Академический Документы

Профессиональный Документы

Культура Документы

Simply Supported Secondary Composite Beam

Загружено:

georgeispasoiuАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Simply Supported Secondary Composite Beam

Загружено:

georgeispasoiuАвторское право:

Доступные форматы

Example: Simply supported secondary composite beam

CALCULATION SHEET

Document Ref:

SX014a-EN-EU

Title

Example: Simply supported secondary composite beam

Eurocode Ref

EN 1994-1-1

Made by

Arnaud LEMAIRE

Date

August 2005

Alain Bureau

Date

August 2005

Checked by

Sheet

of

10

Example: Simply supported secondary

composite beam

This example deals with a simply supported secondary composite beam

under a uniformly distributed loading.

Created on Wednesday, May 15, 2013

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

The following distributed loads are applied to the beam.

self-weight of the beam

concrete slab

imposed load

The beam is a I-rolled profile in bending about the strong axis. This example

includes :

-

the classification of the cross-section,

the calculation of the effective width of the concrete flange,

the calculation of shear resistance of a headed stud,

the calculation of the degree of shear connection,

the calculation of bending resistance,

the calculation of shear resistance,

the calculation of longitudinal shear resistance of the slab,

the calculation of deflection at serviceability limit state.

This example does not include any shear buckling verification of the web.

Partial factors

G = 1,35

(permanent loads)

Q = 1,50

(variable loads)

M0 = 1,0

M1 = 1,0

V = 1,25

EN 1990

EN 1993-1-1

6.1 (1)

EN 1994-1-1

6.6.3.1

EN 1992-1-1

C = 1,5

Example: Simply supported secondary composite beam

CALCULATION SHEET

Document Ref:

SX014a-EN-EU

Title

Example: Simply supported secondary composite beam

Eurocode Ref

EN 1994-1-1

Made by

Arnaud LEMAIRE

Date

August 2005

Alain Bureau

Date

August 2005

Checked by

Sheet

of

10

Basic data

Design a composite floor beam of a multi-storey building according to the

data given below. The beam is assumed to be fully propped during

construction.

Created on Wednesday, May 15, 2013

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

The profiled steel sheeting is transverse to the beam.

Span length :

7,50 m

Bay width :

3,00 m

Slab depth :

12 cm

Partitions :

0,75 kN/m2

Imposed load :

2,50 kN/m2

Reinforced Concrete density : 25 kN/m3

Steel grade :

S355

Try IPE 270

Depth

ha = 270 mm

Width

b = 135 mm

Web thickness

tw = 6,6 mm

Flange thickness

tf = 10,2 mm

Fillet

r = 15 mm

Mass

36,1 kg/m

Euronorm

tf

19-57

tw

y

y

ha

z

b

Section area

Aa = 45,95 cm2

Second moment of area /yy

Iy = 5790 cm4

Elastic modulus /yy

Wel,y = 428,9 cm3

Plastic modulus /yy

Wpl.y = 484,0 cm3

Modulus of elasticity of steel

Ea= 210000 N/mm2

Example: Simply supported secondary composite beam

CALCULATION SHEET

Document Ref:

SX014a-EN-EU

Title

Example: Simply supported secondary composite beam

Eurocode Ref

EN 1994-1-1

Made by

Arnaud LEMAIRE

Date

August 2005

Alain Bureau

Date

August 2005

Checked by

Sheet

of

10

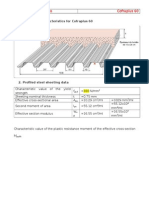

Profiled steel sheeting

Thickness of sheet

t = 0,75 mm

Slab depth

h = 120 mm

Overall depth of the profiled steel sheeting

hp = 58 mm

b1 = 62 mm

e = 207 mm

b2 = 101 mm

Created on Wednesday, May 15, 2013

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

Connectors

Diameter

d = 19 mm

Overall nominal height

hsc = 100 mm

Ultimate tensile strength

fu = 450 N/mm2

Number of shear connectors studs

n = 7500 / e = 36

Number of studs per rib

nr = 1

h0

e

h

hsc

hp

0,5hp

b1

b2

Concrete parameters : C 25/30

EN 1992-1-1

Value of the compressive strength at 28 days

Secant modulus of elasticity of concrete

fck = 25 N/mm2

Ecm = 33 000 N/mm2

To take into account the troughs of the profiled steel sheeting, the weight of

the slab is taken as :

