Академический Документы

Профессиональный Документы

Культура Документы

Vecom - Japanese Black

Загружено:

diaccessltd_171729610 оценок0% нашли этот документ полезным (0 голосов)

84 просмотров2 страницыThe document discusses Japanese Black, a coal tar-based preservative used on steel pipes that is difficult to remove and can cause extensive damage if not removed prior to system installation and operation. It outlines the problems that occur when Japanese Black is not removed, including damage to turbines, motors, and other equipment from detached mill scale particles. The document provides methods for removing Japanese Black from pipes that have not yet been installed, which involves sandblasting or grinding, and from installed systems, which has more limited options such as dismantling or on-site chemical cleaning. It recommends preventing the use of Japanese Black by designers and engineers to avoid incurred costs and issues from its removal.

Исходное описание:

Japanese plack

Оригинальное название

Vecom- Japanese Black

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThe document discusses Japanese Black, a coal tar-based preservative used on steel pipes that is difficult to remove and can cause extensive damage if not removed prior to system installation and operation. It outlines the problems that occur when Japanese Black is not removed, including damage to turbines, motors, and other equipment from detached mill scale particles. The document provides methods for removing Japanese Black from pipes that have not yet been installed, which involves sandblasting or grinding, and from installed systems, which has more limited options such as dismantling or on-site chemical cleaning. It recommends preventing the use of Japanese Black by designers and engineers to avoid incurred costs and issues from its removal.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

84 просмотров2 страницыVecom - Japanese Black

Загружено:

diaccessltd_17172961The document discusses Japanese Black, a coal tar-based preservative used on steel pipes that is difficult to remove and can cause extensive damage if not removed prior to system installation and operation. It outlines the problems that occur when Japanese Black is not removed, including damage to turbines, motors, and other equipment from detached mill scale particles. The document provides methods for removing Japanese Black from pipes that have not yet been installed, which involves sandblasting or grinding, and from installed systems, which has more limited options such as dismantling or on-site chemical cleaning. It recommends preventing the use of Japanese Black by designers and engineers to avoid incurred costs and issues from its removal.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

Technical Bulletin

Number: 2008/02

JAPANESE BLACK YOULL OFTEN PAY FOR IT IN THE END

The use of coal tar as a preservative can lead to extensive damage

It is incomprehensible that Japanese Black is still being

used as a preservative on steel pipe sections, and

particularly on fittings. This preservative, which is very

difficult to remove, has many names: Japanese Black,

Japanese Varnish, Coal tar, Brunswick Black, Black

Coating etc. Its precise composition varies greatly, but is

always based on bitumen, a final distillate of crude oil.

As mentioned above, Japanese Black is used as a

preservative on steel welding flanges, T-pieces, welding

sockets, reducers and various types of welding bends.

This agent is an excellent, inexpensive preservative, but it

is inert and its use extremely hazardous in technology. The

presence of Japanese Black in new construction projects in

both industry and ship-building has already caused a large

number of financial setbacks, sometimes exceeding a

million euros.

Removing Japanese Black

Prior to the assembly of steel pipe systems for steam,

lubricating oil, fuel, hydraulics and process-critical

applications, etc., Japanese Black has to be removed from

the inside of the fittings, that is, before these fittings are

welded into the system in question.

The only cheap way to remove the preservative at this

stage is sandblasting or mechanical grinding. If it is not

removed, big problems will arise after the pipe sections

have been assembled and installed.

Pre-commissioning cleaning and Japanese black

In order to prepare the above-mentioned systems and

installations for the use in the process for which they are

intended, preservative, rust and milling scale must be

removed from the internal metal surfaces.

A chemical surface treatment must be carried out to

achieve a clean surface. This treatment normally takes

place in a metal laundry. The pipe sections are prefab

delivered by the client and are subsequently returned,

ready for assembly, clean with protective caps and/or with

an external coating. If delivery to a metal laundry is not

(or no longer) possible, Vecom Industrial Services B.V.

can carry out this work on site, using chemicals and

auxiliary circulatory materials.

