Академический Документы

Профессиональный Документы

Культура Документы

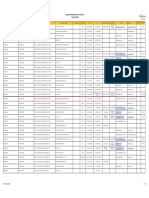

CCRD Mechanical Checklist: Ductwork Specialties/Services/Dampers

Загружено:

oscartxnОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CCRD Mechanical Checklist: Ductwork Specialties/Services/Dampers

Загружено:

oscartxnАвторское право:

Доступные форматы

ccrd Mechanical Checklist

Job Name : ________________________________________________________

Date : ________________________________________

Job Number : ______________________________________________________

Estimated % Complete : _________________________

Designed By : ______________________________________________________

Project Manager : ______________________________

Discipline Coordination

General Coord.

Item

Item

#

Ductwork Specialties/Services/Dampers:

1

Canvas wrap indicated in M.E. rooms

2

Fire Dampers: Combination Fire/Smoke type,

3

Class I, Dynamic

F/S dampers coordinated with electrical

4

5

Motorized dampers coordinated with elec.

Shaft Walls: 3 levels require smoke damper

6

AHU's about 15,000 CFM require smoke

7

damper

Elevators require separate system

8

Stairway requires separate system

9

Shaft corridors treat like stairway

10

11

Chiller:

12

Starter & disconnect Indicated

13

Refrigerant Monitor Indicated

14

Tube Pull Accommodated

15

Chiller Voltage Coord. With Elec.

16

Refrigerant Relief (purge) Indicated

17

Chiller Room Ventilation Indicated

18

16 degree delta T (Medical Center)

19

Chiller Room Controls at doors

20

Electrical power source indicated

21

Electrical power source voltage coordinated

22

with division 16

Starter & disconnect coordinated with

23

electrical (div. 16)

Sequence Of Operation Included

24

25

Chilled Water Appurtenances:

26

CHW Expansion Tank Included

27

CHW Isolation Valves Indicated

28

CHW Flow Measuring Indicated

29

NA

Spec.

Section

Detail

Included

Reviewer Comments

Discipline Coordination

General Coord.

Item

#

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

Item

CHW Diff. Pressure Bypass Ind.

16 degree delta T (Medical Center)

CHW Flow Diagram Complete

Cooling Tower:

Water Side Economizer Indicated

CW Heat Trace Indicated

CW Heat Trace elec power provided

CT Controls Indicated

CT Controls power circuit provided

CT Fan(s) Power Indicated

CT Basin Heater Power Indicated

CT VFD or 2 Speed Control Ind.

CT Bypass Indicated

CT Clearance Coordinated

CT Support Coordinated

CT Make-up Water Indicated

CT Location Coordinated

Sequence Of Operation Included

Air Handling Unit (Indoor / Outdoor):

SAF Power Indicated (emergency?)

RAF Power Indicated (emergency?)

Double wall casing indicated

VFD(s) Indicated (bypass on supply fan)

Pre-Filters Indicated (30% cube type)

Final-Filters Indicated

Economizer Indicated

Housekeeping Pad Indicated (6")

Condensate Drain Indicated (cooling coil)

Unit Clearances Coordinated

Access section between Htg & Clg coil

SSteel coil & drain pan indicated

Air-Flow Monitoring Indicated (Sup/Ret/OA

min. only.....NOT max)

Chilled Water Valve Type Indicated

Hot Water Valve Type Indicated

Preheat Steam Valve Indicated

Steam Pressure Indicated

Steam Condensate Returned (steam

pressure powered pump)

NA

Spec.

Section

Detail

Included

Reviewer Comments

Discipline Coordination

General Coord.

