Академический Документы

Профессиональный Документы

Культура Документы

Week 2 Tutorial Solutions

Загружено:

duraton94Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Week 2 Tutorial Solutions

Загружено:

duraton94Авторское право:

Доступные форматы

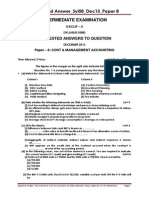

Question 7-3

Value engineering is a systematic evaluation of all aspects of the value-chain business functions,

with the objective of reducing costs while satisfying customer needs. Value engineering via

improvement in product and process designs is a principal technique that companies use to achieve

target costs per unit.

Question 7.11

The downward demand spiral occurs when full costing is used as a basis for pricing, causing an

increase in price when demand for a companys product falls. The price therefore exceeds those of

competitors products and demand consequently drops further. Higher and higher unit costs result

in still less competitive prices, hence the downward demand spiral. Pricing decisions need to

consider competitors and customers as well as costs.

Exercise 7-17 Target operating profit value-added costs, service company

1.

The classification of total costs in 2014 into value-added, non-value-added, or in the grey area in

between follows:

Value

Added

(1)

Grey

Area

(2)

Doing calculations and preparing drawings

75% A$400 000

A$300 000

Checking calculations and drawings

4% A$400 000

A$16 000

Correcting errors found in drawings

7% A$400 000

Making changes in response to client

requests 6% A$400 000

24 000

Correcting errors to meet government

building code, 8% A$400 000

Total professional labour costs

324 000

16 000

Administrative and support costs at 40%

(A$160 000 A$400 000) of professional

labour costs

129 600

6 400

Travel

18 000

Total

A$471 600 A$22 400

Non-valueTotal

added

(4) =

(3)

(1)+(2)+(3)

A$300 000

16 000

A$28 000

28 000

24 000

32 000

60 000

24 000

A$84 000

32 000

400 000

160 000

18 000

A$578 000

Doing calculations and responding to client requests for changes are value-added costs because

customers perceive these costs as necessary for the service of preparing architectural drawings.

Costs incurred on correcting errors in drawings and making changes because they were

inconsistent with building codes are non-value-added costs. Customers do not perceive these costs

as necessary and would be unwilling to pay for them. Stratum should seek to eliminate these costs

by making sure that all associates are well-informed regarding building code requirements and by

training associates to improve the quality of their drawings. Checking calculations and drawings is

in the grey area (some, but not all, checking may be needed). There is room for disagreement on

these classifications. For example, checking calculations may be regarded as value added.

Reduction in professional labour-hours by

a. Correcting errors in drawings (7% 8 000)

b. Correcting errors to conform to building code (8% 8 000)

Total

Cost savings in professional labour costs (1 200 hours A$50)

Cost savings in variable administrative and support

costs (40% A$60 000)

Total cost savings

Current operating profit in 2014

560 hours

640 hours

1 200 hours

A$ 60 000

24 000

A$ 84 000

A$322 000

1

Add cost savings from eliminating errors

Operating profit in 2014 if errors eliminated

84 000

A$406 000

3.

Currently 85% 8000 hours = 6800 hours are billed to clients generating revenues of

A$900 000. The remaining 15% of professional labour-hours (15% 8000 = 1200 hours) is lost in

making corrections. Stratum bill clients at the rate of A$900 000 6800 = A$132.35 per

professional labour-hour. If the 1200 professional labour-hours currently not being billed to clients

were billed to clients, Stratum revenues would increase by 1200 hours A$132.35 = A$158 824

from A$900 000 to A$1 058 824.

Costs remain unchanged

Professional labour costs

Administrative and support (40% A$400 000)

Travel

Total costs

Stratum operating profit would be

Revenues

Total costs

Operating profit

A$400 000

160 000

18 000

A$578 000

A$1 058 824

578 000

A$480 824

Exercise 7-19 Target costs, effect of product-design changes on product costs

1. and 2. Manufacturing costs of HJ6 in 2014 and 2015 are as follows:

2014

Total (1)

Direct materials

A$1 2003 500;

A$1 1004 000

Batch-level costs

A$8 00070;

A$7 50080

Manuf.

operations costs

A$5521 000;

A$5022 000

Engineering

change costs

A$12 00014;

A$10 00010

Total

3.

