Академический Документы

Профессиональный Документы

Культура Документы

Ijems 16 (6) 373-384

Загружено:

Samraj MahalingamОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ijems 16 (6) 373-384

Загружено:

Samraj MahalingamАвторское право:

Доступные форматы

Indian Journal of Engineering & Materials Sciences

Vol. 16, December 2009, pp. 373-384

Surface properties of the cut face obtained by different cutting methods from

AISI 304 stainless steel materials

Adnan Akkurt*

Faculty of Industrial Arts Education, Gazi University, Golbasi, Ankara, Turkey

Received 8 May 2009; accepted 22 September 2009

AISI 304 stainless steel which is widely used almost in all industrial applications is accounted for approximately 50%

of the worlds stainless steel production and consumption. Because of its aesthetic view in architectures, resistance against

corrosion and chemicals, it became as the most preferred material. Today several methods for machining of AISI

304 stainless steel are available. Most of these methods result in loss of superior properties of the stainless steel material and

makes it to act like other ordinary materials within the machined zones. In this study, specimens taken from the AISI

304 material are cut by the cutting methods which are commonly used in machining. The resulting surface properties of

these specimens are compared with original materials with respect to different methods. Finally mechanical and

metallurgical properties of the cut face obtained by each method are examined. The results show that cutting with abrasive

water jet gives the most favorable result while oxygen cutting gives the worst.

Keywords: Cutting methods, Comparison of cutting methods, AISI 304 stainless steel material, Surface characteristic,

Surface quality

With the developments in cutting technologies, surface

properties obtained by pre-manufacturing and

specifically final machining applications have high

importance. Machining quality in the cutting methods,

generally, is characterized by change in material

properties, cut edge deformation, cut surface properties

and cut channel geometry. Common use of many

cutting processes introduces questions like which

cutting method is more efficient for a given material?

Within this context, main aim is to find the fastest,

cheapest, top quality method yielding in the least

deformation on the cut edge and its vicinity. In many

cases, one or more of these criteria may be neglected.

Despite the ongoing evolution of cutting methods

since more than a century, some application

limitations and weaknesses makes it inevitable to

search for new methods. There exist several

limitations and weaknesses in application of new

cutting methods, i.e., abrasive water jet (AWJ), laser

beam cutting (LBC), plasma beam cutting (PBC),

water shield plasma cutting (WSPC), and wire

electrical discharge cutting (WEDC) that have been

invented other than conventional methods like oxygen

flame cutting (OFC), saw cutting (SC) and milling

cutting (MC). It does not appear possible to avoid

_______________

*E-mail: aakkurt@gazi.edu.tr

thoroughly these weaknesses. Having different

machining principles and providing means for

engineering design, these methods facilitates

miniaturizing, using extra ordinary materials and

flexible manufacturing techniques that have serious

impact on todays economy1. The quality of cutting

process done by any method can be determined by

measuring some properties such as surface roughness,

tolerance control, flatness and perpendicularity. These

parameters must be taken into account while

comparing cut faces obtained by different methods.

With the developing technology, deficiencies like

cutting quality, cutting precision, repeatability of

process and time in conventional cutting methods are

discovered. Therefore, new methods are researched

continuously in order to get the fastest, most quality

and least surface deformation with minimum cost.

Several new methods were found and applied as the

result of these researches. Among those, cutting

methods based on jet flow (Fig. 1) which are

becoming widely used day by day constitute as most

preferred methods. In all of these methods based on

jet flow AWJC, LBC, PBC and WEDC, the surfaces

obtained are in parallel lines. However, when the

surface is examined in micro level, micro properties

of the surface differs from each other as the cutting

mechanism is different in each method1-3.

374

INDIAN J. ENG. MATER. SCI., DECEMBER 2009

Fig. 1 Surface obtained by jet flow and quality zones4,5

Fig. 2 Cut face quality zones based on jet flow3

The surface quality obtained by these methods

based on jet flow, can be developed by increasing the

power consumed per each unit of cutting length. More

quality surface can be attained by increasing in the jet

pressure and decreasing the lateral feed rate4-8. The

quality zones of a surface obtained by cutting based

on jet flow are given in Fig. 2.

Recent researches approved abrasive water jet

cutting system (Fig. 3) to be one of the most efficient

cutting methods. AWJC as a cutting system releasing

no corrosion, no evident revolution, no chipping at the

edges, no unwanted forces that can yield in

deformation of material while cutting, no heat effect

and hence never resulting in any problems such as

structural deformation, tarnishing, distortion, melting,

Fig. 3 Abrasive water jet cutting system4

dripping and oxidation, can cut even most complex

shapes at close tolerances and generating very clean

surface properties9.

Evaluation on Cutting Methods

There are many methods to be used in cutting

materials as sheets of specific thicknesses. These

methods are compared by Hashish10 as shown in

Fig. 4. A comparison is made by taking into account

the power levels and typical metal removal ratios of

different machining methods.

