Академический Документы

Профессиональный Документы

Культура Документы

PPDCL ConsolidatedClarifications03 04062015

Загружено:

ghostamirОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PPDCL ConsolidatedClarifications03 04062015

Загружено:

ghostamirАвторское право:

Доступные форматы

Consolidated Replies No.

3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

Punjab Power Development Company Ltd

REPLIES TO THE QUERIES OF BIDDERS 2X55 MW COAL FIRED POWER PROJECT AT SUNDER INDUSTRIAL ESTATE LAHORE

Sr.

No.

Specifica

tion

Volume

Clause

No./Section No.

Clause and Reference

Deviations /Clarifications

PPDCLs Response

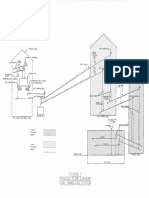

The coordinates system in drawing

Borehole Location Layout is

inconsistent with the coordinates

system in drawing PLOT PLAN.

Please check and provide the

correct

coordinates

of

the

boreholes.

Borehole locations are shown for

providing preliminary information on

soil of the project site. Coordinates

of bore hole location and grid line of

plot plan cannot be correlated.

1.GENERAL Layout

Volume IV

Drawings

in PDF

1.

2.

Volume IV

Drawings

in PDF

Volume IV

Drawings

in PDF

MMD-345023-C

-DR-02-00-0003

-Borehole

Location

Layout.pdf

MMD-320682-ZDR-02-00-0002.

pdf

MMD-320682-ZDR-02-00-0002.

pdf

Borehole Location Layout

PLOT PLAN

1. The coordinates of power plant

boundary should be some mistake.

For example, The coordinate of the

power plant northwest corner is N

346346.461, but the coordinate

adjacent grid line is N 3463500.

Please check and provide the

correct coordinates of power plant

boundary.

2. Please provide the AutoCAD

format of the drawing.

Coordinates of grid line under

revision. The soft copy of Drawing

in AutoCAD format will be provided.

Part A

1.4

Climate

The major Meteorological data from

the nearest meteorological station is

as follows:

As

bidder

understanding,

meteorological data in the table 1.1

is not for guarantee condition.

Please

provide

the

ambient

parameter (e.g. temperature (dry

bulb),

relative

humidity

and

barometric

pressure)

for

Ambient air temperature of 27 C &

RH of 60% has been specified for

guarantee of Boiler efficiency and

auxiliary power condition. Wet bulb

temperature of 28 shall be

considered

for

design

and

guarantee of cooling water system

PLOT PLAN

2 .MECHANICAL

3.

Volume II

P1

Page 1 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

Punjab Power Development Company Ltd

performance guarantee condition.

4.

Volume II

Part A

Part B

5.

P1

P5&6

Volume II

Part B Section

B1 P1

Part B Section B

P1

1.4

Climate

The major Meteorological data from

the nearest meteorological station is

as follows:

Monthly

Mean

Maximum

Temperature

41.8 C

Monthly

Mean

Minimum

Temperature

6.9 C

1.22 Draft fan FD Fan Design

basis

Fan inlet air temp 50C

1.24 Primary Air Fan

Fan inlet air temp 50C

Steam pressure at SH outlet

bar absolute (Tentative)

110

bar

Steam generators will be of semi

outdoor type, sub critical pressure,

natural circulation, non-reheat and

dry

bottom

type

Circulating

Fluidized Bed Combustion (CFBC)

and turbine cycle heat rate.

Please comply with temperature

specified for FD and PA fan design.

The inlet air temperature of FD fan

and PA fan should equal the

environment temperature. It is

changed with the environment

temperature.

110bar is high pressure parameter

not

subcritical,

they

are

contradictory. Bidder recommends

high pressure parameter steam

generator for this project.

110 bar (tentative) has been

specified. This value is aligned with

sub-critical parameter. Bidder may

quote higher parameter if it proven

for this capacity of Boiler and

Turbine offered by the Bidder.

Page 2 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

6.

Volume II

Part B Section

B1 P6

Punjab Power Development Company Ltd

units designed to burn 100%

imported coal and 100% local coal.

1.26 Steam Coil Air Pre-Heaters

(SCAPH)

SCAPH outlet air temperature with

maximum air flow corresponding to

oil firing condition 100

SCAPH outlet air temperature is

determined

by

requirement.

according

to

Bidder

the

manufacture

will

design

manufacture

Please follow the specification

requirement. Bidder may follow

manufacturers requirement if it is

more stringent than specification

requirement

requirement.

7.

Volume II

Part B Section

B1 P7

1.32 Seal Air Fans

Number per SG unit

Seal air fan is not required for

2 x 100%

circulating fluidized bed unit, and

Bidders

proposal

evaluated

during

engineering.

shall

be

detailed

the sealing air will be provided from

8.

Volume II

Part B Section

B1 P11

Condenser design pressure 0.1

Kg/cm2 (abs) at 33 deg. C cooling

water temperature

9.

Volume II

Part B Section

B1

P13

6 Condenser

Design cold water temperature

33 deg C when CT is designed for

32 deg. C outlet temperature

primary air system.

As

bidder

understanding,

0.1Kg/cm2 (abs) is applied to

physical design of the condenser,

but

not

back

pressure for

performance

guarantee

case.

Please kindly confirm that.

The

condenser

inlet

CW

temperature shall be the same as

CT outlet CW temperature which is

32 deg. C.

6 Condenser

Tube thickness 22 BWG

Tube thickness shall as per OEM

optimization.

6 Condenser

Corrosion allowance in water boxes

and tube plates

minimum 3.2 mm

Corrosion allowance shall as per

OEM standardized proven design.

10.

Volume II

11.

Volume II

Part B Section

B1

P14

Part B Section

B1

P14

Condenser pressure of 0.1Kg/cm2

(abs) at at 33 deg. C cooling water

temperature shall be guaranteed by

the bidders

Bidder to comply with specification

requirement

Margin has been considered in CW

temperature at condenser inlet and

cooling water temperature at

cooling tower outlet to take care of

temperature rise in CW pump and

degradation in performance with

time.

Bidder may offer higher thickness

Bidder may offer higher thickness

Page 3 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

12.

Volume II

Part B Section

B1

P14

13.

Volume II

Part B Section

B1

P14

14.

Volume II

Part B Section

B1

P15

15.

Volume II

Part B Section

B1

P15

16.

Volume II

17.

Volume II

Part B Section

B1

P18

Part B Section

B1

P41

6 Condenser

Minimum CW temperature rise

across

condenser at condenser design

condition 10 deg.C

7 Condenser Air Evacuation system

Design of air removal section to

cool the air and vapour mixture

corresponding to 25.4mm Hg (abs)

4.17C

below

saturation

temperature

9 Heat Exchangers type (HP and

LP

Heaters)

Material of tube stainless steel type

316

10 Feed Water Heating Plant (HP

and LP Heaters)

Corrosion allowance on each heater

shell and water box 3.2 mm

4.1 Velocity Limits for calculating

the inside pipe diameter are as

follows:

10.2 Self-Cleaning Strainers

4 Material Of Construction

Strainer screen / section SS 316.

Shaft SS 316.

Supporting cage SS 316.

Differential Measuring System SS

316.

