Академический Документы

Профессиональный Документы

Культура Документы

DC 1

Загружено:

Gustavo ValleОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

DC 1

Загружено:

Gustavo ValleАвторское право:

Доступные форматы

OTC 23353

Simulation of Slug Flow in Oil and Gas Pipelines Using a New Transient

Simulator

Thomas J. Danielson and Kris M. Bansal, CONOCOPHILLIPS

Biljana Djoric, and Dominique Larrey, TOTAL E&P Norge

Stein Tore Johansen, Angela De Leebeeck, and Jrn Kjlaas, SINTEF

Copyright 2012, Offshore Technology Conference

This paper was prepared for presentation at the Offshore Technology Conference held in Houston, Texas, USA, 30 April3 May 2012.

This paper was selected for presentation by an OTC program committee following review of information contained in an abstract submitted by the author(s). Contents of the paper have not been

reviewed by the Offshore Technology Conference and are subject to correction by the author(s). The material does not necessarily reflect any position of the Offshore Technology Conference, its

officers, or members. Electronic reproduction, distribution, or storage of any part of this paper without the written consent of the Offshore Technology Conference is prohibited. Permission to

reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of OTC copyright.

Abstract

LedaFlow is a new transient multiphase flow simulator which includes 1D multi-fluid models consisting of mass,

momentum and energy conservation equations for each field (continuous, bubble and droplet), as well as compositional

tracking. In this paper, a new method called Slug Capturing is employed for slug flow, and the results analyzed and compared

with the field data of two different fields. Additionally, for some cases, differences between the new simulator and another

commercially available transient code results are compared and analyzed.

The first case corresponds to the production of a TOTAL-operated field in the UK. Produced fluids from the wells are

transported through a 21 km long, 16-inch multiphase flowline from the well platforms to the central receiving facilities. The

multiphase line (gas/oil/water) must be operated in a narrow range of pressure and flow rate conditions in order to avoid

severe slugging issues. Flow patterns are compared for various water cuts and superficial gas velocities. When severe

slugging is observed, slug characteristics (frequency, length) are analyzed and compared to simulator predictions.

The second case is from a CONOCOPHILLIPS-operated North Sea asset. The 3-phase, 18-inch ID oil flow line runs 3.7

km from a wellhead platform to a central processing platform. The line drops approximately 6 m over the last 3 km before

flowing up a 130 m riser. The pipeline exhibits severe riser slugging which is not adequately modeled by conventional

transient models, due to the complex interplay between hydrodynamic and riser slugging, as well as 3-phase effects. Slug

frequencies and lengths are analyzed and compared to predictions.

Background

The LedaFlow 1D Model

In this paper, the LedaFlow 1D Slug Capturing model has been used to simulate the field cases. The 1D model employs

a three-fluid-nine-field modeling concept to simulate the thermo- and hydrodynamics of the gas-oil-water three-phase flow in

pipeline systems. In this approach, the various phases are assumed to flow in continuous zones and in the form of dispersed

droplets within another zone. For instance, oil is transported in the form of continuous oil, oil droplets in the water zone, and

oil droplets in the gas zone. In a three-phase situation, the flow generally consists of three zones and nine fields. The

momentum and energy conservation equations are solved for each of the three zones, while the mass equation is solved for

all nine fields, yielding 15 conservation equations altogether.

There are two approaches within LedaFlow to simulate hydrodynamic slugs: the Unit Cell model and Slug Capturing.

