Академический Документы

Профессиональный Документы

Культура Документы

Welding TEST

Загружено:

KarthiАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Welding TEST

Загружено:

KarthiАвторское право:

Доступные форматы

TECHNOZEN GET TEST- WELDING

1. Which one of the following statement is correct?

a. No flux is used in gas welding of MS

b. Borax is commonly used flux coating in electrodes

c. Laser beam welding employs a vacuum chamber and

thus avoids use of a shielding method

d. AC can be used for GTAW process

2. Considering the following processes:

1. Gas welding 2. Thermit Welding 3. Arc Welding

4. Resistance welding

The correct sequence of these processes in increasing

order of their welding temperature.

a. 1-3-4-2

b. 1-2-3-4

c. 4-3-1-2

d. 4-1-3-2

c. UV rays

d. Intense glare

9. In which type of welding a pool of molten metal is

used

a. Electro slag

b. Submerged arc

c. Thermit

d. TIG

10. T joint weld is used

a. Where lomgitudinal shear is presence

b. To join 2 pieces perpendicularly

c. To join 2 pieces of metal in the same manner as rivert

joint.

d. None of the above

3. Arc blow is common in

a. AC welding

b. DC Welding with straight polarity

c. DC Welding with bare electrodes

d. AC Welding with bare electrodes

11. In resistance welding voltage used for heating is

a. 1 volt

b. 10 volt

c. 100 volt

d. 1000 volt

4. Pinch effect in welding is the result of

a. Expansions of gases in the Arc

b. Electro-Magnetic forces

c. Electric force

d. Surface tension of the molten metal

12. Copper Is

a. easily spot welded

b. Very difficult to spot welded

c. Prefered to be welded by spot welding

d. none of the above.

5. In manual arc welding the equipment should have

drooping characteristics in order to maintain

a. Voltage constant when arc length changes

b. Current constant when Arc length changes

c. Temperature in the Arc constant

d. Weld pool red hot.

13. Projection welding is

a. Multi spot welding process

b. Used to make cantilevers

c. Used to form mesh

d. Continuous spot welding process

6. In Arc welding DC reverse polarity is used to bear

greater advantage in

a. Overhead welding

b. Flat Welding of Lap joints

c. Edge welding

d. Flat welding of Butt joints

7. Maximum heat in resistance welding is at the

a. Tip of the positive electrode

b. Tip of the negative electrode

c. Top surface of the plate at the time of electric contact

with the electrode

d. Interface between two plates being joined.

8 .In arc welding Eyes need to protected against

a. Infrared rays

b. Sparks

14. Dry cast iron is usually welded by

a. Gas welding

b. TIG

c. MIG

d. Arc

15 In Thermit welding, the iron oxide and aluminium

oxide is mixed in the ratio of

a. 1:1

b. 3:1

c. 1:3

d. Mixture is of different oxides

16. Preheating is essential in welding

a. HSS

b. Stainless steel

c. cast iron

d. Al

TECHNOZEN GET TEST- WELDING

17. The main criterion for selection of electrode

diameter in arc welding is

a. Materials to be welded

b. Type of welding process

c. Thickness of materials

d. Current used

18. In MIG welding, the metal is transferred in the

form of

a. Fine spray of metal

b. Metal drops

c. Weld pool

d. Molecules

19. Oxy acetylene flame cuts metal by its

a. Evaporation

b. Oxidation

c. Intensive Oxidation

d. Burning

20. Which of the following material is best cut by oxy

cutting process?

