Академический Документы

Профессиональный Документы

Культура Документы

WSA02 2002 Part4 2 3

Загружено:

abhijithavalОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

WSA02 2002 Part4 2 3

Загружено:

abhijithavalАвторское право:

Доступные форматы

Sewerage Code of Australia

Part 4: Standard Drawings

Second Edition

Version 2.3

WSA 022002-2.3

210

CONTENTS

27 INTRODUCTION

212

27.1 GENERAL

27.2 DRAWING COMMENTARY

212

212

28 LISTING OF STANDARD DRAWINGS

213

29 COMMENTARY ON SEW1100 SERIES PIPELINE LAYOUT

215

29.1 GENERAL

215

29.2 SEW1100 TO SEW1102 DESIGN LAYOUTS

215

29.2.1 SEW1100 Locality and site plan

215

29.2.2 SEW1101 Longitudinal sections

215

29.2.3 SEW1102 Schedule of Works

215

29.3 SEW1103 TYPICAL ARRANGEMENTS

216

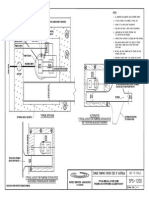

29.4 SEW1104 AND SEW1105 PROPERTY CONNECTION DETAILS

216

29.5 SEW1106 AND SEW1107 PROPERTY CONNECTION DETAILS METHODS 216

29.5.1 SEW1106 IO interface method

217

29.5.2 SEW1107 Buried interface method

218

29.6 SEW1108 PROPERTY CONNECTION DETAILS Y BRANCH AND AROUND

OBSTRUCTIONS

218

29.7 SEW1109 PROPERTY CONNECTION DETAILS PRIVATE PROPERTY & MARKING

SYSTEMS

218

30 COMMENTARY ON SEW1200 SERIES EMBEDMENT AND TRENCH FILL 219

30.1 GENERAL

219

30.2 MAXIMUM DEPTH TO INVERT FOR STANDARD SUPPORT TYPES

220

30.3 SEW1200 SOIL CLASSIFICATION GUIDELINES

224

30.4 SEW1201 EMBEDMENT AND TRENCHFILL TYPICAL ARRANGEMENTS

224

30.5 SEW1202 STANDARD EMBEDMENT FLEXIBLE AND RIGID PIPES

225

30.6 SEW1203 SPECIAL EMBEDMENT INADEQUATE FOUNDATIONS

225

30.7 SEW1204 SPECIAL EMBEDMENT SUPPORT USING PILES

225

30.8 SEW1205 SPECIAL EMBEDMENT CONCRETE AND STABILISED SUPPORTS 225

30.9 SEW1206 BULKHEADS AND TRENCHSTOP

226

30.10 SEW1207 TRENCH DRAINAGE TYPICAL SYSTEMS

226

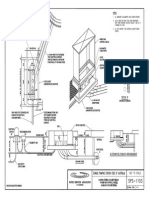

30.11 SEW1208 VERTICALS AND NEAR VERTICALS EXPOSED AND CONCEALED

METHODS

226

31 COMMENTARY ON SEW1300 SERIES MAINTENANCE STRUCTURES

31.1 GENERAL

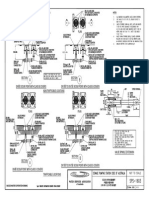

31.2 SEW1300 SEWERS DN 300 PRECAST MH TYPES P1 AND P2

31.3 SEW1301 CAST IN-SITU MH TYPES C1 AND C2

31.4 SEW1302 MH PIPE CONNECTION DETAILS

31.5 SEW1303 SEWERS DN 300 MH CHANGE IN LEVEL ARRANGEMENTS

31.6 SEW1304 AND SEW1305 MH CHANNEL ARRANGEMENTS AND DETAILS

31.7 SEW1306 ALTERNATIVE MH DROP CONNECTIONS

31.8 SEW1307 STEP IRONS AND LADDERS

31.9 SEW1308 TYPICAL MH COVER ARRANGEMENTS

31.10 SEW1309 TO SEW1312 INCLUSIVE SPECIAL MHS

31.10.1 SEW1309 Sewers DN 375 to DN 750 MHs

31.10.2 SEW1310 Special MHs using permanent formwork

31.11 SEW1311 AND SEW1312 DEEP MHS

31.12 SEW1313 TO SEW1316 INCLUSIVE MAINTENANCE SHAFTS

31.13 SEW1317 MH CONNECTION DETAILS PE PIPE

COPYRIGHT

227

227

227

227

227

228

228

228

228

228

229

229

229

229

230

230

211

WSA 022002-2.3

32 COMMENTARY ON SEW1400 SERIES SPECIAL CROSSINGS / STRUCTURES

ARRANGEMENTS

231

32.1 GENERAL

32.2 SEW1400 SYPHON ARRANGEMENT

32.3 SEW1401 TO SEW1403 INCLUSIVE BURIED CROSSINGS

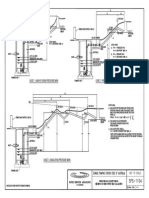

32.4 SEW1404 TO SEW1406 INCLUSIVE AERIAL CROSSINGS

32.5 SEW1407 AND SEW1408 VENTILATION SYSTEMS

32.6 SEW1409 TO SEW1411 INCLUSIVE WATER SEAL ARRANGEMENTS

32.7 SEW1412 EMERGENCY RELIEF STRUCTURES

231

231

231

231

232

232

233

33 COMMENTARY ON SEW1500 SERIES INSERTIONS AND REPAIR SYSTEMS

234

33.1 GENERAL

33.2 SEW1500 CUT-IN METHODS

33.3 SEW1501 INSERTION OF JUNCTIONS

33.4 SEW1502 CONSTRUCTION OF MHS AND MSS OVER EXISTING SEWERS

STANDARD DRAWINGS

234

234

234

234

237

TABLES

TABLE 29.1 MINIMUM RETICULATION AND PROPERTY CONNECTION SEWER

SIZES

TABLE 29.2 EQUIVALENT STIFFNESS CLASSES FOR PVC SEWERS

TABLE 30.1 MAXIMUM DEPTH TO INVERT FOR PVC SEWERS

TABLE 30.2 MAXIMUM DEPTH TO INVERT FOR GRP SEWERS

TABLE 30.3 MAXIMUM DEPTH TO INVERT FOR VC SEWERS

TABLE 30.4 MAXIMUM DEPTH TO INVERT FOR RC SEWERS

TABLE 30.5 MAXIMUM PARTICLE SIZE

COPYRIGHT

217

217

221

222

222

224

225

WSA 022002-2.3

212

27 INTRODUCTION

27.1 GENERAL

Standard Drawings are included in the Sewerage Code of Australia to assist in

understanding of the principles and methodology involved in construction of sewerage

systems and to enhance the design and construction Parts of this Code. The Drawings

should be read in conjunction with the balance of the Code.

The Drawings included in this Part of the Code provide deemed-to-comply solutions for the

installation of most elements of a sewerage system. However, they will not suit all

circumstances or overcome all problems. To meet special needs, Designers and

Constructors are encouraged to identify improved construction methods and other

variations from the requirements set out in the Standard Drawings. Authorisation by the

local Water Agency will be necessary before any major departure from the principles

outlined in the drawings are implemented. Successful initiatives will be considered by

WSAA for inclusion in future editions of this Code.

All Design Drawings should include the name of the Water Agency and have a signature

block to allow confirmation that each drawing complies with Water Agency requirements.

The symbols and markings used on these Drawings are typical only and do not apply to

any particular Water Agency (Refer to the individual Water Agency for their legend, symbol

and layout requirements).

Individual Water Agencies may have specific information and presentation requirements,

which should be determined before commencing any project. Any additional information,

layout or format requirements specified by the Water Agency take precedence over these

Drawings.

All special requirements including, but not limited to geotechnical requirements,

embedment and compaction details, should be shown in the Design Drawings and/or the

Specification.

27.2 DRAWING COMMENTARY

This informative commentary preceding the Drawings provides background information on

the purpose and content of the Standard Drawings and serves as a general guide for

Designers and Constructors, as well as a training aid. The use of separate commentary

avoids excessive detail and complexity in the Drawing notes.