Japanese Black must, however, always be removed

in advance. It is not removed by a standard pickling

procedure.

Removal of Japanese Black by mechanical grinding

Not removing Japanese Black, for example from pipes to

be used in a steam installation, will result in the following

problems. Once the line goes into operation, the

preservative will disappear due to the high temperature of

the steam. Particles of the underlying milling scale will

subsequently become detached and, together with the

steam, may cause extensive damage to the steam turbine

in the line. Similar consequential damage to motors,

gearboxes, regulating valves and hydraulic cylinders can

also be expected in lubricating oil and hydraulic systems.

If Japanese Black is already in the installation

Methods for removing Japanese Black from systems that

have already been assembled and sealed are very limited:

1) Dismantle the pipe sections again and then have the

preservative sandblasted out, after which a chemical

surface treatment must be implemented at a metal

laundry. The cleaned pipe sections are then returned,

with protective caps, ready for assembly. One can then

be absolutely certain that the pipe sections are 100%

clean.

2) A company such as Vecom can try to remove the

Japanese Black on the spot by using alkaline chemicals

specially developed for this type of contamination. A

high temperature must, however, be maintained in the

system throughout the cleaning. A purity of

approximately 90% can be achieved using this method,

depending on the precise composition of the

preservative. In these situations, Vecom determines the

agents and temperature that will yield the optimal result

by cleaning on a laboratory scale in advance.

After the removal of the preservative, a chemical

pickling procedure will be carried out to clean the

internal surface of the pipe sections.

On-site cleaning

Where appropriate, Vecom can also supply expertise,

supervision and chemicals, with which the customer can

carry out the activities with its own equipment and labour.

The waste flows that arise must be delivered to a

recognised processor, such as Vecom, for processing.

Advice for designers, structural engineers, pipe fitters,

assembly managers, plant managers and anyone else who

comes into contact with this preservative:

Japanese Black: prevention is better than cure.

Author: Willem Baris (director Vecom Metal Treatment (Midden) BV)

Reactions and/or questions: e-mail: tb@vecom.nl

www.vecom-group.com

Example of Japanese Black

Вам также может понравиться

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionОт EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionОценок пока нет

- Age-Hardening Alloy Steel Forgings For Pressure Vessel ComponentsДокумент4 страницыAge-Hardening Alloy Steel Forgings For Pressure Vessel ComponentsGustavo SuarezОценок пока нет

- Mobile Offshore Drilling Units 2008: Rules For Building and ClassingДокумент14 страницMobile Offshore Drilling Units 2008: Rules For Building and ClassingmfazioliОценок пока нет

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988От EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockОценок пока нет

- Spe 76-222 Dec 2012Документ10 страницSpe 76-222 Dec 2012akashdruva892Оценок пока нет

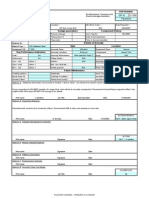

- Inspection & Test Plan Revision: 0 Project: Owner: Location: Contract/PO No.: Engineer(s) : QA/QC Phase: Structural SteelДокумент2 страницыInspection & Test Plan Revision: 0 Project: Owner: Location: Contract/PO No.: Engineer(s) : QA/QC Phase: Structural SteelmetroroadОценок пока нет

- A 1092 - 15Документ3 страницыA 1092 - 15Pavan KumarОценок пока нет

- CW4Документ19 страницCW4Steve Cowan100% (1)

- API 2H50 Data Sheet 2012 04 02Документ2 страницыAPI 2H50 Data Sheet 2012 04 02alvaedison00Оценок пока нет

- Section 11 Piping Systems, Valves and Pumps: I - Part 1 GL 2012 Page 11-1Документ52 страницыSection 11 Piping Systems, Valves and Pumps: I - Part 1 GL 2012 Page 11-1Andy PhoenixОценок пока нет

- Astm A516 1990Документ5 страницAstm A516 1990Indra Gugun GunawanОценок пока нет

- Sfa-5.01 Filler Metal Procurement GuidelinesДокумент10 страницSfa-5.01 Filler Metal Procurement GuidelinesCesar Agustin LimousinОценок пока нет