25 3,0 (0,12 5

0,101 + 0 ,062

0,058) = 7,2 kN/m

2

Self weight of the beam : (36,1 9,81) 10-3 =0,354 kN/m

3.1.3

Table 3.1

Example: Simply supported secondary composite beam

CALCULATION SHEET

Document Ref:

SX014a-EN-EU

Title

Example: Simply supported secondary composite beam

Eurocode Ref

EN 1994-1-1

Made by

Arnaud LEMAIRE

Date

August 2005

Alain Bureau

Date

August 2005

Checked by

Sheet

of

10

Permanent load :

G = 0,354 + 7,2 + 0,75 3,0 = 9,80 kN/m

Variable load (Imposed load) :

Q = 2,5 3,0 = 7,50 kN/m

EN 1990

ULS Combination :

G G + Q Q = 1,35 9,80 + 1,50 7,50 = 24,48 kN/m

6.4.3.2

Moment diagram

M

Created on Wednesday, May 15, 2013

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

172,13 kNm

Maximum moment at mid span :

My,Ed = 0,125 24,48 7,502 = 172,13 kNm

Shear force diagram

91,80 kN

Maximum shear force at supports :

Vz,Ed = 0,5 24,48 7,50 = 91,80 kN

Yield strength

Steel grade S355

The maximum thickness is 10,2 mm < 40 mm, so : fy = 355 N/mm2

Note :

The National Annex may impose either the values of fy from the

Table 3.1 or the values from the product standard.

EN 1993-1-1

Table 3.1

Example: Simply supported secondary composite beam

CALCULATION SHEET

Document Ref:

SX014a-EN-EU

Title

Example: Simply supported secondary composite beam

Eurocode Ref

EN 1994-1-1

Made by

Arnaud LEMAIRE

Date

August 2005

Alain Bureau

Date

August 2005

Checked by

Sheet

of

10

Section classification :

The parameter is derived from the yield strength : =

Note :

235

= 0,81

f y [N/mm 2 ]

The classification is made for the non composite beam. For the

composite beam the classification is more favourable.

EN 1993-1-1

Table 5.2

(sheet 2 of 3)

Outstand flange : flange under uniform compression

c = (b tw 2 r) / 2 = (135 6,6 2 15)/2 = 49,2 mm

c/tf = 49,2 / 10,2 = 4,82 9 = 7,29

Class 1

Internal compression part :

Created on Wednesday, May 15, 2013

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

c = h 2 tf 2 r = 270 2 10,2 2 15 = 219,6 mm

c / tw = 219,6 / 6,6 = 33,3 < 72 = 58,3

Class 1

EN 1993-1-1

Table 5.2

(sheet 1 of 3)

The class of the cross-section is the highest class (i.e the least favourable)

between the flange and the web, here : Class 1

So the ULS verifications should be based on the plastic resistance of the

cross-section since the Class is 1.

Effective width of concrete flange

At mid-span, the total effective width may be determined by :

beff,1 = b0 + bei

b0 is the distance between the centres of the outstand shear connectors, here

EN 1994-1-1

Figure 5.1

b0 = 0 ;

bei is the value of the effective width of the concrete flange on each side of the

web and taken as bei = Le / 8 but bi = 3,0 m

beff,1 = 0 + 7,5 / 8 = 0,9375 m, then beff = 2 0,9375 = 1,875 m < 3,0 m

At the ends, the total effective width is determined by :

beff,0 = b0 + ibei

With i = (0,55 + 0,025 Le / bei) but 1,0

= (0,55 + 0,025 7,5 / 0,9375) = 0,75

beff,0 = 0 + 0,75 7,5 / 8 = 0,703 m, then beff = 2 0,703 = 1,406 m < 3,0 m

EN 1994-1-1

Figure 5.1

Example: Simply supported secondary composite beam

CALCULATION SHEET

Document Ref:

SX014a-EN-EU

Title

Example: Simply supported secondary composite beam

Eurocode Ref

EN 1994-1-1

Made by

Arnaud LEMAIRE

Date

August 2005

Alain Bureau

Date

August 2005

Checked by

Sheet

of

10

Design shear resistance of a headed stud

The shear resistance should be determined by :

0,8 f ud 2 / 4 0,29d 2 f ck Ecm

PRd = k t Min

;

V

V

EN 1994-1-1

6.6.3.1

hsc / d = 100 / 19 = 5,26 > 4, so = 1

Reduction factor (kt)

For sheeting with ribs transverse to the supporting beam, the reduction factor

for shear resistance is calculated by :

Created on Wednesday, May 15, 2013

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

kt =

0,7 b0 hsc

1 but ktmax

nr hp hp

Where : nr = 1

hp = 58 mm

b0 = 82 mm

hsc = 100 mm

So,

kt =

0,7 82 100

1 = 0,717 ktmax = 0,75

1 58 58

for profiled sheeting with holes.