The Designer is responsible for ensuring that Design Drawings and Specifications clearly

address the issues of a particular project. It is the Designers responsibility to provide

detailed requirements such as trench depth, embedment and fill materials, concrete type

and reinforcement in the Design Drawings.

Both the Designer and Constructor should understand information relevant to selecting a

feasible solution to a design and/or construction problem. Many of the Standard Drawings

are typical and are not suitable for use without further design detail.

COPYRIGHT

WSA 022002-2.3

213

28 LISTING OF STANDARD DRAWINGS

DRAWING

NUMBER

ACTIVITY

TITLE

Equivalent

1999

DRAWING

NUMBER

PIPELINE LAYOUT

SEW1100

Design Layouts

Typical Locality & Site Plan

new

SEW1101

Design Layouts

Longitudinal Sections

new

SEW1102

Design Layouts

Connection to Existing Sewer

new

Schedule of Works

SEW1103

Pipelaying

Typical Arrangements

new

SEW1104

Property Connection Details

Sewer in Road Reserve

SEW300

SEW1105

Property Connection Details

Sewer in Easements & Inside Property

SEW301

SEW1106

Property Connection Details

IO Interface Method

SEW1107

Property Connection Details

Buried Interface Method

SEW1108

Property Connection Details

Y Branch & Around Obstructions

SEW303

SEW1109

Property Connection Details

Private Property & Marking Systems

SEW304

SEW302

EMBEDMENT / TRENCHFILL AND SUPPORT SYSTEMS

SEW1200

Soil Classification Guidelines And

Allowable Bearing Pressures for Bulkheads

WAT400

SEW1201

Embedment and Trenchfill

Typical Arrangements

SEW100

SEW1202

Standard Embedment

Flexible & Rigid Pipes

SEW1203

Special Embedment

Inadequate Foundations Requiring Over

Excavation & Replacement

SEW1204

Special Embedment

Support Utilising Piles

SEW1205

Special Embedment

Concrete & Stabilised Supports

SEW1206

Trench Drainage

Bulkheads & Trenchstop

SEW103

SEW1207

Trench Drainage

Typical Systems

SEW104

SEW1208

Verticals & Near Verticals

Exposed & Concealed Methods

SEW211

SEW101

SEW102

ACCESS STRUCTURES

SEW1300

Maintenance Holes

Sewers DN 300

Precast Types P1 & P2

SEW201

SEW1301

Maintenance Holes

Sewers DN 300

Cast Insitu Types C1 & C2

SEW202

SEW1302

Maintenance Holes

Pipe Connection Details

new

SEW1303

Maintenance Holes

Sewers DN 300

Changes in Level Details

SEW203

SEW1304

Maintenance Holes

For Sewers DN 300

Typical Channel Arrangements

SEW204

SEW1305

Maintenance Holes

Typical Channel Details

SEW205

COPYRIGHT

WSA 022002-2.3

DRAWING

NUMBER

214

ACTIVITY

TITLE

Equivalent

1999

DRAWING

NUMBER

ACCESS STRUCTURES continued

SEW1306

Maintenance Holes

Alternative Drop Connections

SEW206

SEW1307

Maintenance Holes

Step Irons & Ladders

SEW208

SEW1308

Maintenance Holes

Typical MH Cover Arrangements

SEW207

SEW1309

Maintenance Holes

Sewers DN 375 to DN 750

new

SEW1310

Maintenance Holes

Permanent Formwork DN 375

new

SEW1311

Maintenance Holes

Depth to Invert 6 m to 15 m

new

SEW1312

Maintenance Holes

Depth to Invert > 15 m

new

SEW1313

Maintenance Holes

MH Connection Details

DN 110 to DN 450 PE Pipe

new

SEW1314

Maintenance Shafts

Typical Installation

SEW209

SEW1315

Maintenance Shafts

MS & Variable Bend Installations

new

SEW1316

Maintenance Shafts

TMS and Connection Installations

SEW210

SEW1317

Maintenance Holes

Typical MS Cover Arrangements

SEW212

SPECIAL CROSSINGS / STRUCTURES ARRANGEMENTS

SEW1400

Buried Crossings

Syphon Arrangement

SEW105

SEW1401

Buried Crossings

Railways

new

SEW1402

Buried Crossings

Major Roadways

new

SEW1403

Buried Crossings

Bored & Jacked Encasing Pipe Details

new

SEW1404

Aerial Crossings

Aqueduct

SEW106

SEW1405

Aerial Crossings

Aqueduct Protection Grille

SEW107

SEW1406

Aerial Crossings

Bridge Crossing Concepts

new

SEW1407

Ventilation Systems

Induct Vent

SEW213

SEW1408

Ventilation Systems

Educt Vent

SEW213

SEW1409

Water Seal Arrangements

Mains Type

SEW214

SEW1410

Water Seal Arrangements

Maintenance Hole System

new

SEW1411

Water Seal Arrangements

Twin Maintenance Hole System

new

SEW1412

Emergency Relief Structures

Typical Arrangement DN 150 to DN 375

new

CONNECTIONS TO EXISTING SYSTEMS

SEW1500

Insertions & Repair Systems

Cutin Methods

new

SEW1501

Insertions & Repair Systems

Insertion of Junctions

new

SEW1502

Insertions & Repair Systems

Maintenance Structures

new

COPYRIGHT

215

WSA 022002-2.3

29 COMMENTARY ON SEW1100 SERIES PIPELINE LAYOUT

29.1 GENERAL

The 1100 series of Drawings deals with the design, layout and placement of sewers and

property connection sewers.

AS 1100 Part 4011984, which specifies standard drawing symbols for sewerage, has not

been adopted by WSAA. A consensus standard is yet to be developed. Water Agencies

should specify their individual requirements.

29.2 SEW1100, SEW1101 AND SEW1102 DESIGN LAYOUTS

SEW1100 and SEW1101 are typical of drawings that should be included in any set of

Design Drawings in order to provide information necessary for the Constructor to construct

and install the Works. SEW1102 is an alternative option for presenting this information.

The Drawings detail the following:

(a)

location and type of sewers;

(b)

depth of sewers and property connection points;

(c)

position of MHs, MSs and variable bends;

(d)

details of property connection sewers; and

(e)

location of other utility mains, services, storm water drains etc.

29.2.1 SEW1100 Locality and site plan

SEW1100 shows a typical locality and site plan arrangement that forms part of the Design

Drawings and shows details of the overall project and other general information required

for the project.

For larger developments, the locality plan may be on a separate drawing. The locality plan

should have a minimum scale of 1:2500 and provide enough information for the site to be

identified.

The site plan drawing(s) should be at a minimum scale of 1:1000 and provide all

information necessary for installation of sewers, maintenance structures, appurtenances

and property connection sewers.

29.2.2 SEW1101 Longitudinal sections

SEW1101 shows a typical longitudinal plan (elevation). Because sewers operate under

gravity flow with critical grades, the longitudinal plan is provided to show depths and

positions of all critical elements and obstructions. It is an extension of the site plan and

directly relates to all individual sections of the sewer e.g. MH to MH.

The preferred scales for longitudinal plans are:

(a)

Horizontal scale 1:1000, and

(b)

Vertical scale 1:100.

An individual Water Agency may have alternative format requirements or may require the

information to be shown in a tabular format.

29.2.3 SEW1102 Schedule of Works

SEW1102 is a typical example of connection to existing sewers and schedule of works

information in tabular format showing requirements for linkins and changes to MHs and is

typical of the type of information that may be required by a Water Agency.

COPYRIGHT

WSA 022002-2.3

216

29.3 SEW1103 TYPICAL ARRANGEMENTS

SEW1103 shows a typical sewer layout and the relative positions of MH, MS, variable

bends, property connection sewers and water seals.

Wherever possible, the sewers should be laid so that the flow is in the direction socket end

to spigot end of each pipe or fitting.

29.4 SEW1104 AND SEW1105 PROPERTY CONNECTION DETAILS

Water Agencies may have different requirements for:

(a)

Location of reticulation sewers e.g. in easement, private property, road reserve.

(b)

Connection of customer sanitary drains.

(c)

Definition of the interface between Agency and customer ownership and

responsibility for maintenance.

Water Agency requirements should be determined before commencing design.

