Академический Документы

Профессиональный Документы

Культура Документы

Commissionning of Atlantic LNG Plant-Passingthebaton

Загружено:

saminasritnОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Commissionning of Atlantic LNG Plant-Passingthebaton

Загружено:

saminasritnАвторское право:

Доступные форматы

RETURN TO MAIN MENU (Click Here)

GASTECH 2000

Passing the Baton Cleanly

F.W. Richardson

Bechtel Commissioning/Start-Up Manager

P. Hunter

Bechtel Deputy Commissioning/Start-Up Manager

T. Diocee

Atlantic LNG Commissioning/Start-Up Manager

J. Fisher

Phillips Petroleum Company Commissioning/Start-Up Senior Engineer

RETURN TO MAIN MENU (Click Here)

Passing the Baton Cleanly

Commissioning & Start-Up of the Atlantic LNG Project in Trinidad

F.W. Richardson

Bechtel Commissioning/Start-Up Manager

P. Hunter

Bechtel Deputy Commissioning/Start-Up Manager

T. Diocee

Atlantic LNG Commissioning/Start-Up Manager

J. Fisher

Phillips Petroleum Company Commissioning/Start-Up Senior Engineer

Introduction

Atlantic LNG Company of Trinidad & Tobago has been successfully operating a single-train LNG plant

in the Atlantic region since the facility was taken over from Bechtel International on June 14th, 1999.

The Project was completed one month ahead of schedule and was under budget. The plant performed

favorably against guarantee rates for LNG production and fuel gas consumption during and after the

performance test. The facility has been supplying LNG to buyers, Cabot LNG Corporation in the United

States and Enagas in Spain utilizing minimal expatriate staff and maximizing national operations and

maintenance staff.

The following paper is a review of the commissioning, start-up and operation of the Atlantic LNG

facilities located at Point Fortin in Trinidad. The main objective of the paper is to highlight the activities

that took place during the commissioning, start-up and operation of the plant allowing final hand over to

the client Atlantic LNG before contractually specified turn over dates. The paper also explains the

performance of the plant since final hand over and highlights the benefits of using the LSTK (Lump Sum

Turn Key) approach where the contractor is responsible for the commissioning, start-up and operation of

the plant until performance test requirements have been met. The paper explains how the transfer of

responsibility for operating the plant from the contractor to the owner after completion of performance

testing can be accomplished in a seamless manner. This approach enabled a very clean break between the

contractor and the owner when the plant was handed over. There were significant benefits to both parties

when this approach was used. The owner got the benefit of a plant that was in operation, had been proven

and had all the little wrinkles ironed out. The owner did not have to go chasing the contractor for

assistance with work items during the commissioning and start-up phases, as this was still the contractors

responsibility. The contractor also benefited from this by allowing a very clean break from the project

having resolved the majority of punch list items thereby allowing a definitive schedule for

demobilization of personnel and equipment.

As in a relay race, success depends on a clean passing of the baton from one member of the team to the

next. In the case of the Atlantic LNG project a fully integrated team from Bechtel, Phillips and ALNG

was formed very early in the project. This team worked together throughout the different phases of the

commissioning, start-up and operation of the LNG plant. All members of the team were fully involved in

the development of all required procedures and the training program.

2

This paper has been republished with the permission of GasTech 2000.

RETURN TO MAIN MENU (Click Here)

The paper explains the development of the intensive training program that was jointly developed by

Bechtel and Phillips and benefited all members of the integrated team. It also highlights the staffing

strategy used by all parties in the team and the involvement of the ALNG personnel in the integrated

team. This enabled the management of ALNG to operate the plant from hand over with a bare minimum

of expatriate support. The paper also highlights details of the problems encountered during start-up and

explains how those problems were resolved. It gives details of the simplicity and ease of plant operation

from an operators perspective. The paper closes with a brief explanation of the plant operation since

final hand over to Atlantic LNG on June 14, 1999 and plans for the future expansions and debottlenecking of existing facilities.

Process Description

Inlet Area and Gas Treating

Natural gas from BPs offshore fields is supplied to Atlantic LNG via a 40 offshore pipeline and a 36

onshore pipeline. Feed gas enters the facility through a slug catcher where the vapor and liquid streams

are separated. The onshore pipeline is pigged once a month. The liquid stream is stabilized and is

exported offsite for further processing. The vapor stream is metered and filtered prior to entering the gas

sweetening system where the CO2 is removed. Diglycolamine (DGA) was selected as the solvent for the

gas sweetening process due to low CO2/H2S concentrations in the feed gas and no other sulfur

components (refer to figure 3). The acid gases CO2/H2S and any incidentally removed hydrocarbon

components are safely disposed of by incineration. Treated gas from the amine system is fed to mol sieve

dehydrators where the water vapor is removed down to 0.1 ppm H2O utilizing 4A molecular sieve. Dry

gas from the dehydrators is further processed through activated carbon bed to remove any mercury that

may be in the feed gas.

