilius MaroДокумент306 страницPublius Vergilius MaroMuhammed YağarkarОценок пока нет

- Paradigm Training Catalog-July2016Документ70 страницParadigm Training Catalog-July2016Halitch HadivitcheОценок пока нет

- The Online World by de Presno, OddДокумент232 страницыThe Online World by de Presno, OddGutenberg.org100% (1)

- Humongous Book of Trigonometry ProblemsДокумент1 157 страницHumongous Book of Trigonometry Problemsallan.villegasОценок пока нет

- Full Download Understanding Human Sexuality 13th Edition Hyde Test BankДокумент13 страницFull Download Understanding Human Sexuality 13th Edition Hyde Test Bankjosiah78vcra100% (29)

- Color PlusДокумент13 страницColor Plusevry1luvspariОценок пока нет

- Palm Prophet by Ran Pink PDFДокумент23 страницыPalm Prophet by Ran Pink PDFfood007100% (18)

- Chinese Grammar Made Easy PDFДокумент336 страницChinese Grammar Made Easy PDFElena LópezОценок пока нет

- Side Entry Sub - InformationДокумент2 страницыSide Entry Sub - Informationoctgdrillstem.inspectionreportsОценок пока нет

- P120NF10Документ15 страницP120NF10marpre1983Оценок пока нет

- Mythcraft MythCraftersGuideCOMPLETED DIGITAL OpcF7tДокумент193 страницыMythcraft MythCraftersGuideCOMPLETED DIGITAL OpcF7tAeneas WoodОценок пока нет

- Operating Manual (Deh-1250mp) (Deh-1250mpg) - Eng - Esp - Por PDFДокумент80 страницOperating Manual (Deh-1250mp) (Deh-1250mpg) - Eng - Esp - Por PDFPhilip Bautista Totanes100% (1)

- BLCR Ip Rights in Mauritius 05Документ11 страницBLCR Ip Rights in Mauritius 05jowaheer jaswanathОценок пока нет

- Intel Meltdown and Spectre Microcode Update GuidanceДокумент12 страницIntel Meltdown and Spectre Microcode Update Guidancegdfeiu dionwdnОценок пока нет

- PDFДокумент3 страницыPDFLuiz Néri Pfützenreuter100% (1)

- D7304 18002 PDFДокумент8 страницD7304 18002 PDFPachomancipecОценок пока нет

- Kindness Flip BookДокумент10 страницKindness Flip BookSharalyn Joy100% (1)

- 50 Little Studies of CzernyДокумент16 страниц50 Little Studies of Czernykato345Оценок пока нет

- Imsus Technology Depo Injection FormulationДокумент1 страницаImsus Technology Depo Injection Formulationamin138irОценок пока нет

- 向神歡呼 鋼琴譜Документ7 страниц向神歡呼 鋼琴譜Mortifera Whisper100% (1)

- E.I Dupont de Nemours & Co. vs. Francisco, Et - Al.Документ3 страницыE.I Dupont de Nemours & Co. vs. Francisco, Et - Al.Carmille Marge MercadoОценок пока нет

- Antenne Andwrew 1.2mДокумент12 страницAntenne Andwrew 1.2mMarius Tresor EdiboussieОценок пока нет