Flushing / Backwashing Unit SS

316

Punjab Power Development Company Ltd

This requirement is not reasonable,

since Owner has already asked

condenser design pressure of

0.1kg/cm2(a) at 33 deg.C, if CW

temperature rise is more than

10deg.C, the condenser TTD will be

less than 2.4 deg.C which does not

comply with HEI requirement.

Thus, CW temperature rise will as

per Bidder optimization/design.

Shall as per HEI.

Bidder to comply with specification

requirement.

Material of tube will be TP304 or

equivalent

as

per

Bidder

optimization.

Bidder to comply with

specification requirement.

the

Corrosion allowance shall as per

OEM standardized proven design

and HEI.

Bidder to comply with

specification requirement.

the

Fluid velocity shall as per Bidder

optimization/design.

Bidder to comply with

specification requirement.

the

Material shall be TP304 or as per

Bidder optimization/design.

Bidder to comply with

specification requirement.

the

Bidder

may

bring

out

the

contradiction with HEI requirement

in its proposal.

Bidder to comply with the

specification requirement. Bidder

may bring out the HEI requirement

in their proposal

Page 4 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

18.

Volume II

19.

Volume II

20.

Volume II

21.

Volume II

22.

Volume II

23.

Volume II

Part B Section

B1

P42

Part B Section

B1

P42

Part B Section

B1

P43

Part B Section

B1

P44

Part B Section

B1

P45

Part B Section

B1

P45

Any other internal hardwares /

pipes,

etc.

SS 316

10.3 Induced Draft Cooling Tower

o

o

Cooling range ( C) 10 C

Splash Fill PVC

10.4 DMCW Pumps for both units

Operating Range 40% to 120 % 0f

rated flow

10.5 Plate Type Heat Exchangers

Heat Transfer plate SS-AISI-316

11.1 Specification Requirement

Schedule for Plant Water System

1 Raw Water Intake system

Capacity M3/hr 435 or process

requirement whichever is higher

11.1 Specification Requirement

Schedule for Plant Water System

1 Raw Water Intake system

Margin in pump flow over

continuous requirement 20%

Punjab Power Development Company Ltd

The CT cooling range shall match

CW temperature rise which shall as

per Bidder optimization/design.

Please confirm is film fill can be

used or not.

Bidder to comply with

specification requirement.

the

Bidder to comply with

specification requirement.

the

DMCW pump flow is not regulable.

Flow control has not been specified

but pump characteristic should

meet the specification requirement.

Heat transfer plate shall be TP304

or

as

per

Bidder

optimization/design.

Capacity shall as per Bidder design.

5% flow margin is to be considered;

otherwise high margin will make the

pump not operate at high efficiency

point during Plant normal operation.

Flow may vary depending on

number of coolers in service and

flow in coolers.

Bidder to comply with the

specification requirement.

Bidder to comply with

specification requirement.

the

Bidder to comply with

specification requirement.

the

Bidder

clarification

generally

applicable to continuously running

pumps without limited storage

capacity in the system. But the

explanation given by bidder is not

applicable for River water intake

system in view of storage capacity

available in Raw water reservoir.

Page 5 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

24.

Volume II

Part B Section

B1

P45

25.

Volume II

Part B Section

B1

P45

26.

Volume II

27.

Volume II

Part B Section

B1

P46

Part B Section

B1

P47

28.

Volume II

Part B- Section

B-Mech

Specification

29.

Volume

II-Part BSection

B-Mech

Specificati

on

Volume

II-Part BSection

B-Mech

6.1

system

description

The coal shall be transported to the

project site through trucks.

6.1.1

Truck

Unloading

Facilities

Capacity of each truck will be 50

Tonnes

30.

11.1 Specification Requirement

Schedule for Plant Water System

1 Raw Water Intake system

Impeller and shaft SS316

Fastener SS316

4 In plant Raw Water Pumps

Rated pump head m As per process

requirement with 10% margin.

Material of clarifier shaft and

Paddle, Flash mixer agitator

SS316

12 Material of Construction of

Pumps handling Clarified, Filtered,

UF, Potable and Service Water

Impeller SS316

Shaft SS316 / SS410

5.6.1.2 Unit Gross Heat Rate

Unit Gross Heat rate in KJ/KWhr

under rated steam conditions at 0.1

Kg/cm2 (abs) design condenser

pressure with zero make up at

100% TMCR, 80% TMCR and 60%

TMCR unit load while firing

performance coal.

Punjab Power Development Company Ltd

Material shall be TP304 or as per

Bidder optimization/design.

Bidder to comply with

specification requirement.

the

5% head margin is to be

considered; otherwise high margin

will make the pump not operate at

high efficiency point during Plant

normal operation.

Material shall as per Bidder

optimization/design.

Bidder to comply with

specification requirement.

the

Bidder to comply with

specification requirement.

the

Material shall be TP304 or as per

Bidder optimization/design.

Bidder to comply with

specification requirement.

the

Since there is already guarantee for

Unit Net Heat Rate (weighted), Unit

Gross Heat Rate for each case shall

not be guaranteed otherwise there

will be reduplicative guarantee.

Please provide the truck transport

distance.

Incorrect section of specification

has been referred. It seems,

clarification refers to Volume-II

Part-A. Please refer to clause 5.3 of

Volume-II Part-A. Net heat rate is

being computed from gross heat

rate and hence gross heat rate shall

be demonstrated and net heat rate

shall be calculated from the

demonstrated Gross Heat Rate.

Transport of coal to the project site

is responsibility of Owner.

Does the truck is Dump truck or

not?

Please provide the truck shape

parameter, including the truck width,

Truck tippler design should take

care of various types of truck

available in the market up to 50 T

capacity

Page 6 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

31.

32.

Specificati

on

Volume

II-Part BSection

B-Mech

Specificati

on

Volume

II-Part BSection

B-Mech

Specificati

on

6.1

system

description

Coal flow diagram has been

depicted

in

Drawing

no

MMD-345023-M-DR-02-00-012

6.1.2

Conveying,

Crushing

and

Bunker Feeding

System

The coal from surge hoppers

SH-1/2 is fed into the crushers

CR-1/ 2 through vibrating feeder

2A/B .Crushed Coal from crushers

is fed to screens SCR-1/2 in screen

house to screen out (-) 6 mm coal

present in the feed. The (+) 6 mm

coal from the screens will be

recycled and will be fed to the

crushers CR-1/ 2 by conveyors

BCN-3A/3B for crushing it down to

(-) 6 mm size.

The motor operated travelling

tripper

TR-1/2

provided

on

conveyors BCN-5A/5B will fill the

coal into the bunkers.

33.

Volume

II-Part BSection

B-Mech

Specificati

on

6.1.2

Conveying,

Crushing

and

Bunker Feeding

System

34.

Volume

II-Part BSection

B-Mech

Specificati

on

6.3.1

Mechanical

Equipment

System

Deck plate of minimum 3.15 mm

thickness shall be provided for full

length of all conveyors.

Punjab Power Development Company Ltd

length, height during normal mode

and unloading mode.

Please provide the coal flow

diagram which in drawing NO.

MMD-345023-M-DR-02-00-012

Already provided to prequalified

bidders.

We suggest canceling the surge

hoppers, to make the crusher house

elevation lower, and set the

crushers and screens capacity

larger than the conveyor belt

system capacity. Please confirm.

And please provide the type of

conveyors BCN-3A/3B.