- Nut & Bolt ScienceДокумент3 страницыNut & Bolt SciencetanujaayerОценок пока нет

- Inspection & Testing Requirements Scope:: Test and Inspection PerДокумент3 страницыInspection & Testing Requirements Scope:: Test and Inspection PerAli Raza100% (1)

- Ipc2012 90308Документ7 страницIpc2012 90308Marcelo Varejão CasarinОценок пока нет

- Astm 890Документ3 страницыAstm 890bsnegi111Оценок пока нет

- Nom Acero A350a350m.10252Документ10 страницNom Acero A350a350m.10252janethОценок пока нет

- Compipe BrochureДокумент48 страницCompipe Brochureninju1Оценок пока нет

- F2620 PDFДокумент19 страницF2620 PDFAhmad Zubair RasulyОценок пока нет

- Seamless Carbon Steel Boiler Tubes For High-Pressure ServiceДокумент2 страницыSeamless Carbon Steel Boiler Tubes For High-Pressure ServiceChandra ClarkОценок пока нет

- NTSB Pipeline Accident ReportДокумент101 страницаNTSB Pipeline Accident ReportkoushkiОценок пока нет

- ASTM D2467-1999 Accesorios PlasticosДокумент8 страницASTM D2467-1999 Accesorios PlasticosRicardoLauferОценок пока нет

- Eadips Manual Engl PDFДокумент390 страницEadips Manual Engl PDFbkarabasevicОценок пока нет

- A338 Steel StandardДокумент2 страницыA338 Steel StandardguilhermehsssОценок пока нет

- Astm A409 A409m 2001Документ6 страницAstm A409 A409m 2001Roland CepedaОценок пока нет

- A FEDS Structural BoltsДокумент6 страницA FEDS Structural BoltsCrimsonPoshОценок пока нет

- EVS en ISO 16137 2006 en PreviewДокумент11 страницEVS en ISO 16137 2006 en PreviewMohamed MOUKHTARIAОценок пока нет

- ASTM F1545 Plastic Lined Pipe 0803Документ6 страницASTM F1545 Plastic Lined Pipe 0803JabranYounasОценок пока нет

- Process Industry Practices Coatings: PIP CTSL1000 Application of Internal LiningsДокумент23 страницыProcess Industry Practices Coatings: PIP CTSL1000 Application of Internal LiningsSujita Sah100% (1)

- FuturePipe Installation Manual 18-7-05 PDFДокумент25 страницFuturePipe Installation Manual 18-7-05 PDFPaul WoworОценок пока нет

- Sa 961 PDFДокумент10 страницSa 961 PDFaruntpeОценок пока нет

- File - 4houldcroft Weldability Test of Aluminium Alloy EN AW 6082 T6 7 - Part - 254-1Документ8 страницFile - 4houldcroft Weldability Test of Aluminium Alloy EN AW 6082 T6 7 - Part - 254-1Corey DodsonОценок пока нет

- SAIC-P-3005 Rev 3 General - Channel, Strut, and Support Materials - Material ReceivingДокумент3 страницыSAIC-P-3005 Rev 3 General - Channel, Strut, and Support Materials - Material ReceivingShaikh Mohd QaisarОценок пока нет

- U1CДокумент4 страницыU1CAdriana HernandezОценок пока нет

- Jeremias INSTALL DS-GOV PDFДокумент28 страницJeremias INSTALL DS-GOV PDFjudi sierОценок пока нет

- Fab Gate ManualДокумент16 страницFab Gate ManualRahul LavandОценок пока нет

- Iso 14692 4 2017Документ15 страницIso 14692 4 2017Mayara AlvesОценок пока нет

- Brosur Globond Alumunium Composite PanelДокумент8 страницBrosur Globond Alumunium Composite PanelDede SubhanОценок пока нет

- Astmf436 PDFДокумент6 страницAstmf436 PDFMiguel Angel Oncoy TahuaОценок пока нет

