Академический Документы

Профессиональный Документы

Культура Документы

Roman Concrete in Gaul

Загружено:

El Lobo RodrigoАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Roman Concrete in Gaul

Загружено:

El Lobo RodrigoАвторское право:

Доступные форматы

Comm. Hum. Litt. Vol.

128

139

The selection and use of lime mortars on

the building sites of Roman Gaul

Arnaud Coutelas

1. Introduction

It was Michel Frizot who undertook the first archaeological and technical studies of GalloRoman mortars in France. His research in the seventies focused on a large number of sites

in Burgundy.1 His analytical protocol was based on the use of acid on the samples, with

chemical analysis of the dissolved phase and in particular granulometric analyses of the

residue. In spite of his remarkable work, it was not until the end of the eighties that the

importance of lime mortar study became apparent, primarily in relation to medieval and

modern building archaeology.2 Several works on medieval mortars then followed.3

Our work on ancient lime mortars began approximately ten years ago. It was based on

identifying the composition of materials, and researching the geological origins of raw

materials. This is why this study is based on a petroarchaeological approach, that is to

say the data are obtained after analysis of materials in petrology (under a microscope).

The results make it possible to establish a typology of the mortars, which is then linked

with the chronology of a buildings construction phases, in order to see more clearly the

evolution of a particular building.

Currently this research relates mainly to the identification of the technical legacy and

expertise of Gallo-Roman masons and stucco workers; in particular it tries to establish

which parameters will influence the final choice of mortar formula. Up to the time of

writing, more than forty Gallo-Roman buildings have been studied.4

1 M. Frizot, Mortiers et enduits peints antiques, tude technique et archologique (Centre de

recherches sur les techniques grco-romaines 4), Dijon 1975.

2 Ch. Sapin, Enduits et mortiers. Archologie mdivale et moderne (Dossier de documentation

archologique 15), Paris 1991.

3 B. Palazzo-Bertholon, Lapport des analyses chimiques ltude des enduits peints:

lexemple des peintures murales gallo-romaines du boulevard Vaulabelle Auxerre, in Cl. Allag

(ed.), Peinture antique en Bourgogne (Revue Archologique de lEst, 21e supplment), Dijon

2003, 31-42. And more recently: S. Bttner, Ltude ptrographique des mortiers de gros uvre

de labbaye Saint-Germain dAuxerre (Yonne). Apports la comprhension stratigraphiques des

structures bties, Revue dArchomtrie 28 (2004) 117-25.

4 A. Coutelas, Ptroarchologie du mortier de chaux gallo-romain, essai de reconstitution et

dinterprtation des chanes opratoires: du matriau au mtier antique (Ph.D thesis), Universit

Paris I Panthon-Sorbonne 2003, http://tel.archives-ouvertes.fr/tel-00528508/. Moreover: A.

Coutelas, Les mortiers de chaux du sanctuaire de Ribemont-sur-Ancre (Somme), Revue

Archologique de Picardie 3:4 (2003) 77-89; A. Coutelas, Les mortiers de chaux gallo-romains en

Bourgogne, Revue Archologique de lEst 54 (2005) [2006] 327-35; A. Coutelas M. Heijmans,

Les mortiers de construction de la ville dArles (Bouches-du-Rhne) au Haut Empire, Revue

Archologique de Narbonnaise 38-39 (2005-2006) 401-408.

140

Coutelas

2. Analysis

For the study of these archaeological materials, the choice of analytical methodology owes

a lot to the authors experience in the field of Earth Sciences. Considering the mortars

as reconstituted rocks, whose natural analogues would be sandstones with carbonated

cement, we chose to employ the analysis methods common in geology, i.e. the petrography

of sedimentary rocks.

Among these methods, one can mention the observation of rough samples with a

magnifying glass, the observation of thin sections under a petrological microscope, and

the examination by scanning electron microscopy (SEM) of thin sections or small rough

fragments.

The advantages of this method lie in the fact that the observations offer a large

number of criteria and data that are directly accessible to the analyst, and subject to his

assessment. The plurality of optical analysis methods is a major asset, which makes it

possible to analyse material on all scales.

In addition to aggregate identification, these observations make it possible to note the

texture and internal structure of mortars, as well as their stratigraphy (for coatings). A lot

of data can be obtained for the aggregate through the study of its appearance, which is

important: this is the case for clay (especially illuviation clay brought with grains of sand,

indicating the exploitation of precise geological locations), and also for the identification

of badly burnt limestone fragments and for fragments of other mortars present as salvaged

material or residues from the mixing process.

Moreover, the combination of these observations with physicochemical analysis

techniques is one possibility frequently used to identify non-observable phases and to

check and validate the observations. The principal techniques are:

Granulometry, for siliceous aggregate, after dissolution of the binder.

X ray diffraction, to identify mineralized compounds in a few milligrams of

powder (useful for clay).

Cathodoluminescence and electronic microscopy, very useful for the

identification, analysis and cartography of neoformation and hydraulic

compounds.

Mass spectrometry.

