Академический Документы

Профессиональный Документы

Культура Документы

Spe 58788 MS

Загружено:

José TimanáОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Spe 58788 MS

Загружено:

José TimanáАвторское право:

Доступные форматы

SPE 58788

Perforating Requirements for Sand Prevention

A. Venkitaraman, SPE, L.A. Behrmann, SPE, Schlumberger Reservoir Completions, A. H. Noordermeer, SPE, BP Amoco

Exploration

Copyright 2000, Society of Petroleum Engineers Inc.

This paper was prepared for presentation at the 2000 SPE International Symposium on

Formation Damage Control held in Lafayette, Louisiana, 2324 February 2000.

This paper was selected for presentation by an SPE Program Committee following review of

information contained in an abstract submitted by the author(s). Contents of the paper, as

presented, have not been reviewed by the Society of Petroleum Engineers and are subject to

correction by the author(s). The material, as presented, does not necessarily reflect any

position of the Society of Petroleum Engineers, its officers, or members. Papers presented at

SPE meetings are subject to publication review by Editorial Committees of the Society of

Petroleum Engineers. Electronic reproduction, distribution, or storage of any part of this paper

for commercial purposes without the written consent of the Society of Petroleum Engineers is

prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300

words; illustrations may not be copied. The abstract must contain conspicuous

acknowledgment of where and by whom the paper was presented. Write Librarian, SPE, P.O.

Box 833836, Richardson, TX 75083-3836, U.S.A., fax 01-972-952-9435.

Abstract

Sand prevention implies an acceptable risk of sand production

over the producing life of the well with no sand control

mechanisms implemented. This paper reviews available

methods to optimize the choice of perforation parameters

(phasing, shot density and charge type) for sand prevention.

Prior work has shown that sand production is preceded by

failure of the perforation tunnels. In order to have successful

sand prevention it is necessary to have stable perforation

tunnels through rate (drawdown) changes, depletion, and

water-cut. Available methods to determine the ability of

perforation tunnels to produce sand free can be classified into

theoretical models, experimental methods and historical

techniques.

Deep penetrating charges are recommended as they

produce smaller diameter perforation tunnels that are more

stable than larger diameter tunnels produced by big hole

charges. Optimum phasing technique relies on the

maximization of distance between adjacent perforations in 3dimensional space for a given wellbore radius and shot

density. This is advantageous in avoiding inter-linking of

failed zones around adjacent perforations. Data from the

Magnus field in the North Sea supports the use of these two

techniques in minimizing sand production. Where there are

significant stress contrasts in the formation and the directions

are known, oriented perforating can be used to increase the

stability of perforation tunnels (especially when increasing

drawdown and when depleting the reservoir).

It is shown how these three main techniques can be used to

perforate for sand prevention. In addition, the paper also

provides guidelines on how to avoid sand production at the

time of perforation, selective perforating where there is a

contrast in formation strength with depth and the use of

experimental techniques to determine perforation stability due

to rate (drawdown) changes, depletion and water-cut.

Introduction

In most unconsolidated and weakly consolidated wells around

the world, traditional approach has been to use sand control

techniques whenever there was a risk of sand production. This

was driven mainly by safety (erosion of surface hardware) and

economic concerns. However many wells where sand control

mechanisms are installed have proven to be costly in terms of

productivity impairment. There has been a two-fold approach

to tackling this problem: a) determine the sources of

impairment to sand control methods and find out how to

minimize them1 , and b) prudent use of sand prevention

techniques as opposed to total sand exclusion.

The essence of sand management is the quantification of

the risk of sand production that helps decide if/how/when sand

exclusion (control) or sand prevention should be implemented.

Sand prevention incorporates methods to minimize the amount

of sand produced and also methods to minimize the impact of

sand produced. The objective of this paper is to outline best

perforating practices for minimizing the amount of sand

produced over the producing life of cased and perforated

wells. Three main events are responsible for sand production:

rate or drawdown changes, depletion (effective stress) and

water cut.

Sand production is a two-part decoupled phenomenon:

Sand must be separated from the perforation tunnel (failure),

and the flowing fluid must transport the failed sand. Stress,

controlled by drawdown and depletion does the first, and rate,

also controlled by drawdown does the second2 . Using this

theory sand production is dictated by the stability of

perforation tunnels. Prior to perforating for sand prevention it

is necessary to determine whether the tunnels would be stable

over the producing life of the well.

