Академический Документы

Профессиональный Документы

Культура Документы

Potential Failure Modes and Effects Worksheet: I I I I I I I I I I I I I I I I I I

Загружено:

soft52Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Potential Failure Modes and Effects Worksheet: I I I I I I I I I I I I I I I I I I

Загружено:

soft52Авторское право:

Доступные форматы

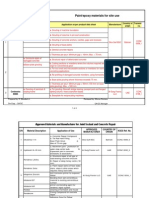

POTENTIAL FAILURE MODES AND EFFECTS WORKSHEET

FMEA Type

Level of Detail

Design

FMEA

Product / Service

Identifier --->

Process

Process

Design or Process Responsibility

------------->

RL-1500 Series Valves

Other relevant information --->

Step

Component

Part

Reginald L. Miller

None

Prepared by --->

Original Date --->

August 28, 2015

Eric Cartman (FMEA Owner), Kenny (Plant Mfg. rep.), Stan Marsh (engineering rep.), Kyle Brovlowski (quality rep.), Mr. Garrison (purchasing / supplier quality rep.), Mr. Hand (Internal Customer r

Design Item or Process

Function Requirements

saw cutting of tube

System

FMEA

345-474494-8475

End Product(s) / Model

Year(s) --->

Core Team --->

Process

Potential Failure Mode

wrong length cut

Potential Effect(s) of Failure

regulatory violation

S

e

v

9

9

7

T

y

p

e

I

I

I

I

Potential Cause(s) /

Mechanism(s) of Failure

wrong setup of saw

tube not fully held against

back stop

9

9

9

I

I

I

I

I

operator tired or

uncomfortable

I

I

tube straightness out of

specification

material expansion

operator distracted

Current Process Controls Detection

setup programs

1st piece verification

OJT

sensor on back stop with

alarm

0

4

OJT process verifies

Training records

competence through testing

regular breaks / table height regular supervisor visits

can be adjusted

D

e

t

R

P

N

81

90

man

machine

wrong saw RPM

machine

4

3

3

backstop becomes loose

5 S program

regular supervisor visits

PM checks every 1000 cuts SPC checks every 2 hours

setup programs

1st piece verification

OJT

SPC checks every 2 hours

135

180

135

81

material

Tube hardness out of

specification

Supplier approval Cpk of

1.8

CofA verified at incoming

inspection

Supplier approval Cpk of .8 CofA verified at incoming

inspection

temperature controlled in

manufacturing to 68 +/- 5

alarm system on

temperature gage / recorder

5S Program

weekly 5S audits

OJT

regular supervisor visits

material

material

I

I

I

unorganized work area

excessive dirt, dust or metal

filings on saw cut table / back

stop

environment

temperature out of

specification

environment

3

PM checks monthly stability of gage

alarm system on

temperature gage / recorder

OJT

1st piece verification

environment

backstop not setup properly measurement error

measurement

gaging out of calibration

2

measurement

SPC checks not being done

5

measurement

Page 1 of 4

calibration frequency

appropriate and methods

are capable - stability

studies

SPC checks every 2 hours

OJT

regular supervisor visits supervisor is required to

verify SPC checks sampling

Recommended Actions

144

machine

Printed: 09/17/2015

man

dull saw blade

Current Process Controls Prevention

man

method

method

9

9

method

O

c

c

operator not trained properly

9

9

Fishbone

Cause

Category

315

Improve clamp on backstop

and add sensor to detect

movement

126

441

Initiate supplier corrective

action and development to

improve Cpk

72

90

225

54

135

90

5

225

FMEA Template Revision: 29-May-07

POTENTIAL FAILURE MODES AND EFFECTS WORKSHEET

FMEA Type

Level of Detail

Design

FMEA

Product / Service

Identifier --->

Process

System

FMEA

Process

Process

Design or Process Responsibility

------------->

345-474494-8475

End Product(s) / Model

Year(s) --->

Core Team --->

RL-1500 Series Valves

Other relevant information --->

Step

Component

Part

Reginald L. Miller

None

Prepared by --->

Original Date --->

August 28, 2015

Eric Cartman (FMEA Owner), Kenny (Plant Mfg. rep.), Stan Marsh (engineering rep.), Kyle Brovlowski (quality rep.), Mr. Garrison (purchasing / supplier quality rep.), Mr. Hand (Internal Customer r

