Академический Документы

Профессиональный Документы

Культура Документы

What Is A Confined Space Entry

Загружено:

droffilcz27Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

What Is A Confined Space Entry

Загружено:

droffilcz27Авторское право:

Доступные форматы

What is a Confined Space?

A space that:

Is large enough and so configured that an employee can enter bodily and

perform work;

Has limited or restricted means of entry or exit;

Is not designed for continuous human occupancy.

Examples of Confined Spaces

Tanks

Manholes

Boilers

Furnaces

Sewers

Silos

Hoppers

Vaults

Pipes

Trenches

Tunnels

Ducts

Bins

Pits

Potential Hazards in Confined Spaces

Oxygen Deficiency

<19.5% or >23.5% oxygen concentration

Combustibles

Methane

o

Hydrogen

o

Acetylene

o

Propane

o

Gasoline fumes

Toxic Materials

Carbon Monoxide

Hydrogen Sulfide

o

Welding fumes

o

Corrosives

Electricity

Mechanical Hazards

o

o

o

o

ENTRY

Mixers

Crushers

The act by which a person intentionally passes through an opening into a

permit required confined space.

Any part of the body passing through the opening is considered entry.

IDLH

IMMEDIATELY DANGEROUS TO LIFE OR HEALTH

Any condition which poses an immediate threat to the health of life on an

entrant, or;

Would cause irreversible adverse health effects, or;

Would interfere with an individuals ability to escape unaided from a permit

space.

ENTRANT

The employee who will physically enter the confined space to perform the

work.

ATTENDANT

The employee who remains outside the confined space and monitors the

entrant(s); guards the space against unauthorized entry; warns the entrants of

any unusual conditions; and summons the rescue personnel if needed.

Permit-Required Confined Space

A Permit-Required Confined Space is confined space that has one or more of

the following characteristics:

o

o

o

o

Contains or has the potential to contain a hazardous atmosphere;

Contains a material that has the potential for engulfing an entrant;

Has an internal configuration such that an entrant could become

trapped or asphyxiated; or

Contains any other serious safety or health hazard.

Entry Supervisor

The employee responsible for coordinating the entry into the confined space.

This must be a team leader or foreman.

Responsible Person

The person directly responsible for the work being performed in the confined

space. This can be the Team Leader, Foreman, journeyman, or other person

qualified by training and experience.

Non-Permit Confined Space

A confined space that does not contain or, with respect to atmospheric

hazards, have the potential to contain any hazard capable of causing death of

serious physical harm.

Two Options for Entering Confined Spaces:

Permit-required confined space entry

o

For hazardous or potentially hazardous confined space work

Non-permit confined space entry

o

For non-hazardous confined space work

Permit-Required Confined Space Entry Procedure

Isolate the space

Ventilate the space

Conduct Tailboard

Complete permit

Test the atmosphere

Enter the space

Isolate the Space from all hazards

Close Valves

Double block & bleed, or

o

Blank flange

Empty the Space

Depressurize, vent & drain

Lockout/Tagout Equipment

Electrical sources

Rotating/reciprocating parts

o

Hazardous materials

Clean residue from the space

o

o

Ventilate the Space

Use mechanical ventilation

Fans

o

Air horns

Ventilate at the rate of at least four (4)

volumes per hour

o

Larger spaces require more

ventilation

Make sure air supply is not

contaminated

o

Ventilation air supply must be

from fresh air uncontaminated

with flammables, toxins, etc.

Conduct a Tailboard Briefing

Entire crew must attend

Attendants, entrants, entry supervisor

Review hazards of entry and work

Review PPE

Review procedure for contacting rescue

verify rescue available

Complete permit

Complete Entry Permit Form

Permit must be correctly and completely filled out prior to entry.

Permit must be activated by Entry Supervisors signature to be valid.

No entry is allowed without a valid permit.

Permits are valid for up to 12 hours.

When work is completed, permit and tailboard form should be returned to

safety.

Canceled permits must be kept on file for at least one year.

Test the Atmosphere

In this Order

Check for Oxygen Content:

o

At least 19.5% and less than 23.5%

Check for Combustibles:

Less than 10% of the LEL

Check for Toxic Gasses:

o

o

o

Most commonly carbon monoxide (PEL <35 ppm)

or any other hazardous materials as determined by the use of the

space.