Two common practices for connection and definition of the interface between the Water

Agency owned (and maintained) sewer and the customer sanitary drain are:

(i)

Inspection opening (IO) interface method.

(ii)

Buried interface method.

For the buried interface method, the junction delineates Water Agency and private

ownership. The property owner is responsible for employing a drainer to connect to the

junction. AS/NZS 3500.2.2 requires the drainer to install an IO as part of the customer

sanitary drain. The property owner is responsible for clearing blockages upstream of the

junction. Due to uncertainty regarding the location of a problem in the section of customer

sanitary drain between IO and junction, some Water Agencies may accept responsibility for

blockages downstream of the customer IO.

SEW1104 and SEW1105 show typical layouts of sewers and general arrangements for

property connection sewers. They also show various configurations as they relate to the IO

and buried interface methods of property connection.

SEW1104 shows various positions for the property connection, which may be authorised

by the Water Agency for locations for a sewer located in the road reserve.

SEW1105 shows various positions for property connections for a sewer located in an

easement or inside a property boundary.

29.5 SEW1106 AND SEW1107 PROPERTY CONNECTION DETAILS METHODS

SEW1106 and SEW1107 show details of property connection sewers and connection

points for the IO interface method and the buried interface method.

Minimum sewer sizes for reticulation and property connection sewers for residential and

commercial zones and buildings are summarised in Table 29.1. Standard laying depth of

the property connection sewer should be in accordance with Water Agency requirements.

The point of connection for a customer drain should be 1.5 m below the surface. The

depth of the connection point should take account of AS 3500.2 requirements for soffit,

minimum cover and grade of the customer sanitary drain. Clause 4.6.5.4 provides details

of property connection requirements.

Details of property connection sewers and points of connection should be included in the

Design Drawings.

COPYRIGHT

WSA 022002-2.3

217

TABLE 29.1

MINIMUM RETICULATION AND PROPERTY CONNECTION SEWER SIZES

Pipe size

Applicability

DN

Reticulation sewers

Customer sanitary drains

100

Not used

Residential buildings

150

Residential zones

Commercial buildings

225

Commercial zones

Exceptional cases only

The vertical drop distances shown in the Standard Drawings relate to the vertical distance

from the invert of the sewer to the invert of the horizontal section of the property

connection sewer.

Where installation is in rock, the trench should be excavated past the end of the interface

point of the property connection sewer. Clause 15.2 specifies a minimum distance, which

enables safe excavation of the property owners sanitary drain without damaging the

property connection fitting.

AS/NZS 1260 now specifies PVC sewer pipe by its stiffness (SN). The PVC pipe stiffness

classes (depending on Water Agency requirements) and equivalent previous system

values are as summarised in Table 29.2.

TABLE 29.2

EQUIVALENT STIFFNESS CLASSES FOR PVC SEWERS

Pipe size

DN

Equivalent stiffness classes

AS/NZS 1260:1996 and earlier

AS/NZS 1260:1999 and following

SN4

100

150

a (SH)

SN6

a*

SN8

a (SEH)

SN10

a (SH)

SN4

SN6

a (SEH)

SN8

SN10

NOTE: * covers existing profiled wall pipe

29.5.1 SEW1106 IO interface method

SEW1106 complements SEW1104 and SEW1105. It relates only to the inspection

opening (IO) interface method.

For the IO interface method, the main reticulation sewer is laid in public property and a

property connection sewer is constructed to provide a point of connection for the property

owners sanitary drain. An IO, constructed as part of the Water Agency property connection

sewer, defines the change of ownership from Agency to property owner. The Agency owns

the IO and the property connection sewer downstream of the IO. The property owner owns

the sanitary drain upstream of the IO and is responsible for its maintenance.

The Drawing shows typical layouts and connection details for various depths of sewer, as

well as the interface point between the Agency sewer and the property owners sanitary

drain.

COPYRIGHT

WSA 022002-2.3

218

The end of the property connection sewer is nominally at the pipe joint on the upstream

side of the IO fitting. Some Agencies may require an additional short length of pipe (with a

threaded coupling and cap) to keep the sanitary drain trench away from the surface cover

and frame. The property connection sewer should be at the required depth to service the

property.

29.5.2 SEW1107 Buried interface method

SEW1107 complements SEW1104 and SEW1105. It relates only to the buried interface

method. There are two variations to this method:

(a)

The point of connection is a junction installed in the sewer within the customers

property. The junction is plugged at the time of construction. The Water Agency

owns the junction and downstream sewer. The Water Agency does not require an

IO to be constructed as part of the reticulation sewer.

The property owner is responsible for providing, connecting and maintaining an IO

and sanitary drain in accordance with AS/NZS 3500.2.2.

(b)

The point of connection is a junction installed at the end of a property connection

sewer terminating within the customers property. The junction is plugged at the

time of construction. The Water Agency may specify a rodding point to be

connected to the junction. The Agency owns the property connection sewer,

junction and any rodding point.

The property owner is responsible for providing, connecting and maintaining an IO

and sanitary drain in accordance with AS/NZS 3500.2.2.

For connection to a deep reticulation sewer, a drop junction or vertical riser (jump up)

may be required to provide a property connection point closer to the surface (Refer to

Clause 4.6.5.4).

29.6 SEW1108 PROPERTY CONNECTION DETAILS Y BRANCH AND AROUND

OBSTRUCTIONS

SEW1108 complements SEW1104 and SEW1105 and shows typical property

connections details for Y branches and around obstructions.

The property connection sizes should be detailed in the Design Drawings.

Minimum clearances from obstructions should be in accordance with Table 4.2.

29.7 SEW1109 PROPERTY

MARKING SYSTEMS

CONNECTION

DETAILS PRIVATE

PROPERTY

&

SEW1109 complements SEW1104 and SEW1105. It shows details for connection to a

deep reticulation sewer using the buried interface method. A vertical riser (jump up) may

be required to raise the point of connection to the customer sanitary drain to 1.5 m below

FSL. The Designer should determine Water Agency requirements where the connection

level required to drain the property is greater than 1.5 m below the surface e.g. when grade

of sewer is against the fall of the land. The Designer should also determine the Water

Agency preference for the base arrangement to the vertical riser.

SEW1109 also shows location marker systems for the buried interface method of property

connection. A marker peg and a marking tape system are detailed. The Designer should

determine the Water Agency preference for the location marker system.

COPYRIGHT

219

WSA 022002-2.3

30 COMMENTARY ON SEW1200 SERIES EMBEDMENT AND TRENCH FILL

30.1 GENERAL

The 1200 series of Drawings deals with appropriate embedment and trench fill for

particular locations and methods of installation, including sewers in difficult soil conditions.

It is the Designers responsibility to make every effort to identify potential problems and

provide appropriate solutions. Although the arrangements shown in these drawings are

deemed to comply solutions, the Designer is required to nominate relevant details for a

specified project. Engineering advice based on geotechnical information from site may

require alternative methods, which should be detailed in the Design Drawings and/or

Specification.

Construction within any public road will generally not be permitted until the relevant Owner

has approved the traffic management plan.

All underground and surface obstructions along the route of the proposed sewer should be

determined and shown on the Design Drawings with appropriate danger notes. This is

particularly important for potentially dangerous services such as gas lines, sewer pressure

mains, oil lines, water mains, underground power cables and telecommunication services.

As necessary, the Design Drawings should address the detail of avoiding any obstruction.

A national one-call service, Dial Before You Dig, is available to assist in locating

underground utility services. The number to call is 1100. Nevertheless, where the sewer is

designed in close proximity to other existing services and location is critical, the actual

location and level of those existing services should be determined by a proving excavation.

Hand digging is generally used to locate underground services prior to machine digging.

One recent innovation is vacuum potholing, which is proving a more efficient means of

locating buried pipes in congested pipe corridors.

The trench width dimensions shown on the drawings are the minimum criteria specified in

the relevant structural design standard e.g. AS/NZS 2566.1 (flexible pipes) or

BS EN 12951 (RC and VC). The dimensions are based on theoretical requirements for

pipe support and do not take into account physical construction requirements or potential

damage to the pipe resulting from loadings imposed during construction prior to full cover

being achieved. The depth of sewers is based on maintaining a grade and is dependent

upon the shallowest connection point to the sewer, which is usually considerably deeper

than an equivalent sized water main.