Item

Item

#

Smoke Detectors Indicated

68

Smoke Detector power circuit(s) provided

69

Return Fan sized for smoke purge duty

70

Sequence Of Operation Included (Smoke

71

purge indicated)

Premium Efficiency Motors Indicated

Verify NO autoflow device on coils !!! Check

detail

Power provided for motorized dampers

72

Dedicated 120V emergency power circuit

73

provided for controls cabinet(s)

Power circuit provided for unit lighting

74

75

76

77

78

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

NA

Power circuit provided for unit control (BAS)

Humidifiers:

Humidifier generator Indicated (Dri-Steem

STS with duct mtd dispersion unit)

15 psi steam supply indicated

Humidifier Water Source Indicated

Humidifier Power Indicated

Control Panel Indicated (provide additional

contacts for alarm monitoring)

Dual condensate traps indicated

Condensate Drain Cooler Indicated

Disconnect coordinated with elec.

Mounting height allows gravity drainage

Sequence Of Operation Included

Steam Condensate Returned (steam

pressure powered pump)

High limit humidistat provided by Carrier (not

Dri-Steem)

Controls power circuit provided (120V)

Heat Exchangers:

Steam to Water type

1/3 - 2/3 steam control indicated

70 psi steam supply indicated

Dual condensate traps indicated

Mounting height allows gravity drainage

Sequence Of Operation Included

Spec.

Section

Detail

Included

Reviewer Comments

Discipline Coordination

General Coord.

Item

#

Item

87

Steam Condensate Returned (steam

pressure powered pump)

88

89

90

91

92

93

94

95

96

97

Boilers:

Steam Pressure Indicated\coordinated

Natural gas indicated (Dual fuel?)

Condensate return coordinated

Feed water indicated

Expansion tank indicated

Isolation valves indicated

Combustion air indicated

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

Boiler

routingand

indicated

Boiler flue

clearance

tube pull area

accommodated

Boiler gas pressure coordinated with

plumbing

Dearator indicated

Heating water and/or steam flow diagrams

complete

Space for steam PRV's and control valves

indicated

Control panel power provided (Div. 16)

Blower motor power provided (Div. 16)

Sequence Of Operation Included

VAV Boxes:

Double wall casing indicated

Hot water re-heat coil indicated

Tags / indentifiers coordinated

Sequence Of Operation Included

Autoflow valve on reheat coil indicated

95 degree DAT (interior)

100 degree DAT (exterior)

Don't use for stairs, exits, elevators, etc.

Exhaust Fans:

Code required clearances coordinated

Roof penetrations coordinated

ZAM's indicated in spec.

High temperature applications: fan motor

located out of air stream

NA

Spec.

Section

Detail

Included

Reviewer Comments

Discipline Coordination

General Coord.

Item

#

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

Item

Starter & disconnect coordinated with

electrical (div. 16)

Power provided (Div. 16)

Sequence Of Operation Included - Must be

fan specific

Steam Specialties:

F & T traps indicated (no exceptions)

70 psi steam supply indicated

All condensate lines double trapped

All equipment mounted to allow gravity

drainage to receiver and pump

Details included

PRV's included (stations)

All condensate returned to system

Spirex/Sarco equipment indicated

Valves (hydronic):

Ball valves 4" and smaller

Butterfly valves 6" and larger

Autoflow on VAV reheat coils

Stem extensions indicated

Piping Specialties:

Canvas wrap indicated in M.E. rooms

Painting scheme indicated (spec)

Expansion loops indicated (straight runs over

100' long)

Insulation:

Canvas wrap indicated in M.E. rooms

(piping and ductwork below 8'-0" AFF)

Removable "plugs" indicated at valves

Verify weld-pins are specified (NO stick-pins)

Variable Frequency Drives:

By-pass indicated (SAF's only)

Power wiring indicated from power source to

VFD and from VFD to equipment

Code required clearances provided

NA

Spec.

Section

Detail

Included

Reviewer Comments

Discipline Coordination

General Coord.