NOTICE:

Any time a limit is exceeded, no matter what the reason, all personnel shall

immediately exit the space, and no others shall enter until atmospheric

conditions are returned to safe levels.

THERE ARE NO EXCEPTIONS TO THIS!

Atmosphere Testing Shall Be Performed:

Prior to every entry when the space is vacant;

After a 10 minute ventilation period (if ventilation is necessary);

At least hourly for permit-required confined spaces.

More frequently, if conditions or suspicions warrant.

Always test the

air at various levels

to be sure that the

entire space is safe.

Good air near the opening

does

NOT mean there is good

air at the bottom!

Good Air

Poor Air

Deadly Air

Enter the Space and Proceed with work:

An attendant shall be posted near the entrance for the duration of the work.

He shall be in constant communication with the entrants while the job is in

progress.

All entrants shall sign the sign in log when entering the space and sign out

when exiting.

The attendant shall maintain the permit and sign in log for the duration of

the work.

When the Job is Done:

Remove all personnel, tools, and debris from the space. Sign off the log.

Close the space.

Cancel the permit.

Review the job with the host employer (hazards, problems, other employers,

etc.)

Non-Permit Confined Space Entry

Isolate the space

Ventilate the space

Evaluate the space

o

o

Test atmosphere

Assure justification conditions are met

Conduct tailboard

Enter the space

Isolate the Space from all hazards

Close Valves

o

o

Empty the Space

o

Depressurize, vent & drain

Lockout/Tagout Equipment

o

o

o

Double block & bleed, or

Blank flange

Electrical sources

Rotating/reciprocating parts

Hazardous materials

Clean residue from the space

Ventilate the Space

Use mechanical ventilation

o

o

Fans

Air horns

Ventilate at the rate of at least four (4) volumes per hour

o

Larger spaces require more ventilation

Make sure air supply is not contaminated

o

Ventilation air supply must be from fresh air uncontaminated with

flammables, toxins, etc.

Evaluate the Space

Determine that the space meets all the conditions set forth in the non-permit

justifications

Conduct atmospheric testing

Evaluation must be certified by Entry Supervisors signature

Determine that the confined space does not:

o

contain or have the potential to contain a hazardous atmosphere

o

o

o

Continuous mechanical ventilation not acceptable as good

atmosphere

contain a material with the potential for engulfment

Has an internal configuration which could trap or asphyxiate, or

contain any recognized serious safety or health hazard

Enter the Space and Proceed with work:

If non-permit conditions change during the job, the space shall be

immediately evacuated, and reclassified as a permit-required confined space;

or conditions shall be returned to non-permit conditions and again certified as

such by the entry supervisor.

Contractor Confined Space Entry

Contractors must be informed of the hazards within the space

Contractors must follow their own established confined space entry procedure

and use their own permit forms

Contractors must supply their own attendants

o

One attendant is acceptable for multiple companies entrants

Contractors must supply their own air monitors

Contractors must review entry after completion of job

Attendant Responsibilities

To monitor entrants during the job and during entry & exit to help insure

their safety.

o

The attendant may not abandon his post for any reason while

personnel are in the space unless relieved by another qualified

attendant.

To monitor atmospheric conditions in the space prior to and during entry.

To control access to the confined space.

To summon emergency assistance as needed.

To assess hazards in and around the space, and take action on the same.

To keep records of confined space work, such as air test results, personnel

entry/exit, etc.

Entrant Responsibilities

To assure that the space has been adequately ventilated, isolated, emptied,

or otherwise made safe for entry.

To immediately exit a space, without question, upon word of the attendant,

no matter what the reason.

To follow all safety rules and procedures that apply to the job.

To be familiar with the work to be performed and the procedures that apply

to the job.

To use the appropriate PPE whenever necessary.

Supervisor Responsibilities

To assure adequate protection is provided to the entrants by verifying

adequate lockout/tagout and that all hazards are securely isolated.

To support the attendants authority in controlling access to a confined space.

To verify that all personnel have exited prior to closing the space.

To assure that all personnel involved are aware of the hazards associated

with the space.