Tables 30.1, 30.2, 30.3 and 30.4 provide default trench dimensions, embedment and

maximum depth to invert for various pipe materials. The Designer may specify alternative

values in accordance with the relevant structural design standard.

Special embedments include those shown in the Standard Drawings and are typically

specified where any portion of the pipe embedment zone is below the natural water table

or in unstable ground.

Embedment material criteria are available in the Purchase Specifications.

Fill material requirements will depend upon dead and live loadings and the maximum

allowable settlement of the fill material. Where the surface is not to be paved and surface

settlement is not important, native fill material above the embedment material is suitable up

to the finished surface.

The minimum densities specified for side support and overlay fill in non-trafficable areas

are the minimum densities required to ensure that they do not settle under trench fill

loading and saturation. Any embedment fill that settles around a flexible pipe would not

provide the lateral support to the pipe assumed in the design method for flexible pipes,

COPYRIGHT

WSA 022002-2.3

220

even if its laboratory measured modulus was apparently sufficient. Note that modulus is

determined in the laboratory using an oscillating dynamic load and extremely low strains.

Even a reasonably high modulus from this test is no guarantee that the material will not

settle or even collapse under its own weight.

Compaction requirements should be in accordance with the Design Drawings and

Clause 22.3. Compaction requirements are specified to ensure pipe structural support and

to prevent settlement that may cause damage to pavements and structures. Settlement at

any depth in a trench is ultimately likely to be reflected at the surface.

Compaction methods associated with the various embedment materials are described in

Part 3 and AS/NZS 2566.2. Except where sewers are being embedded in single size

aggregates, satisfactory compaction of embedment and trench fill usually requires the use

of powered portable compacting machines. In certain circumstances, manual methods of

compaction are suitable. Compaction lift thickness should not exceed 150 mm for hand

tampers and 300 mm for vibrators. Compaction can be achieved using hand tampers,

surface plate vibrators, vibratory rollers and/or internal vibrators.

Where the compactive force and bearing area of the compaction / construction equipment

is known, design in accordance with AS/NZS 2566.1 can be used to determine the

minimum height of cover before that load can be applied.

Flood compaction requires Water Agency approval and may only be suitable for free

draining soils. If used where soil is not free draining, the retained moisture makes

compaction, even mechanical compaction, very difficult, if not impossible.

Some pipe materials e.g. PE have a density less than that of water and can float even

when full of water. Methods used to prevent flotation should be as specified in the Design

Drawings or as authorised by the Superintendent.

Before installation, check all pipes and fittings for damage. Impact damage to GRP pipes

and fittings can be difficult to detect since it typically appears on the internal surfaces as

star cracks within the corrosion layer (gelcoat).

30.2 MAXIMUM DEPTH TO INVERT FOR STANDARD SUPPORT TYPES

Tables 30.1, 30.2, 30.3 and 30.4 specify default maximum depths to invert for trenches

complying with SEW1201 and with pipe support types nominated in SEW1202. The

designs are conservative. Project-specific designs may be undertaken by an appropriately

qualified Designer where the stated assumptions for Tables 30.1, 30.2, 30.3 and 30.4 are

varied e.g. alternative pipe class or for actual geotechnical data from the site.

Applicable design standards are:

(a)

AS/NZS 2566.1 for PVCU, GRP and other flexible pipes.

(b)

BS EN 12951, National Annex A for RC and VC.

Rigid pipe bedding factors and safety factors specified in BS EN 12951, National Annex A

are:

(i)

Type 1 bedding factor = 1.5

(ii)

Type 2 bedding factor = 1.9

(iii)

Type 3 bedding factor = 2.2

(iv)

Safety Factor: 1.25

COPYRIGHT

WSA 022002-2.3

221

The following notes apply to Tables 30.1 to 30.4 inclusive:

1

Embedment

(i)

Granular embedment material should be:

For DN 150, single size or graded aggregate 7, 10 or 14 mm*

For >DN 150, single size or graded aggregate 10, 14 or 20 mm*

NOTE: * Alternative embedment may be used subject to authorisation by the Water

Agency and compliance with the material and compaction requirements of Clause 22.3.

(ii)

Select fill embedment should be excavated material having a maximum particle

size for rock of 20 mm or for other than rock not greater than 75 mm and should

be free from logs, tree loppings, industrial or domestic refuse and organic

materials.

(iii)

Where CLSM embedment is used, the trench width may be reduced by:

75 mm for DN 150<DN 300

100 mm for DN 300DN 450

150 mm for >DN 450DN 900

175 mm for >DN 900DN 1500

Trench fill

(i)

For nontrafficable areas, excavated or imported trench fill material containing

20% by mass of stones with sizes between 75 mm and 150 mm and none

larger than 150 mm.

(ii)

For trafficable areas, trench fill should be as specified in the Design Drawings.

TABLE 30.1

MAXIMUM DEPTH TO INVERT FOR PVC SEWERS

Pipe size

Pipe stiffness

class

DN

SN

150

225

Support type

Minimum trench

width (Note 2)

Maximum depth

to invert

mm

450

5.7

600

5.7

300

750

5.8

375

850

5.9

NOTES:

1

Applicable to plain wall and profile wall pipes.

Trench width to be measured at the spring line. For a supported trench, trench width is the distance

between shields.

Native soil stiffness assumed to be 2 MPa.

Embedment stiffness assumed to be 6 MPa.

Add 150 mm bedding allowance to determine maximum trench depth.

COPYRIGHT

WSA 022002-2.3

222

TABLE 30.2

MAXIMUM DEPTH TO INVERT FOR GRP SEWERS

Pipe size

Pipe stiffness

class

DN

SN

300

5000

375

Support type

Minimum trench

width (Note 1)

Maximum depth

to invert

mm

750

5.4

5000

850

5.4

450

5000

1000

5.5

525

5000

1200

5.5

600

5000

1300

5.6

675

5000

1350

5.7

750

5000

1400

5.8

900

5000

1600

5.9

1000

5000

1800

6.0

NOTES:

1

Trench width to be measured at the spring line. For a supported trench, trench width is the distance

between shields

Native soil stiffness assumed to be 2 MPa.

Embedment stiffness assumed to be 6 MPa.

Add 150 mm bedding allowance to determine maximum trench depth.

TABLE 30.3

MAXIMUM DEPTH TO INVERT FOR VC SEWERS

Pipe size

Pipe class /

crushing strength

Support type

Minimum trench

width (Note 1)

Maximum depth

to invert

mm

450

7.1

450

8.9

450

10.0

550

5.3

550

6.7

550

7.7

600

5.3

600

6.7

600

7.7

650

5.3

650

6.7

650

7.7

750

5.5

750

6.9

750

8.0

DN

150

200

225

250

300

34

Class 160 / 32 kN/m

Class 160 / 36 kN/m

Class 160 / 40 kN/m

Class 160 / 48 kN/m

continued

COPYRIGHT

WSA 022002-2.3

223

TABLE 30.3 continued

MAXIMUM DEPTH TO INVERT FOR VC SEWERS

Pipe size

Pipe class /

crushing strength

Support type

Minimum trench

width (Note 1)

Maximum depth

to invert

mm

850

5.7

850

7.1

850

8.1

900

5.8

900

7.2

900

8.3

950

5.9

950

7.3

950

8.4

1400

4.7

1400

5.8

1400

6.6

1400

4.9

1400

6.0

1400

6.8

1500

5.2

1500

6.3

1500

7.2

1800

4.5

1800

5.5

1800

6.1

DN

350

400

450

600

700

800

1000

Class 160 / 56 kN/m

Class 160 / 64 kN/m

Class 160 / 72 kN/m

Class 120 / 72 kN/m

Class 120 / 84kN/m

Class 120 / 96kN/m

Class 95 / 95 kN/m

NOTES:

1

Trench width to be at the spring line. For a supported trench, trench width is distance between

shields.

Saturated clay native soil assumed.

Add 150 mm bedding allowance to determine maximum trench depth.

