Академический Документы

Профессиональный Документы

Культура Документы

Implementation of Low Cost Automatic Gear Suggestion System

Загружено:

Editor IJRITCCАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Implementation of Low Cost Automatic Gear Suggestion System

Загружено:

Editor IJRITCCАвторское право:

Доступные форматы

International Journal on Recent and Innovation Trends in Computing and Communication

Volume: 3 Issue: 4

ISSN: 2321-8169

2034 - 2036

_______________________________________________________________________________________________

Implementation of Low Cost Automatic Gear Suggestion System

S Venkatesh1 , Dr. B Jai Shankar2, S Finney Daniel Shadrach3, M Singaram4

1

UG Scholar, 2Associate Professor 34Assistant Professor

Department of Electronics and Communication Engineering

KPR Institute of Engineering and Technology, Coimbatore

1234

Abstract The present automatic transmission is fully mechanically controlled and costs very high. But the proposed gear suggestion

mechanism design makes driving much easier and to achieve efficient driving. It is similar to other transmission system on vehicle as it allows

an internal combustion engine, best suited to run at high rotational speed to provide torque outputs necessary for vehicular travel. By this system

the manual mechanical gear-shifting system will remain unchanged because it suggests the gear change based on increased speed. This article

touches on a PIC microcontroller and a Proximity sensor. The main advantage of using mid-range microcontroller is that it is of low-cost and

reliable. This technique can also be used to identify the gear position.

Keywords Motorcycle, Proximity, Manual, Gear-shifting, Microcontroller, Gear.

__________________________________________________*****_________________________________________________

Introduction

An automatic transmission is a type of motor vehicle

transmission they can automatically change gear ratios as the

vehicle moves freeing the driver from having to shift gears

manually. Gearshifts in automatic transmissions involve a

change in the power flow path through the transmission.

Advantages of these automatic transmissions include simplicity

of mechanical design and savings in transmission weight and

size, which are beneficial in terms of fuel economy and

production costs. This enables gain in fuel economy while

meeting drivability and performance goals, these savings

become more significant.

The designed automatic transmission is done in an autoclutch featured bike which can be applied effectively and

efficiently in a clutch featured bikes with suitable control

techniques. The ultimate goal is to transmit the gears without

the human interference and to attain efficient, safe and easy

driving in cost effective way. Microcontroller is the heart of the

system which handles all the sub devices connected across it.

PIC 16F877A microcontroller is used.

The purpose of this paper is to adapt the system which is

prevalent in some of the present luxurious cars, apart from the

safety, driver enhancements and efficiency it supports them by

suggesting the gear change based on RPM. It uses the

hydraulic pressure for changing the gears.

This paper is designed to give a suggestion for people who

have problem in figuring out the varying different gear

changing based on the readings of the speedometer. The Setup

uses the PIC Evaluation Kit for operation, which processes the

data i.e. it receives input from the sensor and gives us the

output. The initial step is that when the rider starts the vehicle

the RPM is calculated or rather counted using a Hall-Effect

sensor using the hall-effect mechanism and the output is LCD

display suggesting to change the gear based on speed.

Automatic gear changer helps us to get a clear view of gear

system. The chip of 18Fseries is used in PIC evaluation board.

This helps us to build a stable system for the two wheelers.

Proposed System

The proposed system consists of a PIC microcontroller,

Proximity sensor and a LCD, Amplifier, voice playback

module. In this proposed work, the Proximity sensor counts

the number of rotations per second and sends it to the

microcontroller, if the sensor is placed in the correct position.

Otherwise it would result in error. Interfacing the sensor with

the microcontroller enables us to know the RPM. Then, based

on the acceleration of the wheel the corresponding output is

displayed. The Fig.1.gives us the broad outline of proposed

system.

Fig.1: Block Diagram of proposed system

Proximity Sensor Fundamentals

Proximity sensor attached to the wheel counts the pulse and

provides a square wave output. The magnetic flux that is

created due to the permanent magnet rotation out of which the

gears are made up of is also another reason. The PIC

microcontroller takes the analog signal into the processor

which processes the input signal and gives us an output in the

form of displaying the gear change. The Fig.2 shows the

proximity sensor.