4 200 000

560 000

2015

Per unit (2)

=(1)/ 3 500

Per unit (4) =

Total (3) (3)/

4 000

1 200 4 400 000

160

1 100

600 000

150

1 155 000

330 1 100 000

275

168 000

6 083 000

48

100 000

1 738 6 200 000

25

1 550

Target manuf. cost per unit of HJ6 in 2015 = Manuf. cost per unit in 201490%

= A$17380.90

= A$1564.20

Actual manufacturing cost per unit of HJ6 in 2015 was A$1550. Hence, Medical

Instruments did achieve its target manufacturing cost per unit of A$1564.20.

4. To reduce the manufacturing cost per unit in 2015, Medical Instruments reduced the

cost per unit in each of the four cost categoriesdirect materials costs, batch-level costs,

manufacturing operations costs and engineering change costs. It also reduced machinehours and number of engineering changes madethe quantities of the cost drivers. In

2014, Medical Instruments used 6 machine-hours per unit of HJ6 (21 000 machine-hours

3500 units). In 2015, Medical Instruments used 5.5 machine-hours per unit of HJ6 (22

000 machine-hours 4000 units). Medical Instruments reduced engineering changes

from 14 in 2014 to 10 in 2015. Medical Instruments achieved these gains through value

engineering activities that retained only those product features that customers wanted

while eliminating non-value-added activities and costs.

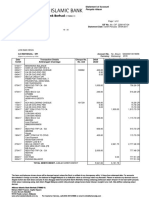

Problem 7-28 Capacity concepts, effect on operating profit

1.

Capacity Concept

Theoretical capacity

Practical capacity

Budgeted Fixed

Manuf.

Overhead per

Period

(2)

(3)

360

350

24

20

28 000 000

350

20

14 000 000

14 000 000

175

175

20

20

Barrels

per

Hour

Budgeted

Budgeted Fixed

Manufacturing

Denominator

Level (Barrels)

Overhead Rate

per Barrel

(5) = (2)

Theoretical capacity

Practical capacity

Normal capacity

utilisation

Master-budget utilisation

(a) January-June 2009

(b) July-December 2009

Hours of

Production

per Day

(1)

A$28 000 000

28 000 000

Normal capacity utilisation

Master-budget utilisation

(a) January-June 2015

(b) July-December 2015

Capacity Concept

Days of

Production

per Period

(4)

540

500

(3)

(4)

4 665 600

3 500 000

(6) = (1) (5)

A$ 6.00

8.00

400

2 800 000

10.00

320

480

1 120 000

1 680 000

12.50

8.33

The differences arise for several reasons:

a. The theoretical and practical capacity concepts emphasise supply factors,

while normal capacity utilisation and master-budget utilisation emphasise

demand factors.

b. The two separate six-month rates for the master-budget utilisation concept

differ because of seasonal differences in budgeted production.

2.

Using column (6) from above,

Per Barrel

Budgeted

Fixed Mfg.

Overhead

Rate per Barrel

(6)

Capacity

Concept

Theoretical

capacity

Practical capacity

Normal capacity

utilisation

Capacity Concept

Theoretical capacity

Budgeted

Total Mfg

Cost Rate

(8) =

(6) + (7)

Budgeted

Variable Mfg.

Cost Rate

(7)

A$6.00

A$30.20a

A$36.20

30.2

38.2

10

30.2

40.2

Fixed

Mfg. Overhead

Variance

(10) =

A$27 088 000 (9)

Fixed Mfg.

Overhead

Costs Allocated

(9) =

2 600 000 (6)

A$15 600 000

A$11 488 000

Practical capacity

20 800 000

6 288 000

Normal capacity utilisation

26 000 000

1 088 000

A$78 520 000

2 600 000 barrel

Absorption-Costing Income Statement

Theoretical

Capacity (a)

Practical

Capacity (b)

Normal

Capacity

Utilisation (c)

Revenues (2 400 000 barrel

A$45 per barrel)

Cost of goods sold

Beginning inventory

Variable mfg. costs

Fixed mfg. overhead costs

allocated

A$108 000 000

A$108 000 000

A$108 000 000

0

78 520 000

0

78 520 000

0

78 520 000

15 600 000

20 800 000

26 000 000

94 120 000

99 320 000

104 520 000

7 240 000

7 640 000

8 040 000

11 488 000 U

98 368 000

9 632 000

0

A$ 9 632 000

6 288 000 U

97 968 000

10 032 000

0

A$ 10 032 000

1 088 000 U

97 568 000

10 432 000

0

A$ 10 432 000

(2 600 000 units

A$6.00; A$8.00; A$10.00

per unit)

Cost of goods available

for sale

Deduct ending inventory

(200 000 units

A$36.20; A$38.20;

A$40.20 per unit)

Add: Adjustment for

variances (all unfavourable)