Multispectral micro-image processing.5

3. An example of a petroarchaeological study: the GalloRoman baths of Le Vieil-Evreux (Eure, France)

Let us consider the case of a complete petroarchaeological study of a Gallo-Roman

building, the baths of Le Vieil-Evreux, in Normandy, excavated between 1996 and 2002

5 A. Coutelas G. Godard Ph. Blanc A. Person, Les mortiers hydrauliques: synthse

bibliographique et premiers rsultats sur des mortiers de Gaule romaine, Revue dArchomtrie 28

(2004) 127-39.

Comm. Hum. Litt. Vol. 128

141

by Laurent Guyard.6 It is a crucial study because this site has the double advantage of

showing many accurately dated construction phases and of having benefited from a very

complete analysis of its masonry mortars (more than two hundred samples were taken).7

3.1 The geological origin of raw materials

Le Vieil-Evreux is located on a chalky plateau covered with a kind of loess (argillaceous

and silty surface formation). In the east and the north-east can be seen the current limits

of erosion of tertiary limestones and sand formations (Lutetian limestone and Sables de

Lozre). This plateau is framed by two rivers; the River Eure in the east and the River

Iton in the west.

It is known that identifying the limestone used to produce lime is very difficult.

Fortunately, many signs of lime manufacture were located in the construction layers,

and in masonry mortars: lime nodules (white lumps), particles of lime which had been

overburned, underburnt limestone, vitrified slag and pieces of lime kiln walls.

The observation of underburnt limestone can help us to identify the stone used

to produce lime. Here, in fact, at least two sources can be noted: chalk, as expected,

sourced two kilometres from the building site, but also Lutetian limestone, sourced

seven kilometres away. It is important to point out that Lutetian limestone is the only

one used for construction, in the opus reticulatum. Perhaps the same quarry was worked

simultaneously for the stone and the lime.

Thanks to petrography, a large number

of clues to the origin of sand could also be

obtained. In the masonry mortars of the baths,

the aggregate is mainly rounded quartz,

with some flints, and there are many clay

illuviation coatings, which had coloured the

mortars. Moreover there are nodules (ochre

nodules) which give us a perfect picture

of the composition of the sand formation

worked (Fig. 1).

By considering the whole, it became

apparent that the sand formation worked

was the Sables de Lozre, but in its

Figure 1. Ochre nodule (sand and illuviation

altered version, rich in illuviation clay. This clay) in a lime mortar. Diameter: 1 mm.

geological formation is, in fact, present on Transmission Optical Microscopy, plane

polarized light. (A. Coutelas)

the whole of the plateau, at one or two meters

depth, under the loess. Thus, in spite of its

6 L. Guyard S. Bertaudire, Les thermes de la ville sanctuaire du Vieil-Evreux, Les Dossiers

dArchologie 323 (2007) 52-59.

7 A. Coutelas L. Guyard Ch. David, Ptroarchologie de mortiers gallo-romains.

Application de mthodes analytiques ltude des thermes du Vieil-Evreux (Eure), Les nouvelles

de larchologie 81 (2000) 31-36.

142

Coutelas

high clay content, this formation was systematically worked during the Roman period for

the construction of the public buildings of Le Vieil-Evreux; undoubtedly because this sand

formation was the most abundant and the easiest to extract.

3.2 Typology

The typology of the mortars consists in the classification of the samples according to the

study of their characteristic features. It is in a way the final aim of the petrographic analyses,

and the basis of the archaeological study of these architectural binders. The cartography of

the types of masonry mortar used enables us to reveal the various construction phases of a

building. The baths of Le Vieil-Evreux, built in four periods between the beginning of the

second century AD and the end of the third century AD, perfectly illustrate this process.

For the first construction phase, in the first half of the second century, a beige mortar

called mortar number 1 (Mo1) is used for the foundations of the central baths only. After

a first halt in the construction process, a more coloured mortar (Mo2) is used for the

foundations of the palaestra, and for the last three courses of the baths foundations (Fig.

2). It ends this first great stage of building on the site, but the initial architectural project

was not completely finished.

The architectural programme was completed towards the end of the second century. At

that time, the Roman monument consists of a central building, made up of a double set

of rooms placed on both sides of a central praefurnium. At the ends, two frigidaria with

pools are preceded by an apodyterium communicating with the palaestra and the south

yard.

A third mortar (Mo3), slightly pink orange, is seen in the first elevation courses of the

baths. After another halt in construction, mortar number 4 (Mo4), pink orange, is used to

complete construction of the baths and the palaestra, and then the south yard. Thus we see

that this mortar is the principal construction material for the building.

At the beginning of the third century, the initial frigidaria are transformed into caldaria.

New frigidaria have taken the place of the initial apodyteria. Cold pools are built with a

masonry mortar rich in brick powder (Mo6). Mortar number 5 (Mo5), dark orange, is used

for the addition of new apodyteria, circular changing rooms.

Several years later, in the middle of the third century, yellow mortars are used for a new

extension, the addition of shops along the palaestra. Mortar Mo7 is only used for a few

walls, with mortar Mo8 used for the major but unfinished phase of the extension.

These construction phases are now well recognised and dated. Thus, it appears that

each type of masonry mortar can be dated with a great deal of precision. In concrete terms

this means that, in these baths, any new wall discovered with one of these types of mortar

can be dated with an accuracy of twenty-five years.