Perforation Tunnel Stability Determination

For successful sand prevention, a good understanding of the

stability of the tunnels over the producing life of the well is

needed before completion. Three different approaches are

used by the industry to accomplish this.

A. VENKITARAMAN, L.A. BEHRMANN, A. H. NOORDERMEER

Theoretical Models: The models originally developed for

borehole stability are extended to perforations. Three steps are

used, determination of rock mechanical properties (using log

data, core samples), determination of in-situ stress conditions,

and determination of failure (conditions) using a particular

model3 . Theoretical models are effective in predicting

perforation stability with change in stress conditions

(drawdown and depletion). Two distinct approaches have been

developed: the tensile failure model and the shear failure

model.

According to the tensile failure criterion the fluid flow into

a cavity at high production rates will induce a tensile stress

near the cavity resulting in formation failure (sand grains

being pulled away from the tunnel) and subsequent sand

production4 . This model is seldom used as numerical studies

and experiments indicated that this criterion predicts

unrealistically high production rates to initiate sand production

in weak but consolidated sandstone. Also, some sand

production experiments showed stress-induced shear failure to

precede sand production5 . Shear failure models can be

classified according to the assumed material behavior: linear

elastic/brittle, elasto-plastic. The models can also be classified

according to the assumed geometry (simple 1D to 3D). The

material property requirements and the complexity increase in

the more sophisticated geometry and material behavior

conditions. Mohr-Coulomb criterion is most widely used for

shear failure assessment.

Experimental Methods: Experimental methods involve

testing of available reservoir core samples or outcrop rock

samples (with similar mechanical properties). There are two

different types of test: drilled hole tests and single-shot

perforation and flow tests.

In a typical drilled hole test, a cylindrical cavity of uniform

diameter is drilled in a core sample. The drilled sample is then

placed inside a rubber sleeve and isotropic confining pressure

is applied on the outside of the core 6 . The stress on the sample

is increased until the yield point is reached. According to

elastic theory when the circumferential stress on the inner wall

of the hole reaches the (apparent) strength of the material the

hole will fail. The main drawback is that the sample size/hole

size ratio of the hollow cylinder can influence the result

obtained7 .

Though not widely used, available core sample from the

well is perforated and flowed at different rate, depletion and

water-cut conditions8 . The test parameters can be chosen

based on the expected conditions during the producing life of

the well. This method can be used to augment analyses from

theoretical models and to check for sand production during

water-cut. The tests can also help determine (the stability of

perforation tunnel or) sand production at the time of

underbalance perforating. The drawbacks to this method are

the discrete nature of data (core sample from specific depths)

and availability of samples.

Historical: Historical sand production prediction criteria rely

on production experiences (rate, drawdown, percentage watercut) on other wells in the same reservoir to arrive at a choice

between sand control and sand prevention. In some cases

SPE 58788

reservoir strength data is used as the yardstick to compare and

predict potential for sanding across different reservoirs. This is

by far the most widely used technique. The best use of this

approach utilizes available data to calibrate theoretical models

for future sand production prediction.

Perforating for Stability

Charge Type, Shot density and Phasing: For maximum

single perforation stability use deep penetrating charges.

Smaller holes (deep penetrating charge) are more stable than

larger holes (big hole charge). In addition to single perforation

stability one has to consider inter-linking of failed zones

around adjacent perforation tunnels. This can lead to collapse

of structure inducing massive sand production. Besides the

stability of individual perforation tunnels this is dictated by the

perforation spacing in the wellbore. The perforation spacing is

dictated by the shot density and phasing. Though the shot

density can be decreased to increase perforation spacing this

will have the undesirable effect of increasing the flow rate per

perforation (which can enhance transport of any failed

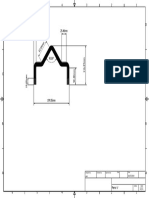

material leading to sand production). Optimum phasing using

SandFreeX guns will allow the maximization of perforation

spacing for a given wellbore radius and shot density. Figure 1

demonstrates the principle behind optimum phasing (not

drawn to scale), showing a gun with charges at 60 degree

phasing, and the perforations in the formation sandface (in

two-dimensional form, with the corresponding angles marked

in the bottom). The idea behind optimum phasing is to

maximize the perforation-to-perforation spacing for a given

shot density to preserve as much as possible, the intervening

formation material. In the figure the three distances between

adjacent perforations are marked L1 , L2 , and L3 . By adjusting

the phasing for a given wellbore radius (R) and shot density,

the distances can be optimized (with the ideal of obtaining L1 =

L2 =L3 ) to avoid interaction between adjacent perforations.