Item

#

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

Item

Line reactors indicated (input & output)

Filter indicated (input only)

Unit Heaters:

Power provided & coordinated (Div. 16)

Summer fan switch indicated

AutoFlow valve indicated

Two-way control valve indicated

Sequence Of Operation Included

Pressure Sensitive rooms

TSI sensor indicated over door

Wall pressure indicator located

TSI sensor monitored by central EMS (add

verbiage to drawing and/or spec)

Positive / Negative pressurization

reguirements confirmed and reviewed?

Isolation Room exhaust fan warning labeling

specified?

Medical Equipment Chiller (process)

Quick connect panel utilized

Quick connect panel located and coordinated

with architectural

Power provided by div. 16

Chiller model coordinated with medical

equipment served (MRI, CT, etc.)

Mounting detail provided

Auxiliary alarms interlocked into BAS

Piping diagram (detail) provided

City water by-pass indicated

City water by-pass coord. with PLBG.

NA

Spec.

Section

Detail

Included

Reviewer Comments

Вам также может понравиться

- Mechanical Inspection Form For Handing Over Completed Room or AreaДокумент12 страницMechanical Inspection Form For Handing Over Completed Room or Areacyno21Оценок пока нет

- StudyДокумент9 страницStudysarangОценок пока нет

- BD List of Approved Foundation SystemДокумент2 страницыBD List of Approved Foundation SystemGary LoОценок пока нет

- Lighting Commissioning.: Check List of Items To ConsiderДокумент1 страницаLighting Commissioning.: Check List of Items To ConsideroscartxnОценок пока нет

- Akron Art MuseumДокумент2 страницыAkron Art MuseumSimona MihaiОценок пока нет

- Commissioning Report E 92 PDFДокумент1 страницаCommissioning Report E 92 PDFSyed ShahbazОценок пока нет

- Underground Storage Tank Installation Checklist: (Photo)Документ7 страницUnderground Storage Tank Installation Checklist: (Photo)mhillebrennerОценок пока нет

- Building Final Inspections: Thurston County Permit Assistance CenterДокумент2 страницыBuilding Final Inspections: Thurston County Permit Assistance CenteryaredОценок пока нет

- Technical Submittal 03656Документ37 страницTechnical Submittal 03656Abdel HamidОценок пока нет

- Work Procedure For CCB Installation of Raised Floor 2Документ13 страницWork Procedure For CCB Installation of Raised Floor 2ResearcherОценок пока нет

- MODEL NR3XL Pressure RegulatorДокумент2 страницыMODEL NR3XL Pressure Regulator63ragtopОценок пока нет

- Checklist 5Документ3 страницыChecklist 5msmkhanОценок пока нет

- Contractor Daily Quality Control ReportДокумент1 страницаContractor Daily Quality Control Reportpuivgi2012Оценок пока нет

- 01 33 00 - Submittal ProceduresДокумент5 страниц01 33 00 - Submittal ProceduresSteve LezamaОценок пока нет

- Structural Inspection Checklist For FactoryДокумент1 страницаStructural Inspection Checklist For FactoryAnonymous FD64zqL6S100% (1)

- Journal: Aabc National Standards For Total System BalanceДокумент27 страницJournal: Aabc National Standards For Total System Balanceapollo jang100% (1)

- Sr. No. Name of Check ListДокумент24 страницыSr. No. Name of Check ListmanishОценок пока нет

- EXW-P015-0000-QM-LNT-IT-00066 Rev CAДокумент4 страницыEXW-P015-0000-QM-LNT-IT-00066 Rev CAbinunalukandamОценок пока нет

- Checklist For Mechanical CompletionДокумент123 страницыChecklist For Mechanical CompletionReza SalimiОценок пока нет

- Low Pressure Test FormДокумент2 страницыLow Pressure Test FormNor Azman OsmanОценок пока нет

- SAIC-M-1003Location, Depth of TrenchBoreholes & Elevation For Types I - V Fences InspectionДокумент3 страницыSAIC-M-1003Location, Depth of TrenchBoreholes & Elevation For Types I - V Fences InspectionAbuAhmedQuaziОценок пока нет