The focus of this paper will be on Slug Capturing. The main difference between Slug Capturing and the basic 1D transient

model is in the treatment of hydrodynamic slugs. The basic 1D model treats hydrodynamic slugs in an averaged manner,

using the steady-state Unit Cell model for slug flow (Dukler & Hubbard 1975). This approach enables simulations on coarse

meshes, which is adequate for calculating average holdup and pressure drop in a pipeline. However, information about

individual slugs is lost, and complex interactions between hydrodynamic slugs and large terrain-induced slugs are not

captured. In many cases, the transient behavior of hydrodynamic slugs can be important, and the Slug Capturing approach is

then needed to obtain more realistic predictions. In the Slug Capturing scheme, the LedaFlow model for stratified flow only

(the Unit Cell solution is suppressed) is used on a relatively fine grid so that hydrodynamic slugs can be resolved

OTC 23353

automatically on the computational mesh. In such simulations, higher-order numerical methods are essential to avoid

smearing out the liquid slugs with numerical diffusion.

By contrast, current commercial codes employ a Slug Tracking methodology, in which a Lagrangian front tracking

scheme for slug fronts and tails is imposed over the Eulerian grid. The method is considerably faster than Slug Capturing,

but lacks the necessary physics of slug growth and decay to accurately predict slug distributions a priori (Danielson, 2011).

Closure models

The closure models applied in Slug Capturing are essentially the same as those used in the regular LedaFlow 1D model.

The modeling of the wall shear stress terms is based on classical single-phase similarity considerations, with some

corrections with respect to the influence of dispersed fields and interfacial shear stresses. The model for interfacial shear

stress between gas and liquid in near-horizontal flows is loosely based on the work of Andritsos (1986). This model has been

carefully calibrated against high-pressure experimental data to optimize the predictions in industrial field cases. A similar

model is used to calculate the shear stress between the oil and water. The entrainment of droplets in near-horizontal flows is

based on the model suggested by Paras & Karbelas (1991). This approach is used for entrainment of liquid droplets in the

gas, oil droplets in water and water droplets in oil. The special case of liquid droplet entrainment in gas is described in detail

by Kjlaas et al. (2011). Bubble entrainment in the liquid has not been accounted for in the Slug Capturing simulations, as

this model is still under development.

In vertical flows, a modified version of the Wallis (1969) model is applied to calculate the interfacial friction. In

particular, the original model is corrected for large film thicknesses, in order to reproduce the gas-liquid slip observed for the

spherical caps of gas bubbles in the churn flow regime. With this model, the flow in vertical pipes is treated in an averaged

manner, as opposed to resolving the small scale structures in churn flow. This is necessary, as the equations in vertical flows

are unconditionally ill-posed in their current form, making the numerical solution fundamentally grid dependent. This issue is

currently under investigation in the Leda R&D program.

Simulation of slug flow

Hydrodynamic slugs are typically 6 100 pipe diameters long, while slugs caused by steep terrains and risers often

called severe slugging - can be significantly longer. Severe slugging is caused by build up of liquid in an incline or riser,

which cause gas compression upstream of the slug and further liquid accumulation, until the gas pressure is sufficiently large

to blow out the accumulated liquid. In such severe slugging cases, the total gas volume available in the system is important

for the correct calculation of the duration of pressure build up and the resulting slug frequency. A consequence of this is that

the actual gas expansion volume must be accounted for in simulations, which often consider only a part of the pipeline

system. If this is not handled properly, the slugging frequency may be over-estimated or slugging may not occur at all. Thus,

it is critically important that the production system be captured as accurately as possible for a accurate simulation.

Applications

UK Field

The first case corresponds to the production of a TOTAL-operated field in the UK, now under decline. Produced,

commingled fluids from HP wells and LP wells activated by topsides MPP (MultiPhase Pump) are transported through a 21

km long, 16 multiphase flowline from the well platforms to the central receiving facilities. The multiphase line

(gas/oil/water) must be operated within a narrow range of pressure and flow rate conditions in order to avoid severe slugging

issues which are anticipated causing the field production to be significantly reduced compared to the plateau production.

Records of operational flow patterns are screened for various water cuts and superficial gas velocities. When severe

slugging is observed, slug characteristics (frequency, length) are analyzed and compared to simulator predictions.