2034

IJRITCC | April 2015, Available @ http://www.ijritcc.org

_______________________________________________________________________________________

International Journal on Recent and Innovation Trends in Computing and Communication

Volume: 3 Issue: 4

ISSN: 2321-8169

2034 - 2036

_______________________________________________________________________________________________

An inductive proximity sensor has four main

components; The oscillator which produces the electromagnetic

field, the coil which generates the magnetic field, the detection

circuit which detects any change in the field when an object

enters it and the output circuit which produces the output

signal, either with normally closed or normally open contacts.

Inductive proximity sensors are used for sensing

ferrous and non-ferrous metals at close proximity. ASI

inductive proximity sensors are available in a wide variety of

barrel diameters, lengths and configurations. Using high

technology electronics, automated assembly and state- of-theart test equipment insures a reliable, high quality proximity

sensor.

When a car or other road vehicle passes over this inductive

loop, the

metallic body of the vehicle changes the loops

inductance and activates the sensor thereby alerting the traffic

lights controller that there is a vehicle waiting.

Fig.3: Simulation in Proteus

Fig.2: Proximity Sensor

PIC Microcontroller

The PIC 16F877A 40-Pin Enhanced Flash

Microcontrollers are essential for low cost operations but also

with better efficiency. It consists of four crystal modes up to

40MHz.It also has a built-in oscillator block.

Working of the System

Automatic gear changer suggestion system based on

Proximity sensor, microcontroller and LCD display is given

already in the fig.1. In this system initially the power supply is

provided to the microcontroller. As the first step when the

motorcycle is started and the accelerometer is raised there

would be an increase in RPM gradually from 0 to some range

of values.

The Proximity sensor attached to the wheel counts the

pulse and provides a square wave output. The magnetic flux

that is created due to the permanent magnet rotation out of

which the gears are made up of is also another reason.

The PIC microcontroller takes the analog signal into

the processor which processes the input signal and gives us an

output in the form of displaying the gear change. The below

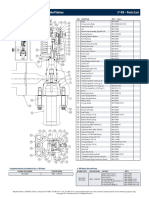

Fig.4 shows us the working model.

Fig.4: Working model

The circuit diagram explains about how the connections can be

made in real time. The setup consists of Proximity sensor

which is connected to one of the analog pins preferably for his

circuit RA0/AN0 which is 2nd pin.

For the display function, in the LCD display pins 4reset, 5-read/write, 6-enable are connected to corresponding

pins 15, 16, 17 pins in Port C. Then the pins starting from 7 to

14 are connected to Port D pins parallel. The built in

connection for the oscillator with the combination of two 33pF

capacitors are given. Along with this enabling of VSS, VDD,

VEE is also given for viewing. The Fig.3.gives us the

simulation result in proteus.

Voice-Record And Playback

Using the voice record and playback module, we can

record our voice and make it repeat it. Voice Module will

playback and record up to 60 seconds of voice message. Audio

output is available to drive a speaker. An Amplifier circuit is

2035

IJRITCC | April 2015, Available @ http://www.ijritcc.org

_______________________________________________________________________________________

International Journal on Recent and Innovation Trends in Computing and Communication

Volume: 3 Issue: 4

ISSN: 2321-8169

2034 - 2036

_______________________________________________________________________________________________

also attached to boost up the recorded sound. It consists of

four modes.

Simulation and Testing

For Software testing C language is being used in the

Keil micro-vision software. After this step, compiler generates

the hex code and is stored in the computer. The hex code of

the program is loaded into the PIC 16F877A through the

WinPIC800 device programmer. Real time simulation is done

using Proteus software.

Conclusion

The Future work of this paper is planned to develop the

system with compatible features inheriting it from those of the

four-wheelers. This setup is cost efficient and also gives better

efficiency.

