Академический Документы

Профессиональный Документы

Культура Документы

Ijcebs 0101142

Загружено:

Rahmat UllahОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ijcebs 0101142

Загружено:

Rahmat UllahАвторское право:

Доступные форматы

International Journal of Chemical, Environmental & Biological Sciences (IJCEBS) Volume 1, Issue 1 (2013) ISSN 23204087 (Online)

Pressure Drop Analysis of Natural Gas Transmission

Line in Bangladesh

Mohd Atiqueuzzaman Khan, Md Shamsuddoha,Syed Al Imran Quraishy

the two major production companies in Bangladesh each

producing 700 and more than 1000 MMSCF gas per day.

BAPEX is mainly the exploration company. To strengthen

BAPEX financially the government allowed operating two

gas fields, Namely Salda and Fenchuganj.

Abstract--The main objective of this study is to implement a

virtual simulation network of natural gas transmission system to

observe the pressure drop along the pipeline when the gas

consumption rate varies effectively. When the pressure falls to a

certain value, higher hydrocarbon content of natural gas becomes

liquid and the reduced pressure hinders the gas transmission

especially when it is expected to transmit across a long distance. The

Reduced pressure also clarifies the importance of setting up

compressor station to boost up the pressure and transmit a larger

volume of gas through an existing pipeline system. As the natural

gas consumption rate of Bangladesh is increasing day by day, it is

necessary to visualize the effect of pressure change when the

consumption rate increases. North-South pipeline and Brahmaputra

Basin gas transmission pipeline have been implemented in this

simulation network of Pipesim and the effect of pressure variations

have been observed.

Currently four companies of Petrobangla are responsible for

transmission and distribution:

1. Jalalabad Gas Transmission and Distribution

Company limited (JGTDGL).

2. Titas Gas Transmission and Distribution Company

limited (TGTDCL)

3. Bakharabad Gas System Limited (BGSL)

4. Paschimanchal Gas Company Limited (PFA)

The north south pipeline contains the major gas producing

fields including Bibiyana (810 MMSCFD) and Jalalabad (230

MMSCFD). A new compressor station has been installed at

Muchai that has increased the capacity of the existing pipeline

and the supply pressure of the Ashuganj main gas

transmission hub. The deigned network only covers the

source and the supply points and simulates the pressure drop

in the upstream when consumption increases downstream of

the Ashuganj.

Keywords-- BAPEX, BEGGS, MMSCF, PIPESIM

I. INTRODUCTION

Behavior of Pressure Change in Natural gas transmission is

important as higher hydrocarbons are liquefiable in low to

moderate pressure levels. Eventually high water content and

hydrocarbon liquid perform as a bad actor for the sales gas

pipeline. Prediction in pressure drop helps to determine the

safe operation limits along with the volume of dry sales gas to

be transmitted in a given situation.

North south pipeline and the Brahmaputra basin pipelines are

two major ones among the total gas transmission network of

Bangladesh. The Gas production wells situated at the northern

part of the country are connected with North South pipeline,

which hardly contains any specific Gas Consumption points.

The only Gas Consumption Point is FPS (Fenchuganj Power

Station).

NATURAL GAS TRANSMISSION SYSTEM OF BANGLADESH

The natural gas transmission pipeline infrastructure in

Bangladesh represents a complex mechanical system that

delivers about 1900 MMSCF [1] of natural gas per day, and is

made up of over 1400 km (870 miles) [2] of pipe. This

system has been developed over the last few years, and is

controlled at a very low level of sophistication. A

mathematical model to simulate pipeline system operation, as

well as the impact of design changes and equipment

enhancements, is urgently needed for this huge system.

The Brahmaputra basin pipeline is the only link of our gas

supply to the western part of the country. Currently this part is

operating at full capacity. But the demand is increasing

specially a new fertilizer company is going to be constructed

at Sirajganj, and gas supply line should be extended to

Khulna.