Design Item or Process

Function Requirements

Printed: 09/17/2015

Potential Failure Mode

Potential Effect(s) of Failure

S

e

v

T

y

p

e

Potential Cause(s) /

Mechanism(s) of Failure

Fishbone

Cause

Category

O

c

c

Page 2 of 4

Current Process Controls Prevention

Current Process Controls Detection

D

e

t

R

P

N

Recommended Actions

FMEA Template Revision: 29-May-07

POTENTIAL FAILURE MODES AND EFFECTS WORKSHEET

5637-2007

FMEA Number --->

August 28, 2015

Telephone #:

Email address:

585-555-1212

test@info.com

FMEA Revision Date

------>

August 28, 2015

.), Mr. Hand (Internal Customer rep.), Chef (Customer rep.)

Responsibility & Target

Completion Date

Stan Marsh - 9/07

Mr. Garrison - 9/07

Actions Taken

clamp improved and sensor

installed

CA completed and Cpk

improved to 1.4

Printed: 09/17/2015

S

e

v

O

c

c

D

e

t

R

P

N

54

189

Page 3 of 4

FMEA Template Revision: 29-May-07

POTENTIAL FAILURE MODES AND EFFECTS WORKSHEET

5637-2007

FMEA Number --->

August 28, 2015

Telephone #:

Email address:

585-555-1212

test@info.com

FMEA Revision Date

------>

August 28, 2015

.), Mr. Hand (Internal Customer rep.), Chef (Customer rep.)

Responsibility & Target

Completion Date

Printed: 09/17/2015

Actions Taken

S

e

v

O

c

c

D

e

t

R

P

N

Page 4 of 4

FMEA Template Revision: 29-May-07

Вам также может понравиться

- Failure Mode and Effective AnalysisДокумент214 страницFailure Mode and Effective AnalysisAddhew PraseetyoОценок пока нет

- Process Effectiveness Assessment Report (PEAR) Form For Weatherford Aerospace.Документ1 страницаProcess Effectiveness Assessment Report (PEAR) Form For Weatherford Aerospace.granburyjohnstevens100% (1)

- FMEA Analysis MaintenanceДокумент28 страницFMEA Analysis MaintenanceBasit AliОценок пока нет

- FMEA Process GuideДокумент31 страницаFMEA Process Guideinder_sandhuОценок пока нет

- FMEA TemplateДокумент3 страницыFMEA TemplateC SОценок пока нет

- Training in MSA PQ Systems Training Material PDFДокумент109 страницTraining in MSA PQ Systems Training Material PDFsaby aroraОценок пока нет

- PPAP PriruckaДокумент10 страницPPAP PriruckaKin MattОценок пока нет

- Reaction PlanДокумент14 страницReaction PlanMariaNilaZaragozaPalacioОценок пока нет

- Escalation ProcessДокумент5 страницEscalation ProcessBote Schijff100% (1)

- Drill Deep Root Cause Analysis WorksheetДокумент1 страницаDrill Deep Root Cause Analysis WorksheetLipecaОценок пока нет

- Change Control: DR - K. Venkateswara Raju & Mr. K. T. Sunil KumarДокумент27 страницChange Control: DR - K. Venkateswara Raju & Mr. K. T. Sunil Kumarmeenu sruthi priyaОценок пока нет

- Xfmea Report Sample - Machinery FMEA: in Addition To This Summary, This Report Includes The Following FormsДокумент6 страницXfmea Report Sample - Machinery FMEA: in Addition To This Summary, This Report Includes The Following FormsRoland JoldisОценок пока нет

