Академический Документы

Профессиональный Документы

Культура Документы

D-01 Noc

Загружено:

Rochdi SahliИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

D-01 Noc

Загружено:

Rochdi SahliАвторское право:

Доступные форматы

NATIONAL OIL CORPORATION

GENERAL ENGINEERING SPECIFICATION

GES D.01

ATMOSPHERIC STORAGE TANKS (API 650)

Rev

0

Date

1999

Description

Issued for Implementation

Checked

Approved

DL

Compiled by Teknica (UK) Ltd

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

GES D.01

Page 2 of 25

Rev 0 1999

INDEX

SECTION

TITLE

1.0

SCOPE OF SPECIFICATION

1.1

1.2

Introduction

Other NOC Specifications

4

4

2.0

DEFINITIONS

2.1

2.2

Technical

Contractual

5

5

3.0

DESIGN

3.1

3.2

Codes and Standards

Additions and Exceptions

6

7

4.0

MATERIALS

15

4.1

4.2

Materials of Construction

Chemical Composition

15

15

5.0

FABRICATION AND ERECTION

16

5.1

5.2

Introduction

Procedures

16

16

6.0

TOLERANCES

18

6.1

6.2

6.3

Fabrication

Curvature

Roundness

18

18

18

7.0

INSPECTION

19

7.1

7.2

Procedures

Methods

19

19

8.0

TESTING

21

8.1

8.2

8.3

Statutory Testing

Test Procedures

Nameplates

21

21

22

PAGE

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

GES D.01

Page 3 of 25

Rev 0 1999

SECTION

TITLE

9.0

DOCUMENTATION

22

9.1

9.2

9.3

9.4

9.5

9.6

Introduction

Schedules/Reports

Data and Calculations

Drawings

Other Documents

Manuals

22

22

23

23

24

24

10.0

PRIOR TO SHIPMENT

24

10.1

10.2

10.3

10.4

10.5

Painting and Coatings

Spares

Packing/Storage

Shipping

Warranties

24

25

25

25

25

DATA SHEETS

Tank (4)

PAGE

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

GES D.01

Page 4 of 25

Rev 0 1999

1.0

SCOPE OF SPECIFICATION

1.1

Introduction

1.1.1

This specification covers the minimum requirements for mechanical design, materials,

fabrication, erection, inspection and testing of welded steel storage tanks for above ground

atmospheric storage with a capacity in excess of 10,000 bbl (1600m3).

1.1.2

These storage tanks shall be designed, fabricated, erected, inspected and tested in accordance

with API 650, plus the additional requirements of this specification.

1.1.3

Low pressure storage tanks suitable for vapour space pressures of up to 15 psig (100 kPag) are

covered by GES D.04. Tanks of 10,000 bbl(1600m3) capacity or smaller are covered by GES D.06.

Accessories for tanks are covered by GES D.02.

1.1.4

This specification applies to equipment for refineries, onshore oil and gas installations and

processing facilities.

1.1.5

The Purchase Order/Contract will state that the tanks will be purchased either by:

(a)

(b)

Owner buying tank materials and a local Vendor/Contractor carrying out the erection, or

local Contractor carrying out procurement and erection.

1.1.6

The Vendor/Contractor shall comply fully with the provisions laid down in this specification.

Any exception must be authorised in writing by the Owner.

1.1.7

In the event of any conflict between this specification and any applicable codes or standards, the

Vendor/Contractor shall inform the Owner in writing and receive written clarification from the

Owner before proceeding with the work.

1.1.8

The tank foundations will be provided by the Vendor/Contractor responsible for the erection of

the tanks.

1.1.9

This General Engineering Specification will form part of the Purchase Order/Contract.

1.2

Other NOC Specifications

1.2.1

Where indicated in this specification the following additional Specifications shall apply:

GES D.02

Accessories for Atmospheric Storage Tanks

GES D.06

Small Storage Tanks

GES D.07

Sump Tanks

GES H.07

Fire-fighting Facilities on Storage Tanks

GES W.01

Welding Procedures and Welder Qualifications

GES W.03

Post-weld Heat Treatment of Materials

GES X.01

Surface Preparation and Painting Application

GES X.02

Colour Coding of Equipment and Piping Systems

GES X.03

External Protective Coatings

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

2.0

DEFINITIONS

2.1

Technical

GES D.01

Page 5 of 25

Rev 0 1999

The technical terms used in this specification are defined as follows:

Low Strength Tank Steel

Steels having a specified minimum yield strength equal to or less than 43,000 psi (296 MPa) and a

specified maximum tensile equal to or less than 85,000 psi (586 MPa).