Reference

[1] Chunsheng Ni, Tongli Lu, Jianwu Zhang, School of

Mechanical Engineering, State Key Laboratory for

Mechanical System and Vibration Shanghai Jiao Tong

University, 800 DongChuan Road, Shanghai, 200240

China: Gearshift control for dry dual-clutch transmissions

[2] Floyd, T.L.: Electronics Fundamentals: Circuits, Devices,

and, 6th edn. Prentice Hall, Englewood Cliffs (2003).

[3] J-O Hahn1, J-W Hur, G-W Choi, Y M Cho and K I Lee.

Department of Mechanical Engineering, Korea Airforce

Academy, South Korea.:Self-learning approach to

automatictransmission shift control in a commercial

construction vehicle during the inertia phase.

[4] Mazidi, M.A.: The 8051 Microcontroller & Embedded

System. Prentice Hall, Englewood Cliffs (1999).

[5] MuntaserMomani, Mohammed Abuzalata, Igried AlKhawaldeh and Hisham Al-M ujafet,Department of

Mechanical Engineering, Faculty of Engineering

Technology, Al-BalqaApplied University, Amman, P.O.

Box 15008, 11134, Jordan.: Pneumatic PLC Controlled,

Automotive Gear Shifting Mechanism

[6] Theraja, B.L.: Basic Electronics Solid State. S. Chand &

Company Ltd., NewDelhi (2002)

[7] Zhenyu Zhu, ChunxinXu, College of Mechanical Science

and Engineering, Jilin University, Changchun, Jilin 130025,

China:Experimental Study on Intelligent Gear-Shifting

Control System of Construction Vehicle Based on Chaotic

Neural Network

2036

IJRITCC | April 2015, Available @ http://www.ijritcc.org

_______________________________________________________________________________________

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Tanker Pipeline SystemsДокумент22 страницыTanker Pipeline SystemsLogovaz91% (11)

- AxialДокумент67 страницAxialAnonymous 6vrljIОценок пока нет

- Pajero Sports Workshop-Service Manual 1999Документ934 страницыPajero Sports Workshop-Service Manual 1999kiran_rm200693% (15)

- Regression Based Comparative Study For Continuous BP Measurement Using Pulse Transit TimeДокумент7 страницRegression Based Comparative Study For Continuous BP Measurement Using Pulse Transit TimeEditor IJRITCCОценок пока нет

- A Review of Wearable Antenna For Body Area Network ApplicationДокумент4 страницыA Review of Wearable Antenna For Body Area Network ApplicationEditor IJRITCCОценок пока нет

- Importance of Similarity Measures in Effective Web Information RetrievalДокумент5 страницImportance of Similarity Measures in Effective Web Information RetrievalEditor IJRITCCОценок пока нет

- A Review of Wearable Antenna For Body Area Network ApplicationДокумент4 страницыA Review of Wearable Antenna For Body Area Network ApplicationEditor IJRITCCОценок пока нет

- IJRITCC Call For Papers (October 2016 Issue) Citation in Google Scholar Impact Factor 5.837 DOI (CrossRef USA) For Each Paper, IC Value 5.075Документ3 страницыIJRITCC Call For Papers (October 2016 Issue) Citation in Google Scholar Impact Factor 5.837 DOI (CrossRef USA) For Each Paper, IC Value 5.075Editor IJRITCCОценок пока нет

- Modeling Heterogeneous Vehicle Routing Problem With Strict Time ScheduleДокумент4 страницыModeling Heterogeneous Vehicle Routing Problem With Strict Time ScheduleEditor IJRITCCОценок пока нет

- Performance Analysis of Image Restoration Techniques at Different NoisesДокумент4 страницыPerformance Analysis of Image Restoration Techniques at Different NoisesEditor IJRITCCОценок пока нет

- Channel Estimation Techniques Over MIMO-OFDM SystemДокумент4 страницыChannel Estimation Techniques Over MIMO-OFDM SystemEditor IJRITCCОценок пока нет

- A Review of 2D &3D Image Steganography TechniquesДокумент5 страницA Review of 2D &3D Image Steganography TechniquesEditor IJRITCCОценок пока нет