Bidder proposal shall be evaluated

during detailed engineering

Considering the economy and easy

operation, Bidder recommended

using plough unloaded to replace

the tripper conveyors. Up to now,

the information about plough

unloader we get from the running

power plant shows that, the plough

unloader is reliable and easily

operated / maintained. please

confirm

Head cleaner device and return belt

cleaner will be provided to avoid the

spillages go into the tail pulley and

take-up pulley, so we suggest

canceling the full length deck plate,

or provide the deck plate under the

loading area only. Please confirm.

Bidder to comply with the

specification requirement. However

bidder may bring it as deviation in

the proposal with price of

withdrawal for this deviation.

Bidder to comply with

specification requirement.

the

Page 7 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

35.

Volume

II-Part BSection

B-Mech

Specificati

on

6.1.3 Coal Feed

from Stockyard

6.3.1

Mechanical

Equipment

System

The coal in two stockyard shall have

adequate storage for at least

30days coal consumption

The capacity of coal stockyard shall

be adequate for storing coal for 20

days

maximum

continuous

requirement (MCR).

Punjab Power Development Company Ltd

These three descriptions are

different, please indicate which is

correct.

Please follow the requirement given

in clause 6.1.3 of Volume II-Part BSection B-Mech Specification

/

Coal storage 45 days.

2

Project

Description

36.

37.

38.

Volume 1

Contractu

al 1

Volume

II-Part BSection

B-Mech

Specificati

on

Volume

II-Part BSection

B-Mech

Specificati

on

Volume

7.1

System

Description

The lime of maximum Lump Size (-)

25 mm shall be transported to the

project site through trucks.

7.1 System

Description

Lime flow diagram has been

depicted in drawing no

MMD-345023-M-DR-02-00-015.

Does the truck is Dump truck or

not?

Please provide the truck shape

parameter, including the truck width,

length, height during normal mode

and unloading mode.

Please provide the limestone flow

diagram which in drawing NO.

MMD-345023-M-DR-02-00-015.

This drawing has been provided to

prequalified bidder

9.1.1 Bed Ash

Bidder recommended use steel

Bidder may provide steel silo for

II-Part B-

Handling

structure silo to instead of RCC type

bed ash.

Section

System

B-Mech

The silo shall be of RCC type

construction.

construction

For the bed ash is only a little, the

Specificati

steel structure is suitable for bed

on

ash storage.

Page 8 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

39.

40.

Punjab Power Development Company Ltd

Volume II-

5.6.2.2 Steam

Efficiency of the steam generator at

The steam generator efficiency of

Part A-

Generator

100% TMCR, 80% TMCR and 60%

60% TMCR cannot guaranteed by

General

Efficiency

TMCR at 27deg C ambient

OEM, so bidder can guaranteed for

Technical

temperature and 60% RH while

100% TMCR, 80% TMCR only.

Requirem

firing the performance coal at rated

ent

steam parameters, and rated

Sundar

excess air.

Volume

1.3.15 Auxiliary

II-Part B-

Steam System

Section

To meet the continuous and startup

auxiliary steam

B-Mech

Specificati

Bidder to comply with specification

requirement.

Please confirm whether new

Auxiliary boiler shall be provided if it

auxiliary boiler is required or not,

is required for commissioning of

Please confirm.

boilers and startup of boiler after

If required please confirm the fuel of

long shutdown. HSD shall be used

auxiliary boiler.

as fuel if Auxiliary Boiler is provided

on

41.

42.

Volume

1.3.17 Draft

b) Induced Draft Fans

The ID fan is radial type with guide

Bidder to comply with specification

II-Part B-

Plant

Two ID fans (2 x 60% BMCR) shall

vane control and considering the

requirement

Section

be provided and they shall be of the

economy and easy operation,

B-Mech

radial backward curved type with

Bidder not recommended use

Specificati

renewable liners and variable

variable frequency drive, please

on

frequency drive.

confirm

Volume

1.3.20.1 Coal

II-Part B-

bunkers

Section

capacity for each boiler shall give

16 hours operation of the boiler at

B-Mech

BMCR, taking 15% filling factor

Specificati

considering Coal as worst fuel firing.

on

43.

The effective bunker live storage

Bidder recommended the effective

Bidder to comply with specification

storage capacity of bunker is 12

requirement.

hours operation of the boiler at

BMCR with design coal, please

confirm.

Volume

1.1 Type of

Steam generators will be of semi

Please confirm the steam generator

Steam generators will be of semi

II-Part B-

Steam

outdoor type, sub critical pressure,

is out door type or semi outdoor

outdoor type

Section

Generator

natural circulation, and non-reheat

type.

Page 9 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

B-Mech

and dry bottom type Circulating

Specificati

Fluidized Bed Combustion (CFBC)

on

units designed to burn 100%

Punjab Power Development Company Ltd

imported coal and 100% local coal.

Provision to fire HSD during start-up

and stabilization will also be made.

The steam generators shall be top

supported, Circulating Fluidized

Bed Combustion (CFBC), balanced

draft, outdoor type with all

auxiliaries, integral piping and

elevators.

44.

Volume

9.1.1 Bed Ash

II-Part B-

Handling

Section

System

In

our

experience,

Mechanical

transporting system is better than

B-Mech

The bed ash collected in the

pneumatic system for bottom ash

Specificati

Denseveyor shall be conveyed to

conveying.

on

bed ash silo through MS pipes by

We

pressure conveying.

conveyer

Bidder to comply with specification

requirement as mechanical

conveying will create dusty

environment. However bidder may

bring this proposal as deviation with

advise

using

and

bucket-chain

bucket

elevator

price of withdrawal for this

deviation.

convey and lift the bottom ash into

the bottom ash silo.

45.

Volume

9.1.3 HCSD

II-Part B-

Disposal

Section

System

B-Mech

Specificati

on

There is a large number of calcium

oxide (CaO) in the ash of CFBC

boiler, when meeting water, the

ash will harden quickly, stick in the

pipeline. So the HCSD system is

not suitable for CFBC boiler ash.

Bidder to comply with specification

requirement. However bidder may

bring this proposal as deviation with

price of withdrawal for this

deviation.

Decision shall be taken after

discussion with all the Bidders

Page 10 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

Punjab Power Development Company Ltd

We

advise

that

Cancel HCSD

during post bid discussion.

system, the ash from fly ash silo

and

bottom

ash

silo

will

be

transported to ash disposal area by

truck.

Bidder will set the limestone mill

outlet size as the requirement of

boiler manufacturer. Please confirm.

Boiler manufacturers requirement

shall be brought out in the proposal.

Decision shall be taken in post bid

discussion.

6.1.2

Conveying,

Crushing

and

Bunker Feeding

System

Size above 0.25mm after

separating from Separators will be

fed again to Mills by Screw

conveyors SC-1/2 by further

crushing to size below 0.25 mm.

Lime size below 0.25 mm will be fed

to Product hoppers-1/2.

The (+) 6 mm coal from the screens

will be recycled and will be fed to

the crushers CR-1/ 2 by conveyors

BCN-3A/3B for crushing it down to

(-) 6 mm size.

Bidder will set the coal crusher and

screen outlet size as the

requirement of boiler manufacturer.

Please confirm.

Boiler manufacturers requirement

shall be brought out in the proposal.