COPYRIGHT

WSA 022002-2.3

224

TABLE 30.4

MAXIMUM DEPTH TO INVERT FOR RC SEWERS

Pipe size

Load class

Support type

Minimum trench

width (Note 1)

Maximum depth

to invert

mm

1350

5.1

1350

6.3

1350

7.2

1500

5.3

1500

6.4

1500

7.3

1800

5.3

1800

6.4

1800

7.3

1900

5.4

1900

6.5

1900

7.4

DN

600

750

900

1050

4

(Z)

4

(Z)

4

(Z)

4

(Z)

NOTES:

1

Trench width is measured at the spring line. For a supported trench, trench width is distance between

shields.

Saturated native clay soil assumed.

Assumed that native soil is nonaggressive to concrete, else pipes require external protection.

Assumed that pipes are internally lined with plastic.

Add 150 mm bedding allowance to determine maximum trench depth.

30.3 SEW1200 SOIL CLASSIFICATION GUIDELINES

SEW1200 provides guidance to Constructors on the estimation of the allowable horizontal

bearing pressure of soils. The results enable Constructors to verify that actual ground

conditions meet the assumptions used in the selection or design of embedments and

bulkheads, as shown in the Design Drawings.

If soil conditions do not comply with those detailed in the Design Drawings, the

Superintendent should be advised so that embedment / bulkhead design can be reviewed

and instruction given to the Constructor.

30.4 SEW1201 EMBEDMENT AND TRENCHFILL TYPICAL ARRANGEMENTS

SEW1201 shows typical arrangements for embedment and trench fill. It also identifies the

terminology used in Part 1 Planning and Design and Part 3 Construction of this Code.

Compaction requirements are not shown on this drawing. These should be determined in

accordance with Clause 22.3 or as nominated in the Design Drawings.

Correct haunch support (shown on Drawing) is the key to providing adequate support for

flexible buried pipes. Before compacting, it is important to manually work the embedment

material into the haunches to ensure all voids are filled.

The Owner may dictate trench fill and compaction requirements for pipelines laid in major

roadways or railways.

Trench fill material requirements will depend upon dead and live loadings and the

maximum allowable settlement of the fill material. Where the surface is not to be paved

COPYRIGHT

WSA 022002-2.3

225

and surface settlement is not important, the Design Drawings may nominate the re-use of

excavated material, after screening and/or removal of organic material and stones

>75 mm, above the embedment material up to the FSL.

30.5 SEW1202 STANDARD EMBEDMENT FLEXIBLE AND RIGID PIPES

SEW1202 shows the deemed-to-comply embedment methods for good supportive soil

conditions for rigid pipes (Types 1 and 2) and for all pipe types (Types 3). Type 4 shows

the system to be used when geotextile filter fabric wrap is specified to prevent migration of

fines from the native soil into the granular embedment.

Single size coarse aggregate with particle sizes in accordance with Table 30.5 is the

preferred embedment material because of its selfcompacting qualities.

TABLE 30.5

MAXIMUM PARTICLE SIZE

Pipe size

Maximum particle size

DN

mm

100

10

>100 to 160

14

>160

20

Selected cohesive soils may be used when approved by the Water Agency. They are more

difficult to place and compact, should only be considered for shallow pipelines not subject

to imposed live loads and require compaction testing.

The higher the granular content of the embedment material, particularly a higher gravel

content, the more supportive it becomes to the pipe, when an equivalent compactive effort

is used.

Embedment materials which are not covered by Purchase Specifications may be specified

by the Designer provided they have the consistency and moisture content suitable for

placement (without segregation) and can be compacted to a density that will achieve an

embedment modulus of at least 6 MPa. Refer to AS/NZS 2566.1 for soil moduli for different

materials at different densities.

30.6 SEW1203 SPECIAL EMBEDMENT INADEQUATE FOUNDATIONS

SEW1203 shows deemed-to-comply embedment where poor ground conditions require

over-excavation and replacement. Engineering advice based on geotechnical information

from site is required to determine the appropriate embedment for poor ground conditions.

30.7 SEW1204 SPECIAL EMBEDMENT SUPPORT USING PILES

SEW1204 shows the deemed-to-comply support and embedment where poor ground

conditions require piling. Engineering advice based on geotechnical information from site is

required to determine the appropriate support and embedment for poor ground conditions

and to provide structural details.

30.8 SEW1205 SPECIAL EMBEDMENT CONCRETE AND STABILISED SUPPORTS

SEW1205 shows the deemed-to-comply concrete or stabilised sand embedment, typically

where protection of the sewer is necessary e.g. where minimum cover is not achievable or

where a structure is to be built over the sewer.

Precautions should be taken to prevent flotation of pipes during concrete encasement.

Methods used to prevent flotation should be as specified in the Design Drawings or as

authorised by the Superintendent.

COPYRIGHT

WSA 022002-2.3

226

30.9 SEW1206 BULKHEADS AND TRENCHSTOP

SEW1206 shows deemed-to-comply bulkheads and trenchstops for use on steep slopes,

primarily to slow groundwater flowing through the embedment material. Unregulated flows

have the potential to wash away pipe support material.

Design requirements are given in Clause 8.10 and construction details should be shown in

the Design Drawings.

The compressible membrane wrap has a secondary effect of restraining pipe movement.

30.10 SEW1207 TRENCH DRAINAGE TYPICAL SYSTEMS

SEW1207 shows deemed-to-comply groundwater discharge systems primarily for

bulkheads and trenchstops, and which can be used in other areas where groundwater is

present in the trench.

It also shows typical placement of drainage pipes laid along the trench for connection to an

authorised discharge point.

30.11 SEW1208 VERTICALS AND NEAR VERTICALS EXPOSED AND CONCEALED

METHODS

SEW1208 shows a range of deemed-to-comply solutions for vertical and near vertical

risers in a variety of pipe materials.

Directional boring of near verticals is becoming a popular option and should be considered

as a replacement for verticals.

Safety fencing is required where there is an unacceptable risk to maintenance personnel

when accessing the inspection opening.

COPYRIGHT

227

WSA 022002-2.3

31 COMMENTARY ON SEW1300 SERIES MAINTENANCE STRUCTURES

31.1 GENERAL

The 1300 series of Drawings deals with installation practices for maintenance structures

and associated appurtenances.

It is the Constructors responsibility to know and understand these installation practices

and to ensure appropriate pipes, fittings and access structures are available prior to

commencing the project. Where irregularities are identified, they should be discussed with

the Superintendent.

In areas subject to surcharge or inundation, only cast insitu MH should be used.

The need for ladders / stepirons within the MH and the type of access covers and frames

should be determined prior to ordering MH components.

Water Agencies may have other standard access structures and requirements should be

determined prior to commencing the project.

31.2 SEW1300 SEWERS DN 300 PRECAST MH TYPES P1 AND P2

SEW1300 shows deemed-to-comply precast MH types P1 and P2 using products

conforming to AS 4198 for sewers up to DN 300.

The makeup / riser ring shown above the conversion slab / taper section is provided to

allow for minor height adjustment, which may be required because of difficulty in

determining the exact height requirement prior to construction. It also allows for

subsequent adjustment of up to 350 mm to accommodate variations in FSL.

31.3 SEW1301 CAST IN-SITU MH TYPES C1 AND C2

SEW1301 shows the deemed-to-comply cast insitu MH types C1 and C2.

The makeup / riser ring shown above the conversion slab / taper section is provided to

allow for minor height adjustment, which may be required because of difficulty in

determining the exact height requirement prior to construction. It also allows for

subsequent adjustment of up to 350 mm to accommodate variations in FSL.

In areas subject to surcharge or inundation, the top segments, riser ring and cover should

be permanently fixed to prevent separation. Typical methods are shown in the Drawing.

Internal and external formwork should be locked together during pouring and vibration. It

may also require other restraint to prevent movement.

31.4 SEW1302 MH PIPE CONNECTION DETAILS

SEW1302 shows typical arrangements for the connection of sewers of various materials

to the MH base.

Jointing methods will vary depending upon the material used and the jointing systems

available.

Socket joints or couplings (RRJ) and a short rocker pipe are required to provide flexibility

necessary to accommodate differential settlement between the MH base and the sewer.

The solvent cement joint (SCJ) option should not be used if the MH foundation has a

bearing pressure less than 100 kPa (See SEW1200).

