Академический Документы

Профессиональный Документы

Культура Документы

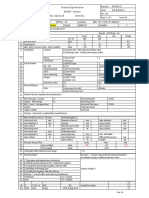

Jacket Piping Notes

Загружено:

reach_arindomАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Jacket Piping Notes

Загружено:

reach_arindomАвторское право:

Доступные форматы

Make jacketing your strong suit

Small details in jacketed-pipe configuration can

have a big impact, according to Chemical

Processing's Contributing Editor Andrew Sloley.

By Andrew Sloley, contributing editor

Dec 05, 2006

Print Email

Tweet

- A A A A +

Utility systems are just as important as process systems for overall plant success. So, they

deserve the same attention to detail and review that process systems demand. Unfortunately,

however, utility systems too often get short shrift.

Consider jacketed piping which is manufactured in relatively short, flanged sections, typically 20

ft long. These short sections allow for isolation of segments of the pipe, to identify the specific

location where a leak between the process fluid and the heating medium may be occurring, and

enable reasonably quick replacement of a damaged section.

If steam is the heating medium, its unusual for each piping segment to have its own steam and

condensate connection. Instead, a jump-over on the jacket side connects the heating utility from

one section to another and allows both steam and condensate to flow downstream to the next

section.

This jump-over connection is one detail thats easily overlooked. Yet, mistakes can prove costly.

In one case, inappropriate connections resulted in a sulfur line setting solid, despite the use of

50-psig (268F) steam, well above the temperature at which sulfur solidifies (238F). The

pressure drop on the steam side of the jacketed piping reduced the actual steam pressure

available to below 5 psig (228F).

Figure 1 shows four different connection configurations. Configuration D most commonly appears

in engineering standards. Configuration B works just as well, if not better. Configurations A and C

both can bring significant problems.

Figure 1. Four different connection configurations are illustrated.

Condensate, of course, accumulates in the bottom of the jacket. Therefore, if the jump-over is at

the top (Configuration A), then the jacket fills up with condensate, which has a much lower heattransfer coefficient than condensing steam. Many applications will completely fail if the pipe fills

with condensate.

Additionally, the condensate increases the pressure drop through the system. Steam pressure

decreases dramatically toward the last pipe segment before the condensate return. At lower

pressure, the condensate may not be able to enter the condensate return system or the steam

may no longer be hot enough to meet process conditions.

Configurations C and D both take the steam and condensate mixture from the bottom and send it

to the top of the next pipe. In the rising part of the jump-over, the two-phase mixture creates a

static head. Downstream pressure may be lower than expected. As long as the pressure drops

through the jacketing system are understood and have been allowed for, Configuration D works

well.

However, the steam connections from one segment to another are rarely engineered to the same

level as process systems. Often, these connections are left to field installers to fit. If the jumpover goes too high (as shown in Configuration C), the extra height increases the pressure drop

through the system. This may not seem like much in a single jump-over, but five, 10 or 20 jumpovers like this in a row can have a big impact.

Configuration B, while less common, takes the steam and condensate mixture from the bottom of

the pipe and returns it to the bottom of the next section. This works well and has

Вам также может понравиться

- SLR Strainer Data Sheet PDFДокумент7 страницSLR Strainer Data Sheet PDFKailas NimbalkarОценок пока нет

- Yanbu: Export Refinery ProjectДокумент7 страницYanbu: Export Refinery ProjectJanakiraman MalligaОценок пока нет

- Introduction To Hydro Testing-Process PipingДокумент2 страницыIntroduction To Hydro Testing-Process Pipingsanthosh thomasОценок пока нет

- LNG - Cryogenic Piping SystemДокумент9 страницLNG - Cryogenic Piping SystemAn le100% (1)

- Piping Handbook 2Документ1 страницаPiping Handbook 2Febri NuansaОценок пока нет

- Liquid Process Piping - Part 5 Valves PDFДокумент23 страницыLiquid Process Piping - Part 5 Valves PDFnitin guptaОценок пока нет

- 01 Competency Matrix For Engineers - Piping STRESS-GROUPДокумент4 страницы01 Competency Matrix For Engineers - Piping STRESS-GROUPShankar Kumar0% (1)

- Screening Reactor For Water HammerДокумент49 страницScreening Reactor For Water HammerYu GanОценок пока нет