- PC - EXHAUST FANS ID #'SДокумент3 страницыPC - EXHAUST FANS ID #'SAbdul Mohid SheikhОценок пока нет

- Construction Baseline Book Development Time FrameДокумент4 страницыConstruction Baseline Book Development Time Framesohail2006Оценок пока нет

- Shop Drawings Oct 2k12Документ30 страницShop Drawings Oct 2k12വർഗീസ് ജോസഫ്Оценок пока нет

- SID 00 YG - QFH E 010 Lighting InstallationДокумент1 страницаSID 00 YG - QFH E 010 Lighting InstallationNaeemОценок пока нет

- Lesson Learned - Design and Build ContractsДокумент1 страницаLesson Learned - Design and Build ContractsRakesh KumarОценок пока нет

- Disk Electrostatic Automatic Coating System - OTSON - DM - OTS - 5000!3!0Документ16 страницDisk Electrostatic Automatic Coating System - OTSON - DM - OTS - 5000!3!0otsontek9227Оценок пока нет

- Handover To QAQC-Anand KumarДокумент6 страницHandover To QAQC-Anand KumarAnonymous fBkcEze1Оценок пока нет

- Civil SpecsДокумент136 страницCivil Specsshravan.office11Оценок пока нет

- Checklist of Fcu-AhuДокумент4 страницыChecklist of Fcu-AhuMoizuddin Khaja100% (1)

- AHU Eurovent ISKID Part 1Документ27 страницAHU Eurovent ISKID Part 1Joaquim MonteiroОценок пока нет

- Syabas - Pressure Test - Devmanual - 34Документ1 страницаSyabas - Pressure Test - Devmanual - 34Ri3zaОценок пока нет

- Quality Standards in The Workplace Book 1Документ29 страницQuality Standards in The Workplace Book 1Annabelle Rigat de LeonОценок пока нет

- Boiler Hydro TestДокумент2 страницыBoiler Hydro TestKarthi KeyanОценок пока нет

- Subcontractor: Equipment / Ref.: Manufacturer: Model: Serial NoДокумент1 страницаSubcontractor: Equipment / Ref.: Manufacturer: Model: Serial NoAzwan SunlineОценок пока нет

- Hermle Brochure Overview en PDFДокумент78 страницHermle Brochure Overview en PDFNguyen GiangОценок пока нет

- Tac Company Profile 2012Документ33 страницыTac Company Profile 2012vista_serverОценок пока нет

- ReinforcementsДокумент1 страницаReinforcementsAnonymous 3eHGEDbxОценок пока нет

- Cold Weather ConcretingДокумент2 страницыCold Weather ConcretingBoris DikovОценок пока нет

- Punchlist PDFДокумент1 страницаPunchlist PDFizra hablaОценок пока нет

- Division 15 Mechanical IBS HVACДокумент164 страницыDivision 15 Mechanical IBS HVACmasahinОценок пока нет

- EPC For ASAB Phase-II Stage-2-LatestДокумент2 страницыEPC For ASAB Phase-II Stage-2-LatestGokulprabhuОценок пока нет

- Structural Steel: Steel Shape Profile Cross Section Chemical Composition Standards I-Beams Second Moments of AreaДокумент5 страницStructural Steel: Steel Shape Profile Cross Section Chemical Composition Standards I-Beams Second Moments of AreaIshwarya SrikanthОценок пока нет

- TrueUnion - True Union Ball ValveДокумент4 страницыTrueUnion - True Union Ball ValveKarthick VenkateshОценок пока нет

- Progress Summary CTR 059 - Engineering Design For Micro Turbine Generator (MTG) at Nui PlatformДокумент14 страницProgress Summary CTR 059 - Engineering Design For Micro Turbine Generator (MTG) at Nui PlatformRokan PipelineОценок пока нет