0,8 450 19 2 / 4 0,29 1 19 2 25 31000

.10 3

;

PRd = 0,717 Min

1

,

25

1

,

25

= 0,717 Min 81,66 kN ; 73,73 kN

PRd = 52,86 kN

EN 1994-1-1

6.6.4.2

Table 6.2

Example: Simply supported secondary composite beam

CALCULATION SHEET

Document Ref:

SX014a-EN-EU

Title

Example: Simply supported secondary composite beam

Eurocode Ref

EN 1994-1-1

Made by

Arnaud LEMAIRE

Date

August 2005

Alain Bureau

Date

August 2005

Checked by

Sheet

of

10

Degree of shear connection

The degree of shear connection is defined by :

=

Where :

EN 1994-1-1

Nc

N c,f

6.2.1.3 (3)

Nc is the design value of the compressive normal force in the

concrete flange

Nc,f is the design value of the compressive normal force in the

concrete flange with full shear connection

At mid-span :

Created on Wednesday, May 15, 2013

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

The compressive normal force in the concrete flange represents the total

connection.

Ac is the cross-sectional area of concrete, so at mid-span Ac = beff hc

with hc = h - hp = 120 58 = 72 mm, Ac = 1875 62 = 116300 mm2

So,

N c,f = 0,85 Ac f cd = 0,85 Ac

f ck

= 0,85 116300

25 3

10 = 1647 kN

1,5

The resistance of the shear connectors limits the normal force to not more

than :

Nc = 0,5 n PRd = 0,5 36 52,86 = 952 kN

So,

Nc

952

=

= 0,578

N c,f 1647

The ratio is less than 1,0 so the connection is partial.

Verification of bending resistance

Minimum degree of shear connection

The minimum degree of shear connection for a steel section with equal

flanges is given by :

355

(0 ,75 - 0 ,03Le ) with Le 25

f

y

min = 1 -

EN 1994-1-1

6.6.1.2

Example: Simply supported secondary composite beam

CALCULATION SHEET

Document Ref:

SX014a-EN-EU

Title

Example: Simply supported secondary composite beam

Eurocode Ref

EN 1994-1-1

Made by

Arnaud LEMAIRE

Date

August 2005

Alain Bureau

Date

August 2005

Checked by

Sheet

of

10

Le is the distance in sagging bending between points of zero bending moment

in metres, for our example : Le = 7,5 m

So,

min = 1 (355 / 355) (0,75 0,03 7,50) = 0,475

Then,

min = 0,475 < = 0,578 OK

Plastic Resistance Moment at mid span

EN 1994-1-1

The design value of the normal force in the structural steel section is given

by :

6.6.1.2 and

Npl,a = Aa fy / M0 = 4595 355 10 / 1,0 = 1631 kN

-3

Created on Wednesday, May 15, 2013

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

So, Npl,a > Nc = Nc,f = 952 kN

With the ductile shear connectors and the cross-section of the steel beam in

Class 1, the resistance moment of the critical cross-section of the beam MRd at

mid span is calculated by means of rigid-plastic theory except that a reduced

value of the compressive force in the concrete flange Nc is used in place of

the force Ncf.

Here, the plastic stress distribution is given below :

Nc= Nc,f = 952 kN

hp

339 kN

MRd

hn

Na = 1291 kN

The position of neutral axis is : hn = 263 mm

Then the design resistance for bending of the composite cross section is :

MRd = 301,7 kNm

So,

My,Ed / MRd = 172,2 / 301,7 = 0,57 < 1 OK

6.2.1.3

Example: Simply supported secondary composite beam

CALCULATION SHEET

Document Ref:

SX014a-EN-EU

Title

Example: Simply supported secondary composite beam

Eurocode Ref

EN 1994-1-1

Made by

Arnaud LEMAIRE

Date

August 2005

Alain Bureau

Date

August 2005

Checked by

Sheet

of

10

Shear Resistance

The shear plastic resistance depends on the shear area of the steel beam,

which is given by:

Av,z = A 2 b tf + (tw + 2 r) tf

Av,z = 4595 2 135 10,2 + (6,6 + 2 15) 10,2 = 2214 mm2

EN 1993-1-1

6.2.6 (3)

Shear plastic resistance

Vpl,z,Rd =

Av,z ( f y / 3 )

M0

2214 (355 / 3 ) -3

10 = 453,8 kN

1,0

EN 1994-1-1

6.2.2.2

Vz,Ed / Vpl,z,Rd = 91,80 / 453,8 = 0,202 < 1 OK

Created on Wednesday, May 15, 2013

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

Verification to shear buckling is not required when :

hw / tw 72 /

may be conservatively taken as 1,0

EN 1993-1-1

6.2.6 (6)

hw / tw = (270 2 10,2) / 6,6 = 37,8 < 72 0,81 / 1,0 = 58,3 OK

Longitudinal Shear Resistance of the Slab

The plastic longitudinal shear stresses is given by :

vEd =

Fd

hf x

Where x = 7,5 / 2 = 3,75 m

The value for x is half the distance between the section where the moment is

zero and the section where the moment is maximum and we have two areas

for the shear resistance.

Fd = Nc / 2 = 951,56 / 2 = 475,8 kN

hf = h - hp = 120 58 = 62 mm

v Ed =

Fd 475,8 10 3

=

= 2,05 N/mm2

hf x

62 3750

To prevent crushing of the compression struts in the concrete flange, the

following condition should be satisfied :

vEd < f cd sin f cos f with = 0,6[1 f ck / 250] and f = 45

EN 1992-1-1

6.2.4

Figure 6.7

Example: Simply supported secondary composite beam

CALCULATION SHEET

Document Ref:

SX014a-EN-EU

Title

Example: Simply supported secondary composite beam

Eurocode Ref

EN 1994-1-1

Made by

Arnaud LEMAIRE

Date

August 2005

Alain Bureau

Date

August 2005

Checked by

25 25

vEd < 0,6 1

0,5 = 4,5 N/mm2

250

1,5

Sheet

10

of

10

OK

The following inequality should be satisfied for the transverse reinforcement :

Asf fyd / sf vEd hf / cot f where fyd = 500 / 1,15 = 435 N/mm2

Assume the spacing of the bars sf = 250 mm and there is no contribution from

the profiled steel sheeting

Asf

2,05 62 250

= 73,05 mm2

435 1,0

Created on Wednesday, May 15, 2013

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

We can take 10 mm diameter bars (78,5 mm2) at 250 mm cross-centres

extending over the effective concrete breadth.

Serviceability Limit State verification

EN 1990

SLS Combination

G + Q = 9,80 + 7,50 = 17,30 kN/m

Deflection due to G+Q : w =

6.5.3

5 (G + Q ) L4

384 E I y

Where Iy depends on the modular ratio (n) depending on the type of loading.

By simplification, we can take :

n0 = Ea / Ecm = 210 000 / 33 000 = 6,36 for primary effects (Q)

So Iy = 24 540 cm4 at mid span

And n = 3Ea / Ecm = 19,08 for permanent loads (G)

So Iy = 18 900 cm4

w=

5 7 ,54

9,80

7 ,50

+

= 16 mm

8

8

384 210000 18900 10

24540 10

The deflection under (G+Q) is L/469

EN 1994-1-1

7.3.1

Note 1: The limits of deflection should be specified by the client. The

National Annex may specify some limits. Here the result may be

considered as fully satisfactory.

Note 2 : The National Annex may specify limits concerning the frequency of EN 1994-1-1

vibration. Here the total deflection is low and the mass fairly high

7.3.2

and by experience there is no problem of vibration.

