Академический Документы

Профессиональный Документы

Культура Документы

Esab kv4

Загружено:

Gokul RajanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Esab kv4

Загружено:

Gokul RajanАвторское право:

Доступные форматы

ESAB KV4

ESAB KV7

A basic coated low hydrogen electrode for welding 5 Cr-0.5 Mo steels

A basic coated low hydrogen electrode for welding 9Cr-1Mo steels

Classification

AWS A5.5: E 8018-B6

Classification

IS 1395: E 55 BB 620

AWS A5.5: E 8018-B8

IS 1395: E 55 BB 820

DESCRIPTION

ESAB KV4 is a basic coated all position electrode used for welding of creep resistant,

Cr-Mo bearing steel. Deposited metal is highly resistant to heat and corrosion. This

electrode is highly suited for welding steel having 4 to 6% Chromium and 0.5%

Molybdenum. The design of the slag system, good arc characteristics, stable arc in

all positions, minimum spatter level and smooth weld bead appeal to the welder.

Weld deposit is of radiographic quality.

DESCRIPTION

ESAB KV7 is basic coated all position electrode for welding of creep - resistant

steels alloyed with 9Cr-1Mo. The weldmetal obtained is ductile and resistant to impact.

The weldmetal is highly resistant to corrosion and hydrogen attack at high

temperatures. The arc and current carrying characteristics, minimum spatter and

smoke level and stable arc in all positions appeal to the welder. The weldmetal is of

radiographic quality and appearance is smooth and even.

WELDING CURRENT: DC+

WELDING CURRENT: DC+

TYPICAL APPLICATIONS

ESAB KV4 finds extensive use in the chemical and petrochemical industries, oil

industries where it has to resist corrosion and hydrogen attack at high temperatures.

It is also used for welding parts of aircraft made out of SAE 4130 steels, heat treatable

steels etc. Also suitable for welding 5% chromium steel castings for use at elevated

temperatures.

TYPICAL APPLICATIONS

ESAB KV7 is intended for welding of steels with similar composition. These steels

are often found in oil refineries, chemical and petrochemical industries, power plants

where it has to resist corrosion and hydrogen attack at high temperatures.

Chemical Composition (%)

TYPICAL ALL WELDMETAL PROPERTIES

Chemical Composition (%)

Mechanical Properties

0.06

Cr

5.60

YS

490 N/mm2

Mn

0.80

Mo

0.60

UTS

575 N/mm2

Si

0.30

0.018

EL (L=4d)

24%

0.018

Mechanical Properties

0.06

0.018

YS

490 N/mm2

Si

0.30

Mo

1.00

UTS

600 N/mm2

Cr

9.1

Mn

0.70

EL (L=4d)

22%

Ni

0.20

0.018

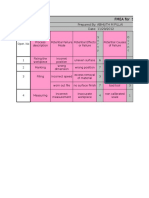

CURRENT RANGE & PACKING DATA

Size

(mm)

CURRENT RANGE & PACKING DATA

Size

(mm)

TYPICAL ALL WELDMETAL PROPERTIES

Length Current Range

(mm)

(Amps)

No. of Electrodes in a

Carton Cardboard box

2.50

350

65-95

135

540

3.15

350

75-130

95

380

4.00

350

115-165

60

240

5.00

450

180-240

45

180

Length Current Range

(mm)

(Amps)

No. of Electrodes in a

Carton Cardboard box

2.50

350

60-100

135

540

3.15

350

90-130

95

380

4.00

350

110-165

60

240

5.00

450

175-240

45

180

PACKING: Electrodes are packed in cartons and four of these cartons are shrink

PACKING: Electrodes are packed in cartons and four of these cartons are shrink

wrapped in a cardboard box.