Decision shall be taken in post bid

discussion.

Part B Section

B1 P5

Margin over 100% BMCR pressure

requirement 44%

Bidder to comply with specification

requirement.

Part B Section

B1 P2

1.8 Combustor

In bed Sulphur Capture (for range of

coal)

90% minimum

According to relevant standard and

project experience, the margin with

20% is recommended by bidder.

As bidder understanding, sulphur

capture efficiency is not key point.

Bidder will meet the environmental

requirements of owner.

Part B Section B

P19

Crushed Lime stone storage bunker

of 16 hrs storage capacity at 100%

BMCR for the range of coal

specified

along with feeding

arrangement

to

each

boiler

considering at least 95% Sulphur

capture

for the range of coal

specified and considering highest

sulphur content in coal with

redundancy in feeding system.

46.

Volume

II-Part BSection

B-Mech

Specificati

on

7.1 System

Description

47.

48.

Volume

II-Part BSection

B-Mech

Specificati

on

Volume II

49.

Volume II

Sulfur capture efficiency, lime stone

utilization, and SO2 emission for

each type of coal specified shall be

brought out in the Proposal.

Page 11 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

Punjab Power Development Company Ltd

3. WATER SUPPLY & CHEMICAL

50.

51.

52.

Volume II

Part

AGeneral

Technical

Requirem

ent

Sundar

Volume II

Part

AGeneral

Technical

Requirem

ent

Sundar

Volume II

Part

AGeneral

Technical

Requirem

ent

1.12 Raw Water

Source

3.2.1.9

System

Water

5.6.12 DM water

consumption

Plant water requirement shall be

met form the Kahna Minor that flows

in front and parallel to the plant site

at a distance of about 20m.

Besides annual maintenance

closures of Kahna Minor, the

extended/ unforeseen closures of

the canal are expected during

floods in respective rivers during

monsoon season to protect the

canal from bank breaches/

overflows/ other possible damages

etc. To meet the raw water

requirement during canal closure a

backup arrangement shall be made

for underground water at Kahna

Minor canal bank by ins telling deep

bore well pumps.

Raw Water reservoir for 20 days

water storage

Make-up water shall be evaluated

based on actual DM water make-up

required for the station for 15 days

while maintaining the boiler steam

quality at recommended levels.

Percentage of DM water

As there is not enough

hydrogeololgy information about the

canal, design scheme is based on

that the water intake and discharge

will not influence the water quality

and hydrologic condition of canal.

After the hydrogeololgy information

about the canal received, the design

base on it will be updated with cost.

Waste water after treatment from

the plant will be discharged into the

canal during drought period of

canal, assuming minimum dilution

1:10 ratio (one cubic meter treated

water have 10 cubic meter canal

water).

Please kindly confirm if there is

existing deep well which can be

used for the project. And provide

the data (capacity, depth, diameter,

influence radius, quantity, location,

etc..) about the deep well.

Water reservoir for 20 days water

storage will be really huge, please

give the explanation about the

storage period design.

No cost update is permitted after

submission of Bid. Bidder may visit

the canal and satisfy itself regarding

the design requirement. All study

required for the design is in the

scope of Bidder.

The quality of DM makeup water

cannot be guaranteed for 15 days.

DM water storage will be designed

to satisfy the requirement of water

consumption for one maximum

boiler start-up, or the 2h~3h steam

Bidder to comply with specification

requirement

Waste

water

shall

not

be

discharged to canal. Please comply

with the specification requirement

regarding discharge of waste water.

Bore well as specified in Clause

11.1.1, Volume II Part B is in the

scope of Bidder. All study required

for the design is in the scope of

Bidder.

Bidder to comply with specification

requirement. Adequate storage

space has been identified in the Plot

Plan to cater this requirement.

Page 12 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

Sundar

consumption shall be computed

based on average percentage of

throttle steam flow during the test

period of 15 days. For the purpose

of tests unit load shall be

maintained between 60% and 100%

of rated values.

11 Plant Water

System

53.

Volume II

Part

BSection

B1 - Mech

Technical

Specificati

on

Schedule

Volume II

Part

AGeneral

Technical

Requirem

ent

Sundar

Volume II

5.6.1.3

Unit

Auxiliary Power

Consumption

10.3

Draft

Tower

Induced

Cooling

Punjab Power Development Company Ltd

flow in BMCR.

DM Water Storage Tank No Two (2)

Total Storage Capacity 500 m3 or

system requirement, whichever is

higher.

The auxiliary power consumption

for all the equipment and system

covered under the scope of this

contract that are required for

continuous unit operation a t 100%

TMCR, 80% TMCR, and 60%

TMCR load under rated steam

conditions at condenser pressure of

0.1 Kg/cm2 (abs) with 0% make-up

and with ambient air temperature of

27 C & RH of 60% while firing

performance coal shall be

guaranteed.

With ambient air temperature of

27 C & RH of 60%, the wet bulb

temperature is 21.3C. Please

confirm the design wet bulb

temperature of cooing tower is

21.3C or 28C.

Wet bulb temperature of 28 shall

be considered for design and

guarantee of cooling Tower.

Design ambient wet bulb temp.()

28.0 (including recirculation

allowance - 0.5 )

Page 13 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

54.

Part

BSection

B1 - Mech

Technical

Specificati

on

Schedule

Volume II

Part B Section A

Civil

11.6

Ducts

C.W.

Punjab Power Development Company Ltd

CW ducts from C.W. pump house

up to condensers and from

condensers up to cooling towers

shall be steel pipe encased in

concrete.

Bidder clarify that CW duct should

be steel pipe encased in epoxy

resin, which is more corrosive

resistant and easier to construct.

Bidder to comply with technical

specification. However Bidder may

bring this proposal as deviation with

price of withdrawal for this

deviation.

3.2.2.2

Generator Main

One

For Generator main connections

please use isolated Phase duct.

Connections

For a 55MW power unit, SEPCOIII

recommend SPB or NSPB for

generator main connections

generator

Please provide the location of the

sunder Industrial estate substation.

It is located within the Sundar

Industrial estate.

4.ELECTRICAL

55.

Volume IIPart

AGeneral

Technical

Requirem

ent

Sundar

(1)

set

three-phase

of

bus

isolated

duct

from

phase

terminals/phase

segregated

box

to

breaker

the

terminal

adaptor

generator

and from

circuit

generator

Circuit breaker terminals to

generator transformer terminals

56.

Volume IIPart

AGeneral

Technical

Requirem

ent

Sundar

3.2.2.16

132kV

Transmission

Line

with current transformers.

4.7 km long 132kV double circuit

line with RAIL conductor.

The transmission line shall run from

the outdoor gantry of the 132kV

Switchyard at the Power Plant to

the outdoor gantry of the 132kV

switchyard at the Sunder Industrial

estate. The length is indicative

and the actual route length

will be determined

by the

Page 14 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

57.

VolumeIIC

Electrical

Technical

Specificati

on

1.4.1

AC

Auxiliary Power

Distribution

System

58.

VolumeIIC

Electrical

Technical

Specificati

on

VolumeIIC

Electrical

Technical

Specificati

on

Volume IV

Drawings

3.3.1

Generator

Circuit Breaker

(GCB)

VolumeIIC

Electrical

Technical

Specificati

on

1.4.3

DC

system

59.