This large number of mortars probably indicates the scale of the building site. This is

revealed by the mortar study due to the heterogeneity of the excavated sand formation,

which involves variations in the material aspect, and to the obvious breaks in construction

on the building site. The latter could be regarded as just seasonal pauses, but current

research, linking the analysis of construction terra cotta and masonry mortars, tends to

Comm. Hum. Litt. Vol. 128

143

Figure 2. Baths of Le Vieil-Evreux (according to Mission Archologique Dpartementale de lEure)

with surface cartography of the various types of masonry mortars. (Final CAD: A. Coutelas)

show that the reasons for these pauses are more complex. They would be linked, at least at

the start of construction (the transition between Mo1 and Mo2), to the end of a financing

cycle and/or the end of a supply of building and other raw materials cycle.

This petroarcheologic approach to the study of lime mortars has been employed many

times for the buildings of Roman Gaul. It was also tested on ancient sites in Roman

provinces, such as buildings of the Italic peninsula. One can cite, for example, the shop

frontages in the Casa del Salone Nero, in Herculaneum, the study results of which are of

real historical significance.

Indeed a type of mortar named MS4 was used to block up three doorways, allowing

passage between the shops and the domus. This discovery of the use of a single mortar

144

Coutelas

made it possible to counterbalance the untidy appearance of the facings. This similarity

of treatment thus allows us to conclude that the occupant of the house ceased to directly

manage the shops located in the frontage, probably about 75 AD.8

4. Lime mortar in the history of construction techniques

The study of lime mortars makes it possible to look at the craft and skills of masons in

ancient times. To do this, we must consider that the composition of mortar results from

both the choice of raw materials and the recipe (or formula). The nature of these choices

gives us information about:

Traditions: i.e. the relationship between mortar function and its composition.

Expertise (savoir-faire): the result, in particular, of practical experience, it

permits adaptations and flexibility of the operational sequence and allows for

modifications and innovations.

External constraints: these constraints are essentially socio-economic or

related to the geological environment.

In order to examine all these parameters, we will now examine the traditional craft of the

Gallo-Roman mason. In particular, we will focus on the known relationship between the

function and composition of lime mortar.

4.1 Masonry mortars

The first and principal function of a lime

mortar is its use as masonry mortar.

In Roman Gaul, as elsewhere in the

Roman Empire, it is masonry with opus

caementicium which predominates when

walls are very thick. In addition, the

mortar from caementicium is usually the

same as that used for the facings. The

mortar is made with lime and siliceous

or calcareous sand. Examples of masonry

mortar containing broken tile and brick

are known, but are essentially used for the

walls of a few small hydraulic structures

such as pools.

Figure 3. Masonry mortar from the aqueduct of

Le Vieil-Evreux (Eure, France). See the ochres

nodules dispersed in the matrix. (A. Coutelas)

8 N. Monteix M. Pernot A. Coutelas, La metallurgia del piombo fra archeometria ed

approcci classici, in P.G. Guzzo M.P. Guidobaldi (ed.), Nuove ricerche archeologiche nellarea

vesuviana (scavi 2003-2006) (Studi della Soprintendenza Archeologica di Pompei 25), Roma 2008,

439-47.

Comm. Hum. Litt. Vol. 128

145

It is important to note the extent to which economic and environmental contexts influence

the choice of raw materials for these construction mortars. By way of illustration, we

may recall the case of Le Vieil-Evreux. Just as with the walls of the baths, the aqueduct

masonries present very coloured, orange mortars, rich in ochre nodules (Fig. 3). These

nodules are evidence of the working and use of very argillaceous sand. In spite of this

presence of clay, and in contradiction with the writings of Vitruvius, which require a sand

which does not leave stains or any particles of earth on a white garment (De Architectura

2.4), the builders decided to use this sand formation. This could be explained partly by the

fact that the mortar obtained is of a sufficiently good quality but also by the fact that this

sand formation is the most abundant and the easiest to extract, in a word the best choice

from an economic point of view.

It appears, therefore, that for Gallo-Roman buildings, masonry mortars were often

prepared with low quality raw materials, because accessibility and the volume of resources

were the most important factors in the choice of the extraction site.

4.2 Refilled joints

Refilled or pointed joints are those where mortar fills gaps between the building stones of

the facing (Fig. 4).9 Their composition is always different from masonry mortars. They are

white, dense, and often seem like scored joints or tooled joints. Thus, occasionally they

are confused with fragments of stucco when these elements are found during excavation.

Moreover, the composition of the refilled joints is reminiscent of stucco. Indeed, they are

characterized by a quasi absence of aggregate (Fig. 5), or by the presence of siliceous, fine

and very pure sand. Thanks to such compositions the mortar is easier to work and to insert

between stones.

Nevertheless, the quality is always very good and suited to its material function, which

is to prevent early degradation of the facings, especially when the quality of the masonry

mortar is poor.

Figure 4. Refilled joints, in white mortar, between

building stones of the facing. (A. Coutelas)

Figure 5. Thin section (3.6 x 2.4 cm) of a

refilled joint. The mortar is characterized

by a quasi absence of (siliceous) aggregate.