LedaFlow version 2.32 and OLGA version 5.3.2.4 (henceforth referred to as the commercial model) were used for

generating results presented here.

Case description

The following input data and assumptions were taken into account:

The available field data covers the time range of one week, from October 10-17. The field data indicates smaller

slug oscillations, typically followed by larger oscillations which occur over a shorter period of time. The most

intensive slugging during the field test occurred in the middle of the selected week, and therefore the time range for

the simulation was chosen to be one day, starting from 7:00AM, October 13 to 7:00AM of October 14. The

measured pressure drop across the line during this period is shown in Figure 1.

OTC 23353

Figure 1 Pipeline pressure drop for one week for the UK multiphase pipeline.

The composition of the fluid was obtained by mixing different fluids in HYSYS. The GOR of the fluid used for this

simulation was 1649 m3/m3, the watercut 60% of the liquid by volume, and the gas flow rate was 2.2 MSm3/d. The

fluid property file was then created in PVTsim version 13 from CalSep.

There is no available field data for outlet pressure and inlet/outlet temperature between October 10-17. Therefore,

the averaged outlet pressure and inlet/outlet temperature from October 18-23 was selected as being the best analogue

for the Oct 10-17 period. The temperature of the fluid (modeled as a mass source) was 86.5C, and the arrival

pressure was set to 68 bara.

The pipeline bathymetry, although sloping moderately upwards in general, includes several low points, one in

particular close to the outlet riser. This profile is believed to induce a combination of hydrodynamic and terrain flow

instabilities. The bathymetry is shown in Figure 2.

Figure 2 Pipeline bathymetry for UK pipeline.

OTC 23353

Two pipe discretizations were used for this study: Slug Capturing requires a very fine mesh, and so the initial

geometry was used for LedaFlow, as a finer discretization is required for Slug Capturing simulations:

o risers cell lengths: 5.5ID-50ID

o pipeline cell lengths: 69ID

Slug Tracking does not require a fine mesh, and therefore the final, adjusted geometry was used. There are 64 pipes

with pipe length up to 1 km to represent the flowline, and 2-20 m pipes in the risers. At least 2 sections are used for

each pipe, with a maximum section length of 50 m.

Discussion of Results

Figure 3 shows that the Unit Cell model in LedaFlow and the commercial model, both of which average over the details

of hydrodynamic slugs in the pipeline, erroneously predicts stable flow in this case, whereas the field measurements clearly

indicate a large-scale instability consistent with riser slugging. Therefore, simulations in the commercial code with Slug

Tracking ON and in LedaFlow with Slug Capturing ON were performed for the remainder of this analysis.

Figure 3 Unit Cell model predictions of slugging behavior in the commercial simulator

(Slug Tracking module off) and LedaFlow (Slug Capturing module off).

In Figure 4 the gas flow rate fluctuations at the pipeline outlet predicted by the Slug Tracking module, with two values of

the Delay Constant (DC), are compared to the field data. This sensitivity analysis on the DC shows that both the default and

tuned DC are able to predict slugging. However, the tuned Delay Constant of DC=3647 shows slugs with a frequency which

is comparable to the field data (not especially surprising, as it was specifically tuned to match the data), whereas the default

recommendation of DC=150 shows much too frequent, hydrodynamic-type slugs which do not remotely match the field data.

Using the correlation of Shea (2004), a DC of roughly 650-1650 is obtained considerably less than the tuned Delay

Constant. It should be emphasized that the Delay Constant is a purely empirical fitting parameter, with no theoretical

underpinning, and values are selected ad hoc to give the best fit to field data.

OTC 23353

Figure 4 Comparison between field data and the commercial Slug Tracking with DC=150 and DC=3647.