60.

61.

6.3.1

Construction

features

EPC Contractor through detailed

survey.

2 Low Voltage Power

3-Phase,4-wire

50Hz

solidly

earthed

3 Low Voltage Emergency

Power supply

400V(10%), 3-Phase,3-wire,50Hz,

unearthed

The circuit breaker (CB) shall be

three

single-pole,

sulphur

hexaflouride (SF6) type.

The switchgear enclosure shall

conform to the degree of protection

IP-43.The LV compartment shall

conform to IP-52.

3.

MMD-345023-C

-DR-02-00-0003

-Borehole

Location Layout

supply

Each set comprises 2x100%

batteries,

2

x

100%

float-cum-Boost-charger and one

DC distribution board.

Further, distribution of DC system

shall be through a number of fuse

boards being distributed in various

areas.

Punjab Power Development Company Ltd

SEPCOIII recommend LV

emergency power supply

3-ph,4-wires same as LV normal

power supply system.

The LV emergency POWER

SUPPLY is derived from the

emergency DG which is 3 wire

source. Hence, all emergency

consumers shall be 3 phase, 3 wire

SEPCOIII recommend vacuum type

circuit breaker used for GCB.

Bidder bring this proposal as

deviation with price of withdrawal for

this deviation. Decision shall be

taken during post bid discussion.

The MV switchboard will be located

in a clean room, degree of

protection IP41 is enough.

Please follow the specified Degrees

of protection

In this drawing, the generator

transformers and auxiliary

transformers are located in the

switchyard, SEPCOIII recommend

remove these transformers to the

front of steam turbine hall.

1. Rated 55MW generator is so

small, each set comprises 1x100%

batteries, 1 x 100%

float-cum-Boost-charger and one

DC distribution board is safe and

reliable enough and this scheme

comply with Chinese standards and

is successful in many engineering

practice. Please confirm.

2. Please confirm that DC breaker

boards can be used instead of fuse

Please

refer

Plot

Plan

MMD-345023-z-DR-02-00-0002 for

location of transformer. Bidders

proposal meets the requirement.

1. Please follow the specification

requirements.

2. Can be reviewed

engineering stage.

at detail

Page 15 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

Punjab Power Development Company Ltd

boards as alternative.

62.

VolumeIIC

Electrical

Technical

Specificati

on

1.7

System

Control,

Metering

and

Protection

The protection of the major

electrical equipment i.e., generator,

generator transformer, unit auxiliary

transformers,

station

auxiliary

transformers shall be effected

through redundant (2 x 100%)

numerical/Microprocessor

based

Digital Protection Relays.

63.

VolumeIIC

Electrical

Technical

Specificati

on

VolumeIIC

Electrical

Technical

Specificati

on

6.3.1.7 Relays

Auxiliary

transformer

buchholz

protection and winding temperature

initiated

trip/alarm

shall

be

interfaced with the numerical

protection relays.

6.3.1.20 AC and

DC

power

supply

The following power supplies shall

be made available to each

switchgear:

a. AC supply : 400V Single Feeder

b. DC supply : 220V Double Feeder

Isolating switch fuse units shall be

provided at each switchgear for the

incoming supplies, 4-pole, single

throw for AC and 2-pole, double

throw for DC Moulded case circuit

breaker (MCCB) shall also be

64.

As

per

Chinese

standards,

Protection of rated and above

100MW generator with generator

transformer, Protection of rated and

above 220kV transformers shall be

effected

through

redundant

(2x100%)

numerical/Microprocessor

based

Digital Protection Relays. Please

allow

us

supply

1x100%

numerical/microprocessor

based

digital protection relay for this

project 55MW generator, generator

transformer,

unit

auxiliary

transformers,

station

auxiliary

transformers. This scheme is safe

and reliable enough and successful

in many engineering practice.

Please confirm.

Bidder understands this clause

requirement is applicable only for oil

filled transformers, not for dry

transformers. Please confirm.

Please follow

requirements.

the

specification

For avoiding circular current

produce, it is not permit two DC

power parallel in DC end distribution

board, so please allow us supply

single 220V DC supply feeder and

use MCCB as an alternative instead

of isolating switch fuse unit.

Double throw is specified to not

permit

DC

powers

supply

paralleling. Hence no change is

needed.

Dry type Transformers shall not

have buchholz relay but are to be

provided with Winding temperature

detector.

Page 16 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

65.

VolumeIIC

Electrical

Technical

Specificati

on

VolumeIIC

Electrical

Technical

Specificati

on

6.3.1.23

Auto

bus

transfer

(ABT) panel

7.3.1.10

Measuring

instruments

67.

VolumeIIC

Electrical

Technical

Specificati

on

68.

VolumeIIC

Electrical

Technical

66.

accepted as an alternative for AC

circuit only.

Panel enclosure shall be fabricated

from 2 mm thick sheet steel and the

same shall be IP 52 protected.

Punjab Power Development Company Ltd

Because ABT panel is placed in a

neat room, for make well heat

emission, Please allow us use IP32

instead of IP52.

IP42 may be acceptable in Air

conditioned room ie Equipment

room

For incomers to PCC/PMCCs and

Air Circuit Breaker operated

outgoing

feeders

Digital

Multi-function

meters with communication facility

with DDCMIS system shall be

provided.

Digital

Multifunction

meters shall be of accuracy class

0.5 for incomers and 1.0 for

outgoing feeders.

Transducers shall be provided in

MCC/ACDBs

to

display

voltage/current/power values on

DDCMIS.

Transducers shall be DC operated

and shall have dual output signal

wired to DDCMIS/remote panel.

Since MCC/ACDBs equipment is

not as important as PCC/PMCCs, it

is not necessary to provide

transducers in MCC/ACDBs to

display

voltage/current/power

values on DDCMIS. Please allow us

provided Voltage meter, current

meter in MCC/ACDBs for local

monitoring

as

per

design

requirement.

To be decided

engineering.

7.3.1.21 AC and

DC

auxiliary

power supplies

Necessary 400/230V AC and 220V

DC power supplies as required for

control and service shall be

arranged inside the Switchgear.

Single supply shall be arranged for

AC supply and duplicate feeder

shall be arranged for DC supply.

Please allow us supply single 220V

DC supply, reason see item 4.5.

Refer our reply as above at 4.10

8.3.1

Construction

features

The Back-up Control Panel and the

Relay Panels shall be totally

enclosed,

floor

mounted,

free-standing,

dead-front

Because relay panels is placed in a

neat room, for make well heat

emission, please allow us use IP32

instead of IP52.

Refer our reply at 4.11

during

detail

Page 17 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

Specificati

on

Punjab Power Development Company Ltd

assemblies conforming to IP-52

degree of protection.

69.

VolumeIIC

Electrical

Technical

Specificati

on

8.3.1.13 Relays

The design of the integrated

generator

protection

and

transformer protection shall be

based on numerical techniques.

2x100%

integrated

numerical

protection along with other standard

protections shall be provided.

Separate numerical relay shall be

provided for overall differential

protection (87OA) of generator,

generator

transformer,

unit

transformers

and

station

transformer.

Please allow us supply 1x100%

numerical/microprocessor

based

digital protection relay for 55MW

generator

with

generator

transformer of this project. Reason

please see item 4.2

Please follow

requirements.