Refrigeration and Liquefaction

The treated gas is fed to the liquefaction unit where it is cooled and sub-cooled prior to entering the LNG

tanks. The liquefaction system utilizes the Phillips Optimized Cascade LNG Process, a modification of

the original Phillips LNG plant design at Kenai, Alaska. This process uses three pure refrigerants propane, ethylene and methane circuits cascaded to provide maximum LNG production by utilizing the

horsepower available from 6 Frame 5C gas turbines. Each refrigerant circuit uses two 50% compressors

with common process equipment. The compressor/turbine packages are manufactured by Nuovo

Pignone. Brazed Aluminum Heat Exchangers and Core-Kettle Exchangers were selected for feed gas,

propane, ethylene and methane refrigeration circuits. All of these heat exchangers with the exception of

the propane chillers are housed in two Cold Boxes. All compressor inter-cooling, after-cooling and

propane refrigerant condensing is provided by fin-fan heat exchangers. The LNG from the last stage flash

drum is pumped to the LNG tanks where it is stored at 70 mbar and 160.6 o C.

Fractionation

Fractionation is provided to remove heavy components from the feed gas to prevent freezing in the

liquefaction process and to recover 70% of the propane and heavier hydrocarbon components. The NGL

stream is exported to a fractionation facility on the island for further fractionation into propane, butane

and condensate.

3

This paper has been republished with the permission of GasTech 2000.

RETURN TO MAIN MENU (Click Here)

Figure 1: Block Diagram

ATLANTIC LNG SIMPLIFIED PROCESS FLOW

FUEL

GAS

PROPANE

SYSTEM

INLET

FEED

INLET

SEPARATION

AND NGL

RECOVERY

GAS

TREATMENT

ETHYLENE

SYSTEM

METHANE

SYSTEM

LIQUEFACTION

VAPORS FROM

STORAGE AND

LOADING

LNG

STORAGE

NGL

STORAGE

TO NGL

PIPELINE

TO LNG

TANKER

Figure 2: Gas Sweetening System DGA

TREATED GAS

ACID GAS TO

INCINERATOR

TREATED GAS

KNOCKOUT DRUM

HYDROCARBONS

TO FLARE

MAKE UP

WATER

FEED

GAS

CO2 ABSORBER

SOLVENT REGENERATOR

LEAN / RICH

SOLVENT

HEAT

EXCHANGER

TO FUEL

GAS

SOLVENT

FLASH

DRUM

HOT OIL

RICH

SOLVENT

FILTER

4

This paper has been republished with the permission of GasTech 2000.

RETURN TO MAIN MENU (Click Here)

Figure 3: Phillips Optimized Cascade LNG Process

Utilities

The utilities required to support the main process are simple and small in size. The major utilities are:

Power generation - three Solar Mars units are utilized

Hot Oil system - two 60% indirect forced air heaters

Firewater System

Instrument Air System - bleed air from power generators with one standby air compressor

Nitrogen System - one membrane N2 generation unit with two liquid N2 units

Demineralization Package - water makeup to Amine system and water for turbine washes

Refrigerant Storage - propane and ethylene storage

Cooling Water - cooling water system for turbine/compressor packages

Flare systems consist of three separate systems, wet, dry and marine

Incinerator disposal of acid gases from amine regenerator

5

This paper has been republished with the permission of GasTech 2000.

RETURN TO MAIN MENU (Click Here)

Commissioning & Start-up

Operator Training

The permanent plant operations staff was hired by Atlantic LNG sufficiently early in the project to ensure

class room training could be provided prior to commissioning and start-up activities. Due to the large

industrial base in Trinidad and Tobago a good selection of candidates with some relevant experience was

available. Since Bechtel was responsible for starting up the plant and the initial operations until plant

hand over to Atlantic LNG, experienced expatriate operations staff were hired. Nationals were also hired

by Bechtel to work with the experienced Bechtel staff during commissioning and start-up. Many of the

nationals were then hired by Atlantic LNG which facilitated technology transfer following hand over.

Bechtel was responsible for providing class room training which consisted of equipment theory, plant

functions and layout, Phillips Optimized Cascade LNG Process, mechanical design, safety concerns, plant

start-up and operation and facility troubleshooting. Personnel with operating and engineering experience

from Phillips Kenai LNG plant provided training based on first hand experience and knowledge of the

long term successful operation of the Kenai facility. Field visits were included as part of the training. A

number of Atlantic LNG operating, maintenance and supervisory personnel trained at Kenai to observe

actual shutdown, start-up and turnaround procedures of a plant in operation. Vendors of critical

equipment such as Solar generators, Altec, Nuovo Pignone, Honeywell and FMC provided additional

operations training.

Once the classroom training was completed Atlantic LNG operations staff with the exception of

maintenance personnel were handed over to Bechtel. This arrangement provided Bechtel with additional

staff for commissioning and start-up activities and provided Atlantic LNG with staff trained in the

operation of the LNG facility.