- Comparative Analysis of Hybrid Algorithms in Information HidingДокумент5 страницComparative Analysis of Hybrid Algorithms in Information HidingEditor IJRITCCОценок пока нет

- A Review of 2D &3D Image Steganography TechniquesДокумент5 страницA Review of 2D &3D Image Steganography TechniquesEditor IJRITCCОценок пока нет

- Channel Estimation Techniques Over MIMO-OFDM SystemДокумент4 страницыChannel Estimation Techniques Over MIMO-OFDM SystemEditor IJRITCCОценок пока нет

- Fuzzy Logic A Soft Computing Approach For E-Learning: A Qualitative ReviewДокумент4 страницыFuzzy Logic A Soft Computing Approach For E-Learning: A Qualitative ReviewEditor IJRITCCОценок пока нет

- Diagnosis and Prognosis of Breast Cancer Using Multi Classification AlgorithmДокумент5 страницDiagnosis and Prognosis of Breast Cancer Using Multi Classification AlgorithmEditor IJRITCCОценок пока нет

- A Study of Focused Web Crawling TechniquesДокумент4 страницыA Study of Focused Web Crawling TechniquesEditor IJRITCCОценок пока нет

- Efficient Techniques For Image CompressionДокумент4 страницыEfficient Techniques For Image CompressionEditor IJRITCCОценок пока нет

- Prediction of Crop Yield Using LS-SVMДокумент3 страницыPrediction of Crop Yield Using LS-SVMEditor IJRITCCОценок пока нет

- Network Approach Based Hindi Numeral RecognitionДокумент4 страницыNetwork Approach Based Hindi Numeral RecognitionEditor IJRITCCОценок пока нет

- Predictive Analysis For Diabetes Using Tableau: Dhanamma Jagli Siddhanth KotianДокумент3 страницыPredictive Analysis For Diabetes Using Tableau: Dhanamma Jagli Siddhanth Kotianrahul sharmaОценок пока нет

- 45 1530697786 - 04-07-2018 PDFДокумент5 страниц45 1530697786 - 04-07-2018 PDFrahul sharmaОценок пока нет

- 44 1530697679 - 04-07-2018 PDFДокумент3 страницы44 1530697679 - 04-07-2018 PDFrahul sharmaОценок пока нет

- Itimer: Count On Your TimeДокумент4 страницыItimer: Count On Your Timerahul sharmaОценок пока нет

- A Clustering and Associativity Analysis Based Probabilistic Method For Web Page PredictionДокумент5 страницA Clustering and Associativity Analysis Based Probabilistic Method For Web Page Predictionrahul sharmaОценок пока нет

- Hybrid Algorithm For Enhanced Watermark Security With Robust DetectionДокумент5 страницHybrid Algorithm For Enhanced Watermark Security With Robust Detectionrahul sharmaОценок пока нет

- Safeguarding Data Privacy by Placing Multi-Level Access RestrictionsДокумент3 страницыSafeguarding Data Privacy by Placing Multi-Level Access Restrictionsrahul sharmaОценок пока нет

- A Content Based Region Separation and Analysis Approach For Sar Image ClassificationДокумент7 страницA Content Based Region Separation and Analysis Approach For Sar Image Classificationrahul sharmaОценок пока нет

- Vehicular Ad-Hoc Network, Its Security and Issues: A ReviewДокумент4 страницыVehicular Ad-Hoc Network, Its Security and Issues: A Reviewrahul sharmaОценок пока нет

- 41 1530347319 - 30-06-2018 PDFДокумент9 страниц41 1530347319 - 30-06-2018 PDFrahul sharmaОценок пока нет

- Image Restoration Techniques Using Fusion To Remove Motion BlurДокумент5 страницImage Restoration Techniques Using Fusion To Remove Motion Blurrahul sharmaОценок пока нет

- Space Complexity Analysis of Rsa and Ecc Based Security Algorithms in Cloud DataДокумент12 страницSpace Complexity Analysis of Rsa and Ecc Based Security Algorithms in Cloud Datarahul sharmaОценок пока нет