Example: Simply supported secondary composite beam

Example: Simply supported secondary composite beam

SX014a-EN-EU

Quality Record

RESOURCE TITLE

Example: Simply supported secondary composite beam

Reference(s)

ORIGINAL DOCUMENT

Name

Company

Date

Created by

Arnaud LEMAIRE

CTICM

14/06/05

Technical content checked by

Alain BUREAU

CTICM

14/06/05

Editorial content checked by

D C Iles

SCI

16/9/05

1. UK

G W Owens

SCI

16/9/05

2. France

A Bureau

CTICM

16/9/05

3. Germany

A Olsson

SBI

15/9/05

4. Sweden

C Mller

RWTH

14/9/05

5. Spain

J Chica

Labein

16/9/05

G W Owens

SCI

10/7/06

Created on Wednesday, May 15, 2013

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

Technical content endorsed by the

following STEEL Partners:

Resource approved by Technical

Coordinator

TRANSLATED DOCUMENT

This Translation made and checked by:

Translated resource approved by:

Вам также может понравиться

- Unrestrained Beam With End MomentsДокумент9 страницUnrestrained Beam With End MomentsNikos StathoulopoulosОценок пока нет

- Simply Supported Primary Composite BeamДокумент17 страницSimply Supported Primary Composite BeamPaul Marceti100% (2)

- Example-Simply Supported Laterally Unrestrained BeamДокумент9 страницExample-Simply Supported Laterally Unrestrained BeamBejan Claudiu100% (2)

- Ec3 Kolon HesabıДокумент5 страницEc3 Kolon HesabınaimalimliОценок пока нет

- Example Elastic Analysis of A Single Bay Portal FrameДокумент29 страницExample Elastic Analysis of A Single Bay Portal FrameYam BalaoingОценок пока нет

- Example - Buckling Resistance of A Pinned Column With Intermediate RestraintsДокумент5 страницExample - Buckling Resistance of A Pinned Column With Intermediate RestraintsAndreea NanОценок пока нет

- LT Buckling Beam Design - Simple Method - 2upДокумент5 страницLT Buckling Beam Design - Simple Method - 2upberto2008Оценок пока нет

- Link Look UpДокумент7 страницLink Look UpValerioZucchelliОценок пока нет

- Eurocode 2 Concrete Design GuideДокумент50 страницEurocode 2 Concrete Design GuideanhkhoacgОценок пока нет

- Example Simply Supported IPE Profile PurlinДокумент10 страницExample Simply Supported IPE Profile PurlinAjay GargОценок пока нет

- Example - Simply Supported Beam With Lateral Restraint at Load Application PointДокумент11 страницExample - Simply Supported Beam With Lateral Restraint at Load Application PointVarga ZoranОценок пока нет

- SX033b-En-EU-Example - Truss or Post End ConnectionДокумент8 страницSX033b-En-EU-Example - Truss or Post End ConnectionWОценок пока нет

- Example Calculation of Alpha-Cr PDFДокумент9 страницExample Calculation of Alpha-Cr PDFHerdean RemusОценок пока нет

- SX028a-EN-EU-Example - Design Resistance of A Screwed Connection of Cold-Formed Members PDFДокумент4 страницыSX028a-EN-EU-Example - Design Resistance of A Screwed Connection of Cold-Formed Members PDFWОценок пока нет

- 07 Sx007a en Eu BeamДокумент11 страниц07 Sx007a en Eu BeamMic PaulaОценок пока нет

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionОт EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionОценок пока нет

- SX020a-En-EU-Example - Tying and The Avoidance of Disproportionate CollapseДокумент6 страницSX020a-En-EU-Example - Tying and The Avoidance of Disproportionate CollapsePatrik AlfredssonОценок пока нет

- EC2 - Concrete Centre (Flat Slabs - 2007)Документ21 страницаEC2 - Concrete Centre (Flat Slabs - 2007)florincinciОценок пока нет

- EN 1997-1 Eurocode 7: Section 3 - Geotechnical Data Section 6 - Spread FoundationsДокумент26 страницEN 1997-1 Eurocode 7: Section 3 - Geotechnical Data Section 6 - Spread FoundationsNeven Ahmed HassanОценок пока нет

- Transfer Floor Loading Strategy Using R/C SoftwareДокумент7 страницTransfer Floor Loading Strategy Using R/C SoftwareKS Lee100% (2)

- Euro CodesДокумент93 страницыEuro CodesPerfumes Importados Salta0% (1)

- SX019a-En-EU-Example - Column Base Connection Under Axial CompressionДокумент5 страницSX019a-En-EU-Example - Column Base Connection Under Axial CompressionWОценок пока нет

- Courses and Seminars CWCT (Centre For Window and Cladding Technology)Документ7 страницCourses and Seminars CWCT (Centre For Window and Cladding Technology)marlontosta5156Оценок пока нет