Milestones

Construction of the facility began in August 1996. Most of the utilities were commissioned by October

1998 to allow the introduction of the hydrocarbons into the inlet area up to the pig receiver for supplying

fuel gas to the power generators. The offshore and onshore pipelines were commissioned in October

1998. The following outlines the commissioning and startup milestones:

Power generators were started up - November 1998.

Start loading ethylene into storage tanks December 1998

Wet flare system started January 1999

Inlet area pressured up January 1999

HP/LP Fuel gas systems started up - January 1999

Hot Oil system started up February 1999

Amine system commissioned February 1999

Cooling water system started up February 1999

Perform Solo & Mechanical runs on Turbine/compressor packages February 1999

Start loading propane into storage tanks February 1999

Startup molecular sieve dryers February 1999

Dry out liquefaction process system March 1999

Purge and dry out LNG tank 1 March 1999

Startup refrigeration compressors March 1999

Cool down process March 1999

6

This paper has been republished with the permission of GasTech 2000.

RETURN TO MAIN MENU (Click Here)

Make LNG March 1999

Cool down LNG Tank 1 April 1999

Load 1st LNG Tanker Mathew April 1999

Cool down LNG Tank 2 April 1999

Complete Performance Test June 14, 1999

Lessons Learned

During commissioning and start-up of the facilities a number of problems were encountered. The nature

and number of the problems was not inconsistent with those one might expect from a project of this size.

Some of these problems are highlighted here.

During commissioning operations in December 1999 a flashback occurred at the dry gas flare

knockout drum causing damage to the vessel and some of the piping.

Spiral wound gaskets had to be changed from single ring CG type to double ring CGI type

Modifications had to be made to some valve trims to improve operations

Propane Chillers

dislodged 3 de-mister pad panels

modified inlet liquid nozzles

modified weir heights

Hydraulic bottlenecks

Replace molecular sieve due to amine carry over

Drier support beds modified

Welding dams in LNG loading lines/vapor lines

Three weld failures

Despite these problems the start-up team was able to find and implement solutions and finish the project

ahead of schedule without compromising safety of the start-up or long term plant operations. The value

of these experiences will be realized when lessons learned as a result of knowledge gained are applied to

design and operations improvements on the future trains.

PerformanceTesting

The contract between Bechtel and Atlantic LNG was truly Turn Key. Bechtel was required to supply

all operating, maintenance, safety, technical support and supervisory personnel for the safe start-up and

initial operation of the plant until at least one ship had been loaded and all final performance tests had

been successfully completed. In actual fact, however, Atlantic LNG operations staff became a part of the

integrated team and continued under Bechtel's direction to be the hands-on-operators for parts of the plant

even during the performance test.

There were two types of acceptance tests which made up the plant performance requirements. These

were commissioning tests for individual equipment or units and an overall performance test of the

operating facility.

Commissioning Tests (process and utility)

Commissioning tests were required for all systems, all package units, various special items such as

loading arms, metering skids, firewater pumps, and of course, all control systems, alarm systems and

shutdown systems. The purpose of the Commissioning tests was to demonstrate that individual systems

7

This paper has been republished with the permission of GasTech 2000.

RETURN TO MAIN MENU (Click Here)

within the facility performed according to design specifications within the EPC contract. There were 44

individual tests each with a procedure and a report documenting the results and individually signed off by

both Bechtel and owner and witnessed by owner. All commissioning tests had to be completed before

Performance Tests could begin.

Performance Tests

Performance tests were conducted to prove plant capacity and fuel efficiency, ship loading capability and

LPG recovery rate. Ship loading was done as a separate test from the plant performance test and

proceeded smoothly. All other plant performance aspects were measured in a continuous 72-hour test.

This test was Bechtel's final deliverable required for contract completion and final turnover. There were

significant incentives (positive and negative) for early contract completion (i.e. performance test

completion) and also for good plant performance relative to guaranteed performance.

Bechtel and Phillips sent additional process engineering representatives to join the start-up team as time

for the performance test approached. Computerized data logging, analysis and calculation routines were

set up well in advance. Plant simulations under the exact conditions expected during the test were done

ahead of time to determine the exact effects of site weather and possible variations in feed gas

composition.

As the official test began, computer calculations were run hourly on plant production and fuel gas

consumption. Data was recorded on major compressor power (torquemeter readings) every hour. LPG

recovery was calculated on a regular basis.

The plant suffered a compressor trip only 4 hours into the performance test. A quick recovery to full

production was made, but the performance test was re-started. The second test proved successful and

smooth. High capacity operation was maintained throughout the 72 hours. The automatic data collection

and calculation routines provided a rich data base at the end of the period and allowed the test report to be

produced and on the Atlantic LNG Start-up Manager's desk the same day as the test was completed. The

results showed that all requirements were met and LNG production was 2.5% above guarantee. During

the performance test contractual requirements limited refrigeration compressor horsepower to account for

air compressor fouling and long term degradation. This horsepower limitation was clearly the

determining limit during the performance test. Subsequently, the plant has operated smoothly at up to

10% above performance guarantee.