70.

VolumeIIC

Electrical

Technical

Specificati

on

00.

Drawing

List

for

2x55 MW

Lahore

9.2.2.3

Float-cum-boost

charger

(SCR

Control)

The triggering of the thyristors is

controlled

by

electronic

voltage/current regulator unit which

senses feedback from both output

voltage and current.

Please allow us use high speed

switch IGBT type charger instead of

thyristors type charger.

Accepted.

MMD-345023-E-DR-02-00-0002

SLD Generator, GT, UT, ST,

Metering & Protection

MMD-345023-E-DR-02-00-0003

SLD Metering and Protection

Scheme for 132kV GIS

MMD-345023-E-DR-02-00-0004

Functional Block Diagram of 220V

DC Power Supply

MMD-345023-CI-DR-02-XX-0002

Single Line Diagram for UPS

These drawing is missing, please

offer if any.

Already provided to the prequalified

bidders.

Volume II

Part

B

Section D

7.1

General

Requirements

The Bidder shall furnish separate

parallel redundant industrial grade

UPS System for DDCMIS Package

Since 55MW is a small generator,

for reduce project investment, we

suggest single UPS system instead

Please follow

requirement

71.

72.

the

the

specification

specification

Page 18 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

73.

74.

75.

76.

-Technical

Specificati

on for C&I

Volume IIPart

AGeneral

Technical

Requirem

ent

Sundar.pd

f

VolumeIIC

Electrical

Technical

Specificati

on-Lahore

_Final-31

Jan

2015.pdf

VolumeIIC

Electrical

Technical

Specificati

on-Lahore

_Final-31

Jan

2015.pdf

VolumeIIC

Electrical

Technical

Specificati

on-Lahore

_Final-31

Jan

2015.pdf

Page-27

Page-1

Page-3

Punjab Power Development Company Ltd

UPS system shall be separate for

each unit.

of parallel redundant UPS system.

Please confirm.

3.2.2.2

Generator

Connections

One (1) set Generator

Breaker (GCB)

The GCB is not required for this

small unit, the startup power will be

from

the

station

auxiliary

transformer.

Please follow

requirement

the

specification

The maximum temperature is

O

41.8 C. So the electrical equipment

installed indoors shall be taken as

O

O

40 C, and 45 C for outdoor.

Please follow

requirement

the

specification

According to Chinese standards

and experience, the DG will only be

provided for the unit more than

200MW. There will no DG for this

project.

Please follow

requirement.

the

specification

Dead-end tower of 132kV will be

made of angle and steel pole? The

tower section will be triangle? As

bellow

Noted.

Main

Circuit

1.2 Environmental Conditions

The equipment shall be installed in

hot, humid and tropical atmosphere.

Unless otherwise specified all

electrical equipment shall be

designed for continuous operation.

Design ambient for all electrical

equipment installed indoors, shall

O

be taken as 50 C.

1.4.2 Emergency Power supply

System

Diesel Generator (DG) sets shall be

provided

to

supply

emergency

power to the plant.

Page-179

17.10.3 Dead-end, Angle, three

post, self-supporting with Tension

Strings

Page 19 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

77.

VolumeIIC

Electrical

Technical

Specificati

on-Lahore

_Final-31

Jan

2015.pdf

Page-185

Punjab Power Development Company Ltd

This transmission line is only about

4.7 km, and there would be about

fifteen towers in total, but there are

four tower type.

Prototype Towers shall be full scale

load tested, so In my opinion there

would be four towers which need a

full-scale load test according to IEC

60652 Loading Tests on Overhead

Line Towers. Please conform.

Noted.

(1)Hot standby 100% redundancy

(1)The DCS will have redundancy in

shall be provided for all input/output

following levels Main processor,

Bidder to comply with the tender

specification.

Network

17.11.1.1 Shop test on Tower

In addition to material tests and

inspections

identified

approved QAP,

in

the

Prototype Towers

shall be full scale load tested (Type

test) at a reputable tower testing

facility.

The

testing

shall

be

conducted on the tallest towers of

each type.

5.C&I

78.

Volume II-

4.2.6.2

Part

Redundancy

in

Section D

Input/output

cards

Modules

used for critical loops like Steam

communication cable and power

Technical

Drum level control, main steam

supply.

Specificati

temp

For

on

control, Turbine bypass control,

instruments will be triple or dual

furnace

and

redundancy, and these redundant

combustion control etc. DO cards

signals will be sent to different I/O

shall be redundant for each HT

modules of DCS. Any one of

C&I.pdf

for

where

inputs/outputs

Control,

draft

feed

water

control

are

flow

interface

important

module,

signal,

the

Page 20 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

Punjab Power Development Company Ltd

drive and critical LT drives, as

redundant I/O module fails, other

applicable to the plant.

signals

(3)Wherever redundant sensors are

module can also be used.

employed each sensor shall be

So the redundancy I/O module will

wired to redundant input modules

not be provided.

so that even if one input module

(2) DO cards will not be redundant.

fails,the signal will be available from

(3)For redundant sensors, each

the other input module.

sensor will be wired to different I/O

resident

un-failure

I/O

modules(one sensor to one input

module, not one sensor to two or

three input module). Even if one

input module fails, other signals will

be available from the other input

module.

79.

Volume II-

4.2.17.1

Alternative I

Steam Turbine Generator Control

Part B

Electro-Hydrauli

Alternative II

System will be provided as per

Section D

c Governor

turbine manufacture standard

Control

design.

Bidders response not clear with

respect to which type of alternative

proposed in the specification is

applicable for the bidders provided

steam turbine.

Technical

Specificati

on for

C&I.pdf

80.

Volume II-

4.2.17.2

(c) ........ The trip coils shall be

According to the turbine

Part B

Turbine

monitored continuously for

manufacturers design, for the

Section D

Protection

healthiness and failure shall be

solenoid valve, the state of the trip

System (TPS)

alarmed.

coils cannot be monitored, and the

Technical

Bidder to comply with the tender

specification however this shall be

evaluated during bid evaluation.

state of the solenoid valve will be

Page 21 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

Punjab Power Development Company Ltd

Specificati

monitored. The power supply status

on for

can be monitored continuously.

C&I.pdf

81.

Volume II-

4.2.17.3

ii)

Absolute as well as relative

Part B

Turbine

shaft vibration measurement, of

design,

Section D

Supervisory

each bearing in both X and Y

ii) the shaft absolute vibration will

System (TSS)

direction (both for Turbine and

not be provided, only provided the

Technical

Generator bearing).

X/Y direction for shaft relative

Specificati

v)

on for

measurement of each bearing in

v) Absolute bearing vibration

C&I.pdf

both X and Y directions (both for

measurement of each bearing in

turbine and generator bearings).

vertical directions (both for turbine

vi)

and generator bearings).

Absolute

Stator

measurement

bearing

winding

in

vibration

vibration

radial

and

As per the turbine manufacture's

vibration.

vi) Stator winding vibration

tangential directions.

measurement will not be provided.

vii)

vii) Axial shift of the rotor, two or

Axial shift of the rotor, (three

sensors).

Bidder to comply with the tender

specification

three sensors, different

manufacture has different design for

the number of axial shift sensor.

82.

Volume II-

4.2.21

PLC

The complete MIS system including

There is not detailed function

Part B

Configuration

hardware, software, cables etc, as

description for MIS in owner's

required shall be provided.

tender document, please provide.