- CK Lau Note PDFДокумент97 страницCK Lau Note PDFYUK LAM WONGОценок пока нет

- Practical Design to Eurocode 2 BasicsДокумент85 страницPractical Design to Eurocode 2 BasicsajayОценок пока нет

- Steel Section Capacities BS 5950 SpreadsheetДокумент366 страницSteel Section Capacities BS 5950 SpreadsheetAfendi AriffОценок пока нет

- Elastic Design of A Single Bay Portal Frame Made of Fabricated Profiles PDFДокумент28 страницElastic Design of A Single Bay Portal Frame Made of Fabricated Profiles PDFing-sergio.pj7684Оценок пока нет

- 06 Eurocodes Steel Workshop WALDДокумент136 страниц06 Eurocodes Steel Workshop WALDIonut SavaОценок пока нет

- 02-Construction Stages and Column Shortening Analysis in Tall BuildingsДокумент49 страниц02-Construction Stages and Column Shortening Analysis in Tall BuildingsMaad Ahmed Al-Maroof100% (3)

- Structural Engineering Design of Reinforced Concrete Framed BuildingsДокумент53 страницыStructural Engineering Design of Reinforced Concrete Framed BuildingsValentin Cirlescu100% (1)

- 1972 Somerville and Taylor IStructE No8Документ13 страниц1972 Somerville and Taylor IStructE No8Simon EdwardsОценок пока нет

- 100.6 - BD5293 Parapets PDFДокумент45 страниц100.6 - BD5293 Parapets PDFjageshwariОценок пока нет

- IESL Charter PresentationДокумент21 страницаIESL Charter PresentationChamin SubhawickramaОценок пока нет

- ACI Section Crack Width ControlДокумент6 страницACI Section Crack Width ControlImaduddin KhajaОценок пока нет

- 1 Way SlabДокумент12 страниц1 Way SlabSemahegn GebiruОценок пока нет

- Design of Steel - Concrete Composite Structures Assignment Case StudyДокумент15 страницDesign of Steel - Concrete Composite Structures Assignment Case StudySyed Ahmed KabeerОценок пока нет

- Lecture 5 FoundationsДокумент30 страницLecture 5 FoundationsCarel De JagerОценок пока нет

- Bridge Abutment DesignДокумент14 страницBridge Abutment Designsharangill100% (1)

- Shear KeyДокумент14 страницShear KeyMbalekelwa MpembeОценок пока нет

- Loads For BuildingsДокумент9 страницLoads For Buildingsburntbread90Оценок пока нет

- Composite ColumnДокумент33 страницыComposite ColumnbsitlerОценок пока нет

- Design of Concrete Slab Elements in Biaxial Bending: October 2010Документ21 страницаDesign of Concrete Slab Elements in Biaxial Bending: October 2010Myron OikonomakisОценок пока нет

- LOADING ACTION ON TALL BUILDINGSДокумент42 страницыLOADING ACTION ON TALL BUILDINGSChi LiОценок пока нет

- AS3600 LosseseДокумент13 страницAS3600 LossesezfanОценок пока нет

- Institution of Structural Engineers Part 3 Exam: Paul MartinДокумент20 страницInstitution of Structural Engineers Part 3 Exam: Paul MartinparamsandhuОценок пока нет

- Design of RC Structures To EC2 - v.2.1 Priyan DiasДокумент78 страницDesign of RC Structures To EC2 - v.2.1 Priyan DiasransajeewaniОценок пока нет

- 07 Eurocodes Steel Workshop WEYNANDДокумент85 страниц07 Eurocodes Steel Workshop WEYNAND^passwordОценок пока нет

- Voided Slabs ProjectДокумент57 страницVoided Slabs ProjectHitesh ShindeОценок пока нет

- Web Openings For Services in Beams in Multi-Storey BuildingsДокумент5 страницWeb Openings For Services in Beams in Multi-Storey Buildingsnguyenthanhtung_bОценок пока нет

- DimitriosДокумент29 страницDimitriosisaych33zeОценок пока нет

- Lecture-Introduction To EC2Документ48 страницLecture-Introduction To EC2denyfate100% (1)

- Beam UnrestrainedДокумент9 страницBeam Unrestrainedgorgika papandОценок пока нет

- Secondary Composite ExampleДокумент12 страницSecondary Composite Examplef2662961Оценок пока нет

- Example Beam Simply Supported With Lateral RestraintДокумент11 страницExample Beam Simply Supported With Lateral RestraintjplezpОценок пока нет