The joint operations and maintenance team during the performance test consisted of:

Atlantic operating personnel - operating gas treating and drying and ship loading

Atlantic maintenance personnel - covering entire plant but still backed up by Bechtel specialists

and skilled craftsman

Bechtel operations staff - operating liquefaction, utilities and LNG storage and providing

technical support and process engineering

Phillips - providing operators, advisors, process engineers, lab analytical experts

The Atlantic LNG permanent plant operation and maintenance staff contained fewer than 10 expatriates

during start-up, initial operations, plant performance testing, and still does. When Bechtel turned over the

plant, a small number of Bechtel and Phillips Alaska Natural Gas Company experienced expatriate

8

This paper has been republished with the permission of GasTech 2000.

RETURN TO MAIN MENU (Click Here)

personnel stayed on to assist during a short transitional period. The plant continued to operate well with

this manning level.

During the performance test and a period time preceding the test, Atlantic operators did assume full

operating duties for parts of the plant, although Bechtel was responsible and provided supervision. This

is a tribute to the quality of the staff and to the ease of operation of the liquefaction process and the plant

in general. Although Bechtel maintained responsibility for the facility, they had enough confidence in the

Atlantic LNG staff to use them in responsible operating positions even during the performance testing.

Operating Experience First 12 Months

Atlantic LNG took over the facility from Bechtel on June 14th, 1999. With the exception of a few key

personnel for technology transfer there was minimal staff carryover from Bechtel and Phillips. Critical

vendors such as Nuovo Pignone and Honeywell representatives were retained to provide assistance to the

permanent operations staff. Out of the total Atlantic LNG staff very few expatriates are utilized for the

day to day operations. All of the Bechtel, Phillips and vendor staff retained were released after four to six

months of assistance with the exception of Nuovo Pignone personnel and one Honeywell representative.

If required, shareholder companies or Phillips Petroleum, the Liquefaction technology licensor and

Bechtel, the EPC contractor of the facility, can provide specialized engineering services as needed.

The operations staff was able to improve on the performance test results by identifying process

bottlenecks and getting a better understanding of the process variables affecting the LNG production.

They also improved on responding to day to night ambient temperature variations, by monitoring key

performance criteria and maximizing plant throughput and production based on ambient conditions.

In October of 1999 Bechtel and Atlantic LNG ran a capacity test on the plant to help identify bottlenecks

for the expansion project and to improve the Train 1 performance. The test was run on the same basis as

the performance test conducted in June 1999. The following table tabulates the capacities achieved:

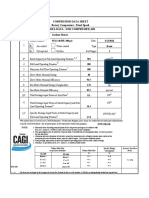

Table 1: Capacity Test Results

Original Simulation

New Simulation

Performance Test

Capacity Test

Net LNG

Production

(MMBtu/day)

Fuel Gas Consumed

(MMBtu/day)

418 000

416 700

425 239

450 000

56 425

56 300

55 419

-

During the early periods of operation there were several operational problems to overcome to increase the

availability of the facility. Some of the difficulties encountered during the early periods of operations

were:

Repair mol sieve bed supports

Replace mol sieve

Piping vibration

Repair weld failure

BP problem with Beachfield slug catcher

~ 10,000 BBL slug had to be processed over several days

9

This paper has been republished with the permission of GasTech 2000.

RETURN TO MAIN MENU (Click Here)

Defrost plant

Instrumentation problems with Nuovo Pignone

Propane level control valve replaced

Heavies removal column liquid carryover

Water breakthrough on the mol sieve dehydrators

Despite these incidents the plant has operated very well overall as we will show in the following

operating statistics. In addition the LNG facility has met all of its LNG delivery obligations to its

customers and Atlantic LNG has been able to sell some spot LNG cargoes. As of July 17th, 2000 Atlantic

LNG has exported 76 cargoes of LNG.

OPERATING STATISTICS

Some key operating statistics from the first year of the facilities operation are presented here.

Definitions for the availability data presented are as follows:

1.

Availability is the proportion of the total time that the plant was able to be used for its intended purpose.

This is a combination of scheduled and unscheduled downtime.

Availability = Total Time Scheduled Downtime Unscheduled Downtime

Total Time

2.

Production Efficiency is the ratio of actual production to its rated output during the time it is operating

(i.e. during the time it is fully available and fully utilized)

Production Efficiency =

Actual Production / Rated Capacity

(Total Time Scheduled Downtime Unscheduled Downtime Standby Time)

To give a true measure of the efficiency of production actual production is adjusted for the reported average

ambient temperature. The guaranteed production rate is used for the Rated Capacity.

3.