To assure that rescue services are available prior to entry.

Вам также может понравиться

- Analysis and Design of Air-Jet Pumps For Pneumatic TransportationДокумент302 страницыAnalysis and Design of Air-Jet Pumps For Pneumatic TransportationMusheer BashaОценок пока нет

- Rossmann Repair Training GuideДокумент276 страницRossmann Repair Training GuideulaОценок пока нет

- List of Routine Jobs Pbs BoilerДокумент8 страницList of Routine Jobs Pbs BoilerBSP CDCPОценок пока нет

- Bamboos PPT 8Документ20 страницBamboos PPT 8Pragati ChaudharyОценок пока нет

- Manual Epilog Laser Mod 8000Документ228 страницManual Epilog Laser Mod 8000damarcrazyОценок пока нет

- Myrra Transformers CatalogДокумент24 страницыMyrra Transformers CataloggksamyОценок пока нет

- CC-0. in Public Domain. Digtized by Muthulakshmi Research AcademyДокумент212 страницCC-0. in Public Domain. Digtized by Muthulakshmi Research AcademyRavi BansalОценок пока нет

- Pulveriser Mill Performance Analysis & Optimisation in Super Critical Thermal Power Plant Using Imported CoalДокумент3 страницыPulveriser Mill Performance Analysis & Optimisation in Super Critical Thermal Power Plant Using Imported CoalSajal JainОценок пока нет

- 2004 9000 0A 0740 - CPP Crane Maintenance Guideline - Rev1Документ67 страниц2004 9000 0A 0740 - CPP Crane Maintenance Guideline - Rev1chuminhОценок пока нет

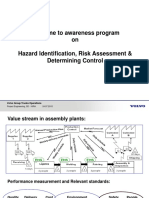

- Welcome To Awareness Program On Hazard Identification, Risk Assessment & Determining ControlДокумент26 страницWelcome To Awareness Program On Hazard Identification, Risk Assessment & Determining ControlshishunalОценок пока нет

- Literature Review - Minor ProjectДокумент9 страницLiterature Review - Minor ProjectIshan TiwariОценок пока нет

- Philips sc17 PDFДокумент58 страницPhilips sc17 PDFramiresSОценок пока нет

- Rajdeep Project On Fire Risk Analysis in Power PlantДокумент29 страницRajdeep Project On Fire Risk Analysis in Power PlantSoumya Bhattacharya100% (1)

- C3.Hiradec - ONLINE BOLT TIGHTENING (FLANGES & UNION JOINTS-GLANDS OF MOV-MCV-MIV-PCV)Документ1 страницаC3.Hiradec - ONLINE BOLT TIGHTENING (FLANGES & UNION JOINTS-GLANDS OF MOV-MCV-MIV-PCV)Pankaj PandeyОценок пока нет

- Grindability of Solid BiocarbonДокумент8 страницGrindability of Solid BiocarbonJJОценок пока нет

- Minor Project - Tata Iron and Steel LimitedДокумент51 страницаMinor Project - Tata Iron and Steel LimitedSonia Dann KuruvillaОценок пока нет

- Bowl MillДокумент10 страницBowl MillAvtarОценок пока нет

- Hira PDFДокумент69 страницHira PDFvinod100% (1)

- Confined Space Training PackДокумент61 страницаConfined Space Training Packmd yasinОценок пока нет

- Torri FactionДокумент16 страницTorri FactionhedayatinluvОценок пока нет

- SES - Drone Based Inspection ServicesДокумент14 страницSES - Drone Based Inspection Servicesअभि ना. कुंभारОценок пока нет

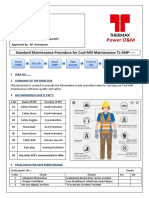

- Coal Mill MaintenanceДокумент16 страницCoal Mill MaintenancePankajОценок пока нет

- Spirit Ls User ManualДокумент136 страницSpirit Ls User ManualY'moon ZahraОценок пока нет

- CHP HiraДокумент57 страницCHP HiraPankaj PandeyОценок пока нет

- 501 2012 6 28 27 39 561Документ26 страниц501 2012 6 28 27 39 561MITHILESH KUMARОценок пока нет