Gas transmission Company Limited (GTCL) is now

responsible for maintenance and operation of the gas

transmission pipeline across the country. They are using

PIPELINE STUDIO for simulation works. In this study

PIPESIM 2009 has been used for gas transmission network

analysis and simulation.

For this increasing demand the existing pipeline is not enough

to transmit such huge volume of gas, unless a new pipeline is

designed and added as a loop to the main gas transmission

network. The largest gas producing field BIBIYANA is

planning to expand its production from 800 MMSCF to 1.2

BCF per day and one dedicated pipeline has been planned to

join the main north-south pipeline and a loop.

At present Gas is Produced by state owned enterprises i.e.

companies of Petrobangla and International Oil Companies

(IOC). Eighteen gas fields are producing around 1900

MMSCF [2] gas per day. BGFCL and Chevron (an IOC) are

196

International Journal of Chemical, Environmental & Biological Sciences (IJCEBS) Volume 1, Issue 1 (2013) ISSN 23204087 (Online)

simulated data have been compared with the actual data from

the GTCL data sheet [2]

II. SIMULATION BY PIPESIM

The Natural Gas transmission process involves pressure and

temperature change due to the frictional loss, difference in

elevation, gas velocity, and Joule-Thompson effect. Effective

heat transfer from or to the surroundings is also responsible

for temperature change across the pipeline. Pressure and

temperature change along with liquid and solid (hydrate)

formation in the line also affects the pressure profile.

Modeling and simulation of multiphase system, even under

steady-state condition, is complex. There are a few tools

designed specifically for modeling and analysis of complex

multiphase systems such as PipePhase, PipeSim, OLGA, etc.

III. SIMULATION RESULTS

The Pipesim simulation report mainly contains two parts.

They are analytical data i.e. pressure, temperature, mass flow

rate, gas flow rate and water cut. The other part of the report

contains graphical representation of data. This part contains

elevation with dissonance, pressure drop with respect to the

length of the pipe and temperature profile along with the

length of the pipe.

Before this simulation, a fluid model has been defined

according to the sales gas specification data of GTCL. Beggs

and Brill [3] fluid flow correlation has been used for

horizontal flow. Though no vertical elevation has been

defined in the gas transmission network Hagedorn & Brown

Correlation has been defined as the fluid flow model for

vertical flow. Allowable amount of water and liquefiable

hydrocarbons are also defined according to the standard

provided by GTCL.

As this report is dealing only with the natural gas

transmission, the temperature profile is not one of the major

factors for discussion. The pressure drop along with distance

is the main concern for this report. The simulated data have

been compared with the actual pressure temperature data and

the compared result has been plotted together. Two separate

graphs have been plotted representing the pressure profile of

N-S and Brahmaputra basin pipeline. Only data from the

specific sources and supply points have been analyzed.

The fluid model [4] is the main prerequisite that should be

defined first when drawing a gas transmission network model.

Here the model has been defined according to the sales gas

specification of GTCL. Maximum allowable water in the

supplied Gas = 7 lbs/MMSCF and maximum allowable

Condensate = 2gal / MMSCF.

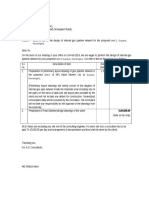

TABLE I: PRESSURE AT DIFFERENT SOURCES IN N-S PIPELINE

Sources

Real

Simulat Supply

Pressure ed

(MMSC

(Psi)

Pressur FD)

e (Psi)

1076

1077.7

100

Kaitashtila

Feni

Rashidpur

Hobiganj

Titas-E

Bibiyana

Jalalabad

Moulavibaza

ar

Table 4.1: Used Fluid Model in PIPESIM [4]

Element

Mol %

Nitrogen

0.339

Methane

95.678

Ethane

2.638

Propane

0.460

CO 2

0.052

Butane

0.080

isobutane

0.326

isopetane

0.087

n pentane

0.025

Hexane

0.084

Heptane+

0.231

1060

1008

970

855

1000

1077

1050

1022.7

891.96

930.46

755.24

1155

1101

922.44

5

50

245

45

450

170

100

Figure A: Pressure of Different Gas

Fields

Finally the pressure drop calculation method with an example

has been shown before presenting the simulation work. The

pressure drop data have been plotted along with the distance.

The detailed result shows the pressure, temperature data at

different points of the network.

The temperature effect has been considered negligible and has

not been considered in the simulation plot. The pressure drop

profile has been plotted with the horizontal distance. The

197

International Journal of Chemical, Environmental & Biological Sciences (IJCEBS) Volume 1, Issue 1 (2013) ISSN 23204087 (Online)

Figure B: Pressure Drop in North South Pipeline

Pressure drop across the horizontal distance may be

clarified on the following pictures. This is evident that the

pressure drop is greater across the Brahmaputra basin

pipeline as the major part of the consumers lies within the

area. Each horizontal point in figure B has several branches

and it clarifies the contribution of different gas processing

fields. As there is limited number of users comparatively,

the pressure drop profile has a less sharp declination across

this pipeline.

From the Ashuganj hub to the Brahmaputra Basin Pipeline

the profile is different. As the section has mainly major

consumers of the north south pipeline producers, steep

pressure drop is expected to be observed along the pipeline.

The Simulated pressure profile has been compared with the

real time data. During Low demand period or high demand

projection in the future.

Figure C: Pressure of Gas Supply Points

On the other plot a completely different behavior of

pressure drop has been observed. On each horizontal point,

different pressure curves have been observed which is quiet

unusual. The presence of different consumption point along

with different supply arrangement has caused this unusual

behavior of pressure drop. However, the overall pressure

drop with horizontal distance is much sharper that that of

the N-S pipeline. The curve has more vertical branches

when the horizontal distance is more than 1, 00,000 ft.

The excel plot shows the value of actual and simulated

pressure and it is evident that different supply points have

higher value of simulated pressure than actual pressure. The

pipe roughness and other contributing factors such as:

temperature and frictional loss may be responsible in this

regard.

198

International Journal of Chemical, Environmental & Biological Sciences (IJCEBS) Volume 1, Issue 1 (2013) ISSN 23204087 (Online)

Figure D: Pressure Drop from Ashuganj to Brahmaputra Basin Pipeline

1.

2.

3.

4.

opportunity to observe the effects on

consumption on the consumer end.

VI.

DISCUSSION

The Pipesim model has simulated the pressure at different

supply points and also at different sources. There are

important issues that have been clarified:

The compressor station at muchai has come online on

April, 2012. On the existing gas transmission pipeline the

quantity of gas transmission has been increased. The

simulation has clarified the justification of installing the

compressor station.

5.

During Eid and other national holiday the consumption

downstream of Ashuganj decreases and the gas

processing plants heavily suffers to swing down their

load during that period. The simulation has projected the

conditions under various pressure conditions.

abnormal

Depending on a transmission system that is more than 30

years old, the existing transmission network has aged

transmission pipelines that could be assumed to posses

different roughness and inside diameter than the

installation period. Changing the parameters in Pipesim

the transmission conditions could be simulated using

more realistic data.

VII.

LIMITATIONS AND IMPROVEMENT OPTIONS

Designing a simulation network that only has the segment

of the total transmission system, has some limitations and

improvements opportunities.

The natural gas consumption has increased exponentially

over the last few years because of heavy industrialization

and intense population. As a result, it is naturally

expected that the demand will rise in the near future. The

pressure plot from the Ashuganj hub to the Brahmaputra

basin pipeline has a lot more clarification about the

condition of the present consumption scenario of

Bangladesh.

The liquid recovery system by individual gas producing

fields has not been monitored by the Gas Transmission

Company Limited. So the amount of liquefiable

hydrocarbons on the sales gas needs to be monitored and

during the sudden pressure drop condition on the

consumer end the effect needs to be observed. This model

has enabled the opportunity to change the fluid model

according the sales gas composition and provided the

199

1.

The government of Bangladesh is planning to extend the

gas transmission network to the southern part of the

country. The proposed expansion network can be added

with the current network.

2.

The transmission network on the south-east part of the

country (Chittagong zone) has not been added with the

existing simulation network. As a number of industries

are waiting to be started the consumption is expected to

rise in the next few years.

3.

The Muchai compressor project has not been considered

for simulation, adding the compressor station will enable

the current model to simulate that how much additional

International Journal of Chemical, Environmental & Biological Sciences (IJCEBS) Volume 1, Issue 1 (2013) ISSN 23204087 (Online)

amount of gas is possible to transmit on this existing

pipeline network.

4.

This section could be added with the existing network

model

REFERENCES

[1]

The biggest gas processing field, Bibiyana gas plant

operated by Chevron is going under an expansion project

and total gas flow from Bibiyana is expected to rise up to

1.2 BCF from the year 2013 with the introduction of 5

additional wells. Considering these conditions an

additional 24 inch dedicated pipeline will be installed for

transmitting the total gas from Bibiyana to Ashuganj.

[2]

[3]

[4]

200

Gas Transmission Company Limited, Daily Gas Production and

consumption Report, pp.1-4, 13 July, 2012

Gas Transmission Company Limited Annual Report 2009-2010 PP. 14, July 2011.

Beggs, H. D.,Brill, J. P., A Study of Two-Phase Flow in Inclined

Pipes, J. Pet. Tech. pp. 607-617, May 1973.

PMRE department, BUET, Gas Analysis of KTL metering station

(Chevron), pp. -1, August 2010

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Regards Md. Ariful Haque Fakir Project Director M-A Parallel ProjectДокумент1 страницаRegards Md. Ariful Haque Fakir Project Director M-A Parallel ProjectRahmat UllahОценок пока нет

- Types of Flame: Diffusion FlameДокумент1 страницаTypes of Flame: Diffusion FlameRahmat UllahОценок пока нет

- HP Laserjet Pro M402D Printer (C5F92A) : Product IdДокумент5 страницHP Laserjet Pro M402D Printer (C5F92A) : Product IdRahmat UllahОценок пока нет

- Fire Lecture002Документ1 страницаFire Lecture002Rahmat UllahОценок пока нет

- Fire Lecture001Документ1 страницаFire Lecture001Rahmat UllahОценок пока нет

- Air-Conditioning Systems: Prof. Dr. M. Zahurul Haq Zahurul@me - Buet.ac - BDДокумент12 страницAir-Conditioning Systems: Prof. Dr. M. Zahurul Haq Zahurul@me - Buet.ac - BDRahmat UllahОценок пока нет

- Air-Conditioning Systems: Prof. Dr. M. Zahurul Haq Zahurul@me - Buet.ac - BDДокумент12 страницAir-Conditioning Systems: Prof. Dr. M. Zahurul Haq Zahurul@me - Buet.ac - BDRahmat UllahОценок пока нет

- Image of Cover StoryДокумент2 страницыImage of Cover StoryRahmat UllahОценок пока нет

- Offer of Fee - Gas Pipe NetworkДокумент1 страницаOffer of Fee - Gas Pipe NetworkRahmat UllahОценок пока нет

- Proposed Project LengthДокумент1 страницаProposed Project LengthRahmat UllahОценок пока нет

- Specification of The Gas Produced in Bangladesh: Interconnecting Pipeline ParametersДокумент1 страницаSpecification of The Gas Produced in Bangladesh: Interconnecting Pipeline ParametersRahmat UllahОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Solutions To Practice Problems, Module 3: Engineering MechanicsДокумент13 страницSolutions To Practice Problems, Module 3: Engineering MechanicsShaun Patrick AlbaoОценок пока нет

- Electrical and Electronic Measurements and InstrumentationДокумент12 страницElectrical and Electronic Measurements and InstrumentationKarthik VОценок пока нет

- SCS Quad Beams SeriesДокумент4 страницыSCS Quad Beams SeriesJeffrey BaldwinОценок пока нет