(A. Coutelas)

9 R. Ginouvs R. Martin, Dictionnaire mthodique de larchitecture grecque et romaine. Tome

I. Matriaux, techniques de construction, techniques et formes du dcor, Paris 1985.

146

Coutelas

4.3 Wall paintings and plasters

In our opinion, there are two types of wall coatings in Roman Gaul. The first is plaster,

whose main function is the protection of the facing. The second is wall painting, the

main function of which is the decoration of walls.

Indeed, plaster is used for non-protected external faces (primarily the faade), and for

non-residential and service rooms. In this case, only one mortar layer is observed, almost

always made with a lime mortar rich in broken tile. Often this coating is painted (one can

then speak of painted plaster), with ochre or black, but without intonaco (the typical

finishing layer of wall paintings).

On the other hand, for wall painting several layers are applied in order to prepare

for the decoration. The stratification of mortar depends in particular on the position in

the building, and on the wall. It may be noted that the stratification sometimes changes

between the lower zone of the wall and the upper zone. Among other explanations, one

can suggest:

the need for good stability of the coating: the addition of a mortar layer on the

lower zone of the wall

the need for good resistance to moisture (caused by capillary rise): the

addition or use of a layer of lime mortar rich in broken tile and brick on the

lower zone of the wall

the desire to keep quality raw materials for the more visible zones of the

wall only: use of an intonaco rich in marble powder only on the lower and

intermediate zones of the wall.

A large number of stratifications of Gallo-Roman wall paintings were identified a few

years ago and results of the studies have been published.10 As expected, no coating shows

a technique as elaborate as that described by Vitruvius, with seven mortar layers (the first

is the coarsest, the three following ones are rich in sand, the three last are rich in crushed

marble; De Architectura 7.3). It even appears, on the contrary, that the most abundant

coatings are the simplest, made up of two layers only. The preliminary layer is made up

of a good quality lime mortar with siliceous or calcareous sand. The finishing layer is also

very often composed of lime mortar with good quality fine siliceous or calcareous sand.

It is noted finally that the aggregate of Gallo-Roman finishing layers is primarily

composed of siliceous or calcareous sand, and secondly of marble sand (not powder)

or one of its substitutes: vein of calcite or limestone with large calcite crystals.

However, it should be understood that the quality of the intonaco composition is always

better than the quality of the other layers. This is obviously shown by the presence of

marble powder, but it can also be apparent when the aggregate is natural sand. In the

10 A. Coutelas, Les mortiers de support des peintures murales de Gaule romaine: premire

synthse, in C. Guiral Pelegrn (ed.), Circulacin de temas y sestemas decorativos en la pintura

mural antigua (Actes du IXe colloque international sur la peinture murale antique, Saragosse, 21-25

septembre 2004), Calatayud 2007, 505-07 et pl. 45.

Comm. Hum. Litt. Vol. 128

example given in Fig. 6, the preliminary layer

is composed of a mortar rich in flint and silt,

whereas the aggregate of the finishing layer is

only pure flint sand, probably selected for this

use.

Clearly, it is not because of the lack of

crushed marble in the intonaco that the quality

of the wall painting is low. Moreover, it is

unlikely that marble in intonaco always gives

the result described by Vitruvius: a perfect,

polished and possibly reflective surface (like

polished marble). Indeed, to achieve such an

effect it is necessary to include a lot of crystals

within the layer of pigments, and of course hard

work of polishing, and sufficient luminosity.

147

(a)

(b)

Figure 6. Preliminary layer (b) and finishing

layer (a) of a Gallo-Roman wall painting

(Ribemont-sur-Ancre, Sommes, France).

The two mortars are made with lime and

flint (white crystals). The aggregate of the

finishing layer is pure and less abundant.

(A. Coutelas)

4.4 Hydraulic structures

One can divide hydraulic structures into two categories: those for waste water and those

for clean water. In fact, there is no particular building material used for the construction

of structures which allow the evacuation of wastewater. If mortar is involved, one finds it

only in masonries, made with lime and natural sand.

The situation is quite different for structures related to the clean water supply. Indeed,

one can observe the extensive use of mortars and concretes with broken tile and brick. But

these materials are always used for coatings (on the walls or the floor). Examples of the

use of lime mortar with broken tile in the walls of hydraulic structures are rare and always

limited to small masonries (especially for small pools).

The question of the origin of the broken terra cotta often arises. In fact, the fragments

in Gallo-Roman mortars almost always come from several sources: different types of

bricks or tiles are present in the material. Thus, one must consider the likelihood that this

aggregate is actually obtained by salvaging materials.

It is interesting to note that the results are similar for Italy, where we may take the

example of the castellum aquae della Porta Romana in Ostia Antica11. Analyses have

shown that the coatings inside the building, like those outside, are in opus signinum,

otherwise called cocciopesto. To be more precise, and because the term opus signinum

is unfortunately often misused, the plaster is made with a lime mortar rich in sand and

broken tile and brick (Fig. 7).

11 E. Bukowiecki H. Dessales J. Dubouloz avec la collaboration de J. Carlut A. Coutelas

E. De Sena M. Leguilloux G. Poccardi, Ostie, leau dans la ville: chteaux deau et rseau

dadduction, (Collection de lEcole franaise de Rome 402), Ecole franaise de Rome, Rome 2008.