In his assessments performed according to the

abrasive water jet, Hashish stresses that, as compared

to the conventional methods, the energy distribution

formed within the water jet which has the capacity to

AKKURT: AISI 304 STAINLESS STEEL

375

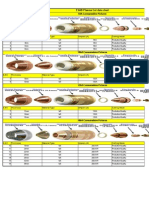

Fig. 4 Comparison of volumetric metal removal ratios related to power levels of machining methods10

Table 1 General comparison of abrasive water jet with other cutting methods3

Comparison of abrasive water jet with other cutting methods

Comparison factor

Material thickness

Cutting quality

Lateral feed rate

Multipurpose use

Heat affected zone

(HAZ)

Precision cutting

Secondary treatment

requirement

Slurry formation

Production flexibility

Total machining time

Abrasive water

jet

A

A

B

A

Laser

cutting

C

A

A

D

Plasma

cutting

B

C

B

B

Water shield

plasma cut

B

B

B

B

Wire electro

discharge

A

A

B

B

Milling

cutting

B

B

B

B

Hydraulic

saw

B

B

A

B

Oxygen

cutting

A

C

B

C

B

A

B

C

B

B

C

C

D

C

C

D

A

B

B

B

A

B

D

C

A

B

D

C

A : Perfect B : Good C: Acceptable D : Unacceptable

cut with fairly low energy consumption, is too dense

and a significant part of this energy is consumed by

friction as in the cases of other single orifice jet beam

cutting processes (LBC, PBC, WSPC). Jet of small

diameter applied on the piece is able to cut in every

direction while being perfectly directed and hence is

able to create quite narrow cuts. Particularly, as there

is no thermal effect on the cut material, it became

more effective than other methods10-12.

A comparison of abrasive water jet with other

cutting methods is given in Table 1. From Table 1, it

can be seen that abrasive water jet cutting method is

the most efficient cutting method regardless to the

material thickness and properties. However, there are

disadvantages of abrasive water jet machining

technology besides its many advantages. The most

important ones are those the system and cutting

parameters are related to many variables and as these

parameters cannot be recognized accurately,

continuous surface quality throughout the cut depth

cannot be achieved. Surface roughness which

increases related to the cut depth is inevitable as in

cutting with laser beam, plasma beam and water

shield plasma and oxygen flame13,14.

There are many studies regarding comparison of

AWJ with other methods (Fig. 5). When referred to

these different results according to different

materials came into picture. Powell et al.15, have

made a research on comparison of laser and AWJ

methods in economics point of view. In their studies,

they focused on relative efficiency of both

machining processes by discussing technical and

commercial advantages and disadvantages of the two

methods.

INDIAN J. ENG. MATER. SCI., DECEMBER 2009

376

Fig. 5 Comparison of cutting abilities of different cutting methods by using single orifice jet beam16

Ohlsson et al.16, have studied the effects of

pressure, abrasive flow rate and lateral speed on cut

depth and surface properties of steel and gray cast

iron in cutting with AWJ. Zeng et al.17, aimed at

providing a conclusion for users on which of the

methods is more convenient for which type of

applications by performing studies based on the

quality and operational cost. They focused on

comparison of cutting stainless steel, plain steel and

aluminum of different thicknesses. In all these studies,

it has been stated that abrasive water jet cutting gives

the best results with respect to laser beam cutting and

plasma beam cutting which are said to be competitors.

When a general evaluation of cutting methods is

made, abrasive water jet comes out to be the most

efficient method despite some deficiencies. Other than

those superiorities shown in Figs 4 and 5 and Table 1,

the advantage of this method is that it is a cold

process. Consequently, no mechanical and thermal

stresses are realized on the cut material. Therefore,

there is no need for stress removal processes

afterwards. All materials can cut without any heat

generation. Hence, unwanted hardening, droplets on

the surface, melt metal dross and poisonous gas

formations are avoided. On the other hand, having, no

negative effect on environment can be declared to be

most important superiority of the method.

Experimental Procedure

Materials

In this study, specimens were taken from AISI

304 austenitic stainless steel (Austenite () stabilizer)

Fig. 6 Preparation of test specimens

of thickness 20 mm as shown in Fig. 6 and are cut

with different cutting methods. The dimensions of the

prepared specimens are a = 20 mm and b = 100 mm.

All specimens are cut by 4 times and 8 different

measurement surfaces are obtained. Chemical

composition of materials is given in Table 2 and

cutting parameters of AWJ are given in Table 3.

Method

Specimens were cut by eight methods of

conventional ones (oxygen flame, hydraulic saw,

milling) and contemporary ones (abrasive water jet,

laser beam, plasma beam, water shield plasma

(focusing), wire electrical discharge). Feed rate of the

material is selected as 20 m/min for each cutting

method (except wire WEDC). Cutting and cooling

conditions are selected in accordance with

the machine manufacturers recommendations with

AKKURT: AISI 304 STAINLESS STEEL

377

Table 2 Chemical composition of stainless steel material; AISI 304 Austenite () stabilizer 304