Figure 2 shows optimum phasing (or optimum perforation

spacing) calculation for different total wellbore radius

(wellbore radius multiplied by shot density). In reality, it is not

possible to have L1 =L2 =L3 for a spiral phased gun. The

optimum solution (maximum perforation-to-perforation

spacing for a given shot density) occurs when any two of the

above perforation spacings are equal. The example shown in

Figure 1 show the critical perforation spacings between the

first two spiral wraps. For R*spf > 42, an additional

perforation spacing, L4 , between the first and third wrap must

be considered and will control the minimum perforation

spacing. Simple algebraic equations are used to calculate these

perforation-to-perforation spacings. The discontinuities in

Figure 2 are a result of different pairs of Ls being equal. For

simplicity, the wellbore radius (R) is used in Figure 2;

however this is only true for a centralized gun. The exact

definition of R is the distance from the perforator jet virtual

origin (a mathematical term for the location within the

perforator where the jet is assumed to originate) to the

sandface. For practical purposes, the distance from the center

X

Mark of Schlumberger

SPE 58788

PERFORATING REQUIREMENTS FOR SAND PREVENTION

of the perforating gun to the sand face can be used to define

the distance (R). For an eccentered or a non-oriented gun, the

minimum distance from the center of the gun to the sandface

will determine the optimum phasing. Thus, the minimum

perforation-to-perforation spacing will be on the low side of

the well.

The increase in perforation-to-perforation spacing for an

optimum phased gun can be substantial when compared with

the standard phased guns. For example, for R*spf=25.5, the

minimum perforation spacing increased from 4.88 inches to

7.61 inches, a 56% increase by changing the phasing from 60

degrees to 99 degrees.

Field Data (Magnus): Evidence of the effectiveness of

optimum phased perforations in minimizing sand production

comes from field data evaluation of BP Magnus in the North

Sea. The Magnus reservoir (age: Upper Jurassic) is split up in

two main selections: Magnus main sand MSM (top sands) and

LKCF (lower sands). There is communication between the

layers but only in some parts of the reservoir. MSM, Magnus

main sand is high permeability (500 md), high porosity, thick

sands with high net to gross ratio whereas LKCF is medium

permeability (200 md), medium porosity, thin sands with low

net to gross ratio. Initially the reservoir pressure was 6653 psi

at 240F (3050m TVD) but this dropped quickly to 3000 psi

due to insufficient water injection in some parts of the

reservoir. Increased and more efficient water injection

reversed this process and the reservoir pressure is back up

(MSM 3000 to 6000 psi & LKCF 3000 to 4000 psi). The oil is

39 API with 0.30 cp viscosity at reservoir conditions and total

production of 90,000 reservoir barrels a day. Watercut varies

from 0 to 95 %. The wells are completed with 5-inch tubing

with 5-inch or 7-inch liner. Most wells are completed with

gaslift. Typical well depths are 4000 to 5000m MD (2900 to

3300m TVD) with deviations from 40 to 60 degrees.

The original perforating strategy used 3 3/8 inch guns at 60

degree phasing (6 spf). This was later changed during 1997 to

99 degree phasing (optimum phasing) while keeping the same

shot density. Comparison of wells perforated with the two

different phasings showed a decline in sand production

evidenced by the decrease in problems associated with sand

production.

Theoretical Validation: A 2-D plane strain model of the two

different perforating strategies was used to simulate

perforation tunnel failure due to increasing effective stress.

For comparative purpose normalized values of effective stress

were used in both cases assuming elasto-plastic behavior of

the rock material. For increasing effective stress (depletion or

drawdown) it can be seen that the inter-linking of failed zones

around adjacent perforation tunnels happen at a 33% lower

effective stress for the 60 degree phased perforation tunnels

than the 99 degree phased perforation tunnels (Figure 3).

Oriented Perforating

In regions where there is a large contrast between the vertical,

maximum and minimum horizontal stresses, perforations

should be oriented in the direction of maximum stability9 . In

these cases, if the rates per perforation are not too high, 0/180

degree phased perforating guns can be used. If the rate per

perforation is a concern: For vertical wells, shoot in direction

of maximum perforation tunnel stability at a +/- angle of phi

(see Figure 4) and for horizontal wells shoot up/down at a +/angle of phi. Phi is dependent on the in situ stresses and will

typically be between 15 and 25 degrees. Phi can also be

optimized using plain strain simulation mentioned in the

previous section if in-situ stress conditions and reservoir

properties are known.