- S-G000-535Z-001 - Specification Nozzle Loads On Mechanical EquipmentДокумент13 страницS-G000-535Z-001 - Specification Nozzle Loads On Mechanical Equipment전아진Оценок пока нет

- Stress and Displacement Analysis of Aerial Oil GasДокумент17 страницStress and Displacement Analysis of Aerial Oil GasDaniel GómezОценок пока нет

- Best Practices For RD - PRV-Fike TB8105-minДокумент4 страницыBest Practices For RD - PRV-Fike TB8105-minRahul ChandrawarОценок пока нет

- TN10 Critical Line List SampleДокумент2 страницыTN10 Critical Line List Sampleyulianus_srОценок пока нет

- Acoustic Induced Vibration - Flare Systems PDFДокумент2 страницыAcoustic Induced Vibration - Flare Systems PDFsri9987Оценок пока нет

- Models For Analysis of Water Hammer in Piping With Entrapped Air - Chaiko - 2002 - PPL CorporationДокумент11 страницModels For Analysis of Water Hammer in Piping With Entrapped Air - Chaiko - 2002 - PPL CorporationElias TascaОценок пока нет

- Flare Line Stress AnalysisДокумент7 страницFlare Line Stress AnalysisdhurjatibhuteshОценок пока нет

- Cryogenic EngineeringДокумент7 страницCryogenic EngineeringArjunОценок пока нет

- Barry Dooley Introducton-to-ACC-FAC-and-Cycle-ChemistryДокумент37 страницBarry Dooley Introducton-to-ACC-FAC-and-Cycle-Chemistrychemicalchouhan9303Оценок пока нет

- Plant Engineering and Design The Ultimate Step-By-Step GuideОт EverandPlant Engineering and Design The Ultimate Step-By-Step GuideОценок пока нет

- PMS VMS OesДокумент4 страницыPMS VMS OesDeepak PalОценок пока нет

- Piping: Piping Sometimes Refers To Piping Design, The Detailed Specification of TheДокумент5 страницPiping: Piping Sometimes Refers To Piping Design, The Detailed Specification of ThesiswoutОценок пока нет

- Chapter 8 Steam PipingДокумент14 страницChapter 8 Steam PipingChen WsОценок пока нет

- Modeling Spring Cans With FrictionДокумент1 страницаModeling Spring Cans With FrictionKirana SbОценок пока нет

- Jord Y-Type Strainer DatasheetДокумент1 страницаJord Y-Type Strainer DatasheetSpoonful BurnsideОценок пока нет

- 16 PR Paper158175Документ5 страниц16 PR Paper158175Jomer J SimpsonОценок пока нет

- Thermowell Calculation Guide V1.3Документ19 страницThermowell Calculation Guide V1.3AymanelorbanyОценок пока нет

- Valve MaterialTypeEquivalent PDFДокумент3 страницыValve MaterialTypeEquivalent PDFInaamОценок пока нет

- EGE13B11Документ18 страницEGE13B11Jhonny Rafael Blanco CauraОценок пока нет

- NTPC Project ReportДокумент31 страницаNTPC Project ReportDeepak Ranjan ParidaОценок пока нет

- 1 - CoolH2O Metric Total A4Документ35 страниц1 - CoolH2O Metric Total A4Bry Buray100% (1)

- Thermal Design Considerations For Centrifugal Compressor Piping SystemsДокумент5 страницThermal Design Considerations For Centrifugal Compressor Piping SystemsSerge Rinaudo100% (1)

- Unlock-B31.3 Process Piping Course - 11 Designing With Expansion JointsДокумент15 страницUnlock-B31.3 Process Piping Course - 11 Designing With Expansion JointsProkopОценок пока нет

- Rev. NO. Date BY Checked MEI Lead MEI Approval Conoco Revision AA 9/15/00 EL TD DJ KM MWJ Issued For BidДокумент19 страницRev. NO. Date BY Checked MEI Lead MEI Approval Conoco Revision AA 9/15/00 EL TD DJ KM MWJ Issued For BidThinh NguyenОценок пока нет

- FRP Flange DesignДокумент29 страницFRP Flange DesignSubhadip RoyОценок пока нет