V

Si

Mn

Mo

Cu

Cr

Ni

Fe

Nb

Co

0.116

0.498

0.979

0.217

0.228

17.30

8.06

72.30

0.0476

0.0338

0.0210

0.147

Table 3 Cutting system and cutting parameters

Abrasive Water Jet Cutting

Water consumption

3.5 l/min

The pump piston diameter

20 mm

System temperature of water

48C

Inlet pressure of water into the pressure booster

6 bar

Working pressure of the booster

200 bar

Inlet diameter of water into the nozzle

0.25 mm

Outlet pressure of water from the

pressure booster

20 bar

Abrasive nozzle inlet diameter into the nozzle

0.75 mm

Water flow rate

3 l/min

Stand - off distance

4 mm

Outlet velocity of water from the nozzle

800 m/s

Water pressure at the instance of discharge

400 MPa

Temperature at the instance of cutting

55C

Jet angle at the nozzle

90

Current consumption during work

380 V

Energy consumption

58 kwh

Amount of abrasive consumed

250 g/min

Material used in the nozzle orifice

Sapphire

Abrasive used

GMA Garnet

Chemical Composition

Fe2O3Al2 (SIO4)3

Abrasive hardness

7.5 - 8 Mohs

Abrasive particle size

300 m

Abrasive water outlet diameter from the

nozzle

0.75 mm

Nozzle length

76.2 mm

Slurry content

% 18

Mixing tube length

88.9 mm

Mixing tube diameter

1.27 mm

Nozzle orifice life

40-50 h

Laser Beam Cutting

Plasma Beam and Water Shield Plasma Cutting

Cutting rate (Lateral feed rate)

20 m/min

Cutting rate (Lateral feed rate)

20 m/min

Position rate

140 m/min

Plate positioning

By Laser

Laser power

1550 Wt

Current for maximum cutting

760 A

Main power supply

GW 0-100 %

Nozzle pressure

12 bar

Pulse type

Mega pulse

Operating pressure

24 bar

Pulse change frequency

2000 Hz

Operating frequency

50 Hz

Pulse time

NP(T)

1500 s

SP(t)

120 s

4000 kcal/h

Cooling capacity

Mod type

Srekli mod (CW) Nominal voltage

400 V

Focus distance

7.5 mm

Average sound level

68 dB(A)

Cutting gas

Nitrogen

Cutting gas

Oxygen+Nitrogen

Cutting gas pressure

1.2 bar

Maximum cutting thickness

35 mm

Cooling temperature

TA=25C

Cutting capacity

4000 7000 mm

Oxygen Flame Cutting

Wire Electrical Discharge Cutting

Cutting rate (Lateral feed rate)

20 m/min

Processing condition

C521

Current for maximum cutting

760 A

Feed rate

3 m/min

Nozzle pressure

10 bar

Processing conditions and parameters

Contd

INDIAN J. ENG. MATER. SCI., DECEMBER 2009

378

Table 3 Cutting system and cutting parameter Contd

Abrasive Water Jet Cutting

Operating pressure

20 bar

ON

OFF

IP

HP

MA

SV

SF

Operating frequency

50 Hz

006

15

17

15

0.3

0.3 005

Cooling capacity

4000 kcal/h

Voltage

32 V

Receiver tank capacity 30 l

Current

5.6 A

Nominal voltage

400 V

Wire tension

Level 8

Average sound level

68 dB(A)

Wire feed rate

7 m/min

Cutting gas

Oxygen+Propane

Control system

Fine APT

C

0

Parameters for each cutting methods are selected in accordance with the machine manufacturers recommendations.

respect to specific methods. Specimens cut are left in

ambient temperatures for cooling. Surface properties

(microstructure, hardness) obtained after cutting

processes are compared with those of original

materials. As the results of measurements taken, it

was observed differentiations in metallurgical

structure of the materials throughout cut faces and

zones close to this face. Therefore, microstructures,

cut face hardness and roughness were evaluated on

these cut faces.

Hardness values were measured at ten points being

randomly selected on the surfaces of specimens

obtained from every method and mean value of

surface hardness were determined by calculating

arithmetic means of these values. Measurements were

taken by Instron Wolpert Testor and HV30 values

were obtained. Hardness measurements were taken at

the cut faces of the specimens of 20 mm thickness

obtained by different methods over five linear gauges

1 mm apart from each other starting from the cut face

and their arithmetic means were calculated. Hardness

changes were observed with respect to the heat

distribution over the material. Consequently, how

different cutting methods affect hardness of materials

on cut faces and to which depth from the cut faces

these effects can be observed. In order to make a

comparison, the original hardness values of specimens

at the center were determined before cutting.

20 measurements were taken by Mitutoyo Surftest

Analyzer 402 at 5 different cut depth selected by

sampling on each cut face and minimum, mean and

maximum roughness values were calculated for each

cutting method by taking the arithmetic means of Ra,

Rz ve Rmax values obtained. It should not be forgotten

that, increase in surface roughness values are

observed in relation with increase in depth from the

upper surface on the cut faces obtained by cutting

methods based on jet flow rates. Therefore,

4 measurements were taken at points which were

selected by sampling from each cut face quality zones

shown in Fig. 2 and mean values for roughness are

found by simply taking the arithmetic average of

20 measurements obtained.