High Strength Tank Steels

Steel having a specified minimum yield strength greater than 43,000 psi (296 MPa) and a

specified maximum tensile strength equal to or less than 100,000 psi (689 MPa).

Peaking

Peaking is the deviation of shell contour from a true circle at vertical joints. Peaking shall be

determined over a horizontal span of 36 (915 mm) centred on the weld.

Banding

Banding is the deviation of the shell at horizontal joints from a vertical line. Banding shall be

determined over a vertical span of 36 in (915 mm) centred on the weld.

Annular Plates

Annular plates are bottom plates forming the annular ring upon which the shell rests.

Production Impact Test Plate

Coupon plate which provides the required impact test specimens for the weld metal and heat

affected zones in the finish product.

Plate as Rolled

Refers to the unit plate from a slab, or rolled directly from an ingot.

2.2

Contractual

The commercial terms used in this specification are defined as follows:

2.2.1

Owner

The oil or gas company, an associate or subsidiary, who is the end user of the equipment and

facilities.

2.2.2

Vendor

The company supplying the equipment and material.

2.2.3

Contractor

The main Contractor for a defined piece of work

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

2.2.4

GES D.01

Page 6 of 25

Rev 0 1999

Sub-Contractor

A company awarded a contract by a Contractor to do part of the work awarded to the Contractor.

2.2.5

Inspection Authority

The organisation representing the Owner or Vendor/Contractor that verifies that the equipment

and facilities have been designed, constructed, inspected and tested in accordance with the

requirements of this specification and the Purchase Order/Contract.

2.2.6

Inspector

A qualified individual representing the Owner, Vendor/Contractor or the assigned Inspection

Authority, who verifies that the equipment and facilities have been designed, constructed,

inspected and tested in accordance with the requirements of this specification and the Purchase

Order/Contract.

3.0

DESIGN

3.1

Codes and Standards

3.1.1

The design and construction of storage tanks shall comply with this specification as well as with

codes, standards and provisions indicated on the data sheets provided by the Owner.

3.1.2

This specification is based on the standards listed below:

API - American Petroleum Institute

API 650

API 2000

API 2517

Welded Steel Tanks for Oil Storage

Venting Atmospheric and Low-Pressure Storage Tanks - Nonrefrigerated and refrigerated

Evaporation Loss from External Floating Roof Tanks

ASME - American Society of Mechanical Engineers

Section II

Section IIC

Section IID

Section V

Section VIII

Section IX

Material Specification Part A Ferrous and Part B Non-ferrous

Specification for Welding Rods, Electrodes and Filler Metals

Material Properties

Non-destructive Testing

Pressure Vessels, Division 1

Welding and Brazing Qualifications

ASTM - American Society Testing & Materials

ASTM E 162

Test Method for Surface Flammability of Materials using a

Radiant Heat Energy Source

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

GES D.01

Page 7 of 25

Rev 0 1999

ANSI - American National Standards Institute

ANSI A12.1

ANSI A14.3

Safety Requirements for Floor and Wall Openings, Railings and

Toe Boards

Safety Requirements for Fixed Ladders

ASME - American Society of Mechanical Engineers

ASME B16.5

ASME B16.9

ASME B16.11

ASME B16.47

ASME B31.3

Pipe Flanges and Flanged Fittings

Factory Made Wrought Steel Butt-welding Fittings

Forged Steel Fittings, Socket-Welding and Threaded

Large Diameter Carbon Steel Flanges

Process Piping

3.1.3

Unless specified otherwise in the Purchase Order/Contract, the current editions of Codes and

Standards at the time of order should be used.

3.2

Additions and Exceptions

In addition to the minimum requirements of the API 650 design code, the following shall be

taken into consideration:

3.2.1

3.2.2

3.2.3

Corrosion Allowance

(a)

Minimum corrosion allowance for tank components constructed from carbon steel shall

be 1/16" (1.5 mm) in sweet service and _" (3 mm) in sour and corrosive service.

(b)

The design diameter of anchor bolts and the design thickness of holding down straps,

shall be increased in all cases by _" (3 mm) as corrosion allowance.

Design Loads

(a)

Design loading of the tank shall take into account cyclic operations, erection and test

loadings.

(b)

During erection, start-up or operation, all applicable loads shall be considered as acting

simultaneously.

(c)

During hydrostatic testing, wind load (wind pressure) equivalent to a 35 mph (16 m/s)

wind velocity shall be considered acting simultaneously with the hydrostatic test load.

(d)

Roof live load shall not be less than 25 lbs/ft (1.2 kN/m2) applied over the projected roof

area.

Bottom

(a)

Bottom plates shall be two pass welded with 70% joint efficiency.

(b)

Minimum shell to bottom fillet size shall be the same as the bottom annular plate

thickness.

(c)

Annular plate thickness shall be the greater of API 650 Table 3-1 or the Table below:

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

BOTTOM SHELL COURSE

THICKNESS

ANNULAR RING PLATE

MINIMUM THICKNESS

Less than or equal to " (12.5 mm)

3.2.4

" (6 mm)

Over " to _" in (12.5 to 22 mm)

Over _" to 1" (22 to 32 mm)

_" (9.5 mm)

Over 1" (32 mm)

GES D.01

Page 8 of 25

Rev 0 1999

/16" (8 mm)

/16" (11 mm)

Shell

The shell course thickness shall be designed per the one foot method of API 650 with the

following modifications:

-

specific gravity, G. Use 1.0 if actual G is 1.0 or less and use actual value if G is greater

than 1.0;

minimum nominal thickness of shell shall not be less than " (6 mm).

Subject to approval by the Owner, shell thickness determination by variable design point method

may also be acceptable for large diameter tanks.

All vertical and horizontal shell joints shall be complete penetration and complete fusion welds.

Single pass butt welds are not permitted.

3.2.5

3.2.6

Wind Girders

(a)

Wind girders for open top and floating roof tanks shall meet the strength as specified per

API 650.

(b)

Wind girders are to be used as walkways and shall be a minimum of 30" (762 mm) wide

and shall be located 42" (1.07 mm) below the top of the tank. Hand railings shall be

provided, only if the tank is equipped with fire fighting foam facilities.

(c)

Top curb angle - where a curb angle is required at the top of the shell of floating roof

tanks, the horizontal leg shall extend outwards.

(d)

Wind girders shall slope outward and shall be provided with drain holes.

Fixed Roof Design

(a)

Roof supports - 1/32" (0.8 mm) corrosion allowance to be provided on all surfaces, i.e.

1

/16" (1.6 mm) total of rafters, girders and columns.

(b)

Live load for roof supports design shall be per the National Building Code, but not less

than 25 lbs/ft2 (1.2 kN/m2) of projected areas.

(c)

For "hot tanks" or tanks subject to earthquakes, rafters shall be able to slide, but shall be

restrained.

(d)

Roof support columns shall be made from pipe only.

Structural sections are

unacceptable. Columns shall be drained and vented. Drains shall not allow liquid to be

trapped in the column when tank is emptied. A " (19 mm) diameter hole shall be

provided on each column 12" (305 mm) above the floor for flushing purposes.

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

3.2.8

3.2.9

3.2.10

GES D.01

Page 9 of 25

Rev 0 1999

(e)

The Owner shall specify to the Vendor/Contractor any lateral loads which may be

imposed on the roof supporting columns, e.g. tank mixers.

(f)

Circumferential roof angle - the horizontal leg of the roof supporting angle shall be

turned inward or outward, as specified by the Owner.

(g)

Overhangs shall not be allowed.

(h)

A frangible joint at the roof-to-shell junction shall be provided for supported cone and

self-supporting cone roof designs.

(i)

When a self-supporting dome or umbrella roof design is specified, emergency venting

per API 2000 shall be provided.

(j)

Bearing plates shall be provided for roof support columns. Plates shall be 24" (600 mm)

round or square by _" (10 mm) thick.

(k)

Roof is to slope to ensure self-draining. However, minimum slope is desirable for

personnel safety, therefore, the Vendor/Contractor shall submit a proposal when

quoting. Minimum roof plate thickness shall be 3/16" in (5 mm).

Internal Floating Roof Design

(a)

Flexible seal material shall have a flame spread index of not more than 35 per ASTM

E162.

(b)

Pan type covered floating roof designs shall not be used.

(c)

The design of internal floating roofs for use in fixed roof tanks greater than 150 ft (46 m)

diameter and having roof support columns, shall be submitted to the Owner for review.

(d)

Covered floating roofs shall be designed in accordance with GES D.07.

Floating Roofs

(a)

Floating roof tanks with specified flush type nozzles shall have the floating roof designed

to permit the outer pontoon to reach a point within 15" (381 mm) of the tank bottom.

(b)

The Owner shall supply the Vendor/Contractor with details regarding tank mixers,

internal piping, etc. The Vendor/Contractor shall ensure that all appurtenances are clear

of the roof in its lowest position.

Floating Roofs Greater than 60 ft (18.3 m) Diameter

Single deck, annular pontoon type roofs shall be per the following:

(a)

All roofs shall be of the low deck (minimum vapour space) type.

(b)

Centre decks greater than 150 ft (46 m) diameter shall have channel stiffeners on the

underside of the deck. Stiffeners shall be installed as concentric rings with a maximum

radial spacing of

20 ft (6 m).

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

GES D.01

Page 10 of 25

Rev 0 1999

(c)

Roofs for tanks greater than 200 ft (61 m) diameter shall be designed for elastic stability

against "gross out-of-plane" buckling and "local" buckling of the outer pontoon, due to

the radial load imposed by deflection of the centre deck. This radial load shall be

determined from the 10" (250 mm) rainfall loading condition as defined in API 650

Appendix "C" or punctured centre deck loading condition, whichever governs.

(d)

Floating roofs shall be of the multiple and liquid tight compartment design.

(e)

All internal bulkhead plates shall be single fillet welded along all edges for liquid

tightness.

(f)

Outer pontoon inspection manholes shall be provided with sealed cover.

(g)

For tanks over 200 ft (61 m) diameter, calculations and tests required to substantiate the

elastic stability of the roof pontoon design, shall be as follows:

-

where roof designs have not been previously approved by the Owner, the

Vendor/Contractor shall submit test data on a roof of similar diameter to

validate the design;

where validation has not been made, the Vendor/Contractor shall conduct a

proof test on the largest tank supplied on the order. Proof test shall be based on

the most critical design loading conditions.

Calculations shall be submitted to the Owner for approval.

Roofs greater than 300 ft (91.5 m) diameter shall have the following construction:

3.2.11

roof shall be of the double-deck type;

the top edge of inner rim plates in the first two central compartments shall be

welded with continuous single fillet welds;

all circumferential compartments other than outer compartment shall be

provided with a minimum of four radial partition plates.

Seals

(a)

Shunts for removing charges, due to lightning, shall be provided on open type floating

roof tanks to connect the weather shield to the roof. Shunts shall be made of stainless

steel and shall be spaced not more than 30 ft (9 m) apart.

(b)

The peripheral roof seal may, unless otherwise specified, be of the metallic shoe type or

the liquid filled tube type. The seal design and materials of construction shall be

approved by the Owner. Liquid filled seals shall be sectionalised, i.e. discontinuous, to

prevent the complete loss of the sealing in the event of leakage.

(c)

Toroidal type seals shall be equipped with a weather shield, or the tank shall be

equipped with a secondary seal. Decision between weather shield and secondary seal

shall be on an economic basis based on calculations using API 2517 (1980 version) and

shall be approved by the Owner.

(d)

The bottom of the roof seal shall contact the shell just below the liquid level for at least

95% of the circumference. The liquid seal shall be unbroken around the circumference.

The maximum precipitation load on the roof shall be taken into account to ensure the seal

is not completely submerged.

(e)

The maximum permissible gap between the primary seal and the tank shell is _" (3mm)

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

GES D.01

Page 11 of 25

Rev 0 1999

throughout the working range of the tank.

3.2.12

(f)

The primary and secondary seal (or weather shield) shall be installed to allow for

removal from the top of the floating roof (when the tank is empty and the roof is resting

on its legs).

(g)

The primary and secondary seals shall be protected against a "roll over".

Supporting Legs for Floating Roofs

(a)

Supports shall be carbon steel pipe, Schedule 80 minimum thickness, or stainless steel if

the roof is aluminium.

(b)

The number of support legs shall be determined on the basis that Schedule 40 pipe would

be used.

(c)

Supports shall be adjustable to two positions:

-

3.2.13

3.2.14

the low position shall be the lowest permitted by tank internals;

the high position shall be such that a minimum of 6 ft (2 m) clearance is provided

underneath the cover.

(d)

For steel roof, bearing plates shall be centred under each support, attached to the tank

bottom by a 3/16" (5 mm) continuous fillet weld. Plates shall be 24" (610 mm) round or

square by _" (10 mm) thick.

(e)

The length of the leg support sleeves shall be such that any opening will be above the

liquid level when the deck is deflected by the 10" (254 mm) rainfall or punctured centre

deck condition. In no case shall the height (ft) of the support sleeve for single deck

pontoon roofs be less than the tank diameter (ft) divided by 60.

Roof Drains

(a)

Emergency drains shall not be provided when the pontoon area is less than 50% of the

roof area. Only for double deck type roofs may credit be taken in the roof design when

emergency drains are furnished.

(b)

Articulated pipe drains shall be provided with Chicksan swivel joints or equal with Viton

seals.

Ladder Runways (Rolling Type)

The designer shall specify the height of the runway to accommodate sand build-up.

3.2.15

Vents for Floating Roof Tanks

The Owner shall specify on the inquiry maximum filling and suction rates for the tank service to

facilitate proper sizing of vents.

3.2.16

Tank Connections and Appurtenances

(a)

All shell opening connections including nozzles, manholes and clean-out fittings shall

meet the requirements of API 650, except that all connections shall be attached by welds

fully penetrating the shell.

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

3.2.17

GES D.01

Page 12 of 25

Rev 0 1999

(b)

Local stresses at tank appurtenances, such as agitators, shall be evaluated and sufficient

reinforcing provided to avoid high local stresses.

(c)

Flanged connections shall be Class 150 rating weld neck type flanges and seamless pipe.

(d)

Manholes shall be constructed as laid down in the relevant section of the code. Shell

manways shall be in accordance with Figure 3.4A of API 650. Roof manways shall be in

accordance with Figure 3.13 of API 650.

(e)

The minimum thickness for nozzle necks shall be in accordance with the code, but where

a corrosion allowance is specified, this should be added to the minimum nominal wall

thickness.

(f)

Reinforcement for all openings must be checked by the Vendor/Contractor against the

code requirements. The minimum outside diameter of the reinforcing ring shall not be

less than twice the nominal bore of the nozzle.

(g)

Nozzle reinforcing rings shall be fitted with tapped tell-tale holes. Rings in more than

one piece require one tell-tale hole per piece. Tell-tale holes for reinforcing rings to

insulated tanks shall be threaded and fitted with piping inserts to project proud of the

insulation.

(h)

Nozzles NPS 2 and larger shall be flanged. All couplings shall be 3,000 psi rating.

(i)

Nozzles shall be designed for static liquid and piping loads.

(j)

Fill and discharge nozzle shall be the API low type unless otherwise specified.

(k)

For apex down cone bottom tanks, the draw-off line shall be piped to the centre of the

tank, turned down and terminated 4" (100 mm) from the bottom by a flanged connector.

The pipe shall be adequately supported to maintain this clearance.

(l)

All shell and roof nozzle projections shall be increased to allow for insulation when

specified.

(m)

Nozzles and manholes which require stress relieving shall be so positioned that the

necks, flanges and reinforcement can be transported to site attached to pre-fabricated

plates.

Reinforcement of such openings shall be tested and inspected at the

Vendor/Contractor's works.

(n)

Bolt holes in flanges of shell nozzles and manholes are to straddle the axial centre line.

Bolt holes in flanges of roof nozzles are to straddle NS/EW centrelines, except where

otherwise stated.

(o)

Drain connections shall be supplied complete with draw-off sump in accordance with

API 650.

(p)

All roof nozzles shall be located close to access stairways and railings. Landing platforms

to cover all required access points shall be provided either side of the stairway.

Gaskets and Bolting

(a)

Gaskets and bolting in joints which form an integral part of the equipment, e.g.

manholes, sight glass pads, etc. and terminal joints shall be supplied by the

Vendor/Contractor.

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

3.2.18

Internal Piping

(a)

(b)

3.2.19

GES D.01

Page 13 of 25

Rev 0 1999

Heating coils are to be fabricated from fully welded seamless pipe. Flanged connections

shall not be used.

Stilling wells and standpipes may be fabricated from electric resistance welded pipe, but

seamless is preferred.

Stairways, Ladders, Platforms and Walkways

Stairways and ladders are to conform to the Vendor/Contractor's standard drawings if specified,

otherwise to be in accordance with the following:

(a)

Stairways

Tanks requiring gauging or sampling from the roof shall be provided with a spiral or

radial stairway and platform, for access to gauge or sampling hatch.

A spiral or radial stairway shall be provided for access to floating roof tanks. In addition,

a top platform with a guard railing shall be provided from the top of this stairway to the

gauge well and the roof ladder.

Stairway design and construction shall be per API 650, and the following:

-

minimum effective width of stair shall be 30" (750 mm), except where connecting

to a 24" (600 mm) wide walkway, in which case the effective width shall be 24"

(600 mm),

stair landings shall not be less than 30" (750 mm) in the direction of the stairway.

Staircase shall be 6" (150 mm) maximum from tank wall. Angle of rise 45. Rises of more

than 15 ft (4.5 m) shall be provided with a rest platform.

(b)

Ladders

Tanks not equipped with spiral or radial stairways shall be provided with an external

vertical ladder.

Ladders and safety cages shall be per ANSI A14.3, except as modified below:

-

(c)

where ladders are the only means of access, they shall provide for side-step

access to platforms unless through ladder type is specified,

where ladders serve as a secondary access to platforms, they may be either the

side-step or through ladder type installation,

chains with safety hooks or safety gates, shall be provided across ladder

openings at each platform landing,

ladder safety devices shall not be used in lieu of cage protection,

ladders shall be designed for a moving concentrated load of 500 lb (227 kg).

Walkways for Interconnecting Tanks

The platforms at the tops of ladders or stairways may be interconnected with walkways,

arranged so that personnel are not required to walk across the roof of any tank.

(d)

Platforms, Guard Railings, Toe Plates

Platform floor plates shall have a raised pattern and " (6 mm) nominal thickness.

Drainage shall be provided by one hole, " (13 mm) diameter, for approximately every

15 sq ft (1.5 m2) of steel floor plate. Holes shall be located at low spots and shall be

drilled after erection.

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

GES D.01

Page 14 of 25

Rev 0 1999

Guard railings and toe plates shall be per ANSI A12.1. Guard railings shall be

constructed of structural steel shapes or pipe. Any pipe railings shall be seal welded to

prevent internal corrosion.

For fixed roof tanks, guard railings shall be installed along the edge of the roof, extending

at least 6 ft (1.8 m) beyond the platform in each direction.

(e)

Additional Requirements for Floating Roof Tanks

If the tank diameter is equal to or greater than the height, a rolling type roof ladder shall

be furnished having a minimum angle of 30 from the vertical. If the tank diameter is

less than the tank height, it shall have a vertical roof ladder.

For floating roof tanks, guard railings shall not be furnished for windgirders specified to

be used as walkways, except for tanks having an air foam system with multiple outlet

foam stations, or if local procedures dictate fire-fighting from the windgirder.

3.2.20

Earthing

(a)

3.2.21

supply:

Supply and Services

If called for on individual tank drawings or tank data sheets, the Vendor/Contractor shall

-

3.2.22

3.2.23

Each tank shall be fitted with two earthing bosses to the code. Bosses to be positioned as

shown on the tank drawing or data sheet.

flame arrestors,

gauge hatch covers (non-sparking, gas or pressure tight to suit design condition),

emergency vent and manhole covers,

liquid level gauges,

vacuum/relief valve,

temperature measuring device.

Fire Prevention System

(a)

For fire-fighting requirements refer to GES H.07.

(b)

The tank Vendor/Contractor shall furnish and install firewater deluge system and

components, terminating at laterals at the base of the tank.

Vents for Fixed Roof Tanks

(a)

Open Type Vents

Open vents are required to be sandstorm-proof.

Vent sizing shall be per API 2000. The maximum pumping rate and the need for

additional venting capacity of tanks handling spiked crudes, those tanks fitted with

heaters, and blending tanks (blending with materials greater than 15 RVP (103.4 kPa))

will be specified.

(b)

Pressure Vacuum Vents

Pressure vacuum vents shall be used when the following conditions apply:

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

GES D.01

Page 15 of 25

Rev 0 1999

The stock stored has a flash point below 100F (38C).

Temperature of stored product is above or within 15F (8C) of its flash point at the

highest operating temperature.

The stocks stored are valuable and have a low vapour pressure, e.g. methanol.

Tank filling and emptying rates for sizing pressure vacuum roof vents shall be specified

on the Tank Data Sheet.

For asphalt service, the following limitations shall apply:

-

goose-neck vents, screens shall not be used;

pressure vacuum vents shall not be used except when the tank is blanketed with

an inert gas system.

4.0

MATERIALS

4.1

Materials of Construction

Materials to be used shall be in accordance with API 650 and the additional requirements of this

specification.

4.1.1

A complete material specification shall be submitted with the Vendor/Contractor's bid proposal.

4.1.2

Annular plates shall be of the same material specification and grade as the lowest shell course.

4.1.3

Pipe and formed plate used for nozzles, manhole necks and flush-type clean-out fitting

assemblies shall comply with the following table:

MATERIAL

LIMITATION

MATERIAL SPECIFICATION

SEAMLESS

Pipe

Formed Plate

WELDED

Attachment to steel

having a yield strength

< 42,900 psi

(296 MPa)

ASTM A53,

A106 GrB or C

API 5L

API 5L submerged

arc weld

Attachment to steel

having a yield strength

> 42,900 psi

(296 MPa)

ASTM A106

GrB or C

Not permitted

Same as plate to which component is attached. Component to be

fabricated using full penetration and full fusion weld.

4.1.4

Cast iron fittings shall not be employed on the shell or bottom.

4.2

Chemical Composition

4.2.1

The carbon equivalent of carbon steel plate used for the tank shell, shell nozzles, annular plates

and bottom plates, as defined by the equation below, shall meet the following limits:

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

GES D.01

Page 16 of 25

Rev 0 1999

Carbon equivalent (CE) = C + (Mn)/6 + (Cr+Mo+V)/5 + (Ni+Cu)/15 = 0.45 max

C = 0.28% max

5.0

FABRICATION AND ERECTION

5.1

Introduction

Fabrication and erection shall comply with the requirements of API 650 code, and the additional

requirements of this specification.

No fabrication shall commence until complete material certification has been received and

written approval of shop drawings, calculations, weld procedures plus welder performance

qualifications has been received by the Vendor/Contractor.

Approval of material certificates and welder qualification certificates are the responsibility of the

Inspection Authority.

Approval of the tank drawings, calculations, and weld procedure are the responsibility of the

Owner.

The Vendor/Contractor shall notify the Owner of the proposed starting date of actual fabrication.

The Vendor/Contractor shall provide erection tools for the Owner to erect and weld the tank.

5.2

Procedures

5.2.1

Plate Cutting and Preparation for Welding

5.2.2

(a)

Carbon and carbon manganese steels may be cut to size and bevelled by thermal or

mechanical methods consistent with accepted practice.

(b)

Care shall be taken to ensure that the weld preparations are correctly profiled.

Shop Inspection

Shop inspection shall be made of the following tankage and components.

5.2.3

(a)

Shell plates may be inspected at the tank fabrication shop, the mill, or both, by the

Owner's Inspector and/or Inspection Authority. Inspection includes witnessing tests of

physical properties.

(b)

Manholes, nozzles and flush-type clean-out fittings shop welded into a tank plate or

reinforcing pad, shall be inspected by the Owner's Inspector at the tank fabricator's shop.

Welding Procedure and Procedure Qualifications

(a)

Prior to carrying out any production welding, the Vendor/Contractor shall submit to the

Owner his proposed welding procedures.

(b)

Welding procedures for field welding shall be established and qualified in the

Vendor/Contractor's works at a time convenient to the proposed erection programme, or

at the construction site.

(c)

Testing and inspection shall be as per the requirements of ASME Code, Section IX and

GES W.01.

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

(d)

Where impact testing is required by API 650, tests shall be made for each weld procedure

qualification test plate required per ASME Code, Section IX as follows:

-

(e)

5.2.4

5.2.5

5.2.6

Welding procedure qualification test welds shall be carried out under conditions

simulating the worst access and environmental conditions expected during production

welding.

(a)

All welders and welding operators shall be qualified in accordance with ASME Code,

Section IX and GES W.01.

(b)

Welder's performance qualifications shall be conducted at the construction site and in the

Vendor/Contractor's works.

Identification and Welders

(a)

All welders qualified for the work shall be assigned identification numbers. A small area

of the weld reinforcement shall be ground flat and the welder's identification mark

stamped in this area. As an alternative, "as-built" drawings showing location and extent

of welding carried out by each welder is acceptable.

(b)

Records showing the date and the results of qualification tests conducted by each welder,

and the identification mark assigned to him, shall at all times be available for scrutiny.

Production Control Test Plates

(b)

Unless production control test plates are specified by the code or other statutory

requirements, then the Owner does not require such tests.

When such tests are called for by the code or other statutory requirements, they shall be

fabricated and tested in accordance with those requirements.

Preheat and Post-weld Heat Treatment

(a)

5.2.8

impact tests shall be made on the weld metal and the HAZ;

impact tests shall be conducted at the design metal temperature;

impact specimens of the weld metal and HAZ shall be taken per API 650.

Welder's Performance Qualification Tests

(a)

5.2.7

GES D.01

Page 17 of 25

Rev 0 1999

Pre-heat and post-weld heat treatment shall be in accordance with API 650 code and GES

W.03.

Welding

(a)

Where bottom plate welding is required per paragraph 3.2.3 (a), the qualification

procedure should be as follows:

-

(b)

24" (600 mm) of the lap weld shall be made using the same type of electrode,

plate material and welding procedure, as will be used for the actual bottom.

Three 3" (75 mm) x 18" (450 mm) tensile test strips shall be cut from this weld.

The minimum breaking load of the strips shall be at least 70% of the specified or

guaranteed minimum tensile strength of the unwelded plate.

Tack welds for shell to bottom fillet welds, if used, shall be removed prior to welding

fittings.

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

6.0

GES D.01

Page 18 of 25

Rev 0 1999

(c)

Weld undercuts and excessive weld metal build-up which creates steep angles at corners

of fillet welds shall be repaired.

(d)

Holes shall not be made in shell plate for erection purpose.

(e)

Mechanical caulking shall not be permitted.

(f)

The roof shall not have depressions that will permit accumulation of water.

(g)

Hardness of hot formed sections and of weld metal and the related Heat Affected Zone

(HAZ) of all welds shall not exceed 225 Brinell.

TOLERANCES

Tolerance shall be in accordance with the API 650 Standard and the following additional

requirements.

6.1

Fabrication

Shell plates shall have dimensional tolerances as follows:

Dimension

Tolerance

Length

Width

Difference in Diagonals

6.2

in

mm

1/16

1/16

_

1.5

1.5

3.0

Curvature

The tolerance for peaking and banding of shell plates is " (6 mm).

6.3

Roundness

The radius of the shell measured at 12" (300 mm) above the bottom corner weld shall be within

the following tolerances which represent deviation from the average radius:

Tank Diameter

ft

< 120

120 to 210

> 210

Tolerance on Radius

m

< 36

36 to 64

> 64

in

mm

1

1

13

25

38

The circumference shall be no smaller than the theoretical circumference for the specified

diameter.

The maximum permissible out-of-plumb of any single course, exclusive of banding effects, shall

be " (6 mm).

7.0

INSPECTION

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

GES D.01

Page 19 of 25

Rev 0 1999

7.1

Procedures

7.1.1

All items of plant and equipment referenced within this specification shall be subject to

inspection by the Owner or its nominated agency.

All inspection activities including those detailed in this specification shall be as agreed with the

Owner. These activities shall be incorporated within the agreed Quality Plan.

7.1.2

Approval of all NDE records are the responsibility of the Owner's Inspector at the

Vendor/Contractor's works or construction site.

7.1.3

The Vendor/Contractor shall furnish the Owner's Inspector with all relevant codes and this

specification.

7.1.4

The Vendor/Contractor shall afford the Owner's Inspector the opportunity to witness all or some

of the following quality control checks. The details shall be agreed mutually between the

Inspector and the Vendor/Contractor, prior to the commencement of fabrication.

7.2

(a)

Welding procedure and welder qualification work,

(b)

Examination of rolled and welded shells,

(c)

Identification of materials against Mill Test Certificates and impact tests, if required,

(d)

Welding examination,

(e)

Examination of radiographic film,

(f)

Internal and external examination of tanks,

(g)

Pressure tests,

(h)

Final dimensional check including peaking and banding,

(i)

Examination after cleaning,

(j)

Examination after painting, if specified,

(k)

Verification of code nameplate details,

(l)

Review and signature of Vendor/Contractor's dossiers.

Methods

Inspection shall be in accordance with API 650 and the additional requirements of this

specification.

7.2.1

Visual Inspection

Final inspection shall be carried out after the removal of all mill scale, dirt, grit, weld spatter,

paint, oil or other foreign matter from the tanks.

It is the Vendor/Contractor's responsibility to offer the tanks in a suitable condition for the

Inspector's examination, which includes the provision of scaffolding/ladders when required.

7.2.2

Inspection of Tank Bottom

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

(a)

Annular plate butt joints shall be 100% radiographed.

(b)

Bottom to shell joint shall be inspected as follows:

-

7.2.3

GES D.01

Page 20 of 25

Rev 0 1999

The inner fillet weld shall be inspected prior to welding the outside fillet weld.

Leak testing shall be performed with penetrating oil after removal of slag. Oil

shall be removed before welding the outer fillet.

The gap between the bottom shell ring and the lap welded bottom plates at radial

weld location shall be a maximum of _" (3 mm).

(c)

All bottom plate joints shall be tested using a vacuum box and soap suds solution.

(d)

Paragraph 5.3.4 (b) of API 650 shall not apply.

Radiographic Method of Inspecting Shell Joints

(a)

For low strength tank steels, radiographic examination of welding shall be per API 650

and the following additional requirements:

-

for shell plates over _" (22 mm), vertical joints shall be fully radiographed,

for shell plates _" (22 mm) or less, one spot radiograph shall be taken for every

50ft (15.25m) of weld and at all junctions of vertical and horizontal joints at a

location selected by the Inspector,

if submerged arc machine welding is used, the first 3 ft (1m) of complete weld

made by each machine for each tank shall be 100% radiographed,

if electro-gas welding is used, the first 8 ft (2.4m) of completed weld made by

each machine shall be fully radiographed and all starts and stops in the welded

joints shall be radiographed,

quality control shall be undertaken progressively throughout the job.

(b)

For high strength tank steels and for tanks with a product of specific gravity greater than

1.0 radiographic requirements shall be the same as for low strength tank steels, except

that all vertical seams shall be 100% radiographed.

(c)

Reference markers, on each film, shall include the tank and seam numbers. Each film

shall have at least two reference markers indicating the correct location of the film on the

weld.

(d)