- 2014 06 23 FMEA SlidesДокумент19 страниц2014 06 23 FMEA SlidesMadhan RajОценок пока нет

- MsaДокумент7 страницMsaGobi PSОценок пока нет

- 8D Corrective Action & Root Cause AnalysisДокумент95 страниц8D Corrective Action & Root Cause AnalysisRawendrraw KuriОценок пока нет

- SOP Quality ProceduresДокумент28 страницSOP Quality ProceduresUttam KumarОценок пока нет

- PFMEA TemplateДокумент19 страницPFMEA Templatejcruz909100% (1)

- MeasureДокумент51 страницаMeasureAshwani KumarОценок пока нет

- 6251 Failure Mode Effect and AnalysisДокумент28 страниц6251 Failure Mode Effect and AnalysisKumar Ashutosh50% (4)

- Fmea Template Qms Adm B F 1002Документ8 страницFmea Template Qms Adm B F 1002Allen de GuzmanОценок пока нет

- Process Capability - ToolДокумент26 страницProcess Capability - ToolFouzan SoniwalaОценок пока нет

- FMEAДокумент55 страницFMEAVijay Kumar100% (1)

- Sample FMEAДокумент20 страницSample FMEATaufikRasyadiОценок пока нет

- QMS-Process Risk Assessment ExampleДокумент2 страницыQMS-Process Risk Assessment ExampleRavi ShankarОценок пока нет

- 8 D Report: 8 Discipline MethdologyДокумент14 страниц8 D Report: 8 Discipline MethdologyAshishkekreОценок пока нет

- FMEA Quality Audit Procedure PDFДокумент5 страницFMEA Quality Audit Procedure PDFsoft52Оценок пока нет

- Aiag-Vda Process Fmea PDFДокумент18 страницAiag-Vda Process Fmea PDFsharif1974Оценок пока нет

- List of PPAP DocsДокумент4 страницыList of PPAP DocsSunilОценок пока нет

- 8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorДокумент4 страницы8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorVasanth KumarОценок пока нет

- COPQДокумент17 страницCOPQJoni Mart sitioОценок пока нет

- Advanced PFMEAДокумент22 страницыAdvanced PFMEAHassan KhanОценок пока нет

- Quality Control PlanДокумент1 страницаQuality Control PlanScha Affin100% (1)

- OOS InvestigationДокумент5 страницOOS Investigationmarkandey gupta100% (2)

- First Article Inspection Report: Purchase Order Number Supplier NameДокумент8 страницFirst Article Inspection Report: Purchase Order Number Supplier NameTuff qualityОценок пока нет

- 06 Breakout D-Quality Risk Management-Key MessagesДокумент26 страниц06 Breakout D-Quality Risk Management-Key MessagesAhmad KhreisatОценок пока нет

- Process Failure Mode Effects AnalysisДокумент20 страницProcess Failure Mode Effects Analysissriramachandira100% (1)

- Delphi Technologies Customer Specific Requirements for ISO 9001 and IATF16949Документ15 страницDelphi Technologies Customer Specific Requirements for ISO 9001 and IATF16949Ram100% (1)

- Supplier Audit FormatДокумент4 страницыSupplier Audit FormatPratik KarekarОценок пока нет

- CAPA Form TemplateДокумент3 страницыCAPA Form TemplateshahiraОценок пока нет

- Module 2 - Process FMEA Training Rev 1Документ47 страницModule 2 - Process FMEA Training Rev 1kkhelilОценок пока нет

- IATF 16949 Mandatory DocumentsДокумент2 страницыIATF 16949 Mandatory DocumentsLuis AlejandroОценок пока нет

- MF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Product InspectionДокумент1 страницаMF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Product InspectionRohit VishwakarmaОценок пока нет

- 5.2 Process Capability Analysis Rev2AДокумент8 страниц5.2 Process Capability Analysis Rev2APollyОценок пока нет