- 347 Stainless Steel Class 2500 Piping SpecificationДокумент3 страницы347 Stainless Steel Class 2500 Piping SpecificationTrevor KanodeОценок пока нет

- Piping Class SpecificationДокумент6 страницPiping Class Specificationcitra puspita sariОценок пока нет

- Pulsation of Flow and Pressure in Piping of Reciprocating CompressorsДокумент26 страницPulsation of Flow and Pressure in Piping of Reciprocating CompressorsSuhas JoshiОценок пока нет

- Mokveld-Brochure Axial Check Valve enДокумент12 страницMokveld-Brochure Axial Check Valve enteacgОценок пока нет

- Stress Analysis of GRPДокумент5 страницStress Analysis of GRPRomner CordovaОценок пока нет

- Ball Valves: Sharma MVSRK 15 October 2013Документ49 страницBall Valves: Sharma MVSRK 15 October 2013Jay Ganta100% (2)

- Knockout DrumsДокумент1 страницаKnockout DrumsCheng Kai CongОценок пока нет

- Spring SupportДокумент51 страницаSpring SupportYinka AkinkunmiОценок пока нет

- Pipeline Equipment - Ball Valves EtcДокумент43 страницыPipeline Equipment - Ball Valves Etckrish69Оценок пока нет

- Leser EngineeringДокумент441 страницаLeser EngineeringEmamokeОценок пока нет

- Pipe Support Design Process Lisega SpedДокумент61 страницаPipe Support Design Process Lisega Spedmuhammad0umar-4Оценок пока нет

- Thermal BowingДокумент8 страницThermal BowingA. VenugopalОценок пока нет

- Piping Design L-002Документ20 страницPiping Design L-002Prakhar Deep KulshreshthaОценок пока нет

- AIGA 083 - 13 Disposal of GasesДокумент82 страницыAIGA 083 - 13 Disposal of GasesIvonn OchoaОценок пока нет

- Data Sheet-Ball ValveДокумент2 страницыData Sheet-Ball ValveJatin Vadhera VCSP100% (1)

- 7 Buried Pipe Modeler PDFДокумент28 страниц7 Buried Pipe Modeler PDFThiên KhánhОценок пока нет

- Crosby Style HL Low Pressure Steel Full Nozzle Safety Valves Installation, Maintenance and Adjustment InstructionsДокумент17 страницCrosby Style HL Low Pressure Steel Full Nozzle Safety Valves Installation, Maintenance and Adjustment InstructionsTarek MohamedОценок пока нет

- Unlock-B31.3 Process Piping Course - 07 Layout and SupportДокумент15 страницUnlock-B31.3 Process Piping Course - 07 Layout and SupportProkopОценок пока нет

- Steps For The Procurement of Piping / Mechanical ItemsДокумент2 страницыSteps For The Procurement of Piping / Mechanical ItemsSanjeev KumarОценок пока нет

- KF Check-Valves PDFДокумент24 страницыKF Check-Valves PDFTaylor RamirezОценок пока нет

- Water Hammer in Steam LinesДокумент5 страницWater Hammer in Steam LinesVijaita Vikas GandhiОценок пока нет

- Layout of Condensate Return LinesДокумент8 страницLayout of Condensate Return Linessimran_99Оценок пока нет

- Graham - Proper Piping For Vacuum SystemДокумент5 страницGraham - Proper Piping For Vacuum SystemAnonymous DJrec2Оценок пока нет

- Condenser Vacuum MarEДокумент4 страницыCondenser Vacuum MarEMayeiaElenorОценок пока нет

- Air Cooled CondenserДокумент20 страницAir Cooled CondenserVivek SinghОценок пока нет

- 13 Stress Strain 1Документ20 страниц13 Stress Strain 1Razell RuizОценок пока нет

- Arindom Kundu Language RussianДокумент1 страницаArindom Kundu Language Russianreach_arindomОценок пока нет

- Understand The Harmonic Analysis and Ensure The Pressure Pulsation Comply With API 674 With PDFДокумент11 страницUnderstand The Harmonic Analysis and Ensure The Pressure Pulsation Comply With API 674 With PDFreach_arindomОценок пока нет

- 1erection Drawing of DM Water Tank - T75.5AB - U-HWS - R2Документ1 страница1erection Drawing of DM Water Tank - T75.5AB - U-HWS - R2reach_arindomОценок пока нет