The concept of optimum phasing for an oriented gun

(using SandFreeX guns) is similar to that of a continuous

phased non-oriented gun: to have a maximum shot density for

a given perforation-to-perforation spacing. The current

practice is to use 0/180 degree phased guns shot in the

direction of maximum perforation stability. As an example,

assume a minimum perforation-to-perforation spacing of 4

inches is required. This allows only 6 spf for a 0/180 degree

phased gun. Because sand production requires both loose sand

(failed perforation tunnel) and sufficient flow velocity to

transport the sand, one would like to increase the shot density

to minimize the transport of any failed sand. Since the

perforation stability changes slowly with modest angular

misalignment between the preferred and proposed perforation

orientation, a substantial increase in shot density is possible by

shooting an angle of +/- phi to the preferred direction. Using

the above example, for a wellbore radius of 4.25 inches,

shooting at +/- 22.5 degrees from the preferred direction gives

an 81% increase in shot density from 6 to 10.9. In this

example, each shot is in a different axial plane.

For larger wellbores, the minimum perforation-toperforation spacing changes from adjacent perforations

separated by an angle of 2*phi to adjacent perforations at the

same azimuth. In this configuration, there are two shots per

axial plane and the maximum shot density is 48/L, where L is

the minimum perforation-to-perforation spacing.

Evidence of the effectiveness of oriented perforating for

sand prevention comes from two earlier published

applications. The technique of optimal phased oriented

perforating was applied to the Eocene C reservoir in Lake

Maracaibo, Venezuela 10 . Another case is the Andrew field in

the North Sea where the perforations were oriented at an angle

+/- 25 degrees in the topside in horizontal wells 11 . In both

cases the perforating strategy used deep penetrating charges.

Other Considerations

Underbalance Perforating: One of the main reasons for

perforating underbalance is to reduce the extent of

permeability damage in the crushed zone (extent of damaged

zone around the perforation tunnel walls). If this material is

not removed at the time of perforation, it will result in a larger

pressure drop at the perforations that can contribute to tensile

failure 12 . This may or may not constitute a sand production

problem (depending on whether the failure occurs

immediately or at later stages when the drawdown is

increased, or reservoir depletes, or during water-cut and also

depending on whether this material is transported). Perforating

at underbalance allows us to produce the sand during the

A. VENKITARAMAN, L.A. BEHRMANN, A. H. NOORDERMEER

initial stages and thus avoid having to manage transient sand

production during later stages of well production13 . The

underbalance value must be chosen to avoid catastrophic

failure of the formation (sanding in the guns) at the time of

perforation. The limit on the underbalance can be chosen

based on values obtained from perforation stability model

(keeping the underbalance value below the critical drawdown

value). Single-shot perforation and flow experiments can be

used to confirm the underbalance value chosen.

Selective Perforating: In formations where the strength varies

drastically with depth, by avoiding perforating in sections that

are weaker, one can maintain sand-free production throughout

the reservoir life 11 . Both productivity analysis using nodal

analysis programs (to study the impact of partial penetration

on productivity) and strength analysis (using methods

mentioned in previous section) need to be carried out prior to

making this choice.

Summary

1. Use deep penetrating charges to minimize perforation

damage, for tunnel stability through depletion and

drawdown, and to have good perforation spacing.

2. Use optimum phasing to minimize inter-linking of failed

zones around adjacent perforations (minimize risk of

collapse

of

structure)

without

compromising

rate/perforation.

3. Use maximum shot density to keep rate/perforation below

a critical value to minimize transport of sand.

4. Perforate at optimum underbalance to minimize

perforation damage. Keep underbalance below a critical

value to minimize perforation failure at the time of

perforation.

5. Orient perforations for maximum perforation stability in

cases where there is a large stress contrast.

6. Manage initial transient sand production.

7. Core Studies will help obtain maximum drawdown/rate to

prevent sand production through failure/transport and also

know the impact of water-cut.