Also, microstructure pictures were taken on each

cut face and the conclusions were made by evaluating

not only the pictures given here but every picture

taken throughout the study. Microstructures of parent

materials and cut edges of cut faces were displayed by

magnifying at 280 using PANASONIC WV CP410 Model Type N334 microscope and personal

computers. Alumina powder and diamond paste were

used in polishing and then etching with a mixture of

5g CuCl2 + 100 mL HCI + 100 mL ethanol + 100 mL

distilled water was applied until the structure can be

detected. Cutting parameters were selected from those

suggested for AISI 304 stainless steel sheets of

20 mm thickness by equipment manufacturers.

Results and Discussion

Evaluation of structural changes generated by different

cutting methods

In order to perform metallographic evaluations, and

to determine structural deformation and changes

picture of microstructure were taken from a zone that

cannot be affected by the cutting process (Fig. 7) and

cut edges (Fig. 8). By examining these microstructure

pictures, microstructures of cut faces obtained by

different cutting methods and zones close to these

faces can be compared with original microstructures.

Cutting with hydraulic saw

It was observed that the structure was undergone

excessive mechanical deformation and the grains

were reoriented. Fractures and cracks were generated

through ferrite grain boundaries, and structural

AKKURT: AISI 304 STAINLESS STEEL

379

A needlelike (Widmannstatten) structure was

observed. This needlelike structure became thicker

and a shift to austenitic structure was observed

proceeding inwards as the affect of heat is decreased.

Chrome-carbide precipitations occurred at the cutting

zone and the vicinity. Besides, the grains became

smaller and hence apparent structural deformation

was evaluated unavoidable.

Plasma beam cutting

Fig. 7 Micro structure of AISI 304 austenitic stainless steel

material

changes were detected related to deformation and

heat. No excessive phase change can be realized

despite deformation hardening.

Milling cutting

The structure was undergone mechanical

deformation and excessive fracture, deep cracks and

flaws were detected through ferrite grain boundaries.

Structural defects can be observed due to deformation

in the cutting zone and its vicinity. As compared with

the structure obtained by hydraulic saw, the grains

were more reoriented as deformation speed and

quantity were more. Heat affect stayed more limited

than structural deformation as milling cutting was

performed under cooling liquid media.

Cutting with water shield plasma

Excessive heating and rapid cooling at the cutting

zone yields in fine granular structure and makes

unstable austenitic structure become clearly detected

martensite at the cutting zone. An increase in hardness

and hence brittleness at the cutting zone is

unavoidable due to rapid heating and rapid cooling.

Also, as ferritic structure was formed at the heat

affected zone, resistance to corrosion is to be

decreased. Although there is a twin structure at the

cutting zone, excessive deformation occurred at the

cut face. Beyond this zone, austenitic structure was

detained due to the application of cooling water but

the grain sizes were explicitly reduced.

Laser beam cutting

Due to excessive heating together with rapid

cooling at the cutting zone, ferrite formation occurred.

Heat affected zone was observed to be wider. Due

to excessive heating together with rapid cooling at the

cutting zone, ferrite formation occurred. Needlelike

(Widmannstatten) structure extends in a wider range

getting away from the cutting zone. On the other

hand, as high temperatures were reached and cooling

rate was not high enough, chrome-carbide

precipitations were observed in the structure. A new

structure were obtained yielding in unavoidable

worsening in corrosion resistance at the cutting zone

and having the most excessive structural deformation

other than that obtained by oxygen flame cutting.

Cutting with abrasive water jet

Low mechanical deformation and no apparent

deformation due to heat was observed at the cutting

zone. For these reasons, it can be declared that the

structure was preserved and no significant change

occurred in the existing structure. Therefore, chromecarbide precipitation and crack formation risks that

constitutes serious problems in cutting of stainless

steel materials were not.

Cutting with wire electrical discharge

Structural changes were realized relating to heat at

the cutting zone and because of rapid cooling

hardness the brittleness of the structure was observed

to be increased. Besides, crack formations occurred,

they were limited to the cutting zone and its close

vicinity. Beyond this zone, austenitic structure was

preserved. It is unavoidable to result in a decrease in

corrosion resistance at the cutting zone and its close

vicinity.

Cutting with oxygen flame

Needlelike (Widmannstatten) structure was formed

due to excessive heating and rapid cooling. This

structure spreads over a wide range. Deep cracks were

formed at the cutting zone and its close vicinity and

phase changes were occurred. Chrome-carbide

precipitation was also observed at the cutting zone

due to excessive heating. Besides, as higher

temperatures is reached an increase in the risk of

380

INDIAN J. ENG. MATER. SCI., DECEMBER 2009

(a)

(e)

(b)

(f)

(c)

(g)

(d)

(h)

Fig. 8 Micro structure pictures of cut edges (a) cutting with hydraulic saw, (b) milling cutting, (c) cutting with water shield plasma,

(d) laser cutting, (e) plasma cutting, (f) cutting with abrasive water jet, (g) cutting with wire electro discharge and (h) cutting with oxygen

flame

AKKURT: AISI 304 STAINLESS STEEL

381

formation of sigma phase become evident. It is an

unavoidable result that corrosion resistance is to

decrease significantly at the cutting zone and wider

range.