- Fmea ExerciseДокумент5 страницFmea ExerciseHamada Ahmed100% (1)

- Sop For Change ManagementДокумент1 страницаSop For Change ManagementGaurav Wadhwa0% (1)

- 43.8D - 20456 - Cyl Bottom - Thread Perpendicular IssueДокумент4 страницы43.8D - 20456 - Cyl Bottom - Thread Perpendicular IssueVasanth KumarОценок пока нет

- Process Layout ImprovementДокумент5 страницProcess Layout ImprovementhappyrockzzОценок пока нет

- A FMEA-based Approach To Prioritize Waste Reduction in Lean ImplementationДокумент22 страницыA FMEA-based Approach To Prioritize Waste Reduction in Lean ImplementationLi NearОценок пока нет

- 203 LSS Gbo - FmeaДокумент47 страниц203 LSS Gbo - FmeaRocker byОценок пока нет

- Fmea & CP FormsДокумент16 страницFmea & CP FormswebtecnicaОценок пока нет

- Example of Design FMEA WorksheetДокумент5 страницExample of Design FMEA Worksheetரஞ்சன் ஞானயோளிОценок пока нет

- Malati Founders PVT Ltd. Risk Analysis For Rework Rev No Rev DateДокумент1 страницаMalati Founders PVT Ltd. Risk Analysis For Rework Rev No Rev DateDhananjay PatilОценок пока нет

- 4.statistical Process ContorlДокумент47 страниц4.statistical Process ContorlMinhajul Haque SarkarОценок пока нет

- 8D Training: Quality Concern ResolutionДокумент16 страниц8D Training: Quality Concern ResolutionKarl SmithОценок пока нет

- Measurement System Analysis (MSA) : Validating Your Measurement Systems Gy yДокумент16 страницMeasurement System Analysis (MSA) : Validating Your Measurement Systems Gy yHesham MahdyОценок пока нет

- Worksheet in SQ Checksheet Part1Документ50 страницWorksheet in SQ Checksheet Part1Jetesh Devgun100% (1)

- Microsoft PowerPoint - ASQ Symposium Core Tools Apr 12 BДокумент69 страницMicrosoft PowerPoint - ASQ Symposium Core Tools Apr 12 Brameshdesign67% (3)

- TPMДокумент32 страницыTPMvignesh_sundaresan_1Оценок пока нет

- Failure Mode and Effective AnalysisДокумент197 страницFailure Mode and Effective AnalysisHarsha MPОценок пока нет

- Design FMEAДокумент10 страницDesign FMEAAbu AzkhaОценок пока нет

- SCMH Root CauseДокумент72 страницыSCMH Root Causesoft52Оценок пока нет

- Flow Drill InstructionsДокумент8 страницFlow Drill Instructionssoft52Оценок пока нет

- FMEA Quality Audit Procedure PDFДокумент5 страницFMEA Quality Audit Procedure PDFsoft52Оценок пока нет

- Potential Failure Modes and Effects Worksheet: I I I I I I I I I I I I I I I I I IДокумент4 страницыPotential Failure Modes and Effects Worksheet: I I I I I I I I I I I I I I I I I Isoft52100% (1)

- Accident Report FormДокумент8 страницAccident Report Formsoft52Оценок пока нет

- IA Audit Plans, Processes, and SchedulesДокумент1 страницаIA Audit Plans, Processes, and Schedulessoft52Оценок пока нет

- P Pap ChecklistДокумент6 страницP Pap Checklistsoft52Оценок пока нет

- 529A Deadman Anchor Type 1 PDFДокумент1 страница529A Deadman Anchor Type 1 PDFAnonymous sfkedkymОценок пока нет

- Beam and Slab Type Combined FootingДокумент6 страницBeam and Slab Type Combined FootingVasanthakumarОценок пока нет

- Mmup Most Common QuestionДокумент9 страницMmup Most Common QuestionGanesh Prasad Bhat100% (1)