- JSA General-Hot-Height-Confined SpaceДокумент26 страницJSA General-Hot-Height-Confined SpaceGMAОценок пока нет

- The Dive Business Guide To Safe Diving OperationsДокумент25 страницThe Dive Business Guide To Safe Diving OperationsWale OyeludeОценок пока нет

- DH3-31HFC-T-SCT-0010 Commissioning Procedure of Coal Pulverizing System REV.0Документ11 страницDH3-31HFC-T-SCT-0010 Commissioning Procedure of Coal Pulverizing System REV.0hungОценок пока нет

- ThesisДокумент248 страницThesisrussell_mahmood100% (1)

- Sansui Seven Operating Instructions & Service ManualДокумент31 страницаSansui Seven Operating Instructions & Service ManualTomas MagalhaesОценок пока нет

- Chapter 7 Pulverisers PlantДокумент11 страницChapter 7 Pulverisers PlantBineet Kumar VarmaОценок пока нет

- Cdi - AliДокумент34 страницыCdi - AliNKSОценок пока нет

- Mundorf MA30 CatalogДокумент8 страницMundorf MA30 CatalogRobert RichardОценок пока нет

- Mecawber DenseveyorДокумент4 страницыMecawber DenseveyorkanthmekalaОценок пока нет

- Coal-Mill Optimisation in Coal-Fired Power Stations Aids FlexibilityДокумент9 страницCoal-Mill Optimisation in Coal-Fired Power Stations Aids FlexibilityTinyiko S. MalulekeОценок пока нет

- Transformer: Navigation SearchДокумент18 страницTransformer: Navigation SearchidigitiОценок пока нет

- Safety Requirements For Design Engineering V1r2bДокумент50 страницSafety Requirements For Design Engineering V1r2bDragan Gostojic GostaОценок пока нет

- 3595 Coal PulverizersДокумент18 страниц3595 Coal PulverizersRamachandrarao MaddaliОценок пока нет

- FLS-pneumatic Transfer From Storage (Tse)Документ22 страницыFLS-pneumatic Transfer From Storage (Tse)Dilnesa EjiguОценок пока нет

- 07-Noise Control1 PDFДокумент75 страниц07-Noise Control1 PDFmarnhy -Оценок пока нет

- Aptech Advances in Pneumatic Conveying EditorialДокумент17 страницAptech Advances in Pneumatic Conveying EditorialMinh Tú PhạmОценок пока нет

- Shailesh Job Safety Analysis in Steel Manufacturing Unit and Recommendations To Improve The Work Safety EnvironmentДокумент21 страницаShailesh Job Safety Analysis in Steel Manufacturing Unit and Recommendations To Improve The Work Safety EnvironmentNandini RajОценок пока нет

- JSA For Confined Space 20 12 2019 - TS3Документ5 страницJSA For Confined Space 20 12 2019 - TS3narasimhamurthy414Оценок пока нет

- Safetyin Welding Gas Cutting OperationsДокумент12 страницSafetyin Welding Gas Cutting OperationsSantanu Kumar SahuОценок пока нет

- Jindal Power Limited O.P.J.S.T.P.P, Tamnar, Raigarh: Commissioning DepartmentДокумент9 страницJindal Power Limited O.P.J.S.T.P.P, Tamnar, Raigarh: Commissioning Departmentjp mishraОценок пока нет

- Silo Overpressurisation Guidance PDFДокумент27 страницSilo Overpressurisation Guidance PDFDorian StiopuОценок пока нет

- Job Safety AnalysisДокумент30 страницJob Safety AnalysisNaveen ChodagiriОценок пока нет

- On-Site Emergency Plan: Captive Power Plant Angul, OdishaДокумент67 страницOn-Site Emergency Plan: Captive Power Plant Angul, OdishaANILОценок пока нет

- ED3300Документ4 страницыED3300Mohamed Tahoun100% (1)

- Supervisors GuideBookДокумент16 страницSupervisors GuideBooklwin_oo2435Оценок пока нет

- Audio Transformer - Final Report - (Pichkalyov KPI Ukraine)Документ9 страницAudio Transformer - Final Report - (Pichkalyov KPI Ukraine)kimbalsummers801Оценок пока нет