a. Brass

b.MS

C.Stainless steel

d. Cu

21. The flux in submerged arc welding in the form of

a. Coating of the electrode

b. Granules

c. Paste

d. An inert gas

22. Seam welding is

a. Arc welding

b. Multispot welding

c. Continuous spot welding

d. Gas welding

23. Distortion in welding occurs due to

a. Use of excessive current

b. improper clamping methods

c. Use of wrong electrodes

d. improper composition of parent material

24. Two sheets of same material but different

thickness can be but welded by

a. Adjustment of current

b. Time duration of current

c. changing the size of 1 electrode

d. Pressure applied

25. Arc welding uses following electric supply

a. AC

b. DC

c. Both AC & DC

d. Spiral wave form

26. Neutral flame has

a. 1 zone

b. 2 zones

c. 3 zones

d. 4 zones

27. Which of the following has the lowest melting point

a. Brazing spelter

b. Cu

c. Soft solder

d. Al

28. The surface cracks in the weldment of non magnetic

alloys can be inspected by

a. X ray test

b. Ultrasonic test

c. Magna flux test

d. Fluorescent test

29. Cylinders in which O2 gas is stored are

a. Fabricated by casting

b. fabricated by welding

c. fabricated by forging

d. seamless steel cylinders

30.Acetelyne gas is generated from

a. carbon

b. Calcium

c. Calcium carbide

d. Calcium chloride

31. Acetylene is stored in the

a. Gas form

b. Liquid form

c. Solid form

d. High pressure

32. Laser welding finds widest application in

a. heavy industry

b. Structural work

c. Process industry

d. Electronics industry

33. O2 TO C2H2 ratio In carburizing flame

a. 0.5:1

b. 1:1

c. 2:1

TECHNOZEN GET TEST- WELDING

d. 1:1.2

34. In resistance welding electrode is made up of

a. Carbon steels

b. Stainless steel

c. Al

d. Cu

35 .Metals like Cu & Brass can be welded by

a. Oxidizing flame

b. Carburizing flame

c. Neutral flame

d. None of the above

36. Filler metal is used in

a. Electric spot welding

b. spot welding

c. Projection welding

d. None of the above

37. Welding spatter refers to

a. Welding electrode

b. flux

c. filler material

d. welding defect

38. Which of the following metals can be suitably

welded by TIG welding

a. Stainless steel

b. Mg

c. Pure titanium

d. All of the above

39. The following gas is used In TIG welding

a. Acetylene

b. O2

c. H2

d. Ar

40. Which of the following material is best weldable

with itself?

a. Stainless steel

b. Cu

c. Al

d. Ms

41. A soldering iron bit is made of

a. Brass

b. Tin

c. Cu

d. Iron

42. The flux in brazing is used in the form of

a. Powder

b. liquid

c. paste

d. any of the above

43. Solder is essentially a

a. tin-silver base

b. tin lead base

c. tin- bismuth base

d. silver lead base

44. Which of the following carbon steel is most

weldable

a. 0.15% carbon steel

b. 0.30% carbon steel

c. 0.50% carbon steel

d. 0.75% carbon steel

45. In arc welding, temperature of following order may

be generated

a. 1000oC

b. 1500oC

c. 5500oC

d. 10000oC

46. Gray iron is usually welded by

a. Gas welding

b. arc welding

c. resistance welding

d. pressure welding

47. In the manual TIG welding, the angle of the

electrode holder with the direction of welding is

a. 30o

b. 45o

c. 60o

d. 70o

48. Which is the following brazing joint is strongest

a. butt

b. scraf(inclined)

c. lap

d. all are equally strong

49. Temperature range of soldering process is

a. 40oC to 100oC

b. 180oC to 250oC

c. 300oC to 500oC

d. around 1000oC

50. In resistance welding the electrode material is made

of

a. carbon steel

b. stainless steel

c. Cu

d. Hss

TECHNOZEN GET TEST- WELDING

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Signature: 1.sincearity 2.confidence 3.leadership Quality 1.emotionalДокумент1 страницаSignature: 1.sincearity 2.confidence 3.leadership Quality 1.emotionalKarthiОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

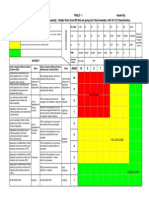

- Process FMEA ExampleДокумент4 страницыProcess FMEA ExampleKarthi0% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Quality Management System - ISO 9001 MIND MAP April 3, 2012: Compiled by Ravi Kiran Muddha Ref: ISO 9001:2008Документ1 страницаQuality Management System - ISO 9001 MIND MAP April 3, 2012: Compiled by Ravi Kiran Muddha Ref: ISO 9001:2008KarthiОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Technozen Quiz MaterialДокумент35 страницTechnozen Quiz MaterialKarthi100% (1)

- Welding QuizДокумент3 страницыWelding QuizKarthiОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Metal Casting AnswersДокумент6 страницMetal Casting AnswersKarthi100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Complete Final Assembly / Sub Assembly / Rubber Parts From BIN That Are Going Into Final Assembly With SC CC Characteristics Table - 1 Issued byДокумент1 страницаComplete Final Assembly / Sub Assembly / Rubber Parts From BIN That Are Going Into Final Assembly With SC CC Characteristics Table - 1 Issued byKarthiОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Flutter WidgetsДокумент14 страницFlutter Widgetsleyan zahdehОценок пока нет