In Figure 5 the gas flow rate fluctuations at the pipeline outlet predicted with the Slug Capturing module are compared to

the field data. The frequency of the peaks is relatively well reproduced, while the amplitude of the fluctuations is

overpredicted; Slug Capturing was able to predict large slugs, lasting for about 5 minutes. The fine mesh of the pipeline

geometry produces a non-uniform slug pattern, which changes slightly from peak to peak a result somewhat similar to the

field data. Note that there is no tuning factor - such as the Delay Constant used in the commercial Slug Tracking - required

to iniate the slugs when using the Slug Capturing technique; the slug patterns are a result of the underlying physics of the

flow.

Figure 5 Slug Capturing predictions of slugging behavior (Fine mesh).

Finally, a comparison between outlet gas flow rate trends in LedaFlow with initial geometry and Slug Tracking with adjusted

geometry and DC=3647 is shown in Figure 6. The slug pattern prediction for Slug Capturing is closer to field data than slug

flow pattern predicted by the commercial Sug Tracking model, which predicts peaks are too sharp (spaced ~1 minute apart)

and slugs that are much smaller that those measured in the field. On the other hand, LedaFlow was able to predict much

larger slugs, lasting for about 5 minutes. Although, LedaFlow slug predictions may not resemble the field data perfectly, the

predictions are more conservative, and appear much closer in frequency and magnitude to the field measurements.

OTC 23353

Figure 6 Comparison of gas outlet rate between field data, commercial Slug Tracking and LedaFlow Slug Capturing.

The comparison of the pressure drop is shown in Figure 7. The Slug Capturing simulation predicts flow pattern which is

similar to the field data, but with smaller-amplitude oscillations, varying between 3-6 bar compared to 1-10 bar field data

measurement; the commercial simulator shows a nearly constant pressure drop of roughly 1 bar.

Figure 7 Comparison of pressure drop between field data, commercial Slug Tracking and LedaFlow Slug Capturing

Outlet oil and water flow rates fluctuations recorded on the field are compared to the Slug Capturing predictions in

Figures 8 and 9, respectively. The maximum instantaneous water flow rate predicted by the commercial Slug Tracking is 540

m3/h, while LedaFlow Slug Capturing shows the maximum instantaneous water flow rate of 865 m3/h (more than 50% higher

than the maximum measured field flow rate). In addition, both simulators predict that water and oil flow rate drops nearly to

0 m3/h during slugging, where the field data never experiences periods of no flow. In addition, both codes largely underestimate liquid surge volumes for both water and oil. This discrepancy could be to to the lack of inclusion of a separator at

the top of the riser, preventing accurate depiction of the time-dependence of the pressure at the top of the riser.

OTC 23353

Figure 8 Comparison of oil flow rate between field data, commercial Slug Tracking and LedaFlow Slug Capturing.

Figure 9 Comparison of water flow rate between field data, commercial Slug Tracking and LedaFlow Slug Capturing.

This analysis indicates that Slug Capturing can provide fairly accurate predictions and pressure drop oscillations, while

the commercial Slug Tracking does not show any significant oscillations in pressure probably due to the inadequacy of the

hydrodynamic slugging predictions. This is achieved by the Slug Capturing module without tuning of modeling parameter(s),

provided a fine enough mesh is used to discretize the geometry. However, the range of pressure drops predicted by Slug

Capturing while an improvement over the commercial simulator - is still smaller than that exhibited by the field data, while

the amplitude of the gas flow rate oscillations is over-predicted (due, perhaps, to not having explicitely modeled the topsides

separator). Lastly, while the commercial simulator shows more reasonable patterns for oil and water flow rates, both

simulators significantly over-estimate the instantaneous flow rates while under-estimating the liquid surges.

OTC 23353

North Sea Field

The second case is from the CONOCOPHILLIPS-operated North Sea asset. The line is a 3-phase, 18-inch ID oil flow line,

running 3.7 km from a wellhead platform to a central processing platform. The line drops approximately 6.0 m over the last

3 km before flowing up a 130 m long riser. In operation, the pipeline exhibits severe riser slugging which has not been

possible to model adequately by conventional transient models, due to the complex interplay between hydrodynamic and

riser slugging, as well as 3-phase effects. This slugging has posed severe challenges for separation and water handling on the

platform. The pipeline bathymetry is given in Figure 10. Note that the infield line drops from the satellite platform to the

base of the riser an ideal bathymetry for the production of terrain slugs.