148

Figure 7. Thin section (3.6 x 2.4 cm) of an

opus signinum: plaster made with lime, sand

and broken tile and brick (angular shape). Ostia

Antica, castellum aquae della Porta Romana. (A.

Coutelas)

Coutelas

Figure 8. Type of joint of tiles used for two

imbrices. Here, two of these joints and,

between, one imbrex. (A. Coutelas)

4.5 Joints of tiles

The joints of tiles consist of mortar applied at the same time as the tiles are laid in order

to protect the tiled roof against wind and gravity (Fig. 8). In Roman Gaul, the joints are

mainly made of lime and siliceous sand; the absence of broken tile in the mortar is probably

explained by the fact that impermeability of the roof is ensured by the tiles.

However, this mixture of lime and sand is not prepared randomly, the joint mortar

quality is better than that of the masonry mortar: always dense, with an aggregate that is

very fine and pure. This quality, which in particular indicates the preliminary layers of wall

paintings, is obviously explained by the particular position of the material.

5. Lime mortars and public building programmes

Thus, there are a lot of principles in Roman Gaul. There is a particular lime mortar formula

for each architectural use: in a word, each function requires an exact composition of

materials, or at the least very specific technical know-how and expertise.

Moreover, recent work relating to the analysis of several public buildings that are part

of a monumental unity (sanctuary, agglomeration) proves that the selection of a lime

mortar recipe is not always restricted to one building only.12 Analysis appears to indicate

that several buildings could show the same construction or decoration materials.

Thus, it is possible to check which buildings of a monumental unity share common

phases of construction and decoration. This result is particularly promising, because it

could enable us to better understand the various phases of city growth through the study

of mortars, especially masonry mortars. In addition, it gives us new opportunities for

understanding the involvement of local elites in providing labour and materials, and their

importance as economic factors in urban development.

12 Coutelas Heijmans, cit. n. 4.

Figure 9. Monumental complex of Cassinomagus. (Chassenon, Charente, France)

Comm. Hum. Litt. Vol. 128

149

150

Coutelas

The building programme of the monumental complex of the Roman town Cassinomagus

(Chassenon, Charente, France) provides an example. This immense complex is organized

around a large temple. Other major constructions have been found: a theatre, smaller

temples, baths and two aqueducts - the major and the secondary (Fig. 9).13 The southwestern area, excavated by Ccile Doulan and Sandra Sicard between 2004 and 200814,

is of particular interest. Here there are the major aqueduct, the secondary aqueduct, the

peribolus of the temple and the south-western tower of the baths.

Analyses have shown the use of the same lime mortar for the construction of the two

aqueducts and for the south tower of the baths. But the masonry mortar of the peribolus is

different. This has enabled us to confirm that the monumental complex of Cassinomagus

had undergone various building programmes, and that one of them included the two

aqueducts as well as the south tower of the baths (a structure for the reception of water?),

even perhaps the baths in their totality. The peribolus of the temple, and undoubtedly the

large temple as a whole, probably belong to another building programme. Without going

into great detail, it is clear that these variations of types of masonry mortars show different

phases of city growth, and therefore various clients for these constructions.

6. Conclusion: the technical chain

In conclusion, mortar analysis will provide information to reveal construction phases.

It may give some details of the building process: for example the number of pauses in

construction. Moreover, when several buildings are studied it seems that a city building

programme can be identified.

The techniques of local builders, and to some extent their know-how, can be compared

with established ideas at the time: essentially the relationship between the function of

materials and their composition. This comparison provides information about technological

skills and traditions: the study of the whole technical chain, as a relationship between

environment, needs, knowledge and expertise, and authorities15, can then be reasonably

considered.

Fig. 10 is a representation of the technical chain for Roman lime mortar. It is important

to note that this is not the chane opratoire, translated as operational sequence, and

described as the different stages of tool production from the acquisition of raw material

to the final abandonment of the objects.

13 D. Hourcade P. Aupert Ph. Poirier, Chassenon Roman Baths, La Crche (F) 2004.

14 S. Sicard J.-P. Bost A. Coutelas Th. Morin S. Soulas, Longeas, commune de Chassenon

(Charente), programme scientifique TherMoNat (2003-2006): fouille programme annuelle.

Systme hydraulique entre temple et thermes du complexe monumental (Rapport de fouille), Poitiers

2005; C. Doulan Chr. Belingard A. Coutelas Th. Lepaon S. Sicard S.Soulas, Systme

hydraulique de lensemble monumental: tour sud-ouest des thermes et aqueduc secondaire

entre temple et thermes. Longeas, commune de Chassenon (Charente), programme scientifique

TherMoNat (2003-2006): fouille programme annuelle (Rapport de fouille), Poitiers 2006.

15 S. Ploux Cl. Karlin, Le travail de la pierre au palolithique, ou comment retrouver lacteur

technique et social grce aux vestiges archologiques, in B. Latour P. Lemonnier (ed.), De la

prhistoire aux missiles balistiques: Lintelligence sociale des techniques, Paris 1994, 65-82.

Comm. Hum. Litt. Vol. 128

151

Figure 10. Technical chain for Roman lime mortar. (A. Coutelas)

The box compositions is related to all the parameters. Choices are made by the builders;

identification of the most frequently recurring choices enables us to characterize the

technical traditions of this social group. As has been described above, many traditions are

present in the craftsmanship of Gallo-Roman masons. Certainly these traditions are the

response to architectural needs, but most are doubtless inherited from a long architectural

legacy: they are widely used but the reasons are forgotten.