Nomenclature

spf =Shots per foot (shot density)

MD =Measured Depth

TVD =True Vertical Depth

R = Radius of Wellbore (Sandface), inches

L =Minimum Perforation Spacing, inches

Acknowledgements

The authors thank the BP-Amoco and Schlumberger Reservoir

Completions organizations for permission to publish the

paper.

References

1. Blok,

R.H.J.,

Welling,

R.W.F.,

Behrmann,

L.A.,

Venkitaraman.A.: "Experimental Investigation on the Influence

of Perforation Induced Gravel-Pack Impairment", SPE 36481,

SPE 58788

presented at the 1997 SPE Annual Technical Conference and

Exhibition, Denver, Colorado, Oct 6-9.

2. Kooijman, A.P., van Den Hoek, P.J., Ph. de Bree, Kenter, C.J.,

Zheng, Z., Khodaverdian, M.: Horizontal Wellbore Stability

and Sand Production in Weakly Consolidated Sandstones, SPE

36419, presented at the 1997 SPE Annual Technical Conference

and Exhibition, Denver, Colorado, Oct 6-9.

3. Bruce, S.: "A Mechanical Stability Log", SPE 19942, presented at

the 1990 IADC/SPE Conference, Houston, Texas, Feb 27 - Mar

2.

4. Weingarten, J., Perkins, T.: "Prediction of Sand Production in Gas

Wells: Methods and Gulf of Mexico Case Studies", SPE 24797,

presented at the 1992 SPE Annual Technical Conference and

Exhibition, Washington DC, Oct 4-7.

5. Behrmann, L.A., Willson, S.M., Ph. De Bree, Presles, C.: "Field

Implications from Full Scale Sand Production Experiments",

SPE 38639, presented at the 1997 SPE Annual Technical

Conference and Exhibition, San Antonio, Texas, Oct 5-8.

6. Presles, C., Cruesot, M.: "A sand Failure Test can cut both

Completions Costs and the Number of Development Wells,

SPE 38186, presented at the 1997 SPE European Formation

Damage Conference, The Hague, The Netherlands, Jun 2-3.

7. Papamichos, E., van Den Hoek, P.: "Size dependency of

Castlegate and Berea Sandstone Hollow Cylinder Strength on

the Basis of Bifurcation Theory", Proceedings, 35th US

Symposium on Rock Mechanics (1995).

8. Venkitaraman, A., Li, H., Leonard, A.J., Bowden, P.R.:

"Experimental Investigation of Sanding Propensity for the

Andrew Completion", SPE 50387, presented at the 1998 SPE

International Conference on Horizontal Well Technology,

Calgary, Alberta, Canada, Nov 1-4.

9. Santarelli, F.J., Ouadfel, H., Zundel, J.P.: "Optimizing the

Completion Procedure To Minimize Sand Production Risk",

SPE 22797, presented at the 1991 SPE Annual Technical

Conference and Exhibition, Oct 6-9.

10. Sulbarban, A.L., Carbonell, R.S., Lopez-de-Cardenas, J.E.:

"Oriented Perforating for Sand Prevention", SPE 57954,

presented at the 1999 SPE European Formation Damage

Conference, The Hague, The Netherlands, May 31 - Jun 1.

11. Mason, J.N.E., Gomersall, S.D.: Andrew/Cyrus Horizontal Well

Completions, SPE 38183, presented at the 1997 SPE European

Formation Damage Conference, The Hague, The Netherlands,

Jun 2-3.

12. Morita, N., Burton, R.C., Davis, E.: "Fracturing, Frac Packing,

and Formation Failure Control: Can Screenless Completions

Prevent Sand Production?", SPE 51187, SPE Drilling &

Completion, Sep 1998, pp 157-162.

13. Behrmann, L.A., Li, J., Venkitaraman, A., Li, H.: "Borehole

Dynamics During Underbalanced Perforating", SPE 38139,

presented at the 1997 SPE European Formation Damage

Conference, The Hague, The Netherlands, Jun 2-3.