Cost of goods sold

Gross margin

Other costs

Operating income

Вам также может понравиться

- Managerial Accounting Quiz 3 - 1Документ8 страницManagerial Accounting Quiz 3 - 1Christian De LeonОценок пока нет

- FInal Exam KeyДокумент27 страницFInal Exam KeyQasim AtharОценок пока нет

- Muthoot FinanceДокумент66 страницMuthoot Financesheetalrahuldewan80% (5)

- SolutionДокумент5 страницSolutionNur Aina Safwani ZainoddinОценок пока нет

- PART A: Compulsory Question: MSC Finance Uow PMC Marking Scheme SUMMER 2011Документ8 страницPART A: Compulsory Question: MSC Finance Uow PMC Marking Scheme SUMMER 2011pinkwine2001Оценок пока нет

- Tutorial 4Документ6 страницTutorial 4FEI FEIОценок пока нет

- BMGT 321 Chapter 13 HomeworkДокумент11 страницBMGT 321 Chapter 13 Homeworkarnitaetsitty100% (1)

- Paper - 4: Cost Accounting and Financial ManagementДокумент20 страницPaper - 4: Cost Accounting and Financial ManagementdhilonjimyОценок пока нет

- FInal Exam KeyДокумент27 страницFInal Exam KeyQasim AtharОценок пока нет

- FInal Exam KeyДокумент27 страницFInal Exam KeyQasim AtharОценок пока нет

- 2006 LCCI Cost Accounting Level 2 Series 4 Model AnswersДокумент15 страниц2006 LCCI Cost Accounting Level 2 Series 4 Model AnswersHon Loon SeumОценок пока нет

- Chapter 2 Activity Based Costing: 1. ObjectivesДокумент13 страницChapter 2 Activity Based Costing: 1. ObjectivesNilda CorpuzОценок пока нет

- SP21 CH5 Practice QuizДокумент4 страницыSP21 CH5 Practice QuizJudith GarciaОценок пока нет

- Week 3 Workshop Exercise SolutionsДокумент6 страницWeek 3 Workshop Exercise SolutionsJenDNg100% (1)

- Week 10 ExercisesДокумент2 страницыWeek 10 ExercisesZaki Al MadaniОценок пока нет

- ACCA F5 Revision Mock June 2013 ANSWERS Version 5 FINAL at 25 March 2013Документ20 страницACCA F5 Revision Mock June 2013 ANSWERS Version 5 FINAL at 25 March 2013Shahrooz Khan0% (1)

- Management Accounting: Level 3Документ18 страницManagement Accounting: Level 3Hein Linn Kyaw100% (3)

- Activity Based Costing Spring 2020 Answers Final - pdf-1Документ20 страницActivity Based Costing Spring 2020 Answers Final - pdf-1b21fa1201Оценок пока нет

- CA FINAL AMA Nov 14 Guideline Answers 15.11.2014Документ16 страницCA FINAL AMA Nov 14 Guideline Answers 15.11.2014Prateek MadaanОценок пока нет

- Week 5 - BUS 5431 - HomeworkДокумент9 страницWeek 5 - BUS 5431 - HomeworkSue Ming FeiОценок пока нет

- 8508 Managerial AccountingДокумент10 страниц8508 Managerial AccountingHassan Malik100% (1)

- Cost Management Problems CA FinalДокумент131 страницаCost Management Problems CA Finalmj192100% (1)

- Maf Mock 01 Q& AДокумент31 страницаMaf Mock 01 Q& ASahan Randheera Perera100% (1)

- Management Accounting/Series-3-2007 (Code3023)Документ15 страницManagement Accounting/Series-3-2007 (Code3023)Hein Linn Kyaw100% (1)

- Cpa Questions Part XДокумент10 страницCpa Questions Part XAngelo MendezОценок пока нет

- Gujarat Technological University: InstructionsДокумент4 страницыGujarat Technological University: InstructionsSnehalkumar PatelОценок пока нет

- Finals SolutionsДокумент9 страницFinals Solutionsi_dreambig100% (3)

- CUACM 413 Tutorial QuestionsДокумент31 страницаCUACM 413 Tutorial Questionstmash3017Оценок пока нет

- Lsbf.p4 Mock QuesДокумент21 страницаLsbf.p4 Mock Quesjunaid-chandio-458Оценок пока нет

- F5 RevДокумент69 страницF5 Revpercy mapetereОценок пока нет

- ABC CostingДокумент5 страницABC CostingMike RobmonОценок пока нет

- Chapter 8Документ71 страницаChapter 8MAN HIN NGAI100% (2)