80

60

elevation (m)

40

20

0

-20

-40

-60

-80

-100

-500

500

1000

1500

2000

2500

3000

3500

4000

distance (m)

Figure 10 North Sea bathymetry.

In the simulations a shorter pipe length with extended diameter was added at the wellhead platform, based on the field

information of the upstream pipe volumes. The simulations were completed for a typical operational flow rate, having a water

cut of 56% by volume. Tables containing the fluid physical and thermodynamic properties, based on compositional

information from well tests, were generated using PVTSim from Calsep. However, for the incoming fluid the Gas-Oil Ratio

and the Water Cut was taken directly from the production logs. The prevailing rates and fluid properties in the pipeline are

given in Table 1.

Table 1 Fluid rates and properties for North Sea case.

Component

Gas

Oil

Water

Rate

1.7 mmsm3/d

5720 m3/d

5360 m3/d

Superficial Velocity

4.2 m/s

0.40 m/s

0.78 m/s

Density

23 kg/m3

780 kg/m3

1000 kg/m3

Viscosity

1.310-5 kg/m-s

1.110-3 kg/m-s

3.510-4 kg/m-s

The simulated pressure drop for the line, determined from LedaFlow, is presented in Figure 11. In the figure we see the

predicted results for two different computational grids. In addition the recorded pressure drop from field data is shown. What

can be seen from this figure is that both the predicted and recorded pressure drop, pressure amplitudes and frequency seems

to be represented well by the model. Another interesting result is that the model results are only weakly affected by doubling

the number of grid points. For the coarser grid (400 grid points) the average slugging period is 11.2 min, while for the finer

grid (800 grid points) the slugging period is 11.7 min.

By contrast, the OLGA-predicted pressure amplitude with Slug Tracking turned on (DC = 150) is much too small and the

pressure frequency far too high. A delay-constant could be selected which might fit the field data better; however, the OLGA

slug model has no predictive capability in this instance.

OTC 23353

12.00

OLGA slug tracking Delta P (DC=150)

Field data Delta P

LedaFlow Slug Capturing (400 grid): Delta P

LedaFlow Slug Capturing (800 grid): Delta P

10.00

Pressure drop (bars)

8.00

6.00

4.00

2.00

0.00

0.00

1.00

2.00

3.00

Time (hours)

4.00

5.00

6.00

Figure 11 Predicted and measured pressure drop for the ConocoPhillips line.

Simulation results for two different computational grids (400 and 800 grid points) are shown.

The prediction data has been further analyzed for the slug size distribution when the flow enters the central processing

platform. The slug sizes are classified by volume, and was measured during the period when the volume rate exceeded the

average rate, and until it falls below the average rate; in this way the slug size distributions, seen in Figure 12, have been

generated. The volumes of the largest liquid slugs - up to 200 m3 - are in accordance with the observations from the field.

Also, the distribution of slugs appears similar to other field measurement campaigns (Brill et al., 1981).

Figure 12 - Predicted frequency distribution of slug volume for the fine grid (800 grid points) simulation

Figure 13 gives the lift curves for this pipeline, for both OLGA and LedaFlow. The lift curves were produced by

assuming that the mass ratios of all phases stay the same as the total mass rate changes. The pressure drop predicted by

OLGA is slightly less than LedaFlow, but the stability characteristics are nearly identical. Note that current operations

(indicated by the black line) indicate that the flow should be stable; however, field measurements (as presented in Figure 11)

clearly indicate that the operations are unstable, with periodic cycling characteristic of riser slugging.