Overall Effectiveness is a measure of how effectively the plant is being used altogether, including all

incidents affecting production.

Overall Effectiveness = Availability * Utilization * Production Efficiency

4.

Utilization is the proportion of the time that the equipment is available that it is actually used for its

intended purpose. This takes out any time that the plant could not be used for reasons outside its control,

i.e. upstream problems or shipping problems causing a reduction in production. This is called standby time

and again because we frequently run at partial rates instead of completely shutting the plant down we have

used the concept of equivalent hours of standby.

Utilization = Total Time Scheduled Downtime Unscheduled Downtime Standby Time

Total Time Scheduled Downtime Unscheduled Downtime

As can be seen from the availability data presented in Figure 4 and Figure 5 the efficiency of the LNG

facility ramped up to 100% in a short time frame and the overall effectiveness for 1999 was 81% and as

of July 2000 it is at 96.4%

10

This paper has been republished with the permission of GasTech 2000.

RETURN TO MAIN MENU (Click Here)

Figure 4: Plant Availability Data - 1999

Atlantic LNG Production Performance for 2000

110.0%

100.0%

90.0%

80.0%

70.0%

60.0%

50.0%

40.0%

30.0%

20.0%

10.0%

0.0%

Q1 2000

Q2 2000

Availability

99.1%

96.8%

98.3%

Efficiency

104.2%

105.0%

102.3%

96.5%

98.5%

96.4%

Overall Effectiveness

2000 (TO DATE)

Figure 5: Plant Availability Data 2000

A tla n t i c L N G P r o d u c t i o n P e r f o r m a n c e f o r 1 9 9 9

110.0%

100.0%

90.0%

80.0%

70.0%

60.0%

50.0%

40.0%

30.0%

20.0%

10.0%

0.0%

Q2 1999

Q3 1999

Q4 1999

1999

Availability

62.3%

76.9%

92.5%

77.9%

85.6%

Efficiency

93.5%

100.9%

104.0%

100.2%

102.1%

Overall Effectiveness

58.2%

73.2%

87.2%

73.5%

81.3%

11

This paper has been republished with the permission of GasTech 2000.

From Handover

RETURN TO MAIN MENU (Click Here)

Conclusions

The success of Trinidad LNG project cannot be overstated. It has met or exceeded the expectations of all

parties involved from engineering design, construction, start-up and normal plant operations. The

performance and attitude of the personnel associated with the project throughout its development has been

the key to its success. This was truly a team effort where there were no boundaries between client and

contractor. There was a common goal that all parties focused on and that goal was to be successful. This

project was going to make the rest of the LNG industry sit up and take notice and it has certainly done

that. All the members of the Trinidad LNG project team from ALNG, Bechtel and Phillips plus the

supporting players must be thanked for their energy, commitment and most of all their belief that this

project was never going to be anything else but SUCCESSFUL.

12

This paper has been republished with the permission of GasTech 2000.

Вам также может понравиться

- Pip 686aДокумент8 страницPip 686asaminasritn50% (2)

- Bahx IomДокумент54 страницыBahx IomIsaac Flores100% (1)

- Sakhalin CommissioningДокумент11 страницSakhalin Commissioningasdfadsfadfsads100% (1)

- Oman PR-1159 - Commissioning and Start-UpДокумент116 страницOman PR-1159 - Commissioning and Start-Upscribd_alpha100% (2)

- Turbo Expander FinalДокумент25 страницTurbo Expander Finalmohamed100% (2)

- 023 BP RefiningДокумент27 страниц023 BP Refiningpartho143Оценок пока нет

- LNG VaporizationДокумент18 страницLNG VaporizationFXS01Оценок пока нет

- Amine ContactorДокумент7 страницAmine ContactorchetanmaleОценок пока нет

- Hazop & Hazid Report - CNG Gas Plant - Tambak Lorok Rev BДокумент110 страницHazop & Hazid Report - CNG Gas Plant - Tambak Lorok Rev BDenstar Ricardo Silalahi94% (16)

- Problems With B16.5 and B16.47 Flange StandardsДокумент1 страницаProblems With B16.5 and B16.47 Flange StandardsManohar SeetharamОценок пока нет

- Session 06 - Sprinkler System (19-20) With Marking (Final)Документ108 страницSession 06 - Sprinkler System (19-20) With Marking (Final)timho yu67% (3)

- NGL Fractionation Operating ManualДокумент335 страницNGL Fractionation Operating ManualBabji Munagala100% (7)

- 2 3 8 A ResidentialwatersupplyДокумент4 страницы2 3 8 A Residentialwatersupplyapi-30037553225% (8)

- Cryogenic ProcessДокумент25 страницCryogenic Processmohamed100% (2)

