Академический Документы

Профессиональный Документы

Культура Документы

Engineering since 1904: Ellehammer ejectors guide

Загружено:

siva0810Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Engineering since 1904: Ellehammer ejectors guide

Загружено:

siva0810Авторское право:

Доступные форматы

Engineering since 1904

0. Ellehammer A/S

Ellehammer A/S is a modern engineering company and a leading worldwide supplier of high

quality marine products, with an export rate above 80%. All products are manufactured

individually in close cooperation with both customers and a wide range of sub-contractors,

and fulfill all demands from respective classification societies.

Ellehammer produce Ejectors, Emergency fire pumps, Transfer pumps and Electrical control

systems.

The Ellehammer name has been manifested as a reliable, innovative and constructive brand

ever since 1904. Where the company was founded by the Danish inventor J.C.H. Ellehammer,

who amongst several inventions made the first powered flight in Europe in 1906.

Ejectors

This is a static pump, for suction of any

substance, motivated by a (Centrifugal)pump. The ejector can be used for all suction

purposes. Ellehammer Ejectors are

customized to every customer for optimal

performance.

Emergency fire pumps

Fire pump for offshore industry e.g. FPSO,

LNG, FSO and rigs.

Transfer pumps

Hydraulic driven pump for transfer of fuel oil.

Electrical control systems

Customized control panels for engine or

pump systems.

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Table of Content

0. Ellehammer A/S

1. Introduction

1.1 Ejectors General knowledge

1.1.1Ejector parts

1.1.2 Functionality

1.1.3 Motive mediums

1.1.4 Suction mediums

1.2 Advantages and disadvantages

1.3 Areas of installation

1.4 Facts about Ellehammer ejectors

1.5 Reference list

2. Product Range

2.1 Ellehammer ejector types

2.2 Ejector type details

2.3 Type designation

2.4 Nozzle material

3. Ejector Capacity Diagrams

3.1 In-line ejectors

3.2 B-type ejectors

3.3 Sewage ejectors

3.4 Transportable ejectors

3.5 Priming ejectors

3.6 Desalt ejectors

3.7 Venting ejectors

3.8 BV-type ejectors

3.9 Diagram data

4. Design and Installation

4.1 Designing for efficiency

4.2 Design with pipes diagrams

4.3 Designing with ejector types - Gauges, valves and strainers

4.4 Designing with pumps

4.5 Designing with ballast ejectors

4.6 Ejector performance diagram

4.7 Start up & After sales

4.8 Error correction

5.-12.Ejector Types: Performance Diagrams & Dimensional Sketches

5. In-line ejectors

6. Side suction ejectors

7. Sewage ejectors

8. Portable ejectors

9. Priming ejectors

10. Desalt ejectors

11. Venting ejectors

12. BV ejectors

13. Inquiry form

14. Representatives

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

1. Introduction

In this booklet you will find information about Ellehammer ejectors. The booklet provides information

for selecting and installing ejectors.

This booklet gives an overview of our standard ejectors. Requests for special ejectors can be retrieved

from our sales department.

Ellehammer has many years experience with ejectors, which has resulted in high performance and

high quality of every ejector. Ellehammer ejectors are specially designed for every customer need for

optimal performance, it is especially the dimensions of bore and nozzle which is essential.

A table of content is found behind the index page.

This first section of the booklet gives an Introduction to ejectors.

The Product range section provides an overview of Ellehammers standard ejectors and describes the

advantages of each ejector. This section will also guide you to select the best ejector for individual

usage.

The section Capacity range contains diagrams of each ejector type, which provides an overview of

individual ejector capacity. This section can therefore help to select an ejector, however, the final

selection will be performed by Ellehammer sales department in order to calculate the optimal

dimensions of bore and nozzle.

The section Design & Installation will guide you towards a successful installation of an ejector. First

some general guidelines will be explained in order to achieve maximum performance of the ejector.

This section also describes how to design and install ejectors with ballast tanks.

The end of this section contains guidelines for error correction, these guidelines can help you to

pinpoint errors and solve common problems.

Details of the individual ejectors can be found in the section Performance diagrams & Dimensional

sketches. This section contains an overview of the different sizes of each ejector type. The

performance diagrams clarify operating details of specific ejectors. The dimensional sketches informs

of the most important dimensions needed for designing and installing an ejector into a system.

The section which contains Inquiry form will help you to provide basic information for inquiries.

Ellehammer A/S has a world wide network of representatives of ejectors, information about these can

be found in the section Representatives.

Further information can be received by contacting our sales department; contact details in the orange

bar at the page footer.

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

1.1 Ejectors General knowledge

3

2

1.1.1 Ejector parts

An ejector consist of 3 parts dependent on ejector size

1. House

The house is the central part of the ejector, containing the suction and motive inlet, this

is also where the suction capabilities emerge.

2. Diffuser

The diffuser is situated after the house or the intermediate pipe. The diffuser contains

the process of mixing and ejecting the motive and sucked medium.

The inner diameter of the diffuser can vary by specific performance requirements.

3. Nozzle

The nozzle is mounted in the house with the purpose of regulating the motive jet

stream.

The nozzle can vary in dimensions for achieving specific performance requirements.

The nozzle is made in stainless steel.

1.1.2 Functionality

Ejectors are pumps of a very simple construction. In principle an Ellehammer ejector works by means

of a high velocity jet of medium (water or gas) shooting through a circular duct, which will carry the

surrounding fluid with it. In this duct, the jet and suction fluid are gradually mixed while increasing the

pressure. This pressure will further increase in the diffuser while the velocity is lowered to a level

suited for normal piping.

Having no moving parts, ejectors are sturdy and need no maintenance. They are contrary to

centrifugal pumps always self-priming, and may be designed to create almost perfect vacuum.

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

1.1.3 Motive mediums

The motive medium drives the ejector. This medium is always injected in the ejector at higher

pressure than atmosphere. Several different mediums can be used as motive mediums. The most

common are water and air; less common are exhaust and gasses.

Basically, the ejector can be motivated by any medium up to a certain viscosity level.

Water is the most efficient medium to drive the ejector.

Air can be a preferable medium to use when pumping gasses.

1.1.4 Suction mediums

Many other applications exist for ejectors, where a liquid (or slurry) needs to be pumped or a vacuum

created using either liquid or gas as the motive source. There is one exception, though; pumping of

liquid using compressed gas will usually be too inefficient to be of practical use.