10

OTC 23353

10

9

pressure drop (bar)

8

7

6

5

4

3

2

1

0

0

20

40

60

80

100

120

140

160

180

200

mass rate (kg/s)

OLGA

LEDA

OPERATIONS

Figure 13 Lift curves for both OLGA and LEDA. Note that the lift curve indicates that current

operations are stable, whereas field data clearly indicates riser slugging.

It seems clear that there is another mechanism, not captured by the classic lift curve analysis, which is responsible for the

system instability in this case. It is the thesis of this paper that there is a complex interplay between hydrodynamic and

terrain slugging in infield lines which leads to a gravity instability that is impossible to capture with conventional 1D models

(i.e., models without some form of Slug Tracking/capturing). The riser length for many infield lines in shallow water is often

on the order of 100 m (130 m in this case, or ~290 pipe diameters). Slug lengths in pipelines have been measured at as much

as 1000 diameters in the field (Brill et al., 1981), even in relatively short pipelines. Therefore, it seems feasible that a

hydrodynamic slug could be created at some point in the infield line, well upstream of the riser. When this slug enters the

riser, it acts in precisely the same manner as a riser slug, slowing the flow behind it until it clears the riser into the HP

separator.

Figure 14 shows an example of the sequence of events during a terrain slugging cycle in a LedaFlow-simulation. The

flow direction is from left to right, and the direction of time is upwards (higher images occur later in time), with each image

80 seconds apart. The liquid fraction is given by the color scale, the blue color indicating pure liquid and the red indicating

pure gas. It should here be noted that the vertical dimension in the figure is scaled and that the amount of liquid in the

horizontal part at the riser base is larger than the liquid mass in the riser itself.

Note that as surmised a large hydrodynamic slug has been created midway through the infield line (bottom image). In

frame four from the bottom, the liquid slug has reached the riser base, where - slowed by gravity - it grows further. Finally, in

frame five and six, the liquid is blown out of the riser because of the build-up of pressure upstream of the slug, in a classic

riser slugging behavior.

This example illustrates a complex cycle of hydrodynamic slugging in an almost horizontal pipe section, and how this

may be enhanced by the presence of a riser, leading to a type of slugging which hitherto has not been well understood. These

results also call into question the common practice of the use of lift curves to determine the stability of pipeline/risers system.

Further, these findings suggests that, in systems where hydrodynamic slugging is suspected, some form of Slug

Tracking/Capturing must be employed to properly capture the dynamics of the system.

OTC 23353

11

Figure 14 This figure shows the predicted liquid distribution (blue regions) in time steps of 80 sec.

Flow comes from left and goes to the right. The time series starts at the bottom and go up in the figure.

Conclusions

It appears that there can be a complex interplay between hydrodynamic and riser slugging. This interplay makes it

impossible to accurately capture the transient behavior of many commonly-encountered production situations with a standard

transient model employing a Unit Cell (i.e., averaged) approach for slug modeling. It appears, from the simulations, that

large hydrodynamic slugs can form far from the riser base, enter the riser, retard the flow, and behave very much like riserinduced slugs. Such behavior is impossible to capture without some form of hydrodynamic slug modeling.

LedaFlow employs a new method for modeling hydrodynamic slugs called Slug Capturing. This method relies on

imposing model physics on a grid fine enough to reproduce these small-scale hydrodynamic slugs. The grid is much finer

than traditionally used for transient multiphase simulations, and as a result the Slug Capturing simulations take

considerably longer than traditional methods. By contrast, current commercial Slug Tracking schemes employ a Lagrangian

front tracking method, imposed over the Eulerian grid a method which runs considerably faster than Slug Capturing. For

example, in the UK field case, 4 hr of run time required in OLGA (with Slug Tracking module ON) is equivalent to 60 hr of

run time in LedaFlow (with Slug Capturing module ON).