- LNGДокумент11 страницLNGMiguel SantosОценок пока нет

- HRSG PreservationДокумент4 страницыHRSG PreservationmadusamОценок пока нет

- Plant Start UpДокумент7 страницPlant Start UpTan JieShengОценок пока нет

- H H. W W W 358.9628.D - .H 6.31533.W D.: AGA Flow Orifice Calculation RoutinesДокумент24 страницыH H. W W W 358.9628.D - .H 6.31533.W D.: AGA Flow Orifice Calculation RoutinescincaohijauОценок пока нет

- LNG Process TrainДокумент23 страницыLNG Process TrainMuhammad Shariq Khan100% (11)

- LNG Regasification: Engineering Solutions - . - Delivering ResultsДокумент5 страницLNG Regasification: Engineering Solutions - . - Delivering Resultsdigeca100% (1)

- Commisioning Plant CourseДокумент25 страницCommisioning Plant CoursePoncho RmzОценок пока нет

- 2016CT Compressor Specs at GlanceДокумент4 страницы2016CT Compressor Specs at GlanceabsahkahОценок пока нет

- 26565e PDFДокумент528 страниц26565e PDFJeEJyZaОценок пока нет

- Optimization of LNG RegasificationДокумент30 страницOptimization of LNG RegasificationShashwat OmarОценок пока нет

- G. Spare Parts ManagementДокумент12 страницG. Spare Parts ManagementVipul TikekarОценок пока нет

- Microsoft Word - LNG Large Scale Background Paper Oct2006 PDFДокумент58 страницMicrosoft Word - LNG Large Scale Background Paper Oct2006 PDFGeoffreyHunter100% (3)

- Indoor Air Quality Lab ReportДокумент10 страницIndoor Air Quality Lab Reportapi-309953189100% (2)

- Com .& Start-Up Strategy 120926Документ24 страницыCom .& Start-Up Strategy 120926rodinsendiong100% (1)

- Essential Practices for Managing Chemical Reactivity HazardsОт EverandEssential Practices for Managing Chemical Reactivity HazardsОценок пока нет

- 11-12 PrecommissioningДокумент2 страницы11-12 PrecommissioningEleonoraОценок пока нет

- PP Aaa PP1 111Документ18 страницPP Aaa PP1 111Rabah AmidiОценок пока нет

- LNG Process Safety - Final04122018Документ50 страницLNG Process Safety - Final04122018Syed Shahid Imdadulla100% (2)

- Commissioning Gas Turbine CompressorДокумент13 страницCommissioning Gas Turbine CompressorLenaldy Nuari Garnoko0% (2)

- The Role of OpercomДокумент7 страницThe Role of OpercomAnonymous 3Y5SgP7100% (5)

- Pipe Line PiggingДокумент7 страницPipe Line PiggingSantosh Kumar BogelaОценок пока нет

- Operation LNG TankДокумент4 страницыOperation LNG TankpramodtryОценок пока нет

- Operation LNG TankДокумент4 страницыOperation LNG TankpramodtryОценок пока нет

- LNG Design StandardДокумент41 страницаLNG Design Standardamirlng100% (1)

- Wave HydrodynamicsДокумент344 страницыWave HydrodynamicsSathishSrsОценок пока нет

- 6604 Issue 2 Testing of Insulating JointsДокумент5 страниц6604 Issue 2 Testing of Insulating Jointssaminasritn100% (1)

- Chapter 1 PumpsДокумент38 страницChapter 1 Pumpsفيصل القاسمОценок пока нет

- Elba LNGДокумент102 страницыElba LNGsourcemenuОценок пока нет

- Standard Cost Coding System (SCCS)Документ326 страницStandard Cost Coding System (SCCS)mirakulОценок пока нет

- PerformanceTest Updated9octДокумент38 страницPerformanceTest Updated9octHossein100% (1)

- LNG Conversion Cost Estimation PDFДокумент4 страницыLNG Conversion Cost Estimation PDF123habib123fikriОценок пока нет

- Advance Process Control in LNG PlantДокумент18 страницAdvance Process Control in LNG PlantthawdarОценок пока нет

- LNG ExampleДокумент48 страницLNG ExampleHeat.MotionОценок пока нет

- Pipeline DryingДокумент2 страницыPipeline DryingAriel Anasco100% (2)

- Oisd 161Документ20 страницOisd 161Arvind BharadwajОценок пока нет

- Natural Gas Knowledge Series - Laying Natural Gas PipelineДокумент15 страницNatural Gas Knowledge Series - Laying Natural Gas PipelineswordprincesОценок пока нет

- Initial Start Up Procedure RevAДокумент62 страницыInitial Start Up Procedure RevACheehoong JoexОценок пока нет

- B&V Mini LNG PlantДокумент84 страницыB&V Mini LNG PlantPugel YeremiasОценок пока нет

- PTT Public Company Limited Ratchaburi World Cogeneration Company LimitedДокумент49 страницPTT Public Company Limited Ratchaburi World Cogeneration Company LimitedzhangjieОценок пока нет

