Академический Документы

Профессиональный Документы

Культура Документы

PHT 3360507

Загружено:

Kartik DesaiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PHT 3360507

Загружено:

Kartik DesaiАвторское право:

Доступные форматы

Pharmaceutical Technology

Course Code: 3360507

GUJARAT TECHNOLOGICAL UNIVERSITY, AHMEDABAD, GUJARAT

COURSE CURRICULUM

COURSE TITLE: PHARMACEUTICAL TECHNOLOGY

(COURSE CODE: 3360507)

Diploma Programme in which this course is offered

Chemical Engineering

Semester in which offered

Sixth

1.

RATIONALE

Gujarat is having more than 30 percent of pharmaceutical production capacity of India.

Medicinal product manufacturing requires special considerations like sterilization, clean

facility development and maintaining strict standards during formulating different dosage.

The content of this subject is designed to enable diploma chemical engineers to develop the

skills required for working in manufacturing of bulk drugs and formulations in special

considerations to comply with standards.

2.

COMPETENCY

The course content should be taught and curriculum should be implemented with the aim to

develop required skills in the students so that they are able to acquire following competency:

Supervise production of drugs following standards for quality and cleanliness.

3.

COURSE OUTCOMES (COs)

The theory should be taught and practical should be carried out in such a manner that students

are able to acquire required learning outcomes in cognitive, psychomotor and affective

domain to demonstrate following course outcomes:

i. Identify appropriate methods in medicine production.

ii. Apply various methods of sterilization.

iii. Use design parameters for clean facilities

iv. Produce different dosage forms.

v. Identify appropriate packaging materials.

4.

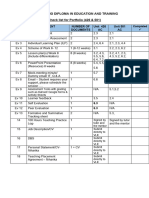

TEACHING AND EXAMINATION SCHEME

Teaching Scheme

(In Hours)

Total Credits

(L+T+P)

Examination Scheme

Theory Marks

Practical Marks

ESE

PA

ESE

PA

70

30

20

30

Legends: L - Lecture; T - Tutorial/Teacher Guided Student Activity; P - Practical;

Credit; ESE - End Semester Examination; PA - Progressive Assessment

GTU/NITTTR/Bhopal/14

Total

Marks

150

C-

Gujarat State

Pharmaceutical Technology

5.

Course Code: 3360507

COURSE CONTENT DETAILS

Unit

Unit I

Basics of

Pharmace

utical

Technolog

y

Major Learning Outcomes

(In Cognitive Domain)

1a. Describe the characteristics of

the Pharmaceutical industries

compared to other industries

1b. Explain the concept of product

standards

1c. Distinguish the different

methods of production

1d. Compare API and formulation

production

2a. Justify the need for in the

Unit II

sterilization pharmaceutical

Sterilizatio

industry

n

2b. Compare methods of

Sterilization, with their

benefits and limitations

2c. Describe the sterile facilities

Topics and Sub-topics

1.1 Characteristics of Pharmaceutical

industries

1.2 Product Standards: IP, BP, USP

1.3 Methods of production, Chemical

synthesis, Isolation from plants,

isolation from animals

1.4 Fermentation

1.5 API and Formulation

2.1 sterility and requirement of sterility,

Concept of sterilization

2.2 Methods of Sterilization with,

applications,

, Heat sterilization,

(a)Steam sterilization, (b) Dry heat

sterilization, Radiation sterilization

Gas sterilization, Filtration sterilization

2.3 Sterile facilities : preparation area,

compounding area, ware housing

Unit III

Clean

Facilities

3a. Describe the important design

parameters for various

processes

3b. Describe Architectural design

issues

Unit IV

Dosage

forms

4a. Describe features of different

types of solid dosage forms

4b. Describe the excipients in

solid dosage forms

4c. Describe features of the semisolid dosage forms

4d. Describe the features of

different types of Gels

4e. Differentiate between Gels,

Commercial Gelling agents

3.1 Design parameters for clean facilities :

Air change rate, Pressurization,

Temperature control, Humidity control

3.2 Architectural design issues : Facility

Layout, Air locks and Pass through,

windows, Gowning room

3c. Select material of construction 3.3 Material of construction for wall, doors,