- Understanding About Inspection and Test PlanДокумент2 страницыUnderstanding About Inspection and Test PlanPageduesca RouelОценок пока нет

- 5 Exterior Doors Inspection ChecklistДокумент10 страниц5 Exterior Doors Inspection ChecklistAhmed Mostafa AL-AboudyОценок пока нет

- Project Tracking Template: Current Status Projects DeliverablesДокумент6 страницProject Tracking Template: Current Status Projects DeliverablesAnkit TrivediОценок пока нет

- ITP Is The Minimum Requirement of The Activities For Quality Control and Inspection of The FieldДокумент3 страницыITP Is The Minimum Requirement of The Activities For Quality Control and Inspection of The FieldvigneshОценок пока нет

- Lockstop SDS GreenstreakДокумент8 страницLockstop SDS Greenstreakrobox514Оценок пока нет

- Lusail Katara Hotel, Lusail District, Doha INSPECTION REQUEST LOG Date 13/8/2016Документ2 страницыLusail Katara Hotel, Lusail District, Doha INSPECTION REQUEST LOG Date 13/8/2016edla3710Оценок пока нет

- Constructing The Roadbed by Max FajardoДокумент23 страницыConstructing The Roadbed by Max FajardoLyka Isabel TanОценок пока нет

- Inspection and Test Plan For Steel StructureДокумент1 страницаInspection and Test Plan For Steel Structureeva maniceОценок пока нет

- ITP For Piping SystemsДокумент6 страницITP For Piping SystemssojeckОценок пока нет

- Basic Electrical Formula PDFДокумент1 страницаBasic Electrical Formula PDFjoo2585Оценок пока нет

- Qa/Qc - HseДокумент7 страницQa/Qc - HseIsmail Hamzah Azmatkhan Al-husainiОценок пока нет

- ABE-34 Document Submittal LogДокумент209 страницABE-34 Document Submittal LogFranklyn GenoveОценок пока нет

- Basics of Pressure Piping For Junior EngineersДокумент36 страницBasics of Pressure Piping For Junior Engineersتدریس زبان ESLОценок пока нет

- SP 192000006 TR 01 Mhrs EstimationДокумент5 страницSP 192000006 TR 01 Mhrs EstimationAshhad LahoreОценок пока нет

- 750 TR Chiller Load LineДокумент2 страницы750 TR Chiller Load Linecalvin.bloodaxe4478Оценок пока нет

- Circuit Breaker Settings (Revision 1.0)Документ2 страницыCircuit Breaker Settings (Revision 1.0)oscartxnОценок пока нет

- VAV ATU Sampling ACBДокумент18 страницVAV ATU Sampling ACBoscartxnОценок пока нет

- Sequence of Operation For The UB SubstationДокумент3 страницыSequence of Operation For The UB SubstationoscartxnОценок пока нет

- Design Guidelines April 2014Документ524 страницыDesign Guidelines April 2014oscartxnОценок пока нет

- Title 25 Chapter 134: Psychiatric HospДокумент172 страницыTitle 25 Chapter 134: Psychiatric HosposcartxnОценок пока нет

- Design and Analysis of Flat Slab Floor SДокумент93 страницыDesign and Analysis of Flat Slab Floor SKousalya MkОценок пока нет

- Arup - PT Design NotesДокумент19 страницArup - PT Design NotesTran VietcuongОценок пока нет

- Item Description Unit QTY Rate Amount Egp. Egp. Division 2: Site Construction EarthworkДокумент15 страницItem Description Unit QTY Rate Amount Egp. Egp. Division 2: Site Construction EarthworkAmr M. AbdallahОценок пока нет

- Fahu - AhuДокумент6 страницFahu - AhuHadi AbdulkaderОценок пока нет

- Ac TermsДокумент5 страницAc TermsJohn Paul BicalanОценок пока нет

- Yzh Affinity Heat Pump Install Manual PDFДокумент16 страницYzh Affinity Heat Pump Install Manual PDFSaid Marino CarrascoОценок пока нет