Section D

-

So that bidder can consider this

Technical

system.

The functional description of MIS is

attached in Annexure I

Specificati

on for

C&I.pdf

Page 22 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

83.

Punjab Power Development Company Ltd

Volume II-

4.5

Vibration

Vibration monitoring for all HT

Vibration monitoring for most HT

Part B

Monitoring for

motors and its associated pumps,

motors and its associated pumps,

Section D

HT Motors

fans, drives etc. for X, Y and Key

fans, drives etc, will be provided,

Phasor ......

the detailed rotation device list

Technical

which will be provided the vibration

Specificati

measuring will be submitted to

on for

owner for reviewing.

Noted.

C&I.pdf

84.

Volume II-

6.1.3

Marshalling/Termination

Part B

Termination/Mar

for the system shall be supplied as

integrated in one cabinet, no

Section D

shalling

part

dedicated Marshalling/Termination

Cabinets and

cabinets/panels for

Technical

Interposing

all

Specificati

Relay Panels

field,

of

cables

DDCMIS/PLC

originating

MCC/SWGR or

of

cabinets

signal

terminating

from

I/O cards and terminals will be

Noted.

cabinets to be provided.

the

any other

on for

source

C&I.pdf

distributing the signals to different

and

for

functional panels and cubicles.

85.

Volume II-

13.5 Ambient Air

AAQMS shall include monitoring of

Please provide the PCB norms for

Part B

Quality

the

bidder reference,

Section D

Monitoring

gases/parameters. However, any

(AAQMS

other

following

pollutant

As per EIA already supplied to the

prequalified bidders as part of

feasibility study report.

gases/parameters

Technical

recommended by relevant central

Specificati

and state regulatory agencies shall

on for

also be provided.

C&I.pdf

Method

of

measurements

and

standards shall be as per pollution

control

boards

(PCBs)

norms.

Page 23 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

There

shall

Punjab Power Development Company Ltd

not

be

any

cost

implication for the same to Owner

86.

Volume II-

8.7.1.2

Part

Cables

Control

Solenoid valve Power supply cables

Solenoid valve Power supply cables

shall be minimum 2.5sq.mm

shall be maximum 1.5sq.mm due to

Section D

Bidder to comply with the tender

specification

the lower voltage and current.

Technical

Specificati

on

for

C&I.pdf

6.CIVIL

87.

Volume

II-partB

Section A Civil

2.2.1 b) All foundations shall be

designed in accordance with

provisions of the relevant parts of

the latest revisions of British

Standards.

Refer Clause 1.1 Last Paragraph

According to the tender document,

the bidder will make overall design

according to American standard.

Please clarify.

2.2.3 Pile Foundations: Type and

size of the Pile foundation shall be

based on the recommendation in

detailed geotechnical investigation

report and subsequent established

by initial pile load test at site and

shall be designed as per relevant

part of American and British

standards.

3.6 Basic Design Concepts for

Design of Structural Steel Work:

Page 24 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

Punjab Power Development Company Ltd

Structural steel design shall be

carried out as per structural steel

design code AISC 12th Edition,

BS 5950 and other relevant code

unless noted otherwise.

3.8 Codes & Standards: The

engineering & execution of all Civil,

Structural & Architectural works

shall be based on the latest edition

or revision of the applicable portion

of the following Codes and

Specifications. List of some of

applicable codes and standards are

given in Appendix-A for ready

reference. In case any particular

aspect of work is not covered by

those Standards, other standard

specifications, as may be specified

by the Engineer, shall be followed.

d) American Codes and standards

(ASTM, ACI,)

88.

Volume

II-partB

Section A Civil

3.4.18 Seismic Load

The project site is in Zone IIA as

per Pakistan seismic code.

According to the Pakistan seismic

code, the earthquake acceleration

(PGA) of Zone-IIA is range of

0.08g~0.16g. Please provide the

accurate earthquake acceleration

(PGA) in this project area.

0.16g shall be used.

Page 25 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

89.

Please clarify: Can Chinese steel

materials be used for steel

structures?

90.

Volume

-Part

B-Section

P55-10.3

P59-11.1

Superstructure of Pump house shall

be of RCC with brick cladding./The

superstructure of all pump houses

shall consist of structural steel

A Civil

frames, side metal sheet cladding

and RCC roof over permanent

91.

Volume

-Part

B-Section

A Civil

P74-12.3.2.3

92.

Volume

-Part

B-Section

A Civil

Volume

-Part

B-Section

A Civil

P76-14.1.5

Volume

-Part

B-Section

93.

94.

Punjab Power Development Company Ltd

shuttering desk sheets.

The following factors of safety shall

be considered for stability of

foundation and underground

structures.

Stability against uplift : 1.25

The documents have a different

Steel materials confirming to British

and American code shall be used.

Please follow the stipulation of

technical specification

description of structure form for the

pump house, whether the

superstructure of pump house can

use steel structure uniformly.

According to the American or BS

code, Ring plate type foundation

dose not allow to produce uplift

force

in

the

working

load

combination and allow uplift of ring

plate foundation which central angle

is less than 30 degrees under the

computational load combination. So

we think the coefficient of uplift is

enough which is 1.2.

Please follow the stipulation of

technical specification

These shall be of RCC construction,

water tight and above ground.

Please consider using steel water

tank.

Please follow the stipulation of

technical specification

P78-15.3

The ash dyke height shall be

designed and constructed

considering design life of power

plant as 30 years.

Considering the demand and cost in

the prior period, Whether primary

dam can design according to the

amount of ash storage for 3~5

years? Later can increase the

height of dam to meet the future

requirement. Please confirm.

Ash dyke height shall be 6 m

including 750 mm free board.

P79-15.6

No protection is required 1m below

FBL for for U/S slope since it will be

submerged under water/ash most of

Please

consider

protection

measures of whole U/S slope.

Bidders proposal if superior to

specification requirement shall be

considered.

Page 26 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

A Civil

the time.

95.

Volume II

-

Part

17.5 Work Shop

Section A

97.

Volume II

- Part B Section A

Civil

17.6 Permanent

Stores

Volume II

Part

A-General

Technical

Requirem

ent

Sundar

1.6 Geology

Volume II

- Part B Section A

Civil

It shall be of RCC structure with

We think the area is large. We

steel truss framing with brick

suggest area may be 1000 m2 and

cladding and roof metal decking

it is enough. Please confirm.

Please follow the stipulation of

technical specification

with minimum built up of 2000 m2.

Civil

96.

Punjab Power Development Company Ltd

Appendix-B.

Details

Boreholes

Permanent Stores shall be of RCC

We think the area is large. We

framed structure with brick cladding

suggest area may be 1000 m2 and

with minimum built up of 2000 m2.

it is enough. Please confirm.

As per soil investigation report of

According to the soil profiles, the

Sunder, Lahore project site, soil is

value of SPT is larger than 30 at a

having minimum bearing capacity of

depth of 3.0m.Therefore, it can be

around 15.0 T/sq.m at a depth of

envisaged that the bearing capacity

3.0 m.

should be more than 15.0 T/sq.m at

Please follow the stipulation of

technical specification

Refer Appendix B 2nd last

Paragraph - last line.