PVC, GRP and ABS pipe and/or fittings, which are to be cast directly into the concrete MH

base, should be prepared to enable a watertight bond either by:

(a)

Sandingby coating the external surface of the pipe or fitting with solvent and,

while the solvent is wet, applying a coating of sand; or

COPYRIGHT

WSA 022002-2.3

(b)

228

Abradingby thoroughly roughening the outside of the pipe or fitting without

destroying its integrity.

31.5 SEW1303 SEWERS DN 300 MH CHANGE IN LEVEL ARRANGEMENTS

SEW1303 shows the typical arrangements for different level changes, using both external

drop junctions and falls across the MH. Design requirements for vertical alignment of a

sewer are specified in Clause 4.6. Construction requirements should be detailed in the

Design Drawings.

31.6 SEW1304 AND SEW1305 MH CHANNEL ARRANGEMENTS AND DETAILS

These two Drawings detail typical MH channel arrangements, orientations and details.

The internal diameter of the selected MH shaft will increase as the sewer diameter

increases and should be of sufficient size that all tangent points (for curves) are located

within the shaft. The internal diameter should also be sufficient to provide two relatively flat

work areas for maintenance purposes i.e. 2 x 300 mm diameter.

The centreline of the shaft sections may be positioned away from the sewer intersection

point to optimise the MH performance and ensure access for maintenance equipment,

while retaining all tangent points within the inside diameter of the MH shaft.

Design Drawings should detail the actual horizontal alignment for construction.

31.7 SEW1306 ALTERNATIVE MH DROP CONNECTIONS

SEW1306 shows the typical arrangements for alternative drop connections at MHs.

Internal drops and drop chambers may be used where the MH is in rock (or similar) and it

is difficult the install a standard external drop (Refer to Standard Drawing SEW1303).

They may also be used for connections to existing MHs where the depth requirements

prevent safe trenching practices.

The design should be such that the sewage flow should be directed (flushed) into the

channel and not onto the bench, where deposited solids have the potential to create

odours.

31.8 SEW1307 STEP IRONS AND LADDERS

SEW1307 shows various deemed-to-comply ladder and step iron arrangements.

Ladder / step iron requirements vary between Water Agencies and should not be included

on Design Drawings until requirements have been confirmed.

For sewers DN 300 the ladder / step irons should be located directly over the outlet to

identify direction of flow and to give a lockin point for plugs etc.

For sewers >DN 300 the ladder/step irons should be located at 90 to the sewage flow to

prevent maintenance personnel from stepping into the flow.

31.9 SEW1308 TYPICAL MH COVER ARRANGEMENTS

SEW1308 shows the deemed-to-comply MH cover arrangements for both trafficable and

non-trafficable areas. The Constructor should ascertain from the Design Drawings or

Superintendent which covers are to be bolted down.

Where other MH cover arrangements are used, they should incorporate the following

conditions / features:

(a)

Covers, slabs and cover frames should be restrained from movement during trench

fill and compaction.

(b)

Covers should be installed to be proud of the finished surface of unsealed nontrafficable areas.

COPYRIGHT

229

(c)

WSA 022002-2.3

Covers should be installed to align with the finished surface of carriageways,

footpaths and other sealed surfaces.

31.10 SEW1309, SEW1310, SEW1311 AND SEW1312 SPECIAL MHs

These four Drawings show deemed-to-comply trunk sewer MHs of various depths.

Structural design and construction details should be determined by an appropriately

qualified engineer. Drawings SEW1311 and SEW1312 represent historical practices

used to construct trunk sewer MHs. While still valid, these practices may not represent the

lowest life cycle costs for trunk sewer MHs.

Where other arrangements are used, they should incorporate the following conditions /

features:

(a)

Inlet and outlet pipework should have flexible joints (rocker pipes).

(b)

Internal surfaces should be manufactured from, or be coated with, acid resistant

material.

(c)

Raised branch connections should have internal or external drops. Branch

connections located near the base should meet soffit to soffit or flow line to flow line

with the trunk sewer.

(d)

The concrete at the soffit of the entrance to upstream and downstream pipework

should be rounded to prevent damage to maintenance equipment e.g. CCTV cables.

Design Drawings should detail the actual requirements for construction.

31.10.1 SEW1309 Sewers DN 375 to DN 750 MHs

SEW1309 shows general requirements for cast in-situ MHs for sewers DN 375 to DN 750

and up to 6 m deep. Water Agency requirements for access e.g. step irons and/or ladder

and protection of concrete from sewer gas attack should be determined by the Designer.

Construction details e.g. concrete thickness, reinforcement, horizontal and vertical

alignment should be shown on the Design Drawings. Sockets cut from pipe should be set

to the specified grade and restrained to prevent flotation. Care is required to prevent

concrete damaging the joint seals.

31.10.2 SEW1310 Special MHs using permanent formwork

SEW1310 shows the deemed-to-comply MH formwork for sewers DN 375.

The use of permanent formwork MHs is innovative and should reduce life cycle costs. It is

based on the concept of creating an impervious lining within the MH area that is

compatible with the trunk sewer pipeline material.

The formwork can be fabricated from any material not subject to corrosion by raw sewage

e.g. PVC, PE, ABS or GRP pipe sections. The fabrication includes a short riser of the

same material to allow the top formwork to be fully encased in concrete.

Recent experience has shown the spiral wound pipe is very suitable for this application

because it can be wound to any size required and various end connections can be

fabricated into the formwork.

It is critical that the MH shaft section, which connects the top of the concrete encasement

to the surface, straddles the sewer so that it is supported on the structural concrete either

side of the sewer and does not transmit a punching load directly onto the sewer.

This system can be utilised for any MH configuration e.g. straight, curved, Y and tee.

31.11 SEW1311 AND SEW1312 DEEP MHs

Very deep MHs may require a project or site-specific design. SEW1311 and SEW1312

are based on historic designs which incorporate functional requirements for deep sewers.

The Water Agency may specify alternative or additional requirements. Structural designs

COPYRIGHT

WSA 022002-2.3

230

for construction should be determined by a professional engineer (CP Eng or equivalent).

This information, together with the horizontal and vertical alignments for construction

purposes, should be shown on the Design Drawings.

31.12 SEW1313, SEW1314, SEW1315 AND SEW1316 MAINTENANCE SHAFTS

These four Drawings detail typical MS, TMS and variable bend installations, connection

details and cover arrangements.

MSs and variable bends together with their installation combinations and practices are

specified in Clause 6.6.

The maximum MS depth should be 5 m.

The MS riser shaft should be sealed using a purpose-designed bayonet, screw or RRJ roll

fit cap with an integral handle for unlocking and/or lifting.

Covers and support system should be as specified (authorised) by the Water Agency.

31.13 SEW1317 MH CONNECTION DETAILS PE PIPE

SEW1317 details typical connection methods for PE sewers into MHs. PE pipe has a

mechanical property that causes it to relieve itself (creep) when under stress, which in turn

has the potential to permit infiltration / exfiltration. The potential is prevented by locally

thickening the appropriate section of pipe combined with the use of a hydrophilic rubber

seal that expands when it comes in contact with water to provide a watertight seal.

COPYRIGHT

231

WSA 022002-2.3

32 COMMENTARY ON SEW1400 SERIES SPECIAL CROSSINGS / STRUCTURES

ARRANGEMENTS

32.1 GENERAL

The 1400 series of Drawings deals with special construction practices. The systems shown

are considered to be deemed-to-comply solutions. These Drawings show general

principles only and will require some design input with regard to sitespecific requirements.

Other variations may also be acceptable. Alternative method(s) should be authorised with

the Water Agency before adoption.

The practices outlined in these Drawings are applicable to new sewerage systems.

Different methods may be applicable to maintenance applications.

For more detailed guidance on the welding of PE pipes and fittings refer to WAT1102 and

for steel pipes and fittings refer to the WAT1400 series in WSA 03. Only certified welders

should carry out insitu welding of both steel and PE pipes and fittings in accordance with

prequalified weld procedures. WSA 01 provides guidance on PE weld prequalification

and welder training programs.

32.2 SEW1400 SYPHON ARRANGEMENT

SEW1400 shows a typical syphon arrangement.