- CoalДокумент89 страницCoalRizki AmeliaОценок пока нет

- Pine Confined SpaceДокумент31 страницаPine Confined Spacemigas_7Оценок пока нет

- Nozzles Conical Nozzle DataДокумент57 страницNozzles Conical Nozzle DatasekharsamyОценок пока нет

- Transformer DesignДокумент47 страницTransformer Designsinergicus100% (2)

- The Flow Chart of Waste Tires Recycling Pyrolysis Equipment For 8TДокумент3 страницыThe Flow Chart of Waste Tires Recycling Pyrolysis Equipment For 8Tpyrolysisoil100% (1)

- 020.abrasive Blasting Rev.0 PDFДокумент12 страниц020.abrasive Blasting Rev.0 PDFYounis KhanОценок пока нет

- Confined Space EntryДокумент33 страницыConfined Space EntryLee Anthony ChingОценок пока нет

- 14 Confined Spaces, LSR 6, OSHAДокумент43 страницы14 Confined Spaces, LSR 6, OSHARichel CacanogОценок пока нет

- Confined Space Entry TrainingДокумент39 страницConfined Space Entry TrainingyounasОценок пока нет

- Compressed Gas SafetyДокумент28 страницCompressed Gas SafetyDiaa Gab-AllahОценок пока нет

- Basic Rigging Training (BRT)Документ38 страницBasic Rigging Training (BRT)droffilcz27100% (1)

- Behavior of Fuel: (Incident Command & Control)Документ16 страницBehavior of Fuel: (Incident Command & Control)droffilcz27Оценок пока нет

- Introduction To Confined Space SafetyДокумент32 страницыIntroduction To Confined Space Safetydroffilcz27Оценок пока нет

- Surface Condenser: Applications of Surface Condensers and Requirement of Surface CondenserДокумент17 страницSurface Condenser: Applications of Surface Condensers and Requirement of Surface Condenserdroffilcz27100% (1)

- 5S - House KeepingДокумент20 страниц5S - House KeepingRawinder100% (2)

- OSHAДокумент37 страницOSHAdroffilcz27Оценок пока нет

- Preliminary Hazard AnalysisДокумент40 страницPreliminary Hazard Analysisdroffilcz27100% (2)

- OSHA 501 Subpart J Confined SpacesДокумент109 страницOSHA 501 Subpart J Confined Spacesdroffilcz27Оценок пока нет

- Industrial Fire Hazard and Risk ManagementДокумент18 страницIndustrial Fire Hazard and Risk Managementdroffilcz27Оценок пока нет

- Quantitative and Qualitative Risk AnalysisДокумент3 страницыQuantitative and Qualitative Risk Analysisdroffilcz270% (1)

- 4 Special Fire Hazards and PreventionДокумент22 страницы4 Special Fire Hazards and Preventiondroffilcz27100% (1)

- 1 Hsef-101Chemistry of FireДокумент15 страниц1 Hsef-101Chemistry of Firedroffilcz27Оценок пока нет

- Brief Idea of HAZOPДокумент8 страницBrief Idea of HAZOPdroffilcz27Оценок пока нет

- First AidДокумент37 страницFirst Aiddroffilcz27100% (1)

- Lock Out Tag OutДокумент31 страницаLock Out Tag Outdroffilcz27Оценок пока нет

- Fall Protection: Slips, Trips, and FallsДокумент10 страницFall Protection: Slips, Trips, and Fallsdroffilcz27Оценок пока нет

- Basic Behavior Based SafetyДокумент7 страницBasic Behavior Based Safetydroffilcz27Оценок пока нет

- LOPAДокумент5 страницLOPAdroffilcz2750% (2)

- Hazop ExampleДокумент4 страницыHazop Exampledroffilcz27Оценок пока нет

- Example Practical ExamДокумент4 страницыExample Practical Examdroffilcz27Оценок пока нет

- What Is A Confined Space Hazard Assessment and Control ProgramДокумент5 страницWhat Is A Confined Space Hazard Assessment and Control Programdroffilcz27Оценок пока нет

- Liquid Analytics Standard Configurations - 2 - 0Документ70 страницLiquid Analytics Standard Configurations - 2 - 0knchnОценок пока нет