- Module Code: PMC Module Name: Performance Measurement & Control Programme: MSC FinanceДокумент9 страницModule Code: PMC Module Name: Performance Measurement & Control Programme: MSC FinanceRenato WilsonОценок пока нет

- P1 March2014 AnswersДокумент14 страницP1 March2014 AnswersGabriel KorleteyОценок пока нет

- Chapter 4 Exercises 1-8Документ9 страницChapter 4 Exercises 1-8deniz turkbayragiОценок пока нет

- Economic Analysis of Industrial Projects: Allied Technical CorporationДокумент4 страницыEconomic Analysis of Industrial Projects: Allied Technical CorporationJoselito DaroyОценок пока нет

- Introduction To Marginal CostingДокумент29 страницIntroduction To Marginal CostingUdaya ChoudaryОценок пока нет

- Suggested Answer - Syl08 - Dec13 - Paper 8 Intermediate ExaminationДокумент13 страницSuggested Answer - Syl08 - Dec13 - Paper 8 Intermediate ExaminationBalaji RajagopalОценок пока нет

- HorngrenIMA14eSM ch13Документ73 страницыHorngrenIMA14eSM ch13Piyal Hossain100% (1)

- Part A: Managerial Accounting Assessment - ACC720 - March 2020Документ4 страницыPart A: Managerial Accounting Assessment - ACC720 - March 2020Helmy YusoffОценок пока нет

- Tamper DataДокумент191 страницаTamper Dataشايك يوسفОценок пока нет

- MA Final Exam Prep Sample 4 PDFДокумент18 страницMA Final Exam Prep Sample 4 PDFbooks_sumiОценок пока нет

- t4 2008 Dec QДокумент8 страницt4 2008 Dec QShimera RamoutarОценок пока нет

- Mac Midterm ExamДокумент5 страницMac Midterm ExamBEA CATANEOОценок пока нет

- Question - Parallel Quiz - Final Term - Cost Accounting 22 - 23Документ6 страницQuestion - Parallel Quiz - Final Term - Cost Accounting 22 - 23Gistima Putra JavandaОценок пока нет

- P.7 - Cost AccumulationДокумент8 страницP.7 - Cost AccumulationSaeed RahamanОценок пока нет

- ACCT 434 Final Exam (Updated)Документ12 страницACCT 434 Final Exam (Updated)DeVryHelpОценок пока нет

- Cost Accounting 15th Edition Horngren Test BankДокумент60 страницCost Accounting 15th Edition Horngren Test Bankantiloquyillesivepch100% (31)

- F5-Test1 (Costing)Документ7 страницF5-Test1 (Costing)Amna HussainОценок пока нет

- Ch5 LimitingFactorsДокумент19 страницCh5 LimitingFactorsali202101Оценок пока нет

- Cost Accounting: Time Allowed: Two Hours Max. Marks: 165Документ4 страницыCost Accounting: Time Allowed: Two Hours Max. Marks: 165hj3012Оценок пока нет

- Accounting Techniques For Decision MakingДокумент24 страницыAccounting Techniques For Decision MakingRima PrajapatiОценок пока нет

- AY 201 2013 EXAMINATION: 1. This Paper Consists of 6 Pages (Excluding Cover Page)Документ8 страницAY 201 2013 EXAMINATION: 1. This Paper Consists of 6 Pages (Excluding Cover Page)Chew Hong KaiОценок пока нет

- E 3Документ7 страницE 3MianAsrarUlHaqОценок пока нет

- Unit2 MultiДокумент39 страницUnit2 MultiStacy BenОценок пока нет

- BhaДокумент25 страницBharishu jainОценок пока нет

- Management AccountingДокумент21 страницаManagement AccountingbelladoОценок пока нет

- Management Accounting Strategy Study Resource for CIMA Students: CIMA Study ResourcesОт EverandManagement Accounting Strategy Study Resource for CIMA Students: CIMA Study ResourcesОценок пока нет

- Values & System ThinkingДокумент4 страницыValues & System Thinkingduraton94Оценок пока нет

- Presentation QUESTION SOLUTIONSДокумент1 страницаPresentation QUESTION SOLUTIONSduraton94Оценок пока нет

- ACCY312 Week 6 Tutorial SolutionsДокумент5 страницACCY312 Week 6 Tutorial Solutionsduraton94Оценок пока нет

- ACCY312 Week 3 Tutorial SolutionsДокумент4 страницыACCY312 Week 3 Tutorial Solutionsduraton94Оценок пока нет