SI Metric Conversion Factors

in. 2.54*

E+00 = cm

psi 6.894757

E+00 = kPa

md 9.869233

E-12 = cm2

* Conversion factor is exact

SPE 58788

PERFORATING REQUIREMENTS FOR SAND PREVENTION

L1

60

120

180

240

300

360

Figure 1 Perforations at the wellbore sandface are shown in 2-D

geometry along with the critical distances between adjacent

perforations

200

4.5

Phase Angle

180

4.0

Perf-spacing/Distance

3.5

160

3.0

Figure 3 Results of 2-D plane strain elasto-plastic simulation of

inter-linking between failed zones around adjacent perforations

(60 degree phasing and 99 degree phasing). The effective stress

is increased (depletion) as one moves down the column. The left

hand column shows the 60 degree phased adjacent perforations

and the right hand column shows the 99 degree phased

perforations. For similar inter-linking to occur for 99 degree

phased perforations the effective stress would have to be a factor

of 1.3 times the stress at which inter-linking occurred for the 60

degree phased perforations

2.5

140

2.0

120

2 phi

1.5

1.0

100

0.5

80

0

30

60

90

120

0.0

150

Distance * SPF

Figure 2 Optimum phasing for a given wellbore radius at the

sandface and shot density (Distance = R, the wellbore radius at

sandface)

60

120

180

240

300

Figure 4 Oriented perforating shown in 2-D

360

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Music: Teachers ManualДокумент208 страницMusic: Teachers Manualmydrina100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Micr Code Meaning of ChequeДокумент3 страницыMicr Code Meaning of Chequeमन्नू लाइसेंसीОценок пока нет

- Piping Presentation - PpsДокумент61 страницаPiping Presentation - PpsVijayabaraniОценок пока нет

- General Systems Theory A Mathematical ApproachДокумент385 страницGeneral Systems Theory A Mathematical Approachselotejp7100% (4)

- Cert Piping W54.5Документ2 страницыCert Piping W54.5SANU0% (1)

- Spe 146968 MSДокумент12 страницSpe 146968 MSJosé TimanáОценок пока нет

- Fatigue of MaterialsДокумент54 страницыFatigue of Materialsc_gaspard0% (1)

- 6-Heat Transfer in Multi Phase Materials PDFДокумент460 страниц6-Heat Transfer in Multi Phase Materials PDFJoselinaSosaZavalaОценок пока нет

- PygmyManual v2 - 31Документ67 страницPygmyManual v2 - 31myplaxisОценок пока нет

- Celda Carga - KIS-2BA - 5KNДокумент4 страницыCelda Carga - KIS-2BA - 5KNJosé TimanáОценок пока нет

- Perno VДокумент1 страницаPerno VJosé TimanáОценок пока нет

- XK3118T4F Technical ManualДокумент4 страницыXK3118T4F Technical ManualJosé TimanáОценок пока нет

- Approvals: Weigh Module Available Paramounts HE Paramounts HSДокумент1 страницаApprovals: Weigh Module Available Paramounts HE Paramounts HSJosé TimanáОценок пока нет

- 2019 Iqube2 Junction BoxДокумент3 страницы2019 Iqube2 Junction BoxJosé TimanáОценок пока нет

- sb14 Beam Datasheet en PDFДокумент3 страницыsb14 Beam Datasheet en PDFJosé TimanáОценок пока нет

- RuedaCocheMinero (AI2018)Документ1 страницаRuedaCocheMinero (AI2018)José TimanáОценок пока нет

- Aluminum Liquidtight ST Series Connectors With Plain ThroatДокумент1 страницаAluminum Liquidtight ST Series Connectors With Plain ThroatJosé TimanáОценок пока нет

- Hoja de Datos 14092018v2Документ1 страницаHoja de Datos 14092018v2José TimanáОценок пока нет

- Cable Glands Cross ReferenceДокумент8 страницCable Glands Cross ReferenceUrip S. Setyadji100% (1)

- ARDYДокумент4 страницыARDYJosé TimanáОценок пока нет

- Spe52170-Dynamic Nodal AnalysisДокумент9 страницSpe52170-Dynamic Nodal AnalysisJosé TimanáОценок пока нет

- Spe 123561 MSДокумент10 страницSpe 123561 MSJosé TimanáОценок пока нет

- Payi : at 1971 American Institute of Mining, Metallurgical, and Petroleum Engineers, IncДокумент12 страницPayi : at 1971 American Institute of Mining, Metallurgical, and Petroleum Engineers, IncJosé TimanáОценок пока нет

- Fluids and Proppants Selection Qa&Qc in Hydraulic FracturingДокумент41 страницаFluids and Proppants Selection Qa&Qc in Hydraulic FracturingJosé TimanáОценок пока нет

- Ardy PDFДокумент4 страницыArdy PDFJosé TimanáОценок пока нет

- Spe 30342 PaДокумент3 страницыSpe 30342 PaJosé TimanáОценок пока нет

- G Function Spe 60291Документ9 страницG Function Spe 60291José TimanáОценок пока нет