3d. Explain the concept of clean

ceilings, floors

construction

3.4 Clean construction

3e. Describe HEPA filters

3.5 HEPA filters

4e. Distinguish various liquid

dosage forms

GTU/NITTTR/Bhopal/14

4.1 Solid dosage forms : Tablets, Coated

tablets, Gelatine capsules, Chewable

tablets, Gum based tablets

4.2 Excipients in solid dosage forms

4.3 Semi-Solid dosages : Ointments and

creams,

4.4 Bases for ointments and creams,

4.5 Packaging and storage of ointments and

creams

4.6 Types of Gels, Commercial Gelling

agents

4.7 Liquid dosage forms: Solutions,

Suspensions, Emulsions

Gujarat State

Pharmaceutical Technology

Course Code: 3360507

Unit

Major Learning Outcomes

(In Cognitive Domain)

5a. Differentiate between the

Unit V

manufacturing of tablets and

Manufactu

capsules

ring and

Packaging 5b. Describe packaging and

storage of ointments and

creams

5c. Describe the critical aspects of

liquid manufacturing

5d. Describe the salient features of

different types of packaging

materials

5e. Describe the process of

maintaining the quality control

of packaging materials.

6.

Topics and Sub-topics

5.1 Manufacturing, tablets and capsules

5.2 Packaging and storage of ointments and

creams

5.3 Critical aspects of liquid

manufacturing: particle size of raw

materials, parameters of compounding,

uniformity, stability problems

5.4 Packaging materials: General

considerations, Glass, Plastic and metal

5.5 Quality control of packaging materials

SUGGESTED SPECIFICATION TABLE WITH HOURS and MARKS (THEORY)

Unit

Unit Title

Teaching

Hours

06

Distribution of Theory Marks

R

U

A

Total

Level

Level

Level

Marks

4

4

2

10

Basics of Pharmaceutical

Technology

II

Sterilization

07

3

3

6

12

III

Clean Facilities

07

3

3

6

12

IV

Dosage forms

13

7

7

7

21

V

Manufacturing and

09

5

5

5

15

Packaging

Total

42

22

22

26

70

Legends: R = Remember, U = Understand, A= Apply and above Level (Blooms revised

taxonomy)

Note: This specification table shall be treated as a general guideline for students and teachers.

The actual distribution of marks in the question paper may vary slightly from above table.

7.

SUGGESTED PRACTICAL / EXERCISES

The practical/exercises should be properly designed and implemented with an attempt to develop

different types of skills (outcomes in psychomotor and affective domain) so that students are

able to acquire the competencies/programme outcomes. Following is the list of practical

exercises for guidance.

Note: Here only outcomes mainly in psychomotor domain are listed as practical/exercises.

However, if these practical/exercises are completed appropriately, they would also lead to

development of certain outcomes in affective domain which would in turn lead to development

of Course Outcomes related to affective domain. Thus over all development of Programme

Outcomes (as given in a common list at the beginning of curriculum document for this

programme) would be assured.

Faculty should refer to that common list and should ensure that students also acquire outcomes

GTU/NITTTR/Bhopal/14

Gujarat State

Pharmaceutical Technology

Course Code: 3360507

in affective domain which are required for overall achievement of Programme

Outcomes/Course Outcomes.

S.

No.

Unit

No.

Practical/Exercise

(Outcomes in Psychomotor Domain)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

I

I

I

II

II

III

IV

IV

IV

IV

IV

IV

IV

V

Separate medicine from plant extract

Synthesise pharmaceutical ingredient in laboratory conditions

Prepare pharmaceutical product by fermentation

Preserve milk by application of heat sterilization

Prepare chart of sterilization techniques

Prepare chart of clean facility development

Prepare tablets

Demonstrate some excipients

Prepare ointment product

Prepare cream product

Prepare solution product

Prepare suspension product

Prepare an emulsion product

Prepare some packaging materials/Demonstrate packaging

process for some drug

Total

Approx.

Hours

Required

2

2

4

2

2

2

2

2

2

2

2

2

2

2

30

8.

SUGGESTED STUDENT ACTIVITIES

Following is the list of proposed student activities. These could be individual and group

based.

i. Explore internet, visit websites of reputed pharmaceutical companies and prepare ppt

presentations on different topics (in group of four-five) and present in class

ii. Study (in group of four-five) the design of some real pharmaceutical production plant

and identify good features of design and also weaknesses in it, present in class to have

a group discussion.

iii. Survey market for different types of packaging available for pharmaceutical items and

identify their features (commercial as well medicinal), further explore packaging

processes required for such type of packaging.

9.

i.

ii.

iii.