Solids

Small particles

Liquids

Mediums

Sewage

Fuel/Oil

Gasses

Water

Steam

Smoke

Air

Solids

Small particles

Include mediums such as sand, powder and coal powder.

Liquids

Sewage

Sewage is characterised by a combination of water and slurry, this includes all sorts of sewage

water and bilge.

Fuel and oil

For transferring and stripping of all types of fuel and all types of oil, using an ejector eliminates

explosive risk.

Water

For removal of any type of water from e.g. ballast tanks, cargo tanks

Gasses

Gas

For emptying of gasses from ballast tanks or other tanks. The ejector has no moving part which

eliminates explosive risks.

Smoke

Ejectors can be used for ventilating and suction of smoke, this can be relevant in the engine

rooms.

Air/vacuum

For priming of centrifugal pumps or other vacuum purposes.

1.2 Advantages and disadvantages of ejectors

Advantages

No maintenance

Various suction purposes

Long lifetime

Extreme robust

Disadvantages

Low efficiency

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

1.3 Areas of installation

Ellehammer ejectors are used in a large range of applications in different industries. Main industries

are the maritime industry and process industry.

Process industry:

Chemical

Petrochemical

Petroleum

Food and Drugs

Marine industry: Stripping

systems Vacuum

systems Ventilation

systems Mixing

systems

Maritime industry

The following picture illustrates where ejectors can be installed on vessels.

Filling and stripping of ballast tanks.

Stripping of bilges from the bottom of the vessel.

Stripping of all sorts of mediums from cargo holds. Includes Oil, Gas, Water

and sewage.

Stripping of bilge from chain lockers

Ejectors in the engine room can both be used for stripping of bilge and for

ventilation of exhaust or other gasses.

Incinerators

Multiple use

Peak tanks

Priming

Removal of ashes from incinerators

Portable ejectors are designed for multiple suction purposes. These ejectors

can be installed with hoses, in order to utilize the ejector various places on

the ship.

Portable ejectors are favourable to use where various suction quantities are

low or where coarse vacuum cleaning are needed.

Peak tanks are situated either in the front or the rear of the vessel. Ejectors

can both be used for stripping and filling these tanks.

Priming of centrifugal pumps. This ejector creates vacuum which will

initiate centrifugal pumps.

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

1.4 Facts about Ellehammer ejectors

This section will inform of basic product information about Ellehammer ejectors

Achievements

Production number:

Over 70,000 delivered ejectors

Ejector size:

Produced ejectors with capacity up to 10,000 m3/h.

Expertise:

Providing customized ejectors with capacity up to 770 m3/h.

Reputation:

Recognized as one of the most flexible ejector manufactures.

Experience

Over 40 years, since 1962.

Ejector production Code of conduct

Certificates:

Ellehammer has close cooperation with many certification agencies and can offer all

types of certification. The most commonly used are DNV, BV, GL and Lloyds register.

Flanges:

Ellehammer can offer all types of flanges. The most common used are to DIN Pn 10,

ANSI, JIS

Lifetime:

In general the lifetime of our ejectors are very high, some might even outlive the

lifetime of the vessel.

The lifetime can be reduced if the ejector is used to suck different kinds of solids,

because they can have a wearing effect.

Materials:

Ellehammer offer ejectors produced in four different materials:

Bronze.

Aluminium-bronze.

Cast-iron, but we recommend a bronze type for maritime usage.

Stainless steel - can be offered by special request.

Performance:

All ejector types are tested at Our test facility; therefore every ejector has the high

Ellehammer quality. We offer to test the performance of individual ejectors.

Quality:

Ellehammer has a long time experience developing, producing and testing ejectors.

Ellehammer always focus on high performance and high material durability.

Therefore Ellehammer can ensure high quality of every ejector.

Test:

Every ejector is tested at our test plant in Glostrup Denmark. Every ejector is tested

for pressure and watertight performance. The ejector is pressure tested at 16 bars;

this ensures the high Ellehammer quality of every ejector.

Technology:

All ejectors are designed by Ellehammer. Our R&D department is always searching

for new ways to improve ejectors with focus on performance, material and usage.

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

1.5 Selected references:

Customer

A.S. Marine

A. De Jong TH B.V.

A.P. Mller

Alfa Laval Copenhagen A/S

Alfa Laval Tumba A/S

ASHSA

Associate Machinery Pte Ltd.

Astilleros Balenciaga S.A.

Axflow AS

Bajk Serwis Sp. z.o.o.

BOMBAS AZCUE S. A.

Bourbon Offshore Surf

Brispes S.L.

Cantiere Navale Visentini s.r.l.

Carnival Cruise Lines plc.

COMERCIAL NAVAL CANARIA

Cunard Line

Damen Shipyards Group

DC Marine Supply ApS

DELTON ENGINEERING PTE LTD

Desmi A/S

DESMI GmbH Rotan Pumpengesellschaft

Erria A/S

Fincantieri Cantieri Navali

Gdansk Shiprepair Yard REMONTOWA

S.A.

Hamworthy Svanehj A/S

Hans Jensen Lubricators A/S

HOH Water Technology A/S

Holm Technoscan

Country

Poland

Holland

Denmark

Denmark

Sweden

Spain

China

Spain

Norway

Poland

Spain

France

Spain

Italy

USA

Spain

USA

Holland

China

China

Denmark

Germany

Denmark

Italy

Poland

Customer

Marine Service Germany MSG GmbH

Marine Technic a/s

Mediterranean Shipping Co.

Meson AB

MS "Novitas-H" Zehnte R.S.T.

Ning Hai Equipment &

Nuovi Cantieri Apuania S.p.A.

Odense Staalskibsvrft A/S

Pacific Engineering & Services PTE Ltd.

PD-Technik GmbH

Peter Dhle Schiffahrts-KG

Pompe Garbarino S.p.A

PROMAT SECURITE

PumpQuip Engineering PTE Ltd.

Rederiet M.H. Simonsen ApS

Ro-Clean Desmi A/S

SEDEF GEMI INSAATI S.A.

Skandinavisk Brandteknik A/S

Stocznia Gdynia S.A.