The geological environment and socio-economic constraints, and between them the

treatment of raw materials carried out when this is really necessary and economically

viable have, therefore, considerable influence on the compositions box. It is expertise

(or practical experience) which allows for adaptations and flexibility of the operational

sequence.

It seems that perfect knowledge of all the boxes of the technical chain can help us

to obtain new data about the Roman building industry. Indeed, once all the traditions

and expertise of the ancient craftsmen are fully understood, and when the constraints

imposed by the geological environment are known, it is possible to tackle the question

of external and mainly socio-economic constraints. Thus, these first factors allow us to

develop research in the area of the organization of work and the supply of raw materials,

notably through the study of pauses in construction and the study of material variation in

the building.

Вам также может понравиться

- Lunca AntiquityДокумент4 страницыLunca Antiquityroxana_munteanuОценок пока нет

- Discovery of a Multi-Chambered Long Cairn at Goasseac’h, Carhaix-Plouguer, Central Brittany, FranceДокумент8 страницDiscovery of a Multi-Chambered Long Cairn at Goasseac’h, Carhaix-Plouguer, Central Brittany, Francesnickercat.meowОценок пока нет

- A Late Roman Ceramic Production From Pompeii (In Journal of Archaeological Science 40, 2013, Pp. 810-826)Документ17 страницA Late Roman Ceramic Production From Pompeii (In Journal of Archaeological Science 40, 2013, Pp. 810-826)Gianluca SoricelliОценок пока нет

- AV 63 2012 Fazioli-Ceramic TechnologyДокумент36 страницAV 63 2012 Fazioli-Ceramic TechnologynedaoooОценок пока нет

- Analisis de Inclusiones de Mica Utilizando LA ICP MS Un Nuevo Enfoque para El Suministro de Materia Prima de Ceramica BENJAMIN GEHRESДокумент9 страницAnalisis de Inclusiones de Mica Utilizando LA ICP MS Un Nuevo Enfoque para El Suministro de Materia Prima de Ceramica BENJAMIN GEHRESRigel AldebaránОценок пока нет

- Columbu Et Al 2014 Marbles HCДокумент11 страницColumbu Et Al 2014 Marbles HCNicola NorìoОценок пока нет

- Rough Stone Monuments and Their BuildersОт EverandRough Stone Monuments and Their BuildersРейтинг: 5 из 5 звезд5/5 (1)

- Wootton MosaicsДокумент12 страницWootton MosaicspostiraОценок пока нет

- GAUTHIER J. TEREYGEOL F. Small ScaleДокумент6 страницGAUTHIER J. TEREYGEOL F. Small ScalesdrabaОценок пока нет

- Ceramic Review 08Документ17 страницCeramic Review 08ginalyn padonatОценок пока нет

- New Data On The Building Site of The TheДокумент92 страницыNew Data On The Building Site of The Thehilal.sevОценок пока нет

- Tite 2008 A CerambicДокумент16 страницTite 2008 A CerambicZeeshan ShaikhОценок пока нет

- Barbieri, M. Et Al. Experiencing Visible and Invisible Metal Casting Techniques in The Bronze Age ItalyДокумент9 страницBarbieri, M. Et Al. Experiencing Visible and Invisible Metal Casting Techniques in The Bronze Age ItalyRenan Falcheti PeixotoОценок пока нет

- Gaied 2009Документ20 страницGaied 2009Mohamed DAMAKОценок пока нет

- The Earliest Use of Lime and Gypsum Mortars in CyprusДокумент11 страницThe Earliest Use of Lime and Gypsum Mortars in CyprusIS AAОценок пока нет

- Roman Pottery Production Tongeren PDFДокумент10 страницRoman Pottery Production Tongeren PDFЙоаножи ДемаухоОценок пока нет

- Lycia Region)Документ10 страницLycia Region)Muhammad Amin SayfullaevОценок пока нет

- A Ceramic Workshop of The Early Byzantin PDFДокумент12 страницA Ceramic Workshop of The Early Byzantin PDFkavanozcgrОценок пока нет

- The White Marbles of The Tomb of Christ in JerusalДокумент35 страницThe White Marbles of The Tomb of Christ in JerusalAlbanian GeologyОценок пока нет

- THE MEANING OF LE MENEC: A Study of The Moon Using Circumpolar Stars and Sidereal Time, in 4000BCEДокумент56 страницTHE MEANING OF LE MENEC: A Study of The Moon Using Circumpolar Stars and Sidereal Time, in 4000BCERichard Heath100% (1)

- CrocichephrenДокумент6 страницCrocichephrenAbdelhameD AlIОценок пока нет

- Skvara 296-298Документ3 страницыSkvara 296-298Marcelo MeyerОценок пока нет

- Bonga L - Pioneering - Potters - Early - Neolithic - MavropigiДокумент56 страницBonga L - Pioneering - Potters - Early - Neolithic - MavropigiIva TintiloОценок пока нет

- Ancient Egyptian concreteДокумент3 страницыAncient Egyptian concreteicarus301Оценок пока нет