- Inspection and Test Plan: Contract NoДокумент2 страницыInspection and Test Plan: Contract NoAhmed Samir SalimОценок пока нет

- Samsung Klima 2012 Katalogus Catalogue SACДокумент79 страницSamsung Klima 2012 Katalogus Catalogue SACKadiri Olanrewaju0% (1)

- Students Industrial Work Experience ScheДокумент16 страницStudents Industrial Work Experience Schejoseph emmanuelОценок пока нет

- AutoCAD Courses, AutoCAD Institute, CAD Training in ChennaiДокумент10 страницAutoCAD Courses, AutoCAD Institute, CAD Training in ChennaiCadd CentreОценок пока нет

- 01 GCB History enДокумент25 страниц01 GCB History enInsan AzizОценок пока нет

- House Design and Floor Plan CostДокумент5 страницHouse Design and Floor Plan CostWelkin SkyОценок пока нет

- Winter CoursesWinter Courses U of CДокумент3 страницыWinter CoursesWinter Courses U of Cmls28Оценок пока нет

- General Supplier, Blasting - Painting & Fabrication ContractorДокумент85 страницGeneral Supplier, Blasting - Painting & Fabrication ContractorMuhammad Rasyid RОценок пока нет

- Madhu Sudan (Designer. SPP&ID) 2 Yrs Experince CVДокумент5 страницMadhu Sudan (Designer. SPP&ID) 2 Yrs Experince CVPavan TejОценок пока нет

- 50 Tips For Designing Constructable Steel Buildings Q and A PDFДокумент15 страниц50 Tips For Designing Constructable Steel Buildings Q and A PDFYoussef AliОценок пока нет

- PLC Final Exam 2012Документ1 страницаPLC Final Exam 2012Hamada Adamah100% (2)

- LICOДокумент16 страницLICOAmrОценок пока нет

- Abcm Notes Sem 6Документ18 страницAbcm Notes Sem 6Sahil pamnani100% (1)

- Sunnik FRP CatalogueДокумент11 страницSunnik FRP CatalogueUttam KumarОценок пока нет

- Final BQДокумент60 страницFinal BQSee Wei ChuanОценок пока нет

- 07-Division 2-Section 02206 VC Pipelines-Version 2.0Документ9 страниц07-Division 2-Section 02206 VC Pipelines-Version 2.0Avaan IvaanОценок пока нет

- Terex Electrical DrawingsДокумент33 страницыTerex Electrical DrawingsSandoval Ramos Eddy100% (1)

- Concrete Design DIN 1045 1 PDFДокумент82 страницыConcrete Design DIN 1045 1 PDFRanjeet Kumar100% (1)

- Research Papers On Automotive EngineeringДокумент4 страницыResearch Papers On Automotive Engineeringnodahydomut2100% (1)

- Paint and EpoxyДокумент3 страницыPaint and EpoxyRahul KalathingalОценок пока нет

- Affordable Earthequake ResistantДокумент11 страницAffordable Earthequake Resistantamin tariqОценок пока нет

- 1 Introduction To Bridge EngineeringДокумент46 страниц1 Introduction To Bridge EngineeringRYAN JOSEPH QUIMOОценок пока нет

- Operating Mechanism ABBДокумент26 страницOperating Mechanism ABBviejoluisОценок пока нет

- Concrete Column and Footing Reinforcement DetailsДокумент1 страницаConcrete Column and Footing Reinforcement DetailsAmr HalabyОценок пока нет

- The Unified Process The Inception PhaseДокумент285 страницThe Unified Process The Inception Phasejavedsajid100% (1)

- TestingPreviewReport - 11013 10 31 2019 - 12 16PM - 20191031121624Документ43 страницыTestingPreviewReport - 11013 10 31 2019 - 12 16PM - 20191031121624PIDCL WITH SUBUDHIОценок пока нет

- FM II Introduction Lect 1aДокумент13 страницFM II Introduction Lect 1aSajad HussainОценок пока нет