- Fin Plate Beam To Column Flange ConnectionДокумент16 страницFin Plate Beam To Column Flange ConnectionVlad MosОценок пока нет

- Example: Simply Supported Primary Composite BeamДокумент17 страницExample: Simply Supported Primary Composite BeamAndrás BurkhardtОценок пока нет

- Wind Loads UK Portal Frame WEДокумент31 страницаWind Loads UK Portal Frame WEmandregomes100% (1)

- Active Vs Passive Earth PressureДокумент2 страницыActive Vs Passive Earth PressuregeorgeispasoiuОценок пока нет

- Active Vs Passive Earth PressureДокумент1 страницаActive Vs Passive Earth Pressuregeorgeispasoiu100% (1)

- Active Vs Passive Earth PressureДокумент1 страницаActive Vs Passive Earth Pressuregeorgeispasoiu100% (1)

- MacLoop 100 ENG Rev01 Dec2013Документ1 страницаMacLoop 100 ENG Rev01 Dec2013georgeispasoiuОценок пока нет

- ACEMДокумент21 страницаACEMvahap_samanli4102Оценок пока нет

- Armare - 2D Frame KM 33+720Документ6 страницArmare - 2D Frame KM 33+720georgeispasoiuОценок пока нет

- Brochure WaterstopДокумент52 страницыBrochure WaterstopbabuliuОценок пока нет

- Tutorial For Temperature Effects in Bridge DecksДокумент1 страницаTutorial For Temperature Effects in Bridge DecksgeorgeispasoiuОценок пока нет

- 1 s2.0 S1687404814000996 Main PDFДокумент16 страниц1 s2.0 S1687404814000996 Main PDFgeorgeispasoiuОценок пока нет

- Presiuni Fundatie KM 21+050 3DДокумент2 страницыPresiuni Fundatie KM 21+050 3DgeorgeispasoiuОценок пока нет

- ACEMДокумент21 страницаACEMvahap_samanli4102Оценок пока нет

- Eurocode 3 steel joint design guideДокумент2 страницыEurocode 3 steel joint design guideneverreturnОценок пока нет

- 2D Frame KM 31+170Документ6 страниц2D Frame KM 31+170georgeispasoiuОценок пока нет

- Maccaferri Solution GuideДокумент32 страницыMaccaferri Solution Guideptopic10Оценок пока нет

- Setra Prestress Concrete BridgeДокумент291 страницаSetra Prestress Concrete BridgepsinguliОценок пока нет

- Composite Floors - Cofraplus60Документ1 страницаComposite Floors - Cofraplus60georgeispasoiuОценок пока нет

- Course4 Plotting Drawings Model and Paper SpacesДокумент21 страницаCourse4 Plotting Drawings Model and Paper SpacesgeorgeispasoiuОценок пока нет

- Simply Supported Primary Composite BeamДокумент17 страницSimply Supported Primary Composite BeamgeorgeispasoiuОценок пока нет

- En Upc3 L6Документ3 страницыEn Upc3 L6georgeispasoiuОценок пока нет

- Brochure WaterstopДокумент52 страницыBrochure WaterstopbabuliuОценок пока нет

- Course6 Dimensioning in AutocadДокумент20 страницCourse6 Dimensioning in AutocadgeorgeispasoiuОценок пока нет

- Course4 Plotting Drawings Model and Paper SpacesДокумент21 страницаCourse4 Plotting Drawings Model and Paper SpacesgeorgeispasoiuОценок пока нет

- Worked Examples Ec2 Def080723Документ120 страницWorked Examples Ec2 Def080723dan_ospir67% (3)

- Angel in AДокумент3 страницыAngel in AdimogrecОценок пока нет

- MSB01 Architect S Guide 2010-08-05Документ75 страницMSB01 Architect S Guide 2010-08-05Sencu Razvan100% (1)

- Cold Formed BendingДокумент8 страницCold Formed BendinggeorgeispasoiuОценок пока нет

- Loads On TunnelsДокумент29 страницLoads On TunnelsAmrend Prasad ShahОценок пока нет

- SUSCOS M General Introduction PresentationДокумент35 страницSUSCOS M General Introduction Presentationda_116107118Оценок пока нет

- Aasen, B. - Eurocode 3 - Design of Joints (2010)Документ18 страницAasen, B. - Eurocode 3 - Design of Joints (2010)dhf_pereiraОценок пока нет