Stocznia Szczecinska Nowa

STX Europe

Szczecin Ship Repair Yard Gryfia S.A.

Sby Vrft

Tanmarine Denizcilik Ve Tic. Ltd. Sti.

Tenix Defence Pty. Ltd.

Country

Germany

Denmark

Italy

Sweden

Germany

China

Italy

Denmark

China

Germany

Germany

Italy

France

China

Denmark

Denmark

Turkey

Denmark

Poland

Poland

Norway

Poland

Denmark

Turkey

Australia

Denmark

Denmark

Denmark

Denmark

THORSMINDE Maskinvrksted

Thyborn Skibs- & Motor

VATTENFALL A/S

Vela International Marine Ltd.

Hvide Sande Skibs- og Baadebyggeri A/S

Hyundai Heavy Industries Co. Ltd.

International Sinoking Co. Limited

Iron Pump A/S

Karstensens Skibsvrft A/S

Kommandor LLC

Kynde & Toft Maskinvrksted

Larsen & Toubro Ltd.

Denmark

Korea

China

Denmark

Denmark

USA

Denmark

India

Vestergaard Company A/S

Vestvrftet

VN-Pumpen GmbH & Co. KG

Volker Nienstdt GmbH & Co. KG

Wrtsil Danmark A/S

Yangzhou Dayang Shipbuilding Co., Ltd.

YDC Denizcilik AS

Denmark

Denmark

Sweden

United

Arab

Emirates

Denmark

Denmark

Germany

Germany

Denmark

China

Turkey

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejectors for the Marine Industry

Ellehammer A/S is a modern engineering company and a leading worldwide supplier of high quality ejectors for

the maritime industry. All ejectors are customized in close cooperation with our customers, especially our

extensive knowledge gathered through 60 years, will provide you one of the best ejectors on the market.

Through our 60 years experience we have developed many ejectors, and can therefore help you with any suction

need.

Our wide range of ejectors fulfils all demands from respective classification societies.

Applications

Cargo tanks and ballast tanks - 1

Peak tanks and chain lockers - 2

Sewage and bilge water - 3

Desalt/Brine systems - 4

Transportable - 5

Priming of centrifugal pumps - 6

Ventilation - 7

Advantages

Long lifetime and extreme robust

High reliability

Simple to install and operate

Low maintenance

Materials

Bronze

Aluminium bronze

Stainless steel

Facts

More than 40 years experience

More than 70.000 delivered

6

7

All ejectors are designed, manufactured

and tested in Denmark.

Expert in customised ejectors

Key competence

Customization of ejectors to improve

efficiency for your benefit.

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

2. Product range

This section provides an overview of Ellehammers standard ejectors and describes the advantages of

each ejector. This section will also guide you to select the best ejector for individual usage. hereafter

Ellehammer sales department will calculate the optimal dimensions for bore and nozzle, so you can

achieve optimal performance of your ejector and your pumping system.

Ellehammer offers also a variety of products to ejectors eg. Additional flanges, hoses and many other

requirements.

2.1 Ellehammer ejector types

Ellehammer offers six types of ejectors:

Standard ejectors

In-line ejectors

Water motivated

Our In-line ejectors have the best efficiency and are therefore our most

commonly sold ejector type. The motive water is coming from the side and

suction is created In-line.

In line ejectors over size 125-150-150 has inspection covers.

Area of use: Ballast tanks, Cargo tanks etc.

More information can be found in section 5

Side suction ejectors

B-type ejectors

Water motivated

Differs in two ways from the In-line ejector. The motive water is coming from

the end and suction is created from the side and it is equipped with an

inspection cover. Ejectors of all makes and designs may be clogged up by

particles. Whereas soft matter normally will pass through the ejector solid

particles larger than the gap between the nozzle and the throat will get

caught in the narrow passage and eventually cause the ejector to cease

pumping. With Ellehammer B-type ejectors the foreign matter can easily be

removed through the inspection cover.

Additionally the B-type ejector can be constructed with enlarged gap

between the nozzle and the throat, which makes it suitable for sewage use.

Area of use: Bilges, Engine room, Chain locker etc.

More information can be found in section 6

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Sewage ejectors

S-type ejectors

Water motivated

Are designed for sewage use, this ejector allows large particles to pass

through the ejector.

Area of use: Sewage, Bilges, Incinerators etc.

More information can be found in section 7

Portable ejectors

T-type ejectors

Water motivated

Are used where a fixed ejector is not required. Ellehammer produce two

different sizes of portable ejectors. These ejectors are connected with Storz

couplings.

Area of use: Cleaning of tanks, several smaller tanks etc.

More information can be found in section 8

Priming ejectors

Inch-type ejectors

Air & water motivated

Are used for 2 purposes: Priming of non-self priming centrifugal pumps and

small suction purposes. These ejectors are motivated by air or water.

Area of use: Priming of centrifugal pumps, small suction purposes etc.

More information can be found in section 9

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Desalt/Brine ejectors

D-type ejectors

Water motivated

Desalt ejectors are specially designed for desalting systems/ Fresh water systems,

where the ejector is used to suck brine out of the system. The ejector is therefore

only a minor part of this system. We deliver many different desalt ejector types,

contact us for further information.

Venting ejectors

V-type ejectors

Water motivated

Our venting ejector is specially designed for suction of large amounts of gasses eg

from cargo tanks and engine rooms (CO2).

Air-vacuum ejectors

BV-type ejectors

Water motivated

This type of ejector is ideal for making vacuum. The ejector is motivated

by water and designed to suck varies types of gasses.

Area of use: Emptying of gasses from cargo holds, engine rooms etc.

More information can be found in section 10

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Motive substance

Designed for

Liquid

Efficiency

40

Delivery height

maximum (m)

770

Suction capacity maximum (m3/h)

8

2 to 12

Operating pressure

(Bar)

Suction height maximum (m)

In-line

Ejector type

Liquid

Flexibility

40

350

2 to 12

B-type

Liquid

Sewage

40

120

2 to 12

S-type

Liquid

Mobility

40

80

2 to 12

Portable

Ventilation

Liquid

Liquid/Ga

s

2800 (gas)

2 to 12

V-type

Priming

21 (gas)

2 to 12

Priming

Liquid/Gas

Air vacuum

10

250 (gas)

2 to 12

BV-type

Liquid

Brine

7,5 (Brine)

2 to 12

D-type

Engineering since 1904

2.2 Ejector type details

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

2.3 Type designation

All ejectors can be specified by two types of numbers. The model number describes a specific ejector

type and size. A different number is marked on every ejector, the serial number.