- Göbekli Tepe, Turkey. Preliminary Site Conservation Inspection and First Mortar and Plaster Documentation ReportДокумент23 страницыGöbekli Tepe, Turkey. Preliminary Site Conservation Inspection and First Mortar and Plaster Documentation ReportElizabeth Dorich SchokОценок пока нет

- Engels Bavay TsingaridaДокумент10 страницEngels Bavay TsingaridaGermanikОценок пока нет

- Ferrier Etal 2017Документ20 страницFerrier Etal 2017Gianfranco BongioanniОценок пока нет

- Glass Mosaic Tesserae From Pompeii: An Archeometrical InvestigationДокумент14 страницGlass Mosaic Tesserae From Pompeii: An Archeometrical InvestigationMalina LibitОценок пока нет

- Sedimentary Petrology: An Introduction to the Origin of Sedimentary RocksОт EverandSedimentary Petrology: An Introduction to the Origin of Sedimentary RocksРейтинг: 4.5 из 5 звезд4.5/5 (3)

- A Cretan Landscape Through Time: Priniatikos Pyrgos and EnvironsДокумент10 страницA Cretan Landscape Through Time: Priniatikos Pyrgos and EnvironsPhool Rojas CusiОценок пока нет

- Workshops and Urban Settlement in Buto - Egyptian Archaeology 40 2012 P. 14-17Документ4 страницыWorkshops and Urban Settlement in Buto - Egyptian Archaeology 40 2012 P. 14-17Loïc MazouОценок пока нет

- Experimentation and Interpretation: the Use of Experimental Archaeology in the Study of the PastОт EverandExperimentation and Interpretation: the Use of Experimental Archaeology in the Study of the PastОценок пока нет

- Geotechnical Characterization of The Subsoil of Pisa Tower: January 2003Документ40 страницGeotechnical Characterization of The Subsoil of Pisa Tower: January 2003Tolaz KoyiОценок пока нет

- Sgeol 0302-2684 1999 Sem 99 1 2220Документ5 страницSgeol 0302-2684 1999 Sem 99 1 2220Madonna MadrigalОценок пока нет

- A Short History of The Use of Lime As AДокумент46 страницA Short History of The Use of Lime As AshshanksОценок пока нет

- Martinon-Torres and Rehren 2006 Crucibles PDFДокумент11 страницMartinon-Torres and Rehren 2006 Crucibles PDFChristophe GarnierОценок пока нет

- 1 s2.0 S0305440315001028 Main PDFДокумент14 страниц1 s2.0 S0305440315001028 Main PDFSasa ZivanovicОценок пока нет

- Articol Bar Vornicu PDFДокумент10 страницArticol Bar Vornicu PDFGabriela DanielaОценок пока нет

- IANSA 2021 02 Porta OnlinefirstДокумент18 страницIANSA 2021 02 Porta OnlinefirstRenan Falcheti PeixotoОценок пока нет

- JBuxedaR0070141995CalcitasecundariaComplutumBuxedaCau PDFДокумент19 страницJBuxedaR0070141995CalcitasecundariaComplutumBuxedaCau PDFPareja Anyosa DanteОценок пока нет

- Lime Pozzolana Mortars in Roman CatacombДокумент11 страницLime Pozzolana Mortars in Roman CatacombAlida CrisОценок пока нет

- Archaeomagnetic dating reveals ancient salt production methodДокумент6 страницArchaeomagnetic dating reveals ancient salt production methodVũ Hoàng LongОценок пока нет

- Late Mousterian Cave Reveals Neanderthal AdaptationДокумент11 страницLate Mousterian Cave Reveals Neanderthal AdaptationEnza SpinapoliceОценок пока нет

- Stone Use in Roman Towns Resources TransДокумент18 страницStone Use in Roman Towns Resources TransJasmina DavidovicОценок пока нет

- GraniteççДокумент23 страницыGraniteççزوبير شطيОценок пока нет

- Gallello Et Al 2017Документ11 страницGallello Et Al 2017Penélope ParraОценок пока нет

- Stone Agricultural Implements From The Island of Kos - The Evidence From Kardamaina, The Ancient Demos of Halasarna PDFДокумент13 страницStone Agricultural Implements From The Island of Kos - The Evidence From Kardamaina, The Ancient Demos of Halasarna PDFKoKetОценок пока нет

- 2013 - Preliminary Archaeometric Study of The Neolithic PotteryДокумент9 страниц2013 - Preliminary Archaeometric Study of The Neolithic PotteryFURY FURIONОценок пока нет

- Analyses of colourless Roman glassДокумент21 страницаAnalyses of colourless Roman glassDanielnjbОценок пока нет

- Radiocarbondates Jewish CatacombsДокумент7 страницRadiocarbondates Jewish CatacombsDaniel Jans-PedersenОценок пока нет

- Salt Deterioration of Angkor Wat TempleДокумент8 страницSalt Deterioration of Angkor Wat TemplePOCKETBEACHОценок пока нет

- 2021 Casas Minerals-11-00746Документ27 страниц2021 Casas Minerals-11-00746Ignasi QueraltОценок пока нет

- 1 s2.0 S0166516206002035 MainДокумент14 страниц1 s2.0 S0166516206002035 MainSardar SaleemОценок пока нет