- ACCY312 Week 4 Tutorial SolutionsДокумент3 страницыACCY312 Week 4 Tutorial Solutionsduraton94Оценок пока нет

- ACCY200 Tutorial Solutions Week 8Документ10 страницACCY200 Tutorial Solutions Week 8duraton94Оценок пока нет

- InvictusДокумент3 страницыInvictusduraton94100% (1)

- Dac 318 AssignmentДокумент6 страницDac 318 AssignmentLenny MuttsОценок пока нет

- A Great Volatility TradeДокумент3 страницыA Great Volatility TradeBaljeet SinghОценок пока нет

- CH 21Документ9 страницCH 21Rica Raditiya0% (1)

- 5 - Allied Thread v. City of Manila G.R. No. L-40296 November 21, 1984Документ1 страница5 - Allied Thread v. City of Manila G.R. No. L-40296 November 21, 1984Pam Otic-ReyesОценок пока нет

- Breach of Obligation - Vasquez V Ayala Corporation Case DigestДокумент2 страницыBreach of Obligation - Vasquez V Ayala Corporation Case DigestKyra Sy-Santos100% (2)

- Student Coin WhitepaperДокумент28 страницStudent Coin WhitepaperBorsa SırlarıОценок пока нет

- Chapter 4 Branch AccountingДокумент17 страницChapter 4 Branch Accountingkefyalew TОценок пока нет

- Amarpali NoticeДокумент4 страницыAmarpali NoticeSharjeel AhmadОценок пока нет

- CH 02Документ23 страницыCH 02Nurhidayati HanafiОценок пока нет

- Quizzes - Topic 5 - Impairment of Asset - Attempt ReviewДокумент11 страницQuizzes - Topic 5 - Impairment of Asset - Attempt ReviewThiện Phát100% (1)

- Departmental Interpretation and Practice Notes No. 34 (Revised)Документ14 страницDepartmental Interpretation and Practice Notes No. 34 (Revised)Difanny KooОценок пока нет

- Fibonacci Price Projections PDFДокумент24 страницыFibonacci Price Projections PDFquan lyhongОценок пока нет

- Data ShortДокумент5 страницData Shortgk concepcion0% (1)

- Sn53sup 20170430 001 2200147134Документ2 страницыSn53sup 20170430 001 2200147134Henry LowОценок пока нет

- Deepak NitriteДокумент169 страницDeepak NitriteTejendra PatelОценок пока нет

- Solutions (Chapter14)Документ7 страницSolutions (Chapter14)Engr Fizza AkbarОценок пока нет

- Proceeding UGEFIC 2021Документ552 страницыProceeding UGEFIC 2021Saya100% (1)

- The Garden PlaceДокумент2 страницыThe Garden Placeaayushi dubeyОценок пока нет

- Let MathДокумент6 страницLet MathJanin R. CosidoОценок пока нет

- A CASE STUDY OF EVEREST BANK LIMITED Mbs ThesisДокумент74 страницыA CASE STUDY OF EVEREST BANK LIMITED Mbs Thesisशिवम कर्ण100% (1)

- Caplin Point An Attractive BetДокумент2 страницыCaplin Point An Attractive BetSivasankaran KannanОценок пока нет

- Materiality Matrix BCAДокумент1 страницаMateriality Matrix BCAGalla GirlОценок пока нет

- Name: Nurul Sari NIM: 1101002048 Case 7.1 7.2 7.7: Case 7.1: Investment Center Problems (A)Документ4 страницыName: Nurul Sari NIM: 1101002048 Case 7.1 7.2 7.7: Case 7.1: Investment Center Problems (A)Eigha apriliaОценок пока нет

- YFC Projects - R-28062017Документ5 страницYFC Projects - R-28062017vinay durgapalОценок пока нет

- Money and Output: Correlation or Causality?: Scott FreemanДокумент7 страницMoney and Output: Correlation or Causality?: Scott FreemanRicardo123Оценок пока нет

- Departmental Directory IncometaxДокумент362 страницыDepartmental Directory IncometaxShubham SinuОценок пока нет

- Lydia Sumipat v. Brigido BangaДокумент2 страницыLydia Sumipat v. Brigido BangaRosanne SoliteОценок пока нет

- Gea Annual Report 2018 Tcm11 52655Документ256 страницGea Annual Report 2018 Tcm11 52655geniusMAHIОценок пока нет

- IM ACCO 20173 Business and Transfer Taxes Module 5 PDFДокумент5 страницIM ACCO 20173 Business and Transfer Taxes Module 5 PDFMakoy BixenmanОценок пока нет