Depending on the changes in microstructure of

materials, when heat affected zone and the size of this

zone are taken into account, structural changes

occurred as the result of high temperatures and rapid

cooling in some methods are of significant

importance. Depending on the properties of cutting

method, coarse granular structure in some methods

and fine granular structure due to rapid cooling in

some other methods are observed. Also depending on

the properties of cutting methods, gas inclusions and

tendency towards micro crack formation is observed

in the structure. Main reason why no deformation in

the microstructure occurs in the cutting zone is that

high temperatures are not reached in cutting with

AWJ. In all methods other than abrasive water jet

cutting, when the microstructures are examined from

the cut face towards inside, the deformed

microstructure views are returned to the original

microstructure of the material after certain depths

based on the method used. The most and the second

most unfavorable ones among those are oxygen flame

cutting and plasma beam cutting methods

respectively. The regaining of the original structure

from the cut face towards inside in the shortest depth

can be seen in cutting by saw and cutting by milling

methods.

A comparison of roughness values of cut faces

obtained by cutting of AISI 304 austenitic stainless

steel material of 20 mm thickness with different

methods are shown in Fig. 9. An analysis of this

figure shows that when the roughness values obtained

for each method are evaluated, it can be observed that

the coarsest cut face is obtained by cutting with

oxygen flame and the finest cut face is obtained by

cutting with wire electrical discharge method.

A comparison of hardness values of cut faces

obtained by cutting with different methods with

original hardness values of materials is shown in

Fig. 10. This figure implies decrease in quantity of

hardness values differs for each cutting method

depending on methods applied. As a result of this, it

can be stated that, changes in the hardness values are

different depending on the individual properties of

cutting methods. This tendency verifies that every

method causes a change in the hardness values

depending on their effects on metallurgical properties

of materials.

It is known that, in conventional methods, most of

the energy consumed for metal removal is released as

heat, some of the energy is converted to

deformation and small amount of energy is converted

to lost energy regarded as elastic loss. It is also

known that; temperature reached caused by the energy

which is converted to heat, if not controlled, would

cause changes in metallurgical properties of work

piece materials. This temperature rise is the main

reason for the significant change in the metallurgical

properties as it exceeds the re-crystallization

temperature of the material. Cooling conditions

applied during metal removal, also, affects the

metallurgical properties of the materials. Therefore,

this can be concluded as the main reason of the

change in mechanical properties such as hardness.

The basis of oxygen flame cutting which is one of the

thermal cutting methods, lies upon the principles of

reaching the melting temperature of the material and

Fig. 9 Comparison of roughness values of cut faces obtained by

cutting of AISI 304 austenitic stainless steel material with

different methods

Fig. 10 Comparison of hardness values of cut faces obtained by

cutting of AISI 304 austenitic stainless steel material with

different methods

382

INDIAN J. ENG. MATER. SCI., DECEMBER 2009

transfer of the resulting melt metal from that zone.

Bringing the material to those temperatures and cooling

conditions afterwards yields in significant changes in

metallurgical and mechanical properties of materials.

In this study, the occurrence most significant changes

with respect to both the metallurgical properties and the

hardness which was observed during oxygen flame

cutting is an expected result.

Regarding the contemporary methods, changes in

metallurgical properties and hardness values depends

on the principles of the methods. The basis of laser,

plasma and wire electrical discharge methods depends

on the principle of cutting the materials at melting

temperatures as in the case of oxygen flame cutting.

The main reason for different metallurgical properties

and hardness values obtained by these methods is that

energy and cooling conditions applied are different.

The reason why hardness values obtained by

conventional methods such as water shield plasma

and wire electrical discharge methods are better than

those obtained by laser and plasma methods, can be

described as in line with the fact that former methods

are performed under shielding liquid and thus the

temperature is relatively controlled.

Among the cutting methods applied, when

comparison is made based on changes in metallurgical

properties and hardness values with respect to the

original materials structure and hardness values, the

best results were obtained by AWJ cutting methods.

Hardness of the surfaces cut by AWJ lies very close

to the values of the original material. This can be

expressed to be in relation with abrasion mechanisms

used in this method. It is known that the change in

temperatures stays in a very limited range (approx.

(t=75C)19. This also explains the absence of heat

affected zone (HAZ) in AWJ cutting. Based on this

feature, cutting with AWJ method becomes prominent

as an effective method by not causing changes in the

original structure and hence mechanical and

metallurgical properties of the materials.

Table 4 shows how different cutting methods

affects hardness changes of cut faces at which ratio

(as % change) in this study. The least change is

obtained by milling cutting and hydraulic saw cutting

methods other than AWJ cutting method. This can be

related to selection of cutting parameters for

conventional methods so as to avoid temperatures

higher than re-crystallization temperatures.

Depending on the cutting method parameters,

depth of heat affected zone changes starting from the

cut face. Depending on the change in metallurgical

structure resulted by cutting method, hardness

measurements, taken at points 1 mm apart from each

other starting from the cut face extending towards the

center of specimens, gives some information

regarding the size of heat affected zone. The results of

these measurements for AISI 304 austenitic stainless

steel were shown Fig. 11.

The most impressive result concluded from these

figures, is that there is no linear tendency in cutting

with AWJ method and hence there is no heat affected

zone (HAZ) in the material cut with this method.