- BC 3004 CementДокумент1 страницаBC 3004 CementRAJОценок пока нет

- Spreadsheets To BS 8110: Single Column BaseДокумент25 страницSpreadsheets To BS 8110: Single Column BaseIr Ahmad AfiqОценок пока нет

- BS 7191 1989 - Weldable Structural Steels For Fixed Offshore StructuresДокумент52 страницыBS 7191 1989 - Weldable Structural Steels For Fixed Offshore StructureskkkelvinОценок пока нет

- AWS - WZC D19.0-72 Welding Zinc-Coated SteelДокумент148 страницAWS - WZC D19.0-72 Welding Zinc-Coated Steelarnoldbatista55Оценок пока нет

- Asme Section Ii B SB-42Документ10 страницAsme Section Ii B SB-42Monica SuarezОценок пока нет

- Astm A240 Uns S32205Документ3 страницыAstm A240 Uns S32205Mintone Sajayah BekabekaОценок пока нет

- Garnituri DIN 2697Документ12 страницGarnituri DIN 2697Dumitru SorinaОценок пока нет

- SSPC SP10 PDFДокумент6 страницSSPC SP10 PDFYen Piankin Wee ValenciaОценок пока нет

- BS en 12502-3Документ18 страницBS en 12502-3laboratorium logamОценок пока нет

- Is 4721Документ7 страницIs 4721dak2anshulОценок пока нет

- ISO1133 Melt Volume Flow Rate MVRДокумент2 страницыISO1133 Melt Volume Flow Rate MVRMichele Preghenella100% (1)

- B729Документ3 страницыB729LambertWayneОценок пока нет

- Soft Magnetic Iron Parts Fabricated by Powder Metallurgy (P/M) TechniquesДокумент4 страницыSoft Magnetic Iron Parts Fabricated by Powder Metallurgy (P/M) TechniquesEduardoОценок пока нет

- Hi - Temp 900Документ5 страницHi - Temp 900bhavesh solankiОценок пока нет

- A780 PDFДокумент3 страницыA780 PDFMauricio Adame100% (1)

- Astm A351 2006Документ5 страницAstm A351 2006Almas AthifОценок пока нет

- 229-79577 - EN - 10204 - Type - 3 - 2 - Certification - Services.2 Inspection Certification PDFДокумент2 страницы229-79577 - EN - 10204 - Type - 3 - 2 - Certification - Services.2 Inspection Certification PDFBranza TelemeaОценок пока нет

- Charles E. Smith - Feasibility of Thermite Sparking With Impact of Rusted Steel Onto Aluminum Coated SteelДокумент66 страницCharles E. Smith - Feasibility of Thermite Sparking With Impact of Rusted Steel Onto Aluminum Coated SteelAlarmakОценок пока нет

- Garlock Metal - Gaskets TorqueДокумент48 страницGarlock Metal - Gaskets TorqueakenathorОценок пока нет

- PI Tectyl-506 TE031-01Документ2 страницыPI Tectyl-506 TE031-01nicusebpОценок пока нет

- Nit Xl3t 600 ManualДокумент214 страницNit Xl3t 600 Manualdiaccessltd_17172961Оценок пока нет

- Article On Tofd WaveletДокумент6 страницArticle On Tofd Waveletdiaccessltd_17172961Оценок пока нет

- Skerik Grey Scale Test (v.03)Документ1 страницаSkerik Grey Scale Test (v.03)diaccessltd_1717296175% (4)

- A Guide To Refinery ProcessДокумент35 страницA Guide To Refinery ProcessBalamurugan100% (3)

- OmniSX - MX2 - Training - 16J TOFD Flaw Sizing and CharacterizationДокумент35 страницOmniSX - MX2 - Training - 16J TOFD Flaw Sizing and Characterizationaldeanucu100% (3)

- Procedure Quality Record (PQR)Документ37 страницProcedure Quality Record (PQR)diaccessltd_17172961Оценок пока нет

- DMS Go Plus Operating Manual EnglishДокумент264 страницыDMS Go Plus Operating Manual EnglishvrapciudorianОценок пока нет

- Adp-Me-Spe-8015-000 C1Документ77 страницAdp-Me-Spe-8015-000 C1diaccessltd_17172961Оценок пока нет