40

41

Вам также может понравиться

- Iso 9001Документ3 страницыIso 9001Gokul RajanОценок пока нет

- Irregular Metal Transfer: Globular WeldingДокумент1 страницаIrregular Metal Transfer: Globular WeldingGokul RajanОценок пока нет

- Ar SsmasДокумент1 страницаAr SsmasGokul RajanОценок пока нет

- ExpenceДокумент2 страницыExpenceGokul RajanОценок пока нет

- Constant Current Power Source: CharacteristicДокумент1 страницаConstant Current Power Source: CharacteristicGokul RajanОценок пока нет

- Crater Cracking: Avoiding Solidification Cracking in WeldsДокумент1 страницаCrater Cracking: Avoiding Solidification Cracking in WeldsGokul RajanОценок пока нет

- Method B This Method Uses A Numerical Designation From The Table As Listed BelowДокумент1 страницаMethod B This Method Uses A Numerical Designation From The Table As Listed BelowGokul RajanОценок пока нет

- Investing in Teacher: Investing For The FutureДокумент2 страницыInvesting in Teacher: Investing For The FutureGokul RajanОценок пока нет

- MantramДокумент1 страницаMantramGokul RajanОценок пока нет

- JtdegtrtДокумент1 страницаJtdegtrtGokul RajanОценок пока нет

- 4.1 Features of The Weld PreparationДокумент1 страница4.1 Features of The Weld PreparationGokul RajanОценок пока нет

- Constant Current Power Source: CharacteristicДокумент1 страницаConstant Current Power Source: CharacteristicGokul RajanОценок пока нет

- Method A This Method Uses An Alpha/numerical Designation From The Tables As Listed BelowДокумент1 страницаMethod A This Method Uses An Alpha/numerical Designation From The Tables As Listed BelowGokul RajanОценок пока нет

- 5 Crater Cracking: Rev 1 January 2009 TIG Welding © TWI LTD 2009Документ1 страница5 Crater Cracking: Rev 1 January 2009 TIG Welding © TWI LTD 2009Gokul RajanОценок пока нет

- Hydrogen Induced Cold Cracking (HICC) But It Is Often Referred To by OtherДокумент1 страницаHydrogen Induced Cold Cracking (HICC) But It Is Often Referred To by OtherGokul RajanОценок пока нет

- Hydrogen Induced Cold Cracking (HICC) But It Is Often Referred To by OtherДокумент1 страницаHydrogen Induced Cold Cracking (HICC) But It Is Often Referred To by OtherGokul RajanОценок пока нет

- EgrnДокумент3 страницыEgrnGokul RajanОценок пока нет

- Irregular Metal Transfer: Globular WeldingДокумент1 страницаIrregular Metal Transfer: Globular WeldingGokul RajanОценок пока нет

- MagnesiumДокумент3 страницыMagnesiumIsidoro LópezОценок пока нет

- FMEA TemplateДокумент5 страницFMEA TemplateGokul RajanОценок пока нет

- JHFDSDFGHДокумент1 страницаJHFDSDFGHGokul RajanОценок пока нет

- JHFDSDFGHДокумент1 страницаJHFDSDFGHGokul RajanОценок пока нет

- GHDFДокумент1 страницаGHDFGokul RajanОценок пока нет

- ZirconiumДокумент4 страницыZirconiumIsidoro LópezОценок пока нет

- SR - No Description Drgno Elevation No. GriedДокумент6 страницSR - No Description Drgno Elevation No. GriedGokul RajanОценок пока нет

- Om Tryambakam Yajamahe Sugandhim Pushtivardhanam Urvarukamiva Bandhanan Mrityor Mukshiya MaamritatДокумент1 страницаOm Tryambakam Yajamahe Sugandhim Pushtivardhanam Urvarukamiva Bandhanan Mrityor Mukshiya MaamritatGokul RajanОценок пока нет

- Electrical Technology 2007 (2006 Ad) PDFДокумент1 страницаElectrical Technology 2007 (2006 Ad) PDFGokul RajanОценок пока нет

- Important PointsДокумент1 страницаImportant PointsGokul RajanОценок пока нет

- .Cover Sheet PDFДокумент3 страницы.Cover Sheet PDFGokul RajanОценок пока нет

- Paint - Notes Q A - 3Документ21 страницаPaint - Notes Q A - 3Gokul Rajan100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- 1530 Specimen Paper & Mark Scheme PDFДокумент100 страниц1530 Specimen Paper & Mark Scheme PDFchuasioklengОценок пока нет