- Usb Hardware TokenДокумент24 страницыUsb Hardware TokenquezeeОценок пока нет

- Clipper Wind PDFДокумент13 страницClipper Wind PDFyanaziОценок пока нет

- BLDC DriverДокумент8 страницBLDC DriverRich ManОценок пока нет

- Clevo D610S D620S D630S NotebookДокумент91 страницаClevo D610S D620S D630S NotebookCaptain444Оценок пока нет

- Descrambler Kit: Ramsey Electronics Model No. SS70AДокумент20 страницDescrambler Kit: Ramsey Electronics Model No. SS70AaledangieОценок пока нет

- Terberg Fifth Wheel Service ManualДокумент11 страницTerberg Fifth Wheel Service ManualSyed Danyal SalamОценок пока нет

- B35D B40D PIN 7.5 It4 TIER 3B ADT RevAДокумент935 страницB35D B40D PIN 7.5 It4 TIER 3B ADT RevAPieter BothaОценок пока нет

- Onkyo TX-NR646Документ132 страницыOnkyo TX-NR646gcataОценок пока нет

- Manual Valvula 3'' Titan RXДокумент2 страницыManual Valvula 3'' Titan RXrolandОценок пока нет

- Diodes Inc - Library - Components - List PDFДокумент5 страницDiodes Inc - Library - Components - List PDFLuciaОценок пока нет

- Motoweld SR350 ManualДокумент101 страницаMotoweld SR350 Manualouyangxin1991Оценок пока нет

- WellheadsДокумент49 страницWellheadsmanoj pОценок пока нет

- Audi AC Control UnitДокумент19 страницAudi AC Control Unitredmouse10Оценок пока нет

- What Is Heat Tracing Steam Tracing Vs Electric Tracing With PDFДокумент9 страницWhat Is Heat Tracing Steam Tracing Vs Electric Tracing With PDFPaulОценок пока нет

- Powerscreen Premiertrak 300 Features & BenefitsДокумент3 страницыPowerscreen Premiertrak 300 Features & BenefitsLuis Paladines BravoОценок пока нет

- Cryogenic Ball Valves: Installation, Operation and Maintenance InstructionsДокумент8 страницCryogenic Ball Valves: Installation, Operation and Maintenance InstructionsDv Maria PradhikaОценок пока нет

- 2010 + Chevrolet Camaro - LightingДокумент203 страницы2010 + Chevrolet Camaro - Lightingsled novaОценок пока нет

- EklavyaДокумент6 страницEklavyaAMITОценок пока нет

- 4 To 20 Ma Remote Indicator: Instructions, Operation Maintenance ManualДокумент24 страницы4 To 20 Ma Remote Indicator: Instructions, Operation Maintenance ManualsancakemreОценок пока нет

- MV Transformer Testing (7200DB1001Документ4 страницыMV Transformer Testing (7200DB1001sulthanabdulОценок пока нет

- Laundry Business Expense EstimateДокумент1 страницаLaundry Business Expense EstimateTommy Wilmark TampubolonОценок пока нет

- RTS5138 One-LUN USB 2.0 Card Reader Controller DatasheetДокумент13 страницRTS5138 One-LUN USB 2.0 Card Reader Controller Datasheetari factoryОценок пока нет

- Energy Du Mali Cable Tray SpecsДокумент2 страницыEnergy Du Mali Cable Tray SpecsNagaRajОценок пока нет

- DWE4120 B3 T1 Dewalt PBДокумент4 страницыDWE4120 B3 T1 Dewalt PBJose MolinaОценок пока нет

- MC56F8013Документ126 страницMC56F8013Asad AhmedОценок пока нет

- Beam Master Gleeson ReelДокумент2 страницыBeam Master Gleeson ReelhecsaorОценок пока нет

- At Itsce Tmax Ul 2005 Kap 06 Schaltplaene enДокумент18 страницAt Itsce Tmax Ul 2005 Kap 06 Schaltplaene enisaiaspaula80Оценок пока нет