- PCP DefinitionsДокумент2 страницыPCP DefinitionsJosé TimanáОценок пока нет

- Qu e Puedes Hacer para No Sentirte Tan Solo: Determina Cu AL Es El ProblemaДокумент2 страницыQu e Puedes Hacer para No Sentirte Tan Solo: Determina Cu AL Es El ProblemaJosé TimanáОценок пока нет

- Searox SL 480: Marine Slab 200Документ1 страницаSearox SL 480: Marine Slab 200sivlag01Оценок пока нет

- Laboratory Investigations On The Causes of Road Failures Constructed AlongДокумент8 страницLaboratory Investigations On The Causes of Road Failures Constructed AlongMulugeta DessieОценок пока нет

- CLT2Документ13 страницCLT2Yagnik KalariyaОценок пока нет

- Data Model and ER Diagram QuestionsДокумент2 страницыData Model and ER Diagram QuestionsMoses MushinkaОценок пока нет

- Coal Lab Assignment 2 - v5 - f2019266302Документ12 страницCoal Lab Assignment 2 - v5 - f2019266302Talha ChoudaryОценок пока нет

- Week 1Документ3 страницыWeek 1DELMAR REYES100% (1)

- Section 5 Section 5: Weight and Balance Weight and BalanceДокумент36 страницSection 5 Section 5: Weight and Balance Weight and Balanceandres felipe sandoval porrasОценок пока нет

- Datasheet Solis 110K 5GДокумент2 страницыDatasheet Solis 110K 5GAneeq TahirОценок пока нет

- HBC 2109 Hps 2106 (Kisii)Документ3 страницыHBC 2109 Hps 2106 (Kisii)123 321Оценок пока нет

- A Tale of Two Cultures: Contrasting Quantitative and Qualitative Research - Mahoney e GoertzДокумент24 страницыA Tale of Two Cultures: Contrasting Quantitative and Qualitative Research - Mahoney e Goertzandre_eiras2057Оценок пока нет

- Keysight N5193A Online Documentation - PDW DefinitionsДокумент3 страницыKeysight N5193A Online Documentation - PDW Definitionssandeep yadavОценок пока нет

- Solution To Q9 (Vii) Tut-Sheet 3 (By Professor Santanu Dey)Документ1 страницаSolution To Q9 (Vii) Tut-Sheet 3 (By Professor Santanu Dey)Prayas JainОценок пока нет

- Chapter 70 Multi Mooring Systems 2010Документ135 страницChapter 70 Multi Mooring Systems 2010Araby Gamal GamalОценок пока нет

- AR-725 (E-V2-M) : Access Control SystemДокумент8 страницAR-725 (E-V2-M) : Access Control SystemIrvan SeptianОценок пока нет

- Current Calculator For Barrel Plating - Chlorize Zinc PlatingДокумент4 страницыCurrent Calculator For Barrel Plating - Chlorize Zinc PlatingARVINDA KUMARОценок пока нет

- Geehy 32 Bit ARM Cortex MCU - 2023 07 13 090801Документ4 страницыGeehy 32 Bit ARM Cortex MCU - 2023 07 13 090801palurdo2Оценок пока нет

- Quarter I Subject: GENERAL Mathematics Date: - Content Standard Performance Standard Learning Competency M11GM-Ia-4Документ4 страницыQuarter I Subject: GENERAL Mathematics Date: - Content Standard Performance Standard Learning Competency M11GM-Ia-4PatzAlzateParaguyaОценок пока нет

- Beam Number: Project Name: 17-Mar-20 Engr. Mark Christian D. Esguerra Passed Engineer: DateДокумент1 страницаBeam Number: Project Name: 17-Mar-20 Engr. Mark Christian D. Esguerra Passed Engineer: DateMark Christian EsguerraОценок пока нет

- Synchronous MachinesДокумент10 страницSynchronous MachinesarnabОценок пока нет

- Physics Midterm Review PacketДокумент6 страницPhysics Midterm Review PacketJasper SendraОценок пока нет

- E 1354 - 02 - Rtezntqtmdm - PDFДокумент18 страницE 1354 - 02 - Rtezntqtmdm - PDFdelta lab sangliОценок пока нет

- Cuda GDBДокумент64 страницыCuda GDBVinícius LisboaОценок пока нет