SPECIAL INSTRCTIONAL STRATEGY (If Any)

Show animations/ videos and drawings/models of pharmaceutical production

processes

Arrange visit to nearby API production plants and formulation plants

Arrange expert lectures.

GTU/NITTTR/Bhopal/14

Gujarat State

Pharmaceutical Technology

Course Code: 3360507

10

SUGGESTED LEARNING RESOURCES

A)

S.

No.

Books

1

2

3

B)

Title of Books

Author

Publication

Pharmaceutical Process

Engineering

Pharmaceutical

Manufacturing

handbook

Good pharmaceutical

Manufacturing practice

Hickey, Anthony

J.;David Ganderton

Marcel Dekker Inc. USA,

2001

Gad, Shayne Cox

John Wiley and Sons, 2008

Sharp, John

CRC press, New York,

2005

Major Equipment/Materials with Broad Specifications

i. Glassware: Conical flask, burette, pipette, round bottom flask, measuring cylinder,

beaker

ii. Glass Assembly: Round bottom flask, condenser, Separating funnel

iii. Burner

iv. Weight balance (minimum 0.1gm)

v. Heating and cooling bath

vi. Refrigerator

C)

i.

ii.

iii.

iv.

11.

Software/Learning Websites

www.pharmaceuticalonline.com

www.pharmaceutical-technology.com

www.pharmamanufacturing.com

www.worldpharmaceuticals.net

COURSE CURRICULUM DEVELOPMENT COMMITTEE

Faculty Members from Polytechnics

Prof. N. N. Hansalia, Lecturer in Chemical Engineering, Government Polytechnic,

Rajkot

Prof R. P. Hadiya, Lecturer in Chemical Engineering, Government Polytechnic,

Rajkot

Prof (Smt.) K. J. Sareriya, Lecturer in Chemical Engineering, Government

Polytechnic, Rajkot

Prof M. R. Aacharya, Lecturer in Chemical Engineering, Government Polytechnic,

Gandhinagar.

Coordinator and Faculty Members from NITTTR Bhopal

Dr. Bashirullah Shaikh, Assistant Professor, Department of Applied Sciences.

Dr. Joshua Earnest, Professor, Department of Electrical & Electronics Engineering.

GTU/NITTTR/Bhopal/14

Gujarat State

Вам также может понравиться

- 3350503Документ2 страницы3350503Kartik Desai100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- GATE 2017 Admit Card: Instructions To The CandidateДокумент1 страницаGATE 2017 Admit Card: Instructions To The CandidateKartik DesaiОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Jivan Samruddhi June 2018Документ1 страницаJivan Samruddhi June 2018Kartik DesaiОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Teacher & School DetailДокумент1 страницаTeacher & School DetailKartik DesaiОценок пока нет

- 3350501Документ5 страниц3350501Kartik DesaiОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Chapter 8 MixingДокумент20 страницChapter 8 MixingKartik DesaiОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- FT 3360501Документ6 страницFT 3360501Kartik DesaiОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- ContentДокумент3 страницыContentKartik DesaiОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Chapter-1 Intro & Properties of Particulate SolidsДокумент11 страницChapter-1 Intro & Properties of Particulate SolidsKartik DesaiОценок пока нет

- Enggquest 2012: N. G. Patel PolytechnicДокумент1 страницаEnggquest 2012: N. G. Patel PolytechnicKartik DesaiОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Enggquest 2012: Who Is Popularly Known As 'Father of Indian Constitution'?Документ15 страницEnggquest 2012: Who Is Popularly Known As 'Father of Indian Constitution'?Kartik DesaiОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Paranjay Practice of ComputerДокумент2 страницыParanjay Practice of ComputerKartik DesaiОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Longman's Encyclopedia - ReptilesДокумент40 страницLongman's Encyclopedia - Reptilesrengachen100% (8)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Course Code: 157 Course Name: Applied Science-I (Physics)Документ10 страницCourse Code: 157 Course Name: Applied Science-I (Physics)Kartik DesaiОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Gujarat Technological University, Ahmedabad.: Engineering Measurements - IДокумент2 страницыGujarat Technological University, Ahmedabad.: Engineering Measurements - IKartik DesaiОценок пока нет

- GTU Winter ExamДокумент4 страницыGTU Winter ExamKartik DesaiОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Contoh Pidato Bahasa InggrisДокумент2 страницыContoh Pidato Bahasa Inggrisalice_dmcОценок пока нет