3m depth. Please confirm the same

of

and provide a final value for design.

7.HVAC

98.

Volume IIPart

AGeneral

Technical

Requirem

ent

Sundar

19 of 222

1.4 Climate

The data quoted in the left is not

The major Meteorological data from

applicable for HVAC system design,

the nearest meteorological station is

as follows:

Table 1.1: Meteorological Data

Parameter Values

Bidders

understanding regarding

use of ASHRE, Metrological data for

The following data might be

HVAC system design is correct. Any

considered to be taken as outdoor

site specific data that is more

design conditions

stringent than ASHRE Metrological

of HVAC system

during the tendering phase, please

Page 27 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

Punjab Power Development Company Ltd

Monthly Mean Maximum

confirm

Temperature C

(Quoted from ASHRAE ,

41.8

Monthly Mean Minimum

Meteorological data of LAHORE city

Temperature C

which latitude is31.52N and

6.9

Average Annual Rainfall mm 288

longitude is 74.40E):

Recorded in July 2010

1) Dry-bulb temperature

Maximum ambient humidity %

100

data shall also be considered.

corresponding to 0.4% /1%annual

Average Relative Humidity over 4

cumulative frequency of occurrence

years % 70

warm conditions and mean

coincident wet-bulb temperature

43.2C/23.2C, 41.8C/23.5C,

2

Dry-bulb

temperature

corresponding to 99.6% /99%

annual cumulative frequency of

occurrence and outdoor design

relative humiditycold conditions

3.9C /5.0C

3)

Evaporation

wet-bulb

temperature corresponding to 0.4%

/1%annual cumulative frequency of

occurrence and mean coincident

dry-bulb

temperature

42.3C/34.2C, 28.7C/33.6C,

Please provide extreme (maximum

and minimum) temperatures used

for HVAC system design.

99.

Volume

II-Part BSection

176 of 235

15.1.1.2 Water Cooled Packaged

Units

The ESP cum VFD Control

Buildings and fly Ash Equipment

Building Control room are far away

Water

cooled

air-conditioning

system has been considered due to

Page 28 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

B-Mech

Specificati

on

Water Cooled Packaged Units

(Precision Type) shall be provided

for air conditioning of the ESP cum

VFD Control room in ESP cum VFD

Control Buildings. No separate

Punjab Power Development Company Ltd

from central refrigeration station

and considering simplifying the

system and convenience for

operation and maintenance, we

consider that air cooled air

conditioner shall be provided for

these rooms, please confirm.

cooling tower have been envisaged

better

efficiency,

more

stable

cooling in extreme hot condition,

and relatively high heat load in the

ESP

cum

VFD

control

room

building.

Bidder to comply with specification

for this system. Condenser cooling

requirement.

water shall be supplied to these

buildings

from the ACW system

Water Cooled Packaged Units

(Precision Type) shall be used for

air conditioning of the Fly Ash

Equipment Building Control room

(One No. common for both the

units). Water for condenser cooling

of such PAC units shall be tapped

from ACW supply system. Hot water

after condenser cooling shall be

returned to the ACW return line for

its cooling in the Main Cooling

Towers of the Power Station.

100.

Volume

II-Part BSection

B-Mech

Specificati

on

183 of 235

15.4.2 Ventilation System

According to ASHRAE, The dry

For all the mechanically ventilated

ventilation system for each area

areas, the supply air fans/louvers,

shall be sized based on a maximum

filters and exhaust air fans/roof

room temperature of

extractors or combination shall be

(maximum) above design ambient

6C

Comply

with

specification

requirement. The requirement is

aligned

with

temperature

high

during

ambient

summer

Page 29 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

Punjab Power Development Company Ltd

provided as required. The

temperature during summer

ventilation system for each area

considering all heat loads or 10

shall be sized based on a maximum

(ten) air change rate/hour (for

room temperature of 3C

general areas) and 15 (fifteen) air

(maximum) above design

change rate /hour (for battery

ambient temperature during

rooms), whichever is higher.

The relative humidity is

controlled

summer considering all heat loads

or 10 (ten) air change rate/hour (for

months.

not

general areas) and 15 (fifteen) air

change rate /hour (for battery

rooms), whichever is higher.

101.

Volume

II-Part BSection

B1 - Mech

Technical

Specificati

on

Schedule

63 of 98

1 Temperature

According to ASHRAE, center

Dry Bulb Temperature to be

control room and Electronic

maintained in manned area (24+

equipment room will be maintained

1.0) C

constant temperature as follows:

Dry Bulb Temperature to be

Summer Temperature 241C

maintained inside the Control rooms

Winter Temperature 221C, the

(22+ 1.0) C

humidity shall be maintained at

2 Relative Humidity

30%~65%;

Max Relative Humidity As per site

Local control rooms, Offices and

requirement

personnel areas shall be

Min Relative Humidity As per site

maintained at:21~26, relative

requirement

humidity is no more than 65%;

Relative Humidity to be maintained

The battery room shall be

inside of building 50% 5%

maintained at25, relative humidity

Bidder understanding regarding use

of ASHRE code for design of

Air-conditioning system is correct.

Further detail shall be considered

during detail engineering.

is not controlled.

According to electrical code IEC,

indoor condition of switchgear

Page 30 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

Punjab Power Development Company Ltd

rooms shall be maintained at no

more than +35, relative humidity

is not controlled.

Please confirm.

102.

Volume

II-Part BSection

B-Mech

Specificati

on

182 of 235

15.1.2 Ventilation

Two types of ventilation system

namely evaporative cooling system

(i.e. Air washer system) and dry

Because the air washer system

can't maintain the Battery Room

indoor temperature at 25, Battery

Room in main plant will be provided

with air conditioning system.

Bidder may provide air conditioning

system in Battery Room as per

requirement.

mechanical system shall be

employed in various areas of the

plant for the purpose of ventilation.

The areas to be ventilated by

evaporative cooling system are as

follows:

d) Battery Room in main plant

103.

Vol 1

Bid Security

With reference to "Form of Bid

Security" Item 2 (c) (ii); if bidder

fails to sign 'Contract Agreement"

the bid bond will be forfeited.

Even though we have sincerest

intentions to achieve financial

close within shortest possible time

with the support of the employer; it

will be unjust to make EPC contractor

solely responsible and liable for the

achievement of financial close.

We suggest this time limitation of 120

days

for

achieving

financial

close shall either be removed from

It is a presumption that successful

bidder will sign contract and furnish

performance security within a

prescribed

time

period

after

achievement of financial close which

eventually ensure accomplishment of

commercial operation date of project

during

desired

time

period.

Therefore, clause 19.1 (c) is

imperative to ensure steadfast

adherence with time driven project

milestones including signing of

Page 31 of 59

Consolidated Replies No.3

2x55MW (Gross) PPDCL Coal Fired Power Project Sunder Lahore

Punjab Power Development Company Ltd

ITB 44.1.

Further elaborated in ITB clause

44.1, Signing of Contract will be

subject to the achievement of

Financial Close which shall be

within 120 days from the date of

Notification of Award.

contract

and

submission

performance security .

of

The complete text of clause 44.1

addresses the concerns of SEPCO III

regarding financial close within 120

days and responsibility of PPDCL

for financial close. The clause 44.1 is

re-produced for clarity purposes;

Signing of Contract will be

subject to the achievement of