- 1 PIXE PIGE & NMR Study of The Masonry of The Pyramid of Cheops at Giza (Demortier 2004)Документ12 страниц1 PIXE PIGE & NMR Study of The Masonry of The Pyramid of Cheops at Giza (Demortier 2004)LurzizareОценок пока нет

- A History of Stone Studies With Respect PDFДокумент55 страницA History of Stone Studies With Respect PDF12341Оценок пока нет

- Publi4 FRX OKOKOKOДокумент10 страницPubli4 FRX OKOKOKOJulio César Sierra PalominoОценок пока нет

- The Chalk Drums From Folkton and LavantДокумент15 страницThe Chalk Drums From Folkton and LavantCelso GarciaОценок пока нет

- Tunnel Muck RecyclingДокумент10 страницTunnel Muck RecyclingbrodieОценок пока нет

- Level 1:: Advanced Financial Modeler (Afm)Документ23 страницыLevel 1:: Advanced Financial Modeler (Afm)munaftОценок пока нет

- 02 Cost of Capital QBДокумент26 страниц02 Cost of Capital QBAbhi JayakumarОценок пока нет

- Dark Matter and Energy ExplainedДокумент3 страницыDark Matter and Energy ExplainedLouise YongcoОценок пока нет

- Group 1 RDL2Документ101 страницаGroup 1 RDL2ChristelОценок пока нет

- Chapter 1 Notes and ReiewДокумент6 страницChapter 1 Notes and ReiewTricia Mae Comia AtienzaОценок пока нет

- Hem Tiwari Vs Nidhi Tiwari Mutual Divorce - Revised VersionДокумент33 страницыHem Tiwari Vs Nidhi Tiwari Mutual Divorce - Revised VersionKesar Singh SawhneyОценок пока нет

- SAP HANA Analytics Training at MAJUДокумент1 страницаSAP HANA Analytics Training at MAJUXIОценок пока нет

- Cronograma Ingles I v2Документ1 страницаCronograma Ingles I v2Ariana GarciaОценок пока нет

- Coek - Info Anesthesia and Analgesia in ReptilesДокумент20 страницCoek - Info Anesthesia and Analgesia in ReptilesVanessa AskjОценок пока нет

- 2009 IBP ElectionsДокумент77 страниц2009 IBP ElectionsBaldovino VenturesОценок пока нет

- Novel anti-tuberculosis strategies and nanotechnology-based therapies exploredДокумент16 страницNovel anti-tuberculosis strategies and nanotechnology-based therapies exploredArshia NazirОценок пока нет

- SQM-Crop Kit Pepper L-EnДокумент96 страницSQM-Crop Kit Pepper L-EnPavel Lilian100% (3)

- Social Media Marketing - AssignmentДокумент8 страницSocial Media Marketing - AssignmentAllen RodaОценок пока нет

- BtuДокумент39 страницBtuMel Vin100% (1)

- Paul Smith - Discerning The SubjectДокумент226 страницPaul Smith - Discerning The SubjectdisconnectaОценок пока нет

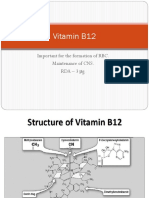

- Vitamin B12: Essential for RBC Formation and CNS MaintenanceДокумент19 страницVitamin B12: Essential for RBC Formation and CNS MaintenanceHari PrasathОценок пока нет

- Exodus Post Apocalyptic PDF 10Документ2 страницыExodus Post Apocalyptic PDF 10RushabhОценок пока нет

- Econometrics IntroductionДокумент41 страницаEconometrics IntroductionRay Vega LugoОценок пока нет

- Second Periodic Test - 2018-2019Документ21 страницаSecond Periodic Test - 2018-2019JUVELYN BELLITAОценок пока нет

- Masala Kitchen Menus: Chowpatty ChatДокумент6 страницMasala Kitchen Menus: Chowpatty ChatAlex ShparberОценок пока нет

- George F Kennan and The Birth of Containment The Greek Test CaseДокумент17 страницGeorge F Kennan and The Birth of Containment The Greek Test CaseEllinikos Emfilios100% (1)

- De Broglie's Hypothesis: Wave-Particle DualityДокумент4 страницыDe Broglie's Hypothesis: Wave-Particle DualityAvinash Singh PatelОценок пока нет

- Completing-Your-Copy-With-Captions-And-Headlines Lesson-1Документ24 страницыCompleting-Your-Copy-With-Captions-And-Headlines Lesson-1api-294176103Оценок пока нет

- mc1776 - Datasheet PDFДокумент12 страницmc1776 - Datasheet PDFLg GnilОценок пока нет

- Evidence Law PDFДокумент15 страницEvidence Law PDFwanborОценок пока нет

- Ashforth & Mael 1989 Social Identity Theory and The OrganizationДокумент21 страницаAshforth & Mael 1989 Social Identity Theory and The Organizationhoorie100% (1)

- LP Moral Decision Making EditedДокумент3 страницыLP Moral Decision Making EditedCiana SacdalanОценок пока нет

- One Shot To The HeadДокумент157 страницOne Shot To The HeadEdison ChingОценок пока нет

- Duah'sДокумент3 страницыDuah'sZareefОценок пока нет