- Workshop Manual 2016 PDFДокумент62 страницыWorkshop Manual 2016 PDFgiridharrajeshОценок пока нет

- Ejercicios EquilibrioДокумент3 страницыEjercicios EquilibrioLorena Mazo TorresОценок пока нет

- AC 43.13-1B-Hardware Identification Table-3d-Ch7 - 11Документ26 страницAC 43.13-1B-Hardware Identification Table-3d-Ch7 - 11MASOUDОценок пока нет

- Sodium Borohydride Amides To AminesДокумент4 страницыSodium Borohydride Amides To AminesalchymystОценок пока нет

- MIRDC Schedule of Fees and Charges for Testing and CalibrationДокумент12 страницMIRDC Schedule of Fees and Charges for Testing and Calibrationnapster386Оценок пока нет

- Sadsd PHYSSДокумент37 страницSadsd PHYSSnaseh__nОценок пока нет

- FRP PipingДокумент19 страницFRP PipingprocesspipingdesignОценок пока нет

- Steel Plate Manufacturing ProcessДокумент1 страницаSteel Plate Manufacturing ProcessMetline IndustriesОценок пока нет

- Electrochemistry lecture notes on galvanic cells and reference electrodesДокумент201 страницаElectrochemistry lecture notes on galvanic cells and reference electrodesShamawn Muktadeer ShovonОценок пока нет

- 3a. Isi-B. Survey Dan Cara Pemeriksaan Kapal-31-55Документ25 страниц3a. Isi-B. Survey Dan Cara Pemeriksaan Kapal-31-55MuhammadRiady100% (1)

- Metallurgy Quiz: Key Concepts and ProcessesДокумент312 страницMetallurgy Quiz: Key Concepts and ProcessesAditya PrasadОценок пока нет

- Passive Layer (EDTA Cleaning)Документ7 страницPassive Layer (EDTA Cleaning)coincoin1Оценок пока нет

- SPM Chemistry QuestionДокумент6 страницSPM Chemistry QuestionSaya MenangОценок пока нет

- Grade 10 Paper 2Документ8 страницGrade 10 Paper 2jfkdmfmdfОценок пока нет

- Available DTD Documents in PDFДокумент11 страницAvailable DTD Documents in PDFdsgaviation100% (2)

- Division of Cebu Province District of Balamban Ii: Curriculum GuideДокумент6 страницDivision of Cebu Province District of Balamban Ii: Curriculum GuideFelix MilanОценок пока нет

- Program Bramat2015Документ32 страницыProgram Bramat2015Buluc GheorgheОценок пока нет

- Heat Treatment of Ferrous AlloysДокумент11 страницHeat Treatment of Ferrous AlloysSyed Mohsin Ali Naqvi100% (2)

- MGDA As A New Biodegradable Complexing AgentДокумент6 страницMGDA As A New Biodegradable Complexing AgentPeterОценок пока нет

- 1.3. Properties of Transition MetalsДокумент2 страницы1.3. Properties of Transition Metalsyash12312Оценок пока нет

- Shahuindo Technical Report 2015Документ307 страницShahuindo Technical Report 2015Diego Eslava BrionesОценок пока нет

- CESL: Una alternativa ambiental superior a la fundiciónДокумент4 страницыCESL: Una alternativa ambiental superior a la fundiciónMargarita FariasОценок пока нет

- Atomic Structure and Periodic TableДокумент19 страницAtomic Structure and Periodic TableZarith Hidayah IsmileОценок пока нет

- Chemistry Revision Grade 9Документ2 страницыChemistry Revision Grade 9Christison AlorciousОценок пока нет

- R-Values of Insulation and Other Building MaterialsДокумент8 страницR-Values of Insulation and Other Building MaterialsDhanyaUnniОценок пока нет

- Element Assignment - IronДокумент2 страницыElement Assignment - IronKartikay TyagiОценок пока нет

- Rusting of IronДокумент15 страницRusting of IronDeepanshu Arya100% (1)

- Submerged Arc Welding (SAW)Документ34 страницыSubmerged Arc Welding (SAW)Gaballah Aman0% (1)

- Alloy DensitiesДокумент4 страницыAlloy DensitiesjphigbyОценок пока нет