Cutting with AWJ method comes into picture as a

method that can perform cutting by not yielding in

any change in metallurgical and hardness properties

of the materials. It is also observed that the method

during which the most significant changes occur with

respect to metallurgical properties and hardness

values is oxygen flame cutting method. In this

method, it can be declared that hardness values differ

significantly from the surface to the center and most

part of the material is affected by heat released. In

laser and plasma cutting methods, which are the main

competitors of AWJ cutting method, the change in

hardness values from the surface towards the center is

continuous and heat affected zone is larger. It can be

seen on the graph given in Fig. 11, losses are

observed in original hardness values of the raw

material in relation with the effect of heat during all

methods yielding in heat generation during cutting.

Measurements taken from the cut edge towards inside

demonstrate that the material regains its original

hardness at certain depths. Similarly, when the

microstructure pictures are examined, material returns

to its original structure at certain depths.

Table 4 Percent change of hardness values of cut faces obtained

by cutting of AISI 304 austenitic stainless steel material with

different methods

Cutting Method

Core material

Abrasive water jet cutting

Milling cutting

Hydraulic saw cutting

Oxygen flame cutting

Laser cutting

Plasma cutting

Water shield plasma cutting

Wire electro discharge cutting

AISI 304 Austenitic Stainless

Steel

Hardness (HV30)

% Change

185.67

184.50

171.50

171.17

145.33

157.67

156.83

163.33

165.83

0.63

7.63

7.81

21.73

15.08

15.53

12.03

10.69

AKKURT: AISI 304 STAINLESS STEEL

383

Fig. 11 Hardness variations from the cut edge toward the center

Taking into consideration all methods, a

continuous change in hardness values occurs in

aluminum group materials, while in AISI 304

stainless steel materials, being very high in a certain

zone this tendency decreases after a certain point.

This can be explained with the thermal conductivity

of the materials. It is known that the thermal

conductivity of commercial pure aluminum and

AL6061 aluminum alloys (190 kcal /s /cm /C), are

much higher than that of steel materials and therefore

heat affected zone is expected to be larger. For

AISI304 austenitic stainless steel, for which the

thermal conductivity (14.00 kcal /s /cm /C) is lower,

Having greater change in hardness values in depths up

to 3 mm from surface and lower beyond that zone

(Fig. 11) clearly shows the effect of thermal

conductivity over the heat affected zone. The size of

the heat affected zone, changes depending on thermal

conductivity of the cut material as well as the cutting

methods. Heat affected zone is much larger in

aluminum

group

and

brass

materials

(103 kcal/s/cm/C), for which the thermal

conductivities are much higher, whereas for steel

materials having lower thermal conductivity and for

AISI 304 austenitic stainless steel material which is

one of the steel materials having lowest thermal

conductivity, heat affected zone in much

smaller3,20,21. It can be concluded that, thermal

conductivity of materials is also as effective on the

qualities of surface obtained and neighboring zones

as heat realized during cutting with different cutting

methods.

Conclusions

The following conclusion may be drawn from the

results obtained by cutting of AISI 304 stainless steel

materials by different cutting methods:

(i) Regarding the effect of cutting methods on

metallurgical properties of cut faces, AWJ

cutting method became prominent yielding in

the most favorable results.

(ii) As different heating and cooling effects

occurred during application of different

cutting methods constitute significant impacts

on metallurgical properties of the material

being tested, no heat affected zone (HAZ)

occurred throughout the surface cut by AWJ

and no deformation can be observed in the

original structure of the material. This does

not mean that there will be no change in

mechanical properties related to the

metallurgical properties. Besides, main reason

for not having a deformation in the

microstructure throughout the cut zone is that

high temperatures do not occur during cutting

with AWJ.

(iii) Among the eight different methods examined,

when an evaluation is made based on changes

in microstructure throughout the heat affected

zone, cutting with oxygen flame is

observed to be the worst method and cutting

with AWJ as the best method. Among the

applied methods, cutting with oxygen flame

method is approved to be the worst one

resulting in greatest change in hardness

INDIAN J. ENG. MATER. SCI., DECEMBER 2009

384

values of materials. Mechanical properties of

materials also changes with respect to the

effect of different methods on metallurgical

properties of materials after cutting. As the

result of the experimental studies performed,

having hardness values measured on the cut

faces different from the original values of

materials justifies this situation.

(iv) All cutting methods applied results in a

change in the hardness of materials. Changes

in hardness values are observed to be

different in relation with different cutting

methods. This situation varies with respect to

heat and temperature realized during cutting

and cooling conditions.

(v) When the size of the heat affected zone is

evaluated taking into account the differences

in hardness values from the edges to the

center based on different cutting methods,

cutting with AWJ method is proved to be the

most effective method with almost no

differences realized. In the laser and plasma

methods which are accepted to be the most

important competitors of AWJ, the

continuous change in hardness values from

the edges to the center shows that the heat

affected zone is so wider as incomparable

with AWJ. This approves itself to be the most

important superiority of AWJ with respect to

these methods.

Acknowledgements

This study is supported by ASSAB-KORKMAZ

CELIK TICARET VE SANAYI A.S.

References

1 jmertz C, A Study on abrasive waterjet milling, department

of production engineering, Ph.D. Thesis, March- Sweden,

1997.