A syphon is a structure used to convey sewage under a deep obstruction. Syphons should

only be used as a last resort because of the associated construction and maintenance

problems. It is preferable to relocate the obstacle. If a syphon is constructed, the following

performance requirements should be verified by the Designer and authorised by the Water

Agency before construction commences:

(a)

Because it lowers a section of the sewer, the velocity through the syphon should be

increased to ensure all solids are carried through the syphon. It is general practice to

have more than one syphon tube to allow partial shutdown for maintenance and to

handle larger flows.

(b)

The inlet structure should be higher than the outlet structure so that a differential

head is provided between the inlet and outlet points such that a flow of at least

0.75 m/s is achieved at least once per day.

(c)

The inlet structure should be constructed so that the normal flow is directed solely

into one syphon pipe with higher flows into the other pipe(s).

(d)

For sealed sewers, an air passage past the syphon should be provided to prevent air

locks and reduce the creation of hydrogen sulphide gas.

32.3 SEW1401, SEW1402 AND SEW1403 BURIED CROSSINGS

These three Drawings show deemed-to-comply methods of constructing sewers under a

railway, major roadway or other major obstruction. The Drawings show general

requirements for pipe installation by trench excavation, boring or pipe jacking. Structural

details and other construction requirements should be shown on the Design Drawings.

Trenchless construction methods are now increasingly being used e.g. directionally bored

PE pipe is a viable option. For further information visit www.astt.com.au.

Water Agency authorisation of any method is required.

32.4 SEW1404, SEW1405 AND SEW1406 AERIAL CROSSINGS

These three Drawings show deemed-to-comply methods for above ground crossings of

depressions, waterways or valleys.

COPYRIGHT

WSA 022002-2.3

232

Aqueduct pipe systems using DI and steel pipe are suitable for use as a carrier pipe or as

an encasing pipe for other pipe materials e.g. PVC or PE. Expansion rates should be taken

into account during the design phase.

Where other arrangements are used, they should incorporate the following conditions /

features:

(a)

For supported / suspended systems, the pipe material should be DI or steel.

(b)

Pipe should be supported at spacings recommended by the manufacturer or

structural designer.

(c)

Allowance should be made in the design for flood conditions.

(d)

Provision should be made for pipe expansion and contraction.

(e)

Provision should be made to prevent unauthorised access onto the pipeline.

(f)

Consideration should be given to corrosion protection of the pipeline.

The Design Drawings should detail all requirements including pipe material, jointing

method, support spacings, expansion control methods, corrosion protection and abutment

details.

32.5 SEW1407 AND SEW1408 VENTILATION SYSTEMS

These two Drawings address the ventilation of sewers, showing deemed-to-comply induct

and educt vents that are constructed on larger diameter branch sewers. On trunk sewers, it

is common to utilise a forced air (fan) station to induce a stronger airflow.

Ventilation of sewers is a topical issue. Some Water Agencies do not allow the use of

venting systems. Water Agency requirements should be determined before commencing

any design.

Corrosion is a problem with all induct and educt vents and where possible, all exposed

surfaces should be manufactured from noncorrosive materials.

Vents should be aesthetically suitable for their installed location.

Note 6 of SEW1408 discusses one method of preventing internal corrosion of galvanised

vent stacks by using it as an encasing pipe for a length(s) of PVC sewer pipe. Where this

system is used, the gap between the PVC pipe and the top of the stack should be sealed

using a mastic sealant, chamfered to deflect water away from the joint. The base should

also be provided with a drainage point to prevent condensation from building up in the

base and causing corrosion.

While galvanised steel vents are shown, other materials may be acceptable to the Water

Agency e.g. FRP and stainless steel.

Canister type air filters are commercially available, but these generally need a forced

airflow to ensure the air passes through the filter medium. Fans used for this purpose

should have flame proof motors and be manufactured from noncorrosive materials.

32.6 SEW1409, SEW1410 AND SEW1411 WATER SEAL ARRANGEMENTS

These three Drawings show deemed-to-comply methods for water seal arrangements on

sewers and MHs.

Water seals are hydraulic features that are used to prevent odours from escaping from

trunk, branch and reticulation sewers into inhabited areas.

Water seals can be incorporated into a conventional sewerage system design by

nominating local lowering the sewer to provide a water trap that prevents the passage of

sewer gases. Water traps should be constructed close enough to an adjacent MH or MS so

that blockages can be easily cleared.

COPYRIGHT

233

WSA 022002-2.3

Water seals can also be incorporated into MH by incorporating a water trap in the MH flow

path as shown on SEW1410 and SEW1411.

The options shown do not represent a national consensus. Some Water Agencies specify a

boundary trap between the sewer and the customer sanitary drain. The Designer should

determine the Water Agency requirement.

Design Drawings should detail the actual requirements for construction.

32.7 SEW1412 EMERGENCY RELIEF STRUCTURES

SEW1412 shows typical flow relief structures for DN 150 to DN 375 sewers.

Flow relief structures are required where there is the potential for sewer overflows because

of blockages or insufficient capacity in the sewer. This type of system is included within the

sewer to ensure flow relief occurs at a planned rather than unplanned location. The Design

Drawings should identify the authorised overflow discharge points.

The Drawing shows one deemed-to-comply solution with baffles / screens to prevent the

release of fats and solids into the discharge area.

COPYRIGHT

WSA 022002-2.3

234

33 COMMENTARY ON SEW1500 SERIES INSERTIONS AND REPAIR SYSTEMS

33.1 GENERAL

The 1500 series of Drawings deals with special practices and systems for insertions and

repairs to existing sewers. The systems shown are deemed-to-comply solutions. Other

methods may also be acceptable. Alternative methods should be authorised by the Water

Agency before adoption.

The Drawings are applicable to PVC and VC sewer systems. Similar methods can be used

for other pipe materials.

Flexible couplings have a shorter life expectancy than other coupling systems and are

generally utilised as part of a maintenance repair or installation. Water Agency approval is

required before they are used on new pipe systems. Only Type B AS/NZS 4327 metal

banded flexible couplings that incorporate a metal shear ring should be used.

33.2 SEW1500 CUT-IN METHODS

SEW1500 shows deemed-to-comply insertion and repair systems using cut-in methods

with stainless steel flexible couplings and repair clamps and slip couplings. The methods

are applicable to both flexible and rigid pipes. Only slip couplings can be used for profile

wall (ribbed) pipes.

If the pipe has been deformed, then slip couplings may not be suitable. Stainless steel

repair clamps are more suitable for deformed pipes.

Any adhesive labels and adhesive residues should be completely removed from stainless

steel couplings and clamps to avoid crevice corrosion.

33.3 SEW1501 INSERTION OF JUNCTIONS

SEW1501 shows deemed-to-comply methods for insertion of junctions into an existing

sewer using cut-ins with a stainless steel junction that incorporate a clamping

arrangement, slip couplings combined with a PVC junction and a PVC saddle restrained

with stainless steel clamping bands. The methods are applicable to both flexible and rigid

pipes. Only slip couplings can be used for inserting junctions in profile wall (ribbed)

sewers.

Cut-ins of plastic, VC and RC sewers should be made using hole saws as recommended

by the pipe manufacturer. Cutouts (biscuits) should be removed from the sewer. Edges of

cut holes should be made smooth.

If the pipe has been deformed, then slip couplings may not be suitable. Stainless steel

junctions that incorporate clamping arrangements are most suitable for deformed pipes.

Any adhesive labels and adhesive residues should be completely removed from stainless

steel surfaces to avoid crevice corrosion.

33.4 SEW1502 CONSTRUCTION OF MHs AND MSs OVER EXISTING SEWERS

SEW1502 shows deemed-to-comply methods of construction of MHs over existing sewers

in both stable and reactive soils and insertion of MSs into existing sewers. Channel and

benching details for concrete MH bases are also specified.

In many cases these methods will be used to start construction of a new sewer from an

existing sewer.

In the case of MH construction on an existing VC or RC sewer, structural assessment of

the existing sewer using CCTV (Refer to WSA 05) and other appropriate methods is

advisable, especially if the existing sewer is likely to require renovation before excavation

commences.

COPYRIGHT

235

WSA 022002-2.3

The Reactive Base option is required for rigid pipes and soils having a bearing pressure

less than 100 kPa (Refer to SEW1200) in order to accommodate differential settlement

between the MH base and the sewer.