On the other hand, the results obtained with LedaFlow Slug Capturing show promising and more accurate slugging

predictions than Slug Tracking - even when the slug Delay Constant is specifically tuned to the field data. LedaFlow shows

the correct slug frequency and amplitude without tuning of any parameter. Typically, the field data is not available during the

design phase and the wrong predictions of slugging phenomena could lead to oversized pipes and severe operational issues

due to slugging later on. The need for a more accurate and reliable slugging predictions is essential during the design phase.

In addition, the accurate predictions are also valuable during the operational phase, to optimize system performance.

Acknowledgements

The permission of TOTAL, CONOCOPHILLIPS, and SINTEF to publish this paper is gratefully acknowledged.

References

Andritsos, N. (1986) Effect of pipe diameter and liquid viscosity on horizontal stratified flow, PhD Thesis, University of Illinois at Urbana

Champaign.

Brill, J.P., Schmidt, Z., Coberly, W.A., Herring, J.D., and Moore, D.W., (1981) Analysis of two-phase tesets in large-diameter flow lines in

Prudhoe Bay Field, SPE Journal, pp. 363-378.

Damielson, T.J., (2011), A simple model for hydrodynamic slug flow, OTC 21255.

Dukler, A. E. & Hubbard, M.G., (1975) A model for gas-liquid flow in horizontal and near horizontal tubes, Ind. End. Chem. Fundam., vol.

14, n. 4, pp. 337-347.

12

OTC 23353

Kjlaas J., Johansen S.T., Ladam Y., Belt R., Danielson T.J., Stinessen M., (2011) Modeling of the droplet field in near-horizontal low

liquid loading flows, BHRG 2011.

Nydal, O.J., and Banerjee, S., (1996) Dynamic slug tracking simulations for gas-liquid flow in pipelines, Chem. Eng. Comm., Vols.1410142, pp.13-39.

Paras, S.V., Karabelas, A.L. (1991) Droplet entrainment and deposition in horizontal annular flow, Int. J. Multiphase Flow 17, 455468.

Schmidt, Z., Brill, J.P., (1979) Choking can eliminate severe pipeline slugging, Oil and Gas Journal, vol. 77, n. 46, pp. 230-238.

Shea, R.H., Eidsmoen, H., Nordsveen, M., Rasmussen, J., Xu, Z.G., Nossen, J., (2004), Slug frequency prediction method comparison,

BHRG 2004.

Wallis G.B. (1969) One-dimensional two-phase flow, NY: McGraw-Hill Book Company

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Dry GasДокумент2 страницыDry GasGustavo ValleОценок пока нет

- Iptc 17798 MSДокумент15 страницIptc 17798 MSGustavo ValleОценок пока нет

- SPE 12895-1984-P.,Griffith - Multiphase Flow in Pipes PDFДокумент7 страницSPE 12895-1984-P.,Griffith - Multiphase Flow in Pipes PDFGustavo Valle100% (1)

- Formation Damage Associated To Hydraulic Fracturing On Shale Gas Reservoirs - COMPLETEДокумент10 страницFormation Damage Associated To Hydraulic Fracturing On Shale Gas Reservoirs - COMPLETEGustavo ValleОценок пока нет

- Correlaciones de FlujoДокумент1 страницаCorrelaciones de FlujoGustavo ValleОценок пока нет

- 09 NaturalGasDehydrationWithTEGДокумент20 страниц09 NaturalGasDehydrationWithTEGGustavo ValleОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- BE Specs VG1000 M9000 TableДокумент3 страницыBE Specs VG1000 M9000 TableKumar sssssОценок пока нет

- Questions & Answers On Synchronous Machine StabilityДокумент20 страницQuestions & Answers On Synchronous Machine Stabilitykibrom atsbha50% (2)

- PEH A2-A6 Process Controller Serv Man 0740801006Документ70 страницPEH A2-A6 Process Controller Serv Man 0740801006Mário Silva100% (1)

- Cat Needle Valve11Документ13 страницCat Needle Valve11Nilesh MistryОценок пока нет