- Film Review - Chak de IndiaДокумент2 страницыFilm Review - Chak de Indiareach_arindomОценок пока нет

- Arindom Kundu Language ItalianДокумент1 страницаArindom Kundu Language Italianreach_arindomОценок пока нет

- Steel-Tables 2 PDFДокумент110 страницSteel-Tables 2 PDFMahmoud AllamОценок пока нет

- British Steel European Ipe Sections DatasheetДокумент3 страницыBritish Steel European Ipe Sections Datasheetreach_arindomОценок пока нет

- Project On Set Up of Day Care CentreДокумент1 страницаProject On Set Up of Day Care Centrereach_arindomОценок пока нет

- New Microsoft Word DocumentДокумент1 страницаNew Microsoft Word Documentreach_arindomОценок пока нет

- Ibr Acceptable Weld JointДокумент10 страницIbr Acceptable Weld Jointreach_arindomОценок пока нет

- Emergency Ramps Reflect Pragmatism After Fatal Runway Overrun IncidentsДокумент8 страницEmergency Ramps Reflect Pragmatism After Fatal Runway Overrun Incidentsreach_arindomОценок пока нет

- IBR Thickness CalculationДокумент17 страницIBR Thickness Calculationreach_arindomОценок пока нет

- IBR DetailsДокумент10 страницIBR Detailsreach_arindomОценок пока нет

- Dyke Sizing CalculationДокумент1 страницаDyke Sizing Calculationreach_arindomОценок пока нет

- Ows Piping Size2BLДокумент3 страницыOws Piping Size2BLreach_arindomОценок пока нет

- Area Reinforcement CalculatorДокумент5 страницArea Reinforcement CalculatorAnonymous Iev5ggSR100% (1)

- 02 - Heat ExchangersДокумент88 страниц02 - Heat ExchangersDana GuerreroОценок пока нет

- Exp LoopДокумент37 страницExp Loopreach_arindomОценок пока нет

- Summary of Anchor / Nozzle Movements Heat Exchanger: Harish Toki 12-Jul-02 SA-516-70N 8-3E-7 1 SA-516-70NДокумент18 страницSummary of Anchor / Nozzle Movements Heat Exchanger: Harish Toki 12-Jul-02 SA-516-70N 8-3E-7 1 SA-516-70Nreach_arindomОценок пока нет

- Exloop 3dimДокумент69 страницExloop 3dimreach_arindomОценок пока нет

- Revised Fire Water Calculation-Pol Depot, Asoj: LPM/M LPM/M LPM/M LPM/M LPM/MДокумент1 страницаRevised Fire Water Calculation-Pol Depot, Asoj: LPM/M LPM/M LPM/M LPM/M LPM/Mreach_arindomОценок пока нет

- DummyДокумент12 страницDummyrajkamal eshwarОценок пока нет

- Thermal Expansion Data PDFДокумент4 страницыThermal Expansion Data PDFFabio OkamotoОценок пока нет

- Bechtel - Use of Startup StrainerДокумент17 страницBechtel - Use of Startup Strainerreach_arindomОценок пока нет

- Summary of Anchor / Nozzle Movements For Vertical VesselДокумент17 страницSummary of Anchor / Nozzle Movements For Vertical Vesselreach_arindomОценок пока нет

- Cantiliver BeamДокумент2 страницыCantiliver Beamreach_arindomОценок пока нет

- Expansion Loop Formula PDFДокумент1 страницаExpansion Loop Formula PDFreach_arindomОценок пока нет

- ASTM Materials Cross Reference ChartДокумент1 страницаASTM Materials Cross Reference Chartsgm6911Оценок пока нет

- Failure theories-IITMДокумент5 страницFailure theories-IITMsunil_patil_38Оценок пока нет

- Masonry: Baker House at MITДокумент10 страницMasonry: Baker House at MITGudeta JifaraОценок пока нет

- Guide To Welding Hot Dip Galvanized Steel v1.0Документ15 страницGuide To Welding Hot Dip Galvanized Steel v1.0pkannanОценок пока нет

- BTS Road 5.4 - 6.00 KMPДокумент21 страницаBTS Road 5.4 - 6.00 KMPrajibchattarajОценок пока нет