COPYRIGHT

WSA 022002-2.3

236

NOTES

COPYRIGHT

237

Standard Drawings

COPYRIGHT

WSA 022002-2.3

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Subnetting Secrets Book 1Документ0 страницSubnetting Secrets Book 1Gulshan NematovaОценок пока нет

- WSA02 2002 Part0 2 3Документ30 страницWSA02 2002 Part0 2 3abhijithavalОценок пока нет

- Kant Twist Clamp AssemblyДокумент6 страницKant Twist Clamp Assemblysuzycreamcheeze60% (5)

- 2 8 16 - Caculation As Per IRC 112Документ203 страницы2 8 16 - Caculation As Per IRC 112snehar redkar100% (1)

- GE6261 CAD Lab ManualДокумент63 страницыGE6261 CAD Lab Manualjawahar kannaОценок пока нет

- Sewerage Code of Australia: Second EditionДокумент26 страницSewerage Code of Australia: Second Editionabhijithaval100% (1)

- Structural Analysis For Two Story Residential BuildingДокумент4 страницыStructural Analysis For Two Story Residential BuildingMathan LuceroОценок пока нет

- Ice PlantДокумент25 страницIce PlantAbenliciousОценок пока нет

- Wind AnalysisДокумент24 страницыWind AnalysisJohn NjorogeОценок пока нет

- Synopsis: Museum Architecture: by Gopika Thaplyal 4 Year B.ArchДокумент5 страницSynopsis: Museum Architecture: by Gopika Thaplyal 4 Year B.ArchPrafull Raut100% (1)

- Design of Composite Structures Against FatigueДокумент272 страницыDesign of Composite Structures Against Fatigueqasda100% (1)

- SPS-1603 1 1Документ1 страницаSPS-1603 1 1abhijithavalОценок пока нет

- Product Details For Pressure Mains: For Dicl, PVC, GRP & Pe Pipes Pipe InstallationДокумент1 страницаProduct Details For Pressure Mains: For Dicl, PVC, GRP & Pe Pipes Pipe InstallationabhijithavalОценок пока нет

- Sewerage Code of Australia: WSA 02-2002 Version 2.3Документ2 страницыSewerage Code of Australia: WSA 02-2002 Version 2.3abhijithavalОценок пока нет

- Pump Scour Elevation: NotesДокумент1 страницаPump Scour Elevation: NotesabhijithavalОценок пока нет

- Concrete Cover Detail: NotesДокумент1 страницаConcrete Cover Detail: NotesabhijithavalОценок пока нет

- Plan of Top Slab ElevationДокумент1 страницаPlan of Top Slab ElevationabhijithavalОценок пока нет

- Quantity (Litres/Second) : Pressure Main ConfigurationДокумент1 страницаQuantity (Litres/Second) : Pressure Main ConfigurationabhijithavalОценок пока нет

- Typical Cover Arrangement: Valve Chamber LegendДокумент1 страницаTypical Cover Arrangement: Valve Chamber LegendabhijithavalОценок пока нет

- SPS-1301 1 1Документ1 страницаSPS-1301 1 1abhijithavalОценок пока нет

- Alternative Configurations: R 8 00 0 (M IN.)Документ1 страницаAlternative Configurations: R 8 00 0 (M IN.)abhijithavalОценок пока нет

- SPS-1302 1 1Документ1 страницаSPS-1302 1 1abhijithavalОценок пока нет

- Minor Cut Fill Fill: SO IL ILДокумент1 страницаMinor Cut Fill Fill: SO IL ILabhijithavalОценок пока нет

- Locality Plan: Notes 1. 3. 4Документ1 страницаLocality Plan: Notes 1. 3. 4abhijithavalОценок пока нет

- SPS-1304 1 1Документ1 страницаSPS-1304 1 1abhijithavalОценок пока нет

- SPS-1203 1 1Документ1 страницаSPS-1203 1 1abhijithavalОценок пока нет

- Typical Site Plan Typical Layout For Pumping Station Sites Not Fronting Adjacent Roadway Alternative Typical Site PlanДокумент1 страницаTypical Site Plan Typical Layout For Pumping Station Sites Not Fronting Adjacent Roadway Alternative Typical Site PlanabhijithavalОценок пока нет

- Location Plan: C Ommerc IALДокумент1 страницаLocation Plan: C Ommerc IALabhijithavalОценок пока нет

- SPS-1103 1 1Документ1 страницаSPS-1103 1 1abhijithavalОценок пока нет

- Case 2 - Pressure Main With A High Point Case 1 - Always Rising Pressure MainДокумент1 страницаCase 2 - Pressure Main With A High Point Case 1 - Always Rising Pressure MainabhijithavalОценок пока нет

- Based On Sydney Water Standard DrawingДокумент1 страницаBased On Sydney Water Standard DrawingabhijithavalОценок пока нет

- Anda Street Oxford Road: MA RT INДокумент1 страницаAnda Street Oxford Road: MA RT INabhijithavalОценок пока нет

- Worksheet2 FacitДокумент4 страницыWorksheet2 FacitMohamed NazeemОценок пока нет

- Design of Seismic ArresterДокумент3 страницыDesign of Seismic ArresterChandan vatsОценок пока нет

- Windows Server 2012 R2 NIC Teaming (LBFO) Deployment and ManagementДокумент52 страницыWindows Server 2012 R2 NIC Teaming (LBFO) Deployment and Managementkarthikri7693Оценок пока нет

- Does NoSQL Have A Place in GIS?Документ28 страницDoes NoSQL Have A Place in GIS?stillifeОценок пока нет

- RIP Version 1 PracticeДокумент7 страницRIP Version 1 PracticeaennekОценок пока нет

- Child Psychology Its Impact On ArchitectureДокумент90 страницChild Psychology Its Impact On ArchitecturegayathriОценок пока нет

- What Is Argouml ?Документ11 страницWhat Is Argouml ?Prasha92Оценок пока нет

- Brochure - Thermalia (R) Dual (55-140) Dual H (35-90) - ExA - 111016Документ28 страницBrochure - Thermalia (R) Dual (55-140) Dual H (35-90) - ExA - 111016Nur Rachman HardiantoОценок пока нет

- CE PROJECT 1 - 1st Semester SY 2019-2020Документ1 страницаCE PROJECT 1 - 1st Semester SY 2019-2020Jose Mari RoldanОценок пока нет

- Aindumps.220 901.v2017!08!15.by - Stephen John.158qДокумент66 страницAindumps.220 901.v2017!08!15.by - Stephen John.158qvhsinsОценок пока нет

- History of Civil EngineeringДокумент42 страницыHistory of Civil EngineeringNoor Azirah Abd AzizОценок пока нет

- How-To 12 Universal 3850 Wireless ConfigДокумент23 страницыHow-To 12 Universal 3850 Wireless ConfigMeAccountHereОценок пока нет

- SO3 - B2+ - Unit Test - U1CДокумент18 страницSO3 - B2+ - Unit Test - U1CirishacrobatОценок пока нет

- Daewoo FR - 530kt-fr - 590kt (ET)Документ36 страницDaewoo FR - 530kt-fr - 590kt (ET)khaled1512Оценок пока нет

- User Guide Yii2Документ21 страницаUser Guide Yii2Luis PedroОценок пока нет

- Inept KeyДокумент13 страницInept KeyElle DraccoОценок пока нет

- Ananlysis of Two Pinned and Three Pinned ArchesДокумент25 страницAnanlysis of Two Pinned and Three Pinned Archesshubham maviОценок пока нет

- Masakan Timur - Vcf3053: Pensyarah: Puan Nor Azizah AhmadДокумент46 страницMasakan Timur - Vcf3053: Pensyarah: Puan Nor Azizah AhmadNur Husnina ZawawiОценок пока нет

- BEA WebLogic Server Frequently Asked QuestionsДокумент8 страницBEA WebLogic Server Frequently Asked QuestionsSanjeev SrivastavaОценок пока нет

- Use Rational Functional Tester Script Assure Technology To Build Test Scripts That Run When Code ChangesДокумент9 страницUse Rational Functional Tester Script Assure Technology To Build Test Scripts That Run When Code ChangesNaveen Kumar BysaniОценок пока нет

- GalvaДокумент17 страницGalvaClaudine Cabico ValdezОценок пока нет