- 2 Polyflow 12.1 Polyflow A IIДокумент95 страниц2 Polyflow 12.1 Polyflow A IIwoongs73Оценок пока нет

- Basic Steel Selection Based On BS 970 en SeriesДокумент8 страницBasic Steel Selection Based On BS 970 en SeriesAmarendra Pendse100% (1)

- XXL Leser PSV ObsoleteДокумент28 страницXXL Leser PSV ObsoleteMuhammad RidwanОценок пока нет

- Blowout PreventerДокумент8 страницBlowout PreventerLaminus DZОценок пока нет

- Instruction Manual D Series: ALLU Screener CrusherДокумент89 страницInstruction Manual D Series: ALLU Screener CrushershekharОценок пока нет

- Al78 - 2018 SD440 Technical Specification-1Документ3 страницыAl78 - 2018 SD440 Technical Specification-1parts bklОценок пока нет

- MH Portable Top Drive - PTD: Key FeaturesДокумент8 страницMH Portable Top Drive - PTD: Key FeaturesShanbo HaoОценок пока нет

- Stability-Calculation For PipelineДокумент2 страницыStability-Calculation For PipelineGeorge100% (1)

- Solving Problems On Projectiles PDFДокумент4 страницыSolving Problems On Projectiles PDFVenkata Allamsetty100% (1)

- Boiling and Condensation PDFДокумент11 страницBoiling and Condensation PDFYeditha Satyanarayana MurthyОценок пока нет

- AD0068959Документ47 страницAD0068959ali_raza117Оценок пока нет

- Pipe Culvert Design Calculations PDFДокумент3 страницыPipe Culvert Design Calculations PDFRohit Kumar BeheraОценок пока нет

- WindSeminar SlidessummaryДокумент36 страницWindSeminar SlidessummaryM Refaat FathОценок пока нет

- NBR Data SheetДокумент1 страницаNBR Data SheetArdiansyah Oktavianus WahyudiОценок пока нет

- MAIN Air Compressor - Instruction Manual HV2-200Документ32 страницыMAIN Air Compressor - Instruction Manual HV2-200Black ScorpionОценок пока нет

- 08 Plasticity 03 Yield CriteriaДокумент21 страница08 Plasticity 03 Yield Criteria한종훈100% (1)

- Assignment - I 26 04 2020Документ2 страницыAssignment - I 26 04 2020JackОценок пока нет

- Win General CatalogДокумент14 страницWin General CatalogSandi AslanОценок пока нет

- Refrigerador True-T-49Документ12 страницRefrigerador True-T-49JOHN AGUILARОценок пока нет

- Reginald Anesu Tobaiwa: Professional ProfileДокумент2 страницыReginald Anesu Tobaiwa: Professional ProfileARUN VISHWAKARMAОценок пока нет

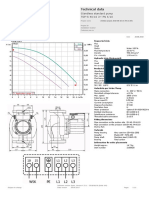

- BOMBAS PRIMARIAS - Data - Sheet - TOP-S - 40 - 10 - 3 - PN - 6 - 10Документ1 страницаBOMBAS PRIMARIAS - Data - Sheet - TOP-S - 40 - 10 - 3 - PN - 6 - 10Sebastian FuentesОценок пока нет

- IJSTM17451382214600Документ14 страницIJSTM17451382214600Viraj GaonkarОценок пока нет

- Socket H PileДокумент9 страницSocket H PilejoeliОценок пока нет

- QM ZG528-L6Документ21 страницаQM ZG528-L6eklovyaОценок пока нет

- Conveyors and Conveying Systems (Lec1b)Документ81 страницаConveyors and Conveying Systems (Lec1b)Rhizhail100% (1)

- 30-2si (Low Ambient Temp - Pressure Control Accessory)Документ16 страниц30-2si (Low Ambient Temp - Pressure Control Accessory)yogbru2010Оценок пока нет