Model number

This number describes a specific ejector measured by 6 numbers. All measurements in millimetre.

Motive

Suction

Discharge

Type

Bore

Nozzle

Inner diameter of motive inlet

Inner diameter of suction inlet

Inner diameter of discharge outlet

B, S, T, BV or none which is equal to in-line ejectors

Inner diameter of bore

Inner diameter of nozzle

Information regarding parts can be found in section 1.

There are three priming ejectors , and 1, See section 9.

Motive

Suction

Discharge

Type

Eg. 40-70-70 S

Serial number

All ejectors are marked with serial numbers

which identifies a specific ejector, which makes it

easy to reorder.

The number can be located on the flanges

between the house and the diffuser. The number

is always marked on the opposite side of the inlet

side.

The number exist of 4-6 digits

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

2.4 Nozzle material

Both SS AISI 329 and Monel 400 are alloys known as well suited for ejector nozzles. The following is a

comparison between the data available from the suppliers of Monel 400 and SS AISI 329.

Monel 400

Stainless steel AISI 329

Composition

Ni

C

Mn

Fe

S

Si

Cu

63 % min

0,3 % max

2,0 % max

2,5 % max

0,024 % max

0,5 % max

remainder

Cr

Ni

Mo

C

Fe

26 %

5%

1,5 %

< 0,04 %

remainder

Structure: Solid solution

Structure: Ferritic-Austenitic

Tensile strength 570 Mpa

Elongation

45 %

Hardness HB 150

Tensile strength 690 Mpa

Elongation

30 %

Hardness

HB 220

Corrosion resistance: in sea water

More resistant to corrosion than its principal

constituents, nickel and copper. Excellent

service under high-velocity conditions, where

cavitations erosion is important.

Corrosion resistance: in sea water

Excellent corrosion properties particularly as

regard to pitting, crevice corrosion, stress

corrosion and corrosion fatigue.

Superior to AISI 316 in chloride-bearing

environments.

Both materials show excellent resistance to corrosion in sea-water. But AISI 329 is a little more

resistant to mechanical-wear than Monel due to the superior hardness.

Therefore Ellehammer A/S has been using AISI 329 for more than 20 years as the standard material

for nozzles in marine applications. During this period the stainless steel AISI 329 has proven itself as

an excellent choice for ejector-nozzles. We can therefore guarantee the durability of this material.

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

3. Ejector Capacity Diagrams

This section visualise the Ellehammer ejectors capacity range, these are visualised by

diagrams.

With the diagrams you will be able to find several suitable ejectors for your purpose; thereby

you will have an idea of the dimensions. Remember that the diagrams can not be used for final

selection of ejectors, which must be performed by the Ellehammer A/S sales department.

When reading the diagrams it is important to consider 3 important variables which affect the

performance of ejectors, these are:

-

Suction height

Delivery height

Motive pressure

Additionally it is important to have sufficient motive water.

Each ejector column in the diagrams span over a Select the upper of the

wide capacity range, this is dependent on the

column if you have:

delivery height and the motive pressure, See the

box to the right.

Select the lower of the

column if you have:

Additionally the diagrams has been divided by

water suction column, see the three colours to

the right.

High pressure

Low delivery height

Low pressure

High delivery height

= 3 Meter water column(suction)

= 5 Meter water column(suction)

= 7 Meter water column(suction)

As standard ejectors are delivered with flanges, but if they are marked with a star, they are:

* Delivered only with threaded connection.

** Delivered with threaded connections or flanges.

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

3.1 In-line ejectors capacity diagrams - .. 3 mWC

770 770

510 510 530 750

1000

46

100

54

72

30

12

10

.. 5 mWC .. 7 mWC

7,5

7

25

35

40

85

55

190 190

130 130

60

100 100

340 340 350

150 150 150 150

250 250

500 600

300 400

10

440 530 530 770 770 770

Capacity m3/h

1000

100

25

10

8,5

18

6

5

35

62

24

62

32

85

47

132 132 154

51

80

75

190

340 340 340

230 240 240

400 400 400

110 135 135 135

1000

47

100

19

10

26

7

4

23

6

47

24

120 126

85 100

40

41

57

50

190

75

300 300 300

120 120 120

540

350 500

200 230 230

770 770 770

400 400 400

14

In-line ejector

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

3.2 B-type ejectors capacity diagrams - .. 3 mWC

.. 5 mWC .. 7 mWC

1000

75

100

45

20

10

4,5

50

115

70

170

100

350

130

15

5

Capacity m3/h

1000

100

105

45

60

40

17

10

70

3,5

160

90

320

120

15

5

4

1

1000

65

100

35

40

14

10

2,5

1

100

50

155

80

280

100

12

3

B-type ejector

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

3.3 Sewage ejectors capacity diagrams - .. 3 mWC

.. 5 mWC .. 7 mWC

120

62

100

50

30

20

10

Capacity m3/h

95

100

54

40

23

15

10

1

70

100

32

16

30

10

10

1

40-70-70S*

50-80-80S

70-100-125S

S-type ejector

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

3.4 Transportable ejectors capacity diagram

Capacity m3/h

30

25

20

15

10

5

0

27

25-50-50T

40-70-70T

Transportable ejector

Capacity m3/h

(air)

3.5 Priming ejectors capacity diagram

93

100

80

60

48

40

21

20

0

Priming*

Priming*

1 Priming*

Priming ejector

Capacity m3/h

(Brine)

3.6 D-type ejectors capacity diagram

8

7

6

5

4

3

2

1

0

7,5

D-type ejectors

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

3.7 V-type ejectors capacity diagram

2800

Capacity m3/h

(air)

3000

2500

2000

1500

1100

1000

800

500

0

50-100-100V

50-125-125V

65-200-200V

V-type ejector

Capacity m3/h

(air)