- PSV SizingДокумент3 страницыPSV SizingpavanОценок пока нет

- Natural Gas Processing - 2010Документ44 страницыNatural Gas Processing - 2010Ahmed Khamees Shatla100% (1)

- PLANT Commissioning PDFДокумент35 страницPLANT Commissioning PDFhenybamОценок пока нет

- LNG Reliquefaction Systems2Документ14 страницLNG Reliquefaction Systems2123habib123fikriОценок пока нет

- Commissioning Manual Unit 21Документ35 страницCommissioning Manual Unit 21Arjun Shantaram Zope100% (1)

- Std-Insp-0127 Procedure For Commissioning ProcedureДокумент54 страницыStd-Insp-0127 Procedure For Commissioning ProcedureAkshay KalraОценок пока нет

- GPA08 PaperДокумент9 страницGPA08 PaperhicherkОценок пока нет

- LNG Terminal Design RelatedДокумент14 страницLNG Terminal Design Relatedpdaga19691383100% (1)

- Report On Student Iw Experience SchemeДокумент9 страницReport On Student Iw Experience SchemeifiokОценок пока нет

- Chiyoda in LNG Plant ProjectsДокумент11 страницChiyoda in LNG Plant ProjectsD K SОценок пока нет

- LNG Permit To ConstructДокумент78 страницLNG Permit To ConstructAly Sera100% (1)

- Uop Benfield DatasheetДокумент2 страницыUop Benfield DatasheetSusan Monteza GrandezОценок пока нет

- Pre-Commissioning ManualДокумент32 страницыPre-Commissioning ManualfernandoОценок пока нет

- AmmoniaДокумент8 страницAmmoniakrishna_pipingОценок пока нет

- Prelude For LNG ProjectДокумент46 страницPrelude For LNG ProjectYan Laksana100% (1)

- Amine Loading To SystemДокумент6 страницAmine Loading To SystemRathinavel PerumalОценок пока нет

- NGL Extraction TechnologiesДокумент10 страницNGL Extraction Technologieswylie010% (1)

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988От EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockОценок пока нет

- Ps2 3 KHДокумент14 страницPs2 3 KHBranden933Оценок пока нет

- GMC2 06Документ36 страницGMC2 06Fahad KhanОценок пока нет

- (0057) 9 - Sample - by PPM & All - Indicative ProposalДокумент26 страниц(0057) 9 - Sample - by PPM & All - Indicative ProposalSixto Gerardo Oña AnaguanoОценок пока нет

- Optimization of H Production in A Hydrogen Generation UnitДокумент6 страницOptimization of H Production in A Hydrogen Generation UnitDidit Andhika SubrataОценок пока нет

- Supersonic SeparatorДокумент4 страницыSupersonic SeparatormortezasabetiОценок пока нет

- Drawer 75 MM Wall For 2940B Cabinet - 2940B-75: DescriptionДокумент1 страницаDrawer 75 MM Wall For 2940B Cabinet - 2940B-75: DescriptionsaminasritnОценок пока нет

- d01c25e978d2f79c771828530390SHIPPING CI PДокумент1 страницаd01c25e978d2f79c771828530390SHIPPING CI PsaminasritnОценок пока нет

- STG2-40 100psi AirCooled 04 11 2016Документ1 страницаSTG2-40 100psi AirCooled 04 11 2016saminasritnОценок пока нет

- VCXT ™ Data Sheet: Debtor in PossessionДокумент2 страницыVCXT ™ Data Sheet: Debtor in PossessionsaminasritnОценок пока нет

- ERFIFRANCE English Catalog PDFДокумент111 страницERFIFRANCE English Catalog PDFsaminasritnОценок пока нет

- Attachement E-Square Catalogue PDFДокумент225 страницAttachement E-Square Catalogue PDFsaminasritnОценок пока нет

- Test Equipment 2 (Accbe) Answer KeyДокумент1 страницаTest Equipment 2 (Accbe) Answer KeysaminasritnОценок пока нет

- Offshore LNG Loading Problem SolvedДокумент13 страницOffshore LNG Loading Problem SolvedpriyoОценок пока нет

- 2.11 FinalReport MFL-DMR-GEO EXAMPLE PDFДокумент19 страниц2.11 FinalReport MFL-DMR-GEO EXAMPLE PDFsaminasritnОценок пока нет

- GPT 1-9CasingSpacerManual OCT2013 LR en-NA 21Документ2 страницыGPT 1-9CasingSpacerManual OCT2013 LR en-NA 21saminasritnОценок пока нет

- 2.11 FinalReport MFL-DMR-GEO EXAMPLE PDFДокумент19 страниц2.11 FinalReport MFL-DMR-GEO EXAMPLE PDFsaminasritnОценок пока нет

- 336 AcДокумент172 страницы336 AcsaminasritnОценок пока нет

- XIX Paper 59Документ15 страницXIX Paper 59saminasritnОценок пока нет

- Integration of Major Liquefaction Units Within Existing Import TerminalsДокумент8 страницIntegration of Major Liquefaction Units Within Existing Import TerminalshortalemosОценок пока нет