- Frida Kunti Setiowati, Barlah Rumhayati: Seminar Nasional XI Pendidikan Biologi FKIP UNS 125Документ6 страницFrida Kunti Setiowati, Barlah Rumhayati: Seminar Nasional XI Pendidikan Biologi FKIP UNS 125Ridwan PutraОценок пока нет

- User Guide: Elcometer 147Документ4 страницыUser Guide: Elcometer 147sergioОценок пока нет

- Exercises in Cell BiologyДокумент65 страницExercises in Cell BiologyZvijezdaОценок пока нет

- Top 40 Civil Engineer Interview QuestionsДокумент18 страницTop 40 Civil Engineer Interview QuestionsAkhtar Ali100% (2)

- Flexibility FactorsДокумент61 страницаFlexibility FactorsCarlos BorgesОценок пока нет

- Form 4 Chemistry Yearly Plan 2019Документ2 страницыForm 4 Chemistry Yearly Plan 2019Jenny WeeОценок пока нет

- ECB Non Turf Cricket Wicket PDFДокумент23 страницыECB Non Turf Cricket Wicket PDFJames OttaОценок пока нет

- Tank Design CalculationДокумент20 страницTank Design CalculationHairil HerliansyahОценок пока нет

- Report WritingДокумент24 страницыReport WritingVasudevanОценок пока нет

- Data Sheets de Todos Cabos Da ListaДокумент20 страницData Sheets de Todos Cabos Da ListaLaercio ChissicoОценок пока нет

- CNTH Skema Fizik Paper 3Документ3 страницыCNTH Skema Fizik Paper 3Norfadila Mat JusofОценок пока нет

- PhysicsДокумент28 страницPhysicsamritam yadavОценок пока нет

- Division 2 - Site WorkДокумент14 страницDivision 2 - Site WorkWincelet CelestinoОценок пока нет

- Introduction To Quaternions With Numerou PDFДокумент249 страницIntroduction To Quaternions With Numerou PDFRicardoОценок пока нет

- Chapter 8 CoordinatesДокумент13 страницChapter 8 CoordinatesWei ZhaoОценок пока нет

- Formsat 5Документ6 страницFormsat 5gramuiitmОценок пока нет

- The Multiple Directions of Antiferromagnetic Spintronics Nature Physics PDFДокумент4 страницыThe Multiple Directions of Antiferromagnetic Spintronics Nature Physics PDFLog LouОценок пока нет

- Nastran DST Group TN 1700Документ69 страницNastran DST Group TN 1700Minh LeОценок пока нет

- Unit-I: Fundamentals of Gas DynamicsДокумент45 страницUnit-I: Fundamentals of Gas DynamicsMuthuvel MОценок пока нет

- Leica ICD Brochure enДокумент4 страницыLeica ICD Brochure enCsaba GibártiОценок пока нет

- Experiences of ISFOC On Concentration Photovoltaic: Francisca RubioДокумент49 страницExperiences of ISFOC On Concentration Photovoltaic: Francisca RubioHikary AcevesОценок пока нет

- ValveTypesSelection - ControlsWikiДокумент42 страницыValveTypesSelection - ControlsWikiMayur PatelОценок пока нет

- SkyscrapersДокумент31 страницаSkyscrapersAnas Shaikh100% (1)

- Basics of Mining and Mineral ProcessingДокумент179 страницBasics of Mining and Mineral Processingminerales&materiales100% (6)

- Is Your Mesh Refined Enough? Estimating Discretization Error Using GCIДокумент10 страницIs Your Mesh Refined Enough? Estimating Discretization Error Using GCIFareena FatimaОценок пока нет

- Disturbance-Rejection vs. SetpointДокумент5 страницDisturbance-Rejection vs. SetpointravaraeОценок пока нет

- Modified Moment Estimation For A Two Parameter Gamma DistributionДокумент9 страницModified Moment Estimation For A Two Parameter Gamma DistributionInternational Organization of Scientific Research (IOSR)Оценок пока нет