- Federal Ministry of Agriculture and Water Resources Proc Record 2009Документ30 страницFederal Ministry of Agriculture and Water Resources Proc Record 2009SulabayoОценок пока нет

- Advantages of GabionsДокумент8 страницAdvantages of GabionsAnkur DesaiОценок пока нет

- Solubility of NaCl, NaBr, and KCL in Water, Methanol, Ethanol, EtcДокумент4 страницыSolubility of NaCl, NaBr, and KCL in Water, Methanol, Ethanol, Etcnour_b_bОценок пока нет

- 08 Activity 2Документ1 страница08 Activity 2Lumiegrace BertuldoОценок пока нет

- EF Final Sept 15Документ170 страницEF Final Sept 15Bobby MccormickОценок пока нет

- DocxДокумент35 страницDocxqweqwe67% (3)

- 38 Frog Frog ShamanismДокумент1 страница38 Frog Frog ShamanismАлександра АнквицОценок пока нет

- Positive Drive Line: Your Best Conveying SolutionДокумент2 страницыPositive Drive Line: Your Best Conveying SolutionSebastian QuintanaОценок пока нет

- rm69 Marine Toilet Electric Mul PDFДокумент16 страницrm69 Marine Toilet Electric Mul PDFurania22000Оценок пока нет

- Ideation Phase: Prototyping: The Design ProcessДокумент18 страницIdeation Phase: Prototyping: The Design ProcessPedro PradoОценок пока нет

- PE6705 Water Flooding and Enhanced Oil Recovery L T P C 3 0 0 3 Objective: Unit I 9Документ6 страницPE6705 Water Flooding and Enhanced Oil Recovery L T P C 3 0 0 3 Objective: Unit I 9Prince ImmanuelОценок пока нет

- Galloway 1973Документ34 страницыGalloway 1973loboclvОценок пока нет

- Competition in The Bottled Water Industry in 2006Документ29 страницCompetition in The Bottled Water Industry in 2006Dhika YogatamaОценок пока нет

- Framework PD 1586 and The Phil EIS System Engr - Divina CamaraoДокумент83 страницыFramework PD 1586 and The Phil EIS System Engr - Divina CamaraoKim Nicole UmadhayОценок пока нет

- 2 - Conservation and The Use of Secondary and Recycled Materials PDFДокумент16 страниц2 - Conservation and The Use of Secondary and Recycled Materials PDFfa_fa67Оценок пока нет

- Eia Report DangoteДокумент234 страницыEia Report Dangotewaseemiqbal133100% (4)

- SamplereportsДокумент5 страницSamplereportsMehul MittalОценок пока нет

- Picture Description Summer HolidaysДокумент1 страницаPicture Description Summer Holidaysmohammad515Оценок пока нет

- CO LAV WC WC WC FD FD LAV: Scale 1: 100 M Scale 1: 100 MДокумент1 страницаCO LAV WC WC WC FD FD LAV: Scale 1: 100 M Scale 1: 100 MFritz NatividadОценок пока нет

- Timber WorksДокумент348 страницTimber WorkshasansalgadoОценок пока нет

- Section 1: Listening (5.0 Points) : Complete The Table. Write ONE WORD ONLY For Each AnswerДокумент19 страницSection 1: Listening (5.0 Points) : Complete The Table. Write ONE WORD ONLY For Each AnswerNhật TiếnОценок пока нет

- Table 2.3: List of Field Crop Varieties/hybrids Released and Notified in 2018Документ37 страницTable 2.3: List of Field Crop Varieties/hybrids Released and Notified in 2018Ruhi AhujaОценок пока нет

- Page 27Документ1 страницаPage 27amalОценок пока нет

- SporActiv Full Catalog Sheet - 003Документ2 страницыSporActiv Full Catalog Sheet - 003TomGaliciaОценок пока нет

- Saturnino Daniel M 201206 PHD ThesisДокумент164 страницыSaturnino Daniel M 201206 PHD ThesisNovember RainОценок пока нет

- ch06 Ecology TestbankДокумент6 страницch06 Ecology Testbankhalabisarah100% (1)