- Energies 05 03892Документ16 страницEnergies 05 03892Daodu Olugbenga OlusegunОценок пока нет

- MEASURING AND TEST EQUIPMENT CALIBRATION AND CONTROL - 01548 - EE37 - PWI - ET - 1907 - 0004 Rev.1Документ3 страницыMEASURING AND TEST EQUIPMENT CALIBRATION AND CONTROL - 01548 - EE37 - PWI - ET - 1907 - 0004 Rev.1saminasritnОценок пока нет

- Paper20508 5121Документ5 страницPaper20508 5121saminasritnОценок пока нет

- EE37 PPR ET 1919 0032 Rev 1 - Drying - Purge ProcedureДокумент7 страницEE37 PPR ET 1919 0032 Rev 1 - Drying - Purge ProceduresaminasritnОценок пока нет

- Support Pipng TechnipДокумент23 страницыSupport Pipng TechnipsaminasritnОценок пока нет

- Corrosion Protection Under Insulation: PanoramaДокумент4 страницыCorrosion Protection Under Insulation: PanoramasaminasritnОценок пока нет

- PE Pipe Joining Procedures PDFДокумент31 страницаPE Pipe Joining Procedures PDFymessaoudОценок пока нет

- Material Class ChevronДокумент29 страницMaterial Class ChevronsaminasritnОценок пока нет

- Typrical Piping TCCIДокумент18 страницTyprical Piping TCCIsaminasritnОценок пока нет

- Jet Pumps & BoostersДокумент24 страницыJet Pumps & BoosterscihuyОценок пока нет

- Allproductscatalog PDFДокумент578 страницAllproductscatalog PDFrajpvikОценок пока нет

- Paj-7e 201906Документ2 страницыPaj-7e 201906Anum AkramОценок пока нет

- DB 05 AirCond 130204Документ33 страницыDB 05 AirCond 130204Nguyen Huu TriОценок пока нет

- 13.kinetic Theory PDFДокумент30 страниц13.kinetic Theory PDFNaliniОценок пока нет

- Experiment 2 CHM207 Intermediate Organic Chemistry Distillation Technique and To Determine The Boiling Point of A LiquidДокумент3 страницыExperiment 2 CHM207 Intermediate Organic Chemistry Distillation Technique and To Determine The Boiling Point of A LiquidMUADZ ARОценок пока нет

- Ship/Shore Safety Check List: Company Forms and Check ListsДокумент3 страницыShip/Shore Safety Check List: Company Forms and Check ListsopytnymoryakОценок пока нет

- Physics Ii: Technological University of The Philippines-Taguig Electrical Engineering DepartmentДокумент129 страницPhysics Ii: Technological University of The Philippines-Taguig Electrical Engineering DepartmentEsmeralda Tapiz0% (2)

- MP96 FluidДокумент1 страницаMP96 Fluidmehmet demirkolОценок пока нет

- 417 Model E Alarm Check ValveДокумент4 страницы417 Model E Alarm Check Valveeng_elbarbaryОценок пока нет

- Whrs ManualДокумент41 страницаWhrs ManualAKHLESH JHALLAREОценок пока нет

- Gas Testing in Saudi AramcoДокумент50 страницGas Testing in Saudi Aramcohusaam waadoОценок пока нет

- Problem Sheet 3 - External Forced Convection - WatermarkДокумент2 страницыProblem Sheet 3 - External Forced Convection - WatermarkUzair KhanОценок пока нет

- Turbomachinery Part4 Turbocompressors Axial v1Документ15 страницTurbomachinery Part4 Turbocompressors Axial v1Sami SaleemОценок пока нет

- (Chapter 1) Fluid Mechanics For Mechanical EngineeringДокумент38 страниц(Chapter 1) Fluid Mechanics For Mechanical EngineeringAnn Razon0% (1)

- Hydrotest Report - Fire HoseДокумент1 страницаHydrotest Report - Fire HoseshivarajОценок пока нет

- QA-QC Checklist - Fire ExtinguisherДокумент1 страницаQA-QC Checklist - Fire Extinguisherabdullah albahraniОценок пока нет

- Lamjed Hadj Taieb Med Amine Guidara Noura Bettaieb Sami El Aoud Ezzeddine Hadj Taieb Water-Hammer Control in An Actual Branched Cast Iron Network by Means of Polymeric PipesДокумент10 страницLamjed Hadj Taieb Med Amine Guidara Noura Bettaieb Sami El Aoud Ezzeddine Hadj Taieb Water-Hammer Control in An Actual Branched Cast Iron Network by Means of Polymeric PipesAli TrikiОценок пока нет

- SNG Ii: Instruction Manual and Replacement Parts ListДокумент146 страницSNG Ii: Instruction Manual and Replacement Parts ListVictor RoblesОценок пока нет