- Washing Machine: User ManualДокумент112 страницWashing Machine: User ManualHadiОценок пока нет

- Transportation Hub - Sample WorkДокумент17 страницTransportation Hub - Sample WorkMohamed LabibОценок пока нет

- Honeywell-Sensing-Switch-5000 Series-Productsheet PDFДокумент2 страницыHoneywell-Sensing-Switch-5000 Series-Productsheet PDFshahrukhОценок пока нет

- Postensioning TIANJINДокумент25 страницPostensioning TIANJINViviana Sofia100% (1)

- Gaugler, R. S. (1944) - U.S.A. Patent No. 2350348.Документ5 страницGaugler, R. S. (1944) - U.S.A. Patent No. 2350348.pathiОценок пока нет

- Astm D 4498Документ2 страницыAstm D 4498Jonathan CastelanОценок пока нет

- (Steel Calculation) MOHANДокумент7 страниц(Steel Calculation) MOHANgopaltryОценок пока нет

- Final Year Project ReportДокумент21 страницаFinal Year Project ReportRAGHAVENDRA V BHAT100% (1)

- Steady Flows in Pressurised NetworksДокумент63 страницыSteady Flows in Pressurised NetworksAyele ErmiyasОценок пока нет

- Howo A7 Cam Nang Sua Chua Dien00028Документ1 страницаHowo A7 Cam Nang Sua Chua Dien00028manhОценок пока нет

- Traditional and Innovative Joints in Bamboo ConstructionДокумент3 страницыTraditional and Innovative Joints in Bamboo ConstructionAulia Rahman FahmiliОценок пока нет

- Determination of Unit WeightДокумент4 страницыDetermination of Unit WeightErika Joy FloresОценок пока нет

- Thermochemistry Final PDFДокумент47 страницThermochemistry Final PDFAyush SinghОценок пока нет

- ASCE Prented PaperДокумент6 страницASCE Prented PaperHafizi GhazaliОценок пока нет

- 1 - C.J. Carter, C.J. Duncan - Recent Changes in U.S. Connection Design PracticeДокумент8 страниц1 - C.J. Carter, C.J. Duncan - Recent Changes in U.S. Connection Design Practiceb52raleighОценок пока нет

- 2009 MCS Atemschutz Poster 800x600 English01 100dpiДокумент1 страница2009 MCS Atemschutz Poster 800x600 English01 100dpiPravatoОценок пока нет

- UntitledДокумент59 страницUntitledYear11RevisionОценок пока нет

- A Study On Composite Honeycomb Sandwich Panel StructureДокумент5 страницA Study On Composite Honeycomb Sandwich Panel StructureÖmer ŞenОценок пока нет

- Staad Out PutДокумент27 страницStaad Out PutEng-Joseph MbuguaОценок пока нет

- Big ProfileДокумент8 страницBig Profilemichael nabusОценок пока нет

- Effect of Welding Current On The Mechanical and StructuralДокумент8 страницEffect of Welding Current On The Mechanical and StructuralBhramandhikaNalendraGhuptaОценок пока нет

- Type AAF by Lindapter 1223Документ3 страницыType AAF by Lindapter 1223CarlotaGomesОценок пока нет

- Steel ConstructionДокумент15 страницSteel ConstructionPn EkanayakaОценок пока нет

- TPV Seal Geometry Effects On Compression Set (CSet) and Compression Load Defglection - Above-The-belt 2006Документ20 страницTPV Seal Geometry Effects On Compression Set (CSet) and Compression Load Defglection - Above-The-belt 2006KAMAL BEHLОценок пока нет

- Failure Analysis of Steam Pipe Flange Gasket: Wei Liu and Hehui WangДокумент4 страницыFailure Analysis of Steam Pipe Flange Gasket: Wei Liu and Hehui WangKelvin IbrahimОценок пока нет

- SEI FEDRO Guidelines For Integral BridgesДокумент6 страницSEI FEDRO Guidelines For Integral BridgesÁlvaro SerranoОценок пока нет

- Fujitsu Klima Uredjaj Zidni Inverter Awyz14lbc Aoyz14lbc Service ManualДокумент18 страницFujitsu Klima Uredjaj Zidni Inverter Awyz14lbc Aoyz14lbc Service ManualDino wowowОценок пока нет