- Boiler RbiДокумент65 страницBoiler Rbidiaccessltd_17172961Оценок пока нет

- Electrical Diagram - LQДокумент124 страницыElectrical Diagram - LQdiaccessltd_17172961100% (1)

- Corrosion Under Insulation - Initial Draft (21MAY04)Документ8 страницCorrosion Under Insulation - Initial Draft (21MAY04)diaccessltd_17172961Оценок пока нет

- API5LX 65 Welding SummaryДокумент25 страницAPI5LX 65 Welding Summarydiaccessltd_17172961Оценок пока нет

- ABS Coating GradingДокумент64 страницыABS Coating Gradingdiaccessltd_17172961Оценок пока нет

- 20090201102513Документ160 страниц20090201102513diaccessltd_17172961100% (1)

- Adp-Me-Spe-8014-000 C1Документ76 страницAdp-Me-Spe-8014-000 C1diaccessltd_17172961Оценок пока нет

- Basics of Nitrogen Purging: Siswanto YДокумент22 страницыBasics of Nitrogen Purging: Siswanto Ydiaccessltd_17172961100% (2)

- ELE Chemicals Rev 1Документ21 страницаELE Chemicals Rev 1diaccessltd_17172961Оценок пока нет

- Corrosion Damage Report (CDR)Документ4 страницыCorrosion Damage Report (CDR)diaccessltd_17172961Оценок пока нет

- Corrosion Damage Report (CDR)Документ4 страницыCorrosion Damage Report (CDR)diaccessltd_17172961Оценок пока нет

- Corrosion Damage Report (CDR)Документ4 страницыCorrosion Damage Report (CDR)diaccessltd_17172961Оценок пока нет

- Corrosion Damage Report (CDR)Документ4 страницыCorrosion Damage Report (CDR)diaccessltd_17172961Оценок пока нет

- Corrosion Damage Report (CDR)Документ4 страницыCorrosion Damage Report (CDR)diaccessltd_17172961Оценок пока нет

- Pds Hempel's Silicone Acrylic 56940 En-GbДокумент2 страницыPds Hempel's Silicone Acrylic 56940 En-GbsenthilkumarОценок пока нет

- Heating and Cooling CurveДокумент4 страницыHeating and Cooling CurveADogThat GoesBarkОценок пока нет

- EXPERIMENT 1 Introduction To Chemistry LabДокумент6 страницEXPERIMENT 1 Introduction To Chemistry LabDulce DeОценок пока нет

- MSDS Songnox - 1680Документ8 страницMSDS Songnox - 1680Seshagiri KalyanasundaramОценок пока нет

- WSS-M21P36 10-09-2014Документ4 страницыWSS-M21P36 10-09-2014Ronald AraujoОценок пока нет

- Chapter 4 Light Emitting DiodeДокумент33 страницыChapter 4 Light Emitting DiodeRufiat KhanОценок пока нет

- Four Steps To Effective Pigment Dispersions Jadel Baptista DCC LanscoДокумент5 страницFour Steps To Effective Pigment Dispersions Jadel Baptista DCC LanscoEyad AlsheiikhОценок пока нет

- BHGFGДокумент11 страницBHGFGbsaimukeshreddy 820Оценок пока нет

- 02.01.23 SR - Star Co-Sc (Model-A & B) Jee Main Ctm-2 QPДокумент20 страниц02.01.23 SR - Star Co-Sc (Model-A & B) Jee Main Ctm-2 QPTanay1 MitraОценок пока нет

- Mil-B-007883 Brazing - Cancelled - See Cancellation NoteДокумент26 страницMil-B-007883 Brazing - Cancelled - See Cancellation NoteChris NenovОценок пока нет

- Magpro BrochureДокумент20 страницMagpro BrochuresabiuОценок пока нет

- Hi-Tech Gaskets Catalogue PDFДокумент60 страницHi-Tech Gaskets Catalogue PDFVivek AnandОценок пока нет