2 Engel S L & Labus T J, Industrial applications and comparison

of lazer and abrasive waterjet technologies, in Fluid Jet

Technology Fundamentals and Applications, 2nd ed, (WJTA,

St. Louis, MO, USA), 1993.

3 Akkurt A, Comparative examination surface properties,

hardness and micro structure changes of several materials

when cut by abrasive water jet with those cut by different

cutting methods, Ph D Thesis, Gazi University, Institute of

Science, Ankara, 2002.

4 http://www.cncmachines.us/images

5 http://www.iw.uni-hannover.de

6 Ansorge A, Fluid jet principles and application, Proc

Nontraditional Machining Conf (Society of Carbide &

Tool Engineers, American Society for Metals, Metcut

Research Associates, Abrasive Engineering Society,

USA), 1985

7 Prusse U, Fox B, Kirchhof M, Bruske F, Breford J & Vorlop

K D, Chem Eng Technol, 21 (1998) 29-33.

8 Himmelreich U & Rae W, in Proc 6th American Water jet

Conf, edited by Labus T J, (Water Jet Technical Association,

St. Louis, USA), 1991, 355-369.

9 jmertz C, Abrasive water jet machining, (Chalmers

Teknska Hgskola, Chalmers Unversty of Technology,

Gteborg, Sweden), 1994, 91-96.

10 Hashish M, Applications of metal cutting with abrasive water

jets, Proc Conf Nontraditional Machining, 1988, 1-11.

11 Matsumoto O, Sugihara M & Miya K, J Nuclear Sci

Technol, 29(11) (1992) 1074- 1079.

12 Engel S L & Labus T J, Industrial applications and comparison

of lazer and abrasive waterjet technologies, in Fluid Jet

Technology Fundamentals and Applications, 2nd ed, (WJTA,

St. Louis, MO, USA), 1993

13 Hashish M, Prediction models for ASJ machining

operations, 7th American Water Jet Conf, Seattle, USA,

1993, 205-216.

14 Guo N S, Louis H & Meier G, in Jet Cutting Technology,

edited by Lichtarowicz A, (Kluwer Acad Publ, Dordrecht),

1992, 503-523.

15 Powell J, Ohlsson L & Olofsson E M, An economc

comparson of laser and abrasive water jet cutting, Lulea

University of Technology Division of Materials Processing,

Sweden, 1995.

16 http://www.ma-kon.com

17 Ohlsson L, Powell J & Magnusson C, Mechanisms of

striation formation in abrasive waterjet cutting, Proc 12th Int

Conf Jet Cutting Technology, France, 1994, 151-164

18 Zeng J, Hines R & Kim T J, Characterization of energy

dissipation Phenomena in abrasive water jet cutting, Proc 6th

American Water Jet Conf, (Water Jet Technology

Association, St. Louis, USA), 1991, 163-177.

19 Ohadi M M & Cheng K L, ASME J Heat Transfer, 115

(1993) 446-452.

20 Akkurt A, J Polytech, 8(1) (2005) 69-79.

21 Akkurt A, Kleki M K, eker U & Ercan F, J Mater

Process Technol, 147 (2004) 389-396,

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- ProductionДокумент1 страницаProductionSamraj MahalingamОценок пока нет

- Ap 894410pfam PDFДокумент1 страницаAp 894410pfam PDFSamraj MahalingamОценок пока нет

- How To Talk About Mechanized Plasma Cut SamplesДокумент23 страницыHow To Talk About Mechanized Plasma Cut SamplesSamraj MahalingamОценок пока нет

- FA Fabricator ImprovCutQuality Sep07Документ0 страницFA Fabricator ImprovCutQuality Sep07Merk ErikОценок пока нет

- FA Fabricator ImprovCutQuality Sep07Документ0 страницFA Fabricator ImprovCutQuality Sep07Merk ErikОценок пока нет

- ART Plasma Cut Quality - DrossДокумент1 страницаART Plasma Cut Quality - DrossSamraj MahalingamОценок пока нет

- ART Plasma Cut Quality - DrossДокумент1 страницаART Plasma Cut Quality - DrossSamraj MahalingamОценок пока нет

- Resume: ObjectiveДокумент2 страницыResume: ObjectiveSamraj MahalingamОценок пока нет

- Combine - Thesis - PDF Plasma Arc MachiningДокумент104 страницыCombine - Thesis - PDF Plasma Arc Machininggourab19Оценок пока нет

- 53281Документ11 страниц53281Samraj MahalingamОценок пока нет

- ESAB Plasma Cut Data Chart: S.No Thickness Material Type Ampers (A) Cutting ModeДокумент2 страницыESAB Plasma Cut Data Chart: S.No Thickness Material Type Ampers (A) Cutting ModeSamraj MahalingamОценок пока нет

- Resume: ObjectiveДокумент2 страницыResume: ObjectiveSamraj MahalingamОценок пока нет

- Resume: ObjectiveДокумент2 страницыResume: ObjectiveSamraj MahalingamОценок пока нет

- Resume: ObjectiveДокумент2 страницыResume: ObjectiveSamraj MahalingamОценок пока нет