3.8 BV-type ejectors capacity diagram

250

200

200

150

100

50

84

42

0

25-32-70BV*

40-50-80BV

50-80-100BV

BV-type ejector

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

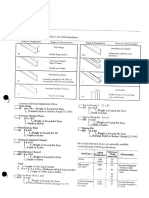

3.9 Diagram data

Minimum

3 MWC

Maximum

3 MWC

Minimum

5 MWC

Maximum

5 MWC

Minimum

7 MWC

Maximum

7 MWC

0

7

10

25

35

40

55

60

100

100

150

150

150

150

250

250

300

400

500

600

7,5

12

30

46

54

72

85

130

130

190

190

340

340

350

510

510

530

750

770

770

0

5

8

18

24

32

47

51

80

75

110

135

135

135

230

240

240

400

400

400

6

8,5

25

35

62

62

85

132

132

154

190

340

340

340

440

530

530

770

770

770

0

3

6

14

23

24

40

41

57

50

75

120

120

120

200

230

230

400

400

400

4

7

19

26

47

47

85

100

120

126

190

300

300

300

350

500

540

770

770

770

0

0

5

15

50

70

100

130

4,5

6

20

45

75

115

170

350

0

0

4

15

45

60

90

120

3,5

5

17

40

70

105

160

320

0

0

3

12

40

50

80

100

2,5

4

14

35

65

100

155

280

0

20

50

30

62

120

0

15

40

23

54

95

0

10

30

16

32

70

25-50-50T

40-70-70T

Priming ejectors (Air)

0

0

9

27

Priming*

Priming*

1 Priming*

BV- type ejectors (Air)

0

0

0

21

48

93

0

0

0

42

84

200

In-line ejectors

25-50-40*

25-50-50**

40-70-70**

50-80-80

50-80-100

70-100-100

70-100-125

100-125-125

100-125-150

125-150-150

125-150-200

150-200-200

150-200-250

200-200-250

200-250-250

200-250-300

250-250-300

250-300-350

300-300-350

300-300-450

B-type ejector

25-32-32B*

25-40-50B

40-50-80B

50-80-100B

70-100-125B

100-125-150B

125-150-200B

150-200-250B

Sewage ejector

40-70-70S*

50-80-80S

70-100-125S

Transportable ejector

25-32-70BV*

40-50-80BV

50-80-100BV

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

4. Design and installation

This section will guide you towards a successful installation of an ejector. First some general

guidelines will be explained in order to achieve maximum performance of the ejector.

This section also describes how to design and install ejectors with ballast tanks.

The end of this section contains guidelines for maintenance and error correction, these can help you to

pinpoint errors, solve common problems and find spare parts.

4.1 Designing for efficiency

This paragraph will guide you to achieve maximum efficiency of an ejector.

Increase efficiency by:

Decrease suction height, rather than delivery height.

Avoid multiple and sharp bends on pipe.

Avoid bends close to ejector. Bends should be placed 5 x diameter of the pipe from the ejector.

Bend radius should be more than 1.5 x diameter of the pipe.

Install the ejector with pipes of similar diameter.

Ranking of installation possibilities by efficiency. All examples are made with fluid tanks.

Installation 1

This type of installation is characterised by simplicity, very few bends and low suction height. Which

makes this installation type top recommended.

Installation 2

Increasing the suction height and adding additional bends on pipe will decrease efficiency and more

motive medium will be needed.

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Installation 3

If the ejector is installed with deep suction pipe it will decrease efficiency. Therefore suction height

should be kept as minimal as possible.

Installation 4

Installation of ejectors in narrow and complex places can lead to additional bends on pipe, which can

increase resistance of medium flow. It is therefore recommended to avoid multiple bends and install

the ejector with as straight pipes as possible.

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

4.2 Design with pipes

In general a straight length of pipe at the connections of the ejector is not required. All the testing of

Ellehammer ejector is performed at the test plant in Glostrup Denmark with a bend directly before the

suction connection. Hence the ejectors specified by Ellehammer A/S will perform according to

specifications even when fitted with a bend directly to the ejector suction connection.

Recommendation:

Very sharp bends should be avoided; bend radius should be 1.5 times the pipe diameter or

more.

On the discharge side, if possible, a straight pipe of not less than 3 times the diameter should

be mounted, this to avoid possible pitting problems in the following bend.

On the suction side, multiple bends in different planes should be avoided, as this will cause a

rotating flow, which may adversely affect the suction capacity. If this is not possible a straight

length of 10 times the diameter should be installed either between the bends or between the

last bend and the ejector. Multiple bends in the same plane will not have this effect and a

straight length of pipe is not needed.

Recommended

NON- Recommended

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

4.3 Designing with ejector types - Gauges, valves and strainers

This section will guide you to install in-line, B- and S-type ejectors.

Ejectors can be installed in any possible position, although it might decrease efficiency, see section 4.1.

For correct installation of suction-, motive- and discharge connections please see the sketches below.

For easy function check gauges can be connected on the piping to the ejectors. Remember to in stall a

vacuum gauge on the suction pipe.

To avoid the ejector from clogging, it is recommended to install a strainer on the suction pipe, this will

collect the majority of large particles.

Designing with homogenous suction medium - In line type ejectors

Designing with ejectors for particles B- & S-type ejectors

B & S-type ejectors are designed with an inspection cover, which should be accessible for easy and

quickly removal of clogging material.

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

4.4 Designing with pumps

An ejector is designed to operate at exact motive pressure and motive capacity; this section will clarify

what happens if the motive flow changes.

Specification of ejectors will be delivered with the individual ejector. It is recommended to follow the

specifications.

The specified motive flow is measured at the ejector entry, friction within the piping to the ejector

should be considered in each individual installation, particularly, long distance to the pump, many

bends on motive piping and varying pipe dimensions should be taken into account.

Changing motive flow can result in:

Varying motive flow will decrease ejector performance.

Decreasing motive flow from the specifications might result in insufficient or none performing

of an ejector.

Increasing motive flow might cause the ejector to malfunction.

Ejectors are designed for maximum suction capacity, therefore, increasing motive flow might

not increase suction capacity.

Pumps are often designed to operate a specific operating point. The pump, however might deliver any

variety of capacities up to its maximum depending on the pressure. The pump supplier documents this

by a performance curve/diagram.

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

4.5 Designing with ballast ejectors

This section will guide you with two scenarios of stripping ballast tanks. Stripping with positive

suction head and stripping with negative suction head.

For most efficient performance the designer should consider high positive head and high negative

head, this is illustrated below.