- Bill of Quantities For Iloilo Convention Center (Fits-Out To Complete The Operation and Management of The Iloilo Convention Center)Документ5 страницBill of Quantities For Iloilo Convention Center (Fits-Out To Complete The Operation and Management of The Iloilo Convention Center)Manuel MejoradaОценок пока нет

- INTERTEK Racking Shear Test Report FinalДокумент63 страницыINTERTEK Racking Shear Test Report FinalrycproyectistaОценок пока нет

- Mar 18 AvlДокумент1 страницаMar 18 AvlBala KrishnanОценок пока нет

- Vintar Ilocos NorteДокумент118 страницVintar Ilocos Norteton carolinoОценок пока нет

- Plinth Area For Rough Cost Est TN Pwd. 2021-2022Документ15 страницPlinth Area For Rough Cost Est TN Pwd. 2021-2022Golden KingОценок пока нет

- Umur Salih OKYAY - PRESENTATION 07-OKYAY-U-S-20130408-CFMSДокумент30 страницUmur Salih OKYAY - PRESENTATION 07-OKYAY-U-S-20130408-CFMSusosanОценок пока нет

- Heat LoadДокумент23 страницыHeat LoadHARSHAОценок пока нет

- Cu Metpr Fpol PDДокумент52 страницыCu Metpr Fpol PDALBERTO FELIX CORDOVA AVILESОценок пока нет

- Building Construction Terms: English VernacularДокумент14 страницBuilding Construction Terms: English VernacularAira Lyn ManapatОценок пока нет

- รายการคำนวณวิศวกรรมโครงส้ราง แบบที่ 4Документ21 страницаรายการคำนวณวิศวกรรมโครงส้ราง แบบที่ 4jackcoolsОценок пока нет

- MM35 Product SheetДокумент2 страницыMM35 Product Sheetpablo ReynesОценок пока нет

- Architecture Yr2 Industrial TrainingДокумент33 страницыArchitecture Yr2 Industrial TrainingKintu Philly100% (2)

- HVAC Training PresentationДокумент55 страницHVAC Training PresentationSridhar Chary KammariОценок пока нет

- Energy Efficient Ventilation Solutions: Paul ComptonДокумент24 страницыEnergy Efficient Ventilation Solutions: Paul ComptonArun CherianОценок пока нет

- Ceiling MaterialsДокумент14 страницCeiling Materialschristian benitezОценок пока нет

- Rammed Earth - Module3Документ24 страницыRammed Earth - Module3Aditi Sharma100% (1)

- Finale Versie Thesis Bie3 PDFДокумент230 страницFinale Versie Thesis Bie3 PDFFlorina PtlОценок пока нет

- Quietrock Es Submittal 35235C86 AB5D 23DF 33D2 22F0D808BDA9Документ2 страницыQuietrock Es Submittal 35235C86 AB5D 23DF 33D2 22F0D808BDA9RobertОценок пока нет

- Study of Strength of RC Shear Wall at Different Location On Multi-Storied Residential BuildingДокумент8 страницStudy of Strength of RC Shear Wall at Different Location On Multi-Storied Residential BuildingSyed Ehtesham aliОценок пока нет

- Checklist of Construction SiteДокумент7 страницChecklist of Construction SiteSurya PОценок пока нет

- Lessons Learned From Underfloor Air Distribution SystemsДокумент21 страницаLessons Learned From Underfloor Air Distribution SystemsSyerifaizal Hj. Mustapha100% (1)

- Heat Load Calculations SampleДокумент15 страницHeat Load Calculations SampleleelaОценок пока нет

- High Performance Concrete by TC HollandДокумент3 страницыHigh Performance Concrete by TC HollandWahyuBudiPrakosoОценок пока нет