- Email From IRCTC: Ticketadmin@irctc - Co.in Mon, Nov 5, 2012 at 4:23 PMДокумент3 страницыEmail From IRCTC: Ticketadmin@irctc - Co.in Mon, Nov 5, 2012 at 4:23 PMSamraj MahalingamОценок пока нет

- ONLINE Application For GATE 2011: Page - 1Документ4 страницыONLINE Application For GATE 2011: Page - 1Vivek AlliОценок пока нет

- Hardware Implementation of FPGA Based Direct Torque Control of Induction Motor DriveДокумент10 страницHardware Implementation of FPGA Based Direct Torque Control of Induction Motor DriveSamraj MahalingamОценок пока нет

- A Modified Back Emf Detection Technique of BLDC Motor Drive For Wide Range ControlДокумент16 страницA Modified Back Emf Detection Technique of BLDC Motor Drive For Wide Range ControlSamraj MahalingamОценок пока нет

- DS Catalogue Fuses Redspot English UkДокумент48 страницDS Catalogue Fuses Redspot English UkSamraj MahalingamОценок пока нет

- 2 Marks Special Machines.Документ26 страниц2 Marks Special Machines.Samraj MahalingamОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Dungs ATEX en 161 Solenoid ValvesДокумент12 страницDungs ATEX en 161 Solenoid Valvesstefan-romocki-4927Оценок пока нет

- Niper Model Paper 6.Документ37 страницNiper Model Paper 6.GANESH KUMAR JELLAОценок пока нет

- AESW011Документ50 страницAESW011Arputharaj Maria LouisОценок пока нет

- Biodegradable Polymers For Bone Tissue Engineering: M. Susana Cortizo and M. Soledad BelluzoДокумент29 страницBiodegradable Polymers For Bone Tissue Engineering: M. Susana Cortizo and M. Soledad BelluzoRajeshwari MalliОценок пока нет

- Chapter 12 Points To RememberДокумент7 страницChapter 12 Points To RememberSaksham YadavОценок пока нет

- Principles and Practices of Modern Coal Mining - R. D. Singh - Ch2Документ49 страницPrinciples and Practices of Modern Coal Mining - R. D. Singh - Ch2rrathore50% (4)

- Coefficient of Thermal ExpansionДокумент6 страницCoefficient of Thermal ExpansionemiljuchiacОценок пока нет

- Pil 12636 EngДокумент4 страницыPil 12636 EngDr. Bishundat YaneshОценок пока нет

- Industrial - Cord Chemicals IncДокумент1 страницаIndustrial - Cord Chemicals IncEddie Resurreccion Jr.Оценок пока нет

- Dokument HORIBA PG-250Документ4 страницыDokument HORIBA PG-250AMIRОценок пока нет

- Chemistry For Engineers Group 17 Assignment 3Документ5 страницChemistry For Engineers Group 17 Assignment 3Vỹ KhangОценок пока нет

- Compressor Io ManualДокумент58 страницCompressor Io ManualasgharОценок пока нет

- CRM47885 Lrac9768Документ5 страницCRM47885 Lrac9768Sergio mauricio sergioОценок пока нет

- Jacob ExcelДокумент8 страницJacob ExcelPeter KiruiОценок пока нет

- Biochem AnswersДокумент3 страницыBiochem AnswersPat FerrerОценок пока нет

- 2 PDFДокумент5 страниц2 PDFpramothОценок пока нет

- Beetroot IA JilleanДокумент10 страницBeetroot IA Jilleanzeen2011Оценок пока нет

- SSPC SP5Документ6 страницSSPC SP5Julio Bacilio Cruz100% (2)

- Reinforced Thermosetting Resin Conduit:: Type RTRCДокумент2 страницыReinforced Thermosetting Resin Conduit:: Type RTRCFlorabel Tolentino Sera JosefОценок пока нет

- Thiruppathiajan R - CVДокумент4 страницыThiruppathiajan R - CVThiruppathirajanОценок пока нет

- M1226e Peristaltic Pump Compact b19b PDFДокумент12 страницM1226e Peristaltic Pump Compact b19b PDFRenatoОценок пока нет

- Cambridge IGCSE: Biology 0610/22Документ16 страницCambridge IGCSE: Biology 0610/22jad obaidОценок пока нет

- MSS SP 95Документ16 страницMSS SP 95JUAN DAVID GOMEZ PATIÑOОценок пока нет

- DEC Proposal For OU7Документ9 страницDEC Proposal For OU7MonicaОценок пока нет

- Serial DilutionДокумент9 страницSerial DilutionSaranya KannanОценок пока нет

- Polymer PDFДокумент34 страницыPolymer PDFHoa Cỏ MayОценок пока нет

- Nitoprime 25 TDS PDFДокумент2 страницыNitoprime 25 TDS PDFgalih mahardikaОценок пока нет

- Cisalite Safety Data SheetДокумент5 страницCisalite Safety Data SheetVandangombo Undrakh-ErdemОценок пока нет

- Electrodeposition of Cu - SWCNT CompositesДокумент14 страницElectrodeposition of Cu - SWCNT CompositesSorina gОценок пока нет

- Defi Making 2011Документ41 страницаDefi Making 2011JonardoОценок пока нет