It is recommended to design the system by equalised water levels, and it is most important to ensure

safe performance in negative suction head situations.

Positive head

When stripping the ballast tanks,

ejectors might have a positive suction

head.

The ejector will therefore not need

motive pressure, before the water

levels has equalised.

Negative suction head

In situation when cargo has been fully

loaded and the water level is low in the

ballast tanks, will result in a high

negative suction head.

This situation will be the most critical

when designing with ballast tanks.

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

4.6 Ejector performance diagram

Performance diagrams visualise efficiency of ejectors. The graph shows operating details for the

ejector measured by total meter water column (horizon) and suction capacity (horizontal). The graph

is a measurement of static performance.

The vertical line express total meter water column. The total meter water column is an addition of

suction height and delivery height. Suction height is defined as the height from suction point to the

ejector. Delivery height is defined as the height from the ejector to the discharge.

The graph should be read from left to right, following

the colour pattern from yellow over green and ending

with red.

The graph is beginning with high water column and

low capacity, this is visualised by the yellow line,

meaning that the ejector will function with low

efficiency.

As the water column decrease the capacity increase,

this effect can be seen as the yellow colour changes to

green. The green fraction of the graph visualise best

efficiency of the ejector, and this is the normal

operating range.

At the end of the green area the graph is breaking,

meaning that the ejector has reached its maximum

performance level. The breaking point should at all

times be avoided, because of the high possibility of

non performing ejector visualised by the red fraction.

Total meter water column (MWC)

Total suction capacity is defined as the amount of sucked medium, measured in cubic meter pr. hour.

Suction capacity (m3/h)

4.7 Start up & After sales

Start up

Open the motive water valve and check that the motive pressure gauge shows the correct pressure.

The ejector will prime and function within few seconds.

If the ejector has zero or insufficient performance, please see section 4.8.

After sales

You are always welcome to contact us for after sales service see our contact information at the

bottom of the page.

If you have questions about previous orders, then please refer to the ejector drawing for part numbers.

You will be asked for the ejector type number and serial number. See section 2.3

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

4.8 Error correction

In many cases the best and quickest way to find the cause of a malfunction is to exclude the wrong

explanations. This can often be achieved by drilling threaded holes in the pipes close to the ejector and

mount pressure gauges. The pressure readings during a test-running of the ejector will most often

point in the direction of the cause of the malfunction.

Error

Possible causes

Solution

The ejector has

no suction

capacity.

The motive water is not turned on.

The strainer is blocked.

The nozzle is blocked.

This may be indicated by unusual high

motive pressure.

The throat or suction side is blocked.

The motive water runs through the

ejector without creating any suction.

This problem can occur if there is no

piping on the discharge side.

Turn on the motive water.

Clean the strainer and the suction well.

Check and clean the nozzle.

The ejector has

insufficient

suction capacity.

The motive water has been incorrect

connected.

Delivery height is too high.

The suction piping has a leak.

Insufficient motive pressure. Compare

against specification of working data.

Suction head is too large.

In normal installation, the suction

pressure should be above 0,8 Bar.

The motive water nozzle is lacking or

heavily worn.

The water flows

backwards

Motive pressure is insufficient.

Delivery height is too high.

The motive water has been incorrect

connected.

Check and clean the throat and nozzle casing.

The problem arises because the motive

water can not fill the ejector, allowing air to

flow from the discharge side back to the

suction side (an internal short circuit). Is

remedied by adding a short piece of pipe

with a 90 bend to the discharge side.

Check that the motive water enters the

correct connection. Refer to the drawing.

Decrease the delivery head or increase the

motive pressure.

Check the piping, its connections and

gaskets. The suction piping must be airtight!

Find and repair the cause for the low

pressure.

Check the piping for obstructions, partly

closed valves etc.

Check the nozzle and if necessary change it.

The standard nozzle diameter is indicated by

the last figure in the type no. (in mm)

Increase the motive pressure.

Decrease the delivery head or increase the

motive pressure.

Check that the motive water enters the

correct connection, namely the one that

leads to the motive nozzle. Refer to the

ejector drawing.

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

5. In-Line Ejectors - Dimensions and weights

Our In-line ejectors have the best efficiency and are therefore our most commonly sold type.

The motive water is coming from the side and suction is created In-line.

In line ejectors over size 125-150-150 has inspection covers.

Ejector

25-50-40

385

40

39

1 BSP socket

2 BSP socket

1 BSP nipple

25-50-50

447

40

39

1 BSP socket

2 BSP socket

2 BSP nipple

25-50-50F

491

85

70

DN 25

DN 50

DN 50

40-70-70

600

60

70

1 BSP socket

2 BSP socket

2 BSP nipple

9,5

40-70-70F

645

100

115

DN 40

150

DN 65

185

DN 65

185

22

50-80-80

792

115

130

DN 50

165

DN 80

200

DN 80

200

35

50-80-100

940

115

130

DN 50

165

DN 80

200

DN 100

220

43

70-100-100

963

123

138

DN 65

185

DN 100

220

DN 100

220

47

70-100-125

1230

123

138

DN 65

185

DN 100

220

DN 125

250

65

100-125-125

1231

114

170

DN 100

220

DN 125

250

DN 125

250

70

100-125-150

1263

114

170

DN 100

220

DN 125

250

DN 150

285

75

125-150-150

1341

162

180

DN 125

250

DN 150

285

DN 150

285

110

125-150-200

1606

162

180

DN 125

250

DN 150

285

DN 200

340

180

150-200-200

1855

180

215

DN 150

285

DN 200

340

DN 200

340

240

150-200-250

1905

180

215

DN 150

285

DN 200

340

DN 250

395

260

200-200-250

1905

180

215

DN 200

340

DN 200

340

DN 250

395

260

200-250-250

2188

215

245

DN 200

340

DN 250

395

DN 250

395

300

200-250-300

2295

215

245

DN 200

340

DN 250

395

DN 300

445

315

250-250-300

2295

215

245

DN 250

395

DN 250

395

DN 300

445

315

250-300-350

2510

280

275

DN 250

395

DN 300

445

DN 350

505

485

300-300-350

2510

280

275

DN 300

445

DN 300

445

DN 350

505

485

300-300-450

2510

280

275

DN 300

445

DN 300

445

DN 450

615

515

115

165

165

Kgs

2

3

11,5

All flanges can be drilled according to DIN Pn 10, ANSI, JIS standards or other requirements.

See dimensional sketches for detailed information

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejector Performance Diagram - 25-50-50

Performance curve 1

Motive water pressure

pDR [BarG]

Motive water consumption

QDR [m3/h]

3

4

5

6

7

10

11

12

13

14

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejector Performance Diagram - 25-50-50

Performance curve 2

Motive water pressure

pDR [BarG]

Motive water consumption

QDR [m3/h]

3

4

5

6

12

14

15

17

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejector Performance Diagram - 40-70-70

Performance curve 3

Motive water Consumption [PDR]

Motive water Pressure

[QDR]

2 BarG

3 BarG

4 BarG

5 BarG

6 BarG

Suction Head

[PSUC]

3 mWC

5 mWC

7 mWC

14,2 m3/h

16,9 m3/h

19,4 m3/h

21,6 m3/h

23,6 m3/h

14,9 m3/h

17,5 m3/h

19,9 m3/h

22,0 m3/h

23,9 m3/h

15,4 m3/h

18,1 m3/h

20,5 m3/h

22,6 m3/h

24,4 m3/h

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejector Performance Diagram - 40-70-70

Performance curve 4

Motive water Consumption [PDR]

Motive water Pressure

[QDR]

2 BarG

3 BarG

4 BarG

5 BarG

6 BarG

Suction Head

[PSUC]

3 mWC

5 mWC

7 mWC

16,0 m3/h

19,1 m3/h

20,5 m3/h

24,4 m3/h

36,6 m3/h

16,8 m3/h

19,8 m3/h

22,5 m3/h

24,8 m3/h

27,0 m3/h

17,4 m3/h

20,4 m3/h

23,1 m3/h

25,5 m3/h

27,5 m3/h

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejector Performance Diagram - 40-70-70

Performance curve 5

Motive water Consumption [PDR]

Motive water Pressure

[QDR]

2 BarG

3 BarG

4 BarG

5 BarG

6 BarG

Suction Head

[PSUC]

3 mWC

5 mWC

7 mWC

18,0 m3/h

21,9 m3/h

24,9 m3/h

27,6 m3/h

30,2 m3/h

18,7 m3/h

22,2 m3/h

25,3 m3/h

28,1 m3/h

30,6 m3/h

19,5 m3/h

22,8 m3/h

25,7 m3/h

28,3 m3/h

30,7 m3/h

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejector Performance Diagram - 50-80-80

Performance curve 6

*)

Motive water

pressure pDR

[BarG]

Motive water consumption*)

QDR [m3/h]

10

9

8

7

6

5

4

3

2

53

51

48

45

42

39

35

31

26

at 5 mWC suction head

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejector Performance Diagram - 70-100-125

Performance curve 7

*)

Motive water pressure

pDR [BarG

Motive water consumption*)

QDR [m3/h]

10

9

8

7

6

5

4

3

2

67

64

61

57

53

49

45

40

34

at 5 mWC suction head

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

In-line 25-50-50F

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

In-line 25-50-40

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

In-line 40-70-70

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

In-line 40-70-70F

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

In-line 50-80-80

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

In-line 50-80-100

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

In-line 70-100-100

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

In-line 70-100-125

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

In-line 100-125-125

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

In-line 100-125-150

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

In-line 125-150-150

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

In-line 150-200-200

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

In-line 200-200-250

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

In-line 200-250-250

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

In-line 250-250-300

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

In-line 250-300-350

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

In-line 300-300-350

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

6. B -Type Ejectors - Dimensions and weights

Side suction water motivated

B-t ype ejectors differs in two ways from the In-line ejector. The motive water is coming from

the end and suction is created from the side and it is equipped with an inspection cover.

Ejectors of all makes and designs may be clogged up by particles. Whereas soft matter

normally will pass through the ejector solid particles larger than the gap between the nozzle

and the throat will get caught in the narrow passage and eventually cause the ejector to cease

pumping. With Ellehammer B-type ejectors the foreign matter can easily be removed through

the inspection cover.

Additionally the B-type ejector can be constructed with enlarged gap between the nozzle and

the throat, which makes it suitable for sewage use.

Ejector type

25-32-32B*

308

38

47

25-40-50B

497

97

85

40-50-80B

695

105

100

40

150

50-80-100B

875

125

115

50

70-100-125B

1080

140

130

70

100-125-150B

1295

160

150

125-150-200B

1655

180

150-200-250B

2060

210

1 BSP socket

25

115

1 BSP socket

40

150

1 BSP nipple

50

165

Kgs

1,9

13

50

165

80

200

21

165

80

200

100

220

31

185

100

220

125

250

55

100

220

125

250

150

285

56

170

125

250

150

285

200

340

115

220

150

285

200

340

250

405

220

*Without flanges, installation by threads.

All flanges can be drilled according to DIN Pn 10, ANSI, JIS standards or other requirements.

See dimensional sketches for detailed information

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejector Performance Diagram - 25-32-32B

Performance curve 8

Motive water pressure

pDR [BarG]

Motive water consumption

QDR [m3/h]

3

4

5

6

1.45

1.65

1.81

1.98

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejector Performance Diagram -25-32-32B

Performance curve 9

Motive water pressure

pDR [BarG]

Motive water consumption

QDR [m3/h]

2

3

4

5

6

3.7

4.3

4.8

5.2

5.7

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejector Performance Diagram - 25-32-32B

Performance curve 10

Motive water pressure

pDR [BarG]

Motive water consumption

QDR [m3/h]

3

4

5

6

4.5

5.1

5.5

6.0

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

B-type 25-32-32B

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

B-type 25-40-50B

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

B-type 40-50-80B

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

B-type 50-80-100B

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

B-type 100-125-150B

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

B-type 150-200-250B

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

7. S-Type Ejectors - Dimensions and weights

S-type ejectors are designed for sewage usage, this ejector allows large particles to pass

through the ejector

Ejector type

1 BSP Socket

2 BSP Socket

2 BSP Nipple

Kgs

40-70-70S

580

80

75

50-80-80S

500

130

120

62

165

80

200

80

160

9.5

23

70-100-125S

700

140

150

80

185

100

220

125

250

37

Dimensions and weight are subject to alterations. All flanges are drilled according to DIN Pn 10 unless another standard is s pecified.