- Discovery of A New Energy VortexДокумент4 страницыDiscovery of A New Energy Vortexnblack3335140Оценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Mathematical Model of Transportation ProblemДокумент14 страницMathematical Model of Transportation ProblemwasimghghОценок пока нет

- Introduction To The Visual Basic Programming LanguageДокумент24 страницыIntroduction To The Visual Basic Programming Languageapi-3749038100% (1)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- LG FlatRon RepairДокумент55 страницLG FlatRon Repairdany89roОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Fiber Series CTCДокумент31 страницаFiber Series CTCJorge GaitanОценок пока нет

- Pulsar 150 PDFДокумент41 страницаPulsar 150 PDFAdi Hermansyah100% (3)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- English To MetricДокумент2 страницыEnglish To MetricJohn Reynard PacsonОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Chapter3 Torsion FinalДокумент78 страницChapter3 Torsion FinalNaveen KumarОценок пока нет

- CE325 - 06 Stability of Gravity Retaining WallsДокумент29 страницCE325 - 06 Stability of Gravity Retaining WallsRobert PrinceОценок пока нет

- Neil - Bernardo@eee - Upd.edu - PH Bernalyn - Decena@eee - Upd.edu - PH Ephraim - Lizardo@eee - Upd.edu - PHДокумент3 страницыNeil - Bernardo@eee - Upd.edu - PH Bernalyn - Decena@eee - Upd.edu - PH Ephraim - Lizardo@eee - Upd.edu - PHbdec95Оценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- 141A Service PDFДокумент101 страница141A Service PDFAndrás SzabóОценок пока нет

- Minerals Down The Microscope PDFДокумент8 страницMinerals Down The Microscope PDFArijit LaikОценок пока нет

- Triboelectric Nanogenerators As New Energy Technology For Self-Powered Systems and As Active Mechanical and Chemical SensorsДокумент25 страницTriboelectric Nanogenerators As New Energy Technology For Self-Powered Systems and As Active Mechanical and Chemical SensorsAnonymous AEicha08AF100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Getting Started With Experion Software GuideДокумент28 страницGetting Started With Experion Software Guidebeerman81Оценок пока нет

- Sci Problem SolutionsДокумент10 страницSci Problem SolutionsVS PUBLIC SCHOOL BangaloreОценок пока нет

- Conte R Fort WallДокумент30 страницConte R Fort Wallmirko huaranccaОценок пока нет

- Predicting Residual Stresses Due To Solidification in Cast Plastic Plates VladoTropsaPhDДокумент225 страницPredicting Residual Stresses Due To Solidification in Cast Plastic Plates VladoTropsaPhDAghajaniОценок пока нет

- Cabinas de Bioseguridad HealforceДокумент8 страницCabinas de Bioseguridad HealforceJose HurtadoОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- rc218 CDW Jenkins Workflow PDFДокумент8 страницrc218 CDW Jenkins Workflow PDFVictor SantiagoОценок пока нет

- Elysium TranslatorДокумент24 страницыElysium Translatorfilip_bonacic3908Оценок пока нет

- MWM Parts ListДокумент6 страницMWM Parts ListRuy PeñaОценок пока нет

- ASTMD2196 05 - StandardTestMethodsforRheologicalPropertiesofNon NewtonianMaterialsbyДокумент5 страницASTMD2196 05 - StandardTestMethodsforRheologicalPropertiesofNon NewtonianMaterialsbyJesus SerranoОценок пока нет

- X2 ParametersДокумент6 страницX2 Parametersmanson_dataОценок пока нет

- MAT3700-MayJune ExamДокумент3 страницыMAT3700-MayJune ExamNhlanhla NdebeleОценок пока нет

- Miscellaneous Measurements: and ControlsДокумент50 страницMiscellaneous Measurements: and ControlsJeje JungОценок пока нет

- Unit 3 Study Guide and ExercisesДокумент2 страницыUnit 3 Study Guide and ExercisesTuan NguyenОценок пока нет

- Third Space Learning - Fluent in Five - Spring Term 2 Week 5Документ11 страницThird Space Learning - Fluent in Five - Spring Term 2 Week 5ZoonieFRОценок пока нет

- Production ManagementДокумент14 страницProduction Managementavinasss1963_3707255Оценок пока нет

- Addressable Loop Isolator Module AI 520Документ2 страницыAddressable Loop Isolator Module AI 520ராஜா கிருஷ்ணன்Оценок пока нет