- Unpacking Learning CompetenciesДокумент16 страницUnpacking Learning CompetenciesAngela BonaobraОценок пока нет

- Davison 2012Документ14 страницDavison 2012Angie Marcela Marulanda MenesesОценок пока нет

- Summer Internship Completion Certificate FormatДокумент1 страницаSummer Internship Completion Certificate FormatNavneet Gupta75% (12)

- Test Manual: English ComprehensionДокумент9 страницTest Manual: English ComprehensionAnonymous EU0KgOEPОценок пока нет

- Armstrong & Hauser 2009Документ30 страницArmstrong & Hauser 2009Sandra Janeth Santacruz SilvaОценок пока нет

- English Vi October 29Документ3 страницыEnglish Vi October 29Catherine RenanteОценок пока нет

- Obembe Adebola's Personal StatementДокумент1 страницаObembe Adebola's Personal Statementeunice bimpeОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Gonzalez SanmamedДокумент14 страницGonzalez SanmamedGuadalupe TenagliaОценок пока нет

- Checklist For Portfolio Evidence (426 & 501) (Final)Документ1 страницаChecklist For Portfolio Evidence (426 & 501) (Final)undan.uk3234Оценок пока нет

- Cambridge International General Certificate of Secondary EducationДокумент16 страницCambridge International General Certificate of Secondary EducationAhmed ZeeshanОценок пока нет

- Volume X Issue X October XXДокумент16 страницVolume X Issue X October XXMaya BabaoОценок пока нет

- DLP DIASS Q2 Week B-D - Functions of Applied Social Sciences 3Документ7 страницDLP DIASS Q2 Week B-D - Functions of Applied Social Sciences 3Paolo Bela-ongОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Curriculum Research in Nursing-Lesson PlanДокумент13 страницCurriculum Research in Nursing-Lesson Planavinash dhameriyaОценок пока нет

- Template - MC SSE 113 Module 2Документ4 страницыTemplate - MC SSE 113 Module 2Zenabi IbañezОценок пока нет

- Hawaii High School Hall of HonorДокумент1 страницаHawaii High School Hall of HonorHonolulu Star-AdvertiserОценок пока нет

- Eligible Candidates List For MD MS Course CLC Round 2 DME PG Counselling 2023Документ33 страницыEligible Candidates List For MD MS Course CLC Round 2 DME PG Counselling 2023Dr. Vishal SengarОценок пока нет

- Recent Trends in CompensationДокумент2 страницыRecent Trends in Compensationhasanshs12100% (1)

- STA228414e 2022 Ks2 English GPS Paper1 Questions EDITEDДокумент32 страницыSTA228414e 2022 Ks2 English GPS Paper1 Questions EDITEDprogtmarshmallow055Оценок пока нет

- Media Information Literacy: Final ExaminationДокумент3 страницыMedia Information Literacy: Final ExaminationRodessa Marie Canillas LptОценок пока нет

- Osborne 2007 Linking Stereotype Threat and AnxietyДокумент21 страницаOsborne 2007 Linking Stereotype Threat and Anxietystefa BaccarelliОценок пока нет

- Planning Manual Punjab PDFДокумент115 страницPlanning Manual Punjab PDFMunir HussainОценок пока нет

- Group Dynamics and Teamwork: Ian GrigorДокумент15 страницGroup Dynamics and Teamwork: Ian GrigorKhabir IslamОценок пока нет

- Knowledge: Skills: Attitude: ValuesДокумент3 страницыKnowledge: Skills: Attitude: ValuesVincent Paul TepaitОценок пока нет

- Assignment 2Документ2 страницыAssignment 2CJ IsmilОценок пока нет

- MQ 63392Документ130 страницMQ 63392neeraj goyalОценок пока нет

- ENGLISH A1 01 Greet People and Introduce YourselfДокумент15 страницENGLISH A1 01 Greet People and Introduce YourselfNayaraОценок пока нет

- Babcock University Bookshop An Babcock University BookshopДокумент11 страницBabcock University Bookshop An Babcock University BookshopAdeniyi M. AdelekeОценок пока нет

- Carnap, R. (1934) - On The Character of Philosophical Problems. Philosophy of Science, Vol. 1, No. 1Документ16 страницCarnap, R. (1934) - On The Character of Philosophical Problems. Philosophy of Science, Vol. 1, No. 1Dúber CelisОценок пока нет

- Approach Method TechniqueДокумент2 страницыApproach Method TechniquenancyОценок пока нет