Max sewage particle size

Ejector type

Max particle size diameter mm

40-70-70S

50-80-80S

70-100-125S

30

45

65

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejector Performance Diagram - 40-70-70 S

Performance curve 11

Motive water pressure

pDR [BarG]

Motive water consumption

QDR [m3/h]

2

3

4

5

17.4

20.8

23.6

26.2

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejector Performance Diagram - 50-80-80S

Performance curve 12

Motive water consumption

QDR [m3/h]

Motive water pressure

PDR [BarG]

31,9

36,3

40,4

3,0

4,0

5,0

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

S-type 40-70-70S

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

S-type 50-80-80S

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

S-type 70-100-125S

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

8. Portable Ejectors - Dimensions and weights

Portable ejectors are used where a fixed ejector is not required. Ellehammer produce two

different sizes of portable ejectors.

Ejector type

25-50-50T

40-70-70T

1720

2774

80

127

Easy to handle

Optimised capacity

Motivated from Fire System

Discharge through standard fire hose

Easy to Stow Away

Rugged Design

Capacities up to 30 m3/h

Storz C

Storz C

N/A

N/A

108

Storz C

Storz B

Kgs

9

22

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejector Performance Diagram - 25-50-50T

Performance curve 13

Suction hose

1m

Motive water pressure

pDR [BarG]

Motive water consumption

QDR [m3/h]

2

3

4

5

6

7

8

9

10

8,1

9,5

10,8

11,8

12,9

13,9

14,8

15,7

16,5

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejector Performance Diagram - 40-70-70T

Performance curve 14

Suction hose

2m

Motive water pressure

pDR [BarG]

Motive water consumption

QDR [m3/h]

2

3

4

5

6

7

8

9

10

18

22

25

28

30

33

35

37

39

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejector Performance Diagram - 70-100-100T

Performance curve 15

Motive water

(Suction Head PSUC=0 mWC)

Motive water consumption

Motive water pressure

QDR [m3/h]

pDR [BarG]

2

3

4

5

6

7

48

57

66

72

78

83

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

T-type 40-70-70T

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

9. Priming Ejectors Dimensions & weights

Priming ejectors are used for priming of non-self priming centrifugal pumps. These ejectors are

motivated by compressed air.

Ejector type

Priming

Priming

1 Priming

154,5

221

302

53

55

82,5

50

56

100

BSP

BSP

1 BSP

BSP

BSP

1 BSP

BSP

1 BSP

1 BSP

Kgs

1

2,15

6,1

Preferably, the priming suction connection should be situated above the centrifugal pump, or

if this is not possible, on the pump casing, ensuring the best possible filling of the impeller.

When priming, the discharge

piping must be shut off to

enable the priming ejector to

build up vacuum. Upon

starting up the centrifugal

pump the priming ejector pipe

must be shut off to prevent

leakage through the ejector

and the main discharge valve

must be opened. The latter can

be automated by using a check

valve.

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejector Performance Diagram - inch priming

Water motivated

Performance curve 16

Motive water pressure

pDR [BarG]

Motive water consumption

QDR [m3/h]

4

6

8

10

0.6

0.7

0.8

0.9

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejector Performance Diagram - inch priming unit

Air motivated

The following performance diagram shows the capabilities of the ejector at different

operating pressure. When activating the ejector it will perform from 0 mWC vacuum up to -9

mWC vacuum. Therefore the ejector will have high gas consumption at startup, which

decreases as the vacuum increases.

Performance curve 17

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejector Performance Diagram - 1 inch priming

Air motivated

The following performance diagram shows the capabilities of the ejector at different

operating pressure. When activating the ejector it will perform from 0 mWC vacuum up to 8

mWC vacuum. Therefore the ejector will have high gas consumption at startup, which

decreases as the vacuum increases.

Performance curve 18

Motive air pressure

[BarG]

Motive air consumption

(free air) [m3/h]

3

4

5

6

1.5

1.9

2.2

2.6

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Priming ejector

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Priming ejector 1

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

10. Desalt/Brine ejectors Dimensions and weights

Desalt ejectors are specially designed for desalting systems/ Fresh water systems, where the ejector is

used to suck brine out of the system. The ejector is therefore only a minor part of this system. We

deliver many different desalt ejector types, contact us for further information.

Ejector type

D1

470

80

60

D2

520

80

60

D3

692,5

127,5

110

D4

912,5

127,5

110

D5

912,5

127,5

110

Universal

flanges

Universal

flanges

Universal

flanges

Universal

flanges

Universal

flanges

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

11 . Venting ejector Dimensions and weights

Venting ejectors are designed for emptying of gas from rooms.

Kgs

STORZ-C

100

160

11.5

240

STORZ-C

125

288

17

320

STORZ-B

200

260

45

Ejector type

50-100-100V

1230

290

160

110 mm hose

50-125-125V

1480

288

130

125

65-200-200V

2320

320

150

200

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejector Performance Diagram Venting ejector 50-100-100

Performance curve 19

Motive water pressure

pDR [BarG]

Motive water consumption*)

QDR [m3/h]

2

3

4

5

6

11,9

14,6

16,9

18,8

20,6

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejector Performance Diagram - Venting ejector 50-125-125

Performance curve 20

Motive water pressure

pDR [BarG]

Motive water consumption*)

QDR [m3/h]

2

3

4

5

6

11,9

14,6

16,9

18,8

20,6

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Ejector Performance Diagram - Venting ejector 65-200-200

Performance curve 21

Motive water pressure

pDR [BarG]

Motive water consumption*)

QDR [m3/h]

2

3

4

5

6

30

38

44

50

55

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Venting ejector 50-100-100

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Venting ejector 50-125-125

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

Venting ejector 65-200-200

MARITIME DIESEL ELECTRIC 10308 West McNab Road Tamarac, FL 3321 Phone +1 (954) 597-7602 Fax +1 (954) 597-7608 www.mardiesel.com support@mardiesel.com

Engineering since 1904

12. BV Ejector - Dimensions and weights

Air vacuum water motivated

This type of ejector is ideal for making vacuum. The ejector is motivated by water and designed to suck

varies types of gasses

Ejector type