- List of ABS Notations and SymbolsДокумент270 страницList of ABS Notations and SymbolsLucian100% (1)

- CHE485 Chemistry Laboratory Lab 5 Determination of Chromium (VI) Concentrations Via Absorption SpectrosДокумент27 страницCHE485 Chemistry Laboratory Lab 5 Determination of Chromium (VI) Concentrations Via Absorption SpectrostuesdayofjulyОценок пока нет

- Evergreen Chiller 04 811 50026Документ2 страницыEvergreen Chiller 04 811 50026Hanan SFОценок пока нет

- Survive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveОт EverandSurvive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveОценок пока нет

- Welcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthОт EverandWelcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthРейтинг: 4 из 5 звезд4/5 (59)

- Crazy for the Storm: A Memoir of SurvivalОт EverandCrazy for the Storm: A Memoir of SurvivalРейтинг: 3.5 из 5 звезд3.5/5 (217)

- Will to Wild: Adventures Great and Small to Change Your LifeОт EverandWill to Wild: Adventures Great and Small to Change Your LifeРейтинг: 4.5 из 5 звезд4.5/5 (3)

- The Lost Explorer: Finding Mallory on Mount EverestОт EverandThe Lost Explorer: Finding Mallory on Mount EverestРейтинг: 4.5 из 5 звезд4.5/5 (31)

- The Art of Resilience: Strategies for an Unbreakable Mind and BodyОт EverandThe Art of Resilience: Strategies for an Unbreakable Mind and BodyРейтинг: 4.5 из 5 звезд4.5/5 (118)

- The Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsОт EverandThe Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsОценок пока нет

- 438 Days: An Extraordinary True Story of Survival at SeaОт Everand438 Days: An Extraordinary True Story of Survival at SeaРейтинг: 4.5 из 5 звезд4.5/5 (189)

- Beastmaking: A fingers-first approach to becoming a better climberОт EverandBeastmaking: A fingers-first approach to becoming a better climberОценок пока нет

- The Last of His Kind: The Life and Adventures of Bradford Washburn, America's Boldest MountaineerОт EverandThe Last of His Kind: The Life and Adventures of Bradford Washburn, America's Boldest MountaineerРейтинг: 4 из 5 звезд4/5 (23)

- Grandma Gatewood's Walk: The Inspiring Story of the Woman Who Saved the Appalachian TrailОт EverandGrandma Gatewood's Walk: The Inspiring Story of the Woman Who Saved the Appalachian TrailРейтинг: 4.5 из 5 звезд4.5/5 (309)

- Dark Summit: The True Story of Everest's Most Controversial SeasonОт EverandDark Summit: The True Story of Everest's Most Controversial SeasonРейтинг: 4 из 5 звезд4/5 (154)

- Prepared: The 8 Secret Skills of an Ex-IDF Special Forces Operator That Will Keep You Safe - Basic GuideОт EverandPrepared: The 8 Secret Skills of an Ex-IDF Special Forces Operator That Will Keep You Safe - Basic GuideРейтинг: 4.5 из 5 звезд4.5/5 (10)

- One Man's Climb: A Journey of Trauma, Tragedy and Triumph on K2От EverandOne Man's Climb: A Journey of Trauma, Tragedy and Triumph on K2Рейтинг: 4.5 из 5 звезд4.5/5 (15)

- Laws of UX: Using Psychology to Design Better Products & ServicesОт EverandLaws of UX: Using Psychology to Design Better Products & ServicesРейтинг: 5 из 5 звезд5/5 (9)

- How to Survive Anything: From Animal Attacks to the End of the World (and Everything in Between)От EverandHow to Survive Anything: From Animal Attacks to the End of the World (and Everything in Between)Рейтинг: 4.5 из 5 звезд4.5/5 (3)

- Last Child in the Woods: Saving Our Children From Nature-Deficit DisorderОт EverandLast Child in the Woods: Saving Our Children From Nature-Deficit DisorderРейтинг: 4 из 5 звезд4/5 (283)

- Bushcraft 101: A Field Guide to the Art of Wilderness SurvivalОт EverandBushcraft 101: A Field Guide to the Art of Wilderness SurvivalРейтинг: 4.5 из 5 звезд4.5/5 (47)