- SECTION 16050 Basic Electrical Materials and MethodsДокумент18 страницSECTION 16050 Basic Electrical Materials and MethodsAyman SaberОценок пока нет

- Oracle HFM Beginner's Guide Part IДокумент28 страницOracle HFM Beginner's Guide Part IAmit Sharma100% (1)

- Marketing Management Chapter 22Документ31 страницаMarketing Management Chapter 22Soumya Jyoti BhattacharyaОценок пока нет

- Recruitment Application for Officer & Office Assistant PostsДокумент3 страницыRecruitment Application for Officer & Office Assistant PostsJitendra KumarОценок пока нет

- (PDF) The Demon's Sermon On The Martial Arts: and Other Tales TRIAL EBOOKДокумент77 страниц(PDF) The Demon's Sermon On The Martial Arts: and Other Tales TRIAL EBOOKMarka Bolivie0% (3)

- GX Boehringer Ingelheim Case StudyДокумент1 страницаGX Boehringer Ingelheim Case StudySomansh BansalОценок пока нет

- Hunan Coventry MenuДокумент2 страницыHunan Coventry MenueatlocalmenusОценок пока нет

- Hans J. Morgenthau: April 1967Документ13 страницHans J. Morgenthau: April 1967Michael RossiterОценок пока нет

- Baroque and Rococo Architecture (Art Ebook)Документ136 страницBaroque and Rococo Architecture (Art Ebook)DanielE.Dzansi100% (2)

- PAREDES After MidtermДокумент296 страницPAREDES After MidtermblimjucoОценок пока нет

- Shanthi CVДокумент3 страницыShanthi CVCarolina ButlerОценок пока нет

- Walk in Urgent Care ServicesДокумент2 страницыWalk in Urgent Care ServicesMichel harryОценок пока нет

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceДокумент56 страницStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceRahul ReddyОценок пока нет

- Assignment No. 2Документ6 страницAssignment No. 2cmv mendozaОценок пока нет

- Maezy Roniz R. Tordil: Pearl Street Palmera Homes II, Taytay Rizal, Philippines +63 945 4718 171Документ3 страницыMaezy Roniz R. Tordil: Pearl Street Palmera Homes II, Taytay Rizal, Philippines +63 945 4718 171Mary Anne AlenioОценок пока нет

- Fire Risk AssessmentДокумент30 страницFire Risk AssessmentMufti Sinergi Solusi100% (1)

- The Magna Carta For Public School TeachersДокумент110 страницThe Magna Carta For Public School TeachersJhem MartinezОценок пока нет

- Project proposALДокумент12 страницProject proposALJesica Q PobadoraОценок пока нет

- Jamba Juice Company AnalysisДокумент24 страницыJamba Juice Company AnalysisMary Kim100% (6)

- Customer 2022-10-29 160743296Документ2 страницыCustomer 2022-10-29 160743296Mukund DagaОценок пока нет

- Resilience WorkbookДокумент54 страницыResilience WorkbookLeo Siu100% (1)

- Procedure For Election of The President of IndiaДокумент20 страницProcedure For Election of The President of IndiaAnanya Karan0% (1)

- Organization and Management ReviewerДокумент13 страницOrganization and Management ReviewerSunghoon ParkОценок пока нет

- Cdi 1 Fundamentals of Criminal Investigation & Intelligence - PowerpointДокумент22 страницыCdi 1 Fundamentals of Criminal Investigation & Intelligence - PowerpointJoey Figueroa94% (17)

- KCC Social Entrepreneurship Case StudyДокумент1 страницаKCC Social Entrepreneurship Case Studyvivek ghatbandhe50% (2)

- Comparative Rhetorical AnalysisДокумент7 страницComparative Rhetorical Analysisapi-308816815Оценок пока нет

- Sample Post Negotiation Report 1Документ40 страницSample Post Negotiation Report 1Syed Faisal AhsanОценок пока нет

- Factors affecting demand of Cadbury products in IndiaДокумент7 страницFactors affecting demand of Cadbury products in IndiaNajish FarhanОценок пока нет

- Importance of Zakat in IslamДокумент5 страницImportance of Zakat in Islammarou92stОценок пока нет

- Gmail - IIM Admissions - Confirmation of WAT and PI ScheduleДокумент2 страницыGmail - IIM Admissions - Confirmation of WAT and PI ScheduleNaman BansalОценок пока нет