- Lab 12 - Bunsen Burner Flame PDДокумент2 страницыLab 12 - Bunsen Burner Flame PDvictoria kairoo50% (2)

- Admira Fusion - VC-84-002750-GB PDFДокумент10 страницAdmira Fusion - VC-84-002750-GB PDFkomanjoeОценок пока нет

- Condorled Reflector Technical SheetДокумент2 страницыCondorled Reflector Technical SheetDiseño Lexu LightОценок пока нет

- Carbohydrates - Specific ReactionsДокумент5 страницCarbohydrates - Specific ReactionsVanessa ParaisoОценок пока нет

- التجربة الثانية الانكسارДокумент3 страницыالتجربة الثانية الانكسارAymen AbdulrahmanОценок пока нет

- HW 3Документ2 страницыHW 3Christina HillОценок пока нет

- PH - Wikipedia, The Free EncyclopediaДокумент11 страницPH - Wikipedia, The Free EncyclopediaShikhar MahajanОценок пока нет

- XS NanoДокумент24 страницыXS NanoAnonymous GgEgellVnU100% (1)

- Gen Chem 2Документ2 страницыGen Chem 2Ream MairОценок пока нет

- Acacia ReactorДокумент11 страницAcacia ReactorPedrin Cha OlivosОценок пока нет

- LOVIBOND Reagents Suited For HachДокумент6 страницLOVIBOND Reagents Suited For HachKacem BenaoumeurОценок пока нет

- CFBC BoilerДокумент7 страницCFBC Boilerkaruna346Оценок пока нет

- Semi-Mechanical Pulping of Napier GrassДокумент98 страницSemi-Mechanical Pulping of Napier GrassAmelyate NamatОценок пока нет

- Question Paper CodeДокумент4 страницыQuestion Paper CodeBalaji ArunОценок пока нет

- Design and Analysis of Gas Turbine BladeДокумент7 страницDesign and Analysis of Gas Turbine BladeFurqanОценок пока нет

- Sl. No. Name of The Sponsor Location Contact NoДокумент12 страницSl. No. Name of The Sponsor Location Contact NoSampath R0% (1)

- Catalyst: Generalized Expression For The Effectiveness Factor of Porous PelletsДокумент3 страницыCatalyst: Generalized Expression For The Effectiveness Factor of Porous PelletsEduardo Antonio Burgos RuidíasОценок пока нет

- MSDS MEGAFLOC 515 Revisi OkДокумент5 страницMSDS MEGAFLOC 515 Revisi OkYafie Al IslamiОценок пока нет

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontОт EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontРейтинг: 4.5 из 5 звезд4.5/5 (18)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionОт EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionРейтинг: 3 из 5 звезд3/5 (1)

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaОт EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaРейтинг: 4 из 5 звезд4/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretОт EverandWaste: One Woman’s Fight Against America’s Dirty SecretРейтинг: 5 из 5 звезд5/5 (1)

- Principles of direct and superior responsibility in international humanitarian lawОт EverandPrinciples of direct and superior responsibility in international humanitarian lawОценок пока нет

- Did Your Can of Soda Kill A Whale? Water Pollution for Kids | Children's Environment BooksОт EverandDid Your Can of Soda Kill A Whale? Water Pollution for Kids | Children's Environment BooksОценок пока нет

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksОт EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksОценок пока нет

- The Rights of Nature: A Legal Revolution That Could Save the WorldОт EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldРейтинг: 5 из 5 звезд5/5 (1)

- Busted!: Drug War Survival Skills and True Dope DОт EverandBusted!: Drug War Survival Skills and True Dope DРейтинг: 3.5 из 5 звезд3.5/5 (7)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionОт Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionОценок пока нет

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933От EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933Оценок пока нет

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontОт EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontРейтинг: 4.5 из 5 звезд4.5/5 (9)

- Environmental Education in Practice: Concepts and ApplicationsОт EverandEnvironmental Education in Practice: Concepts and ApplicationsОценок пока нет

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawОт EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawРейтинг: 4 из 5 звезд4/5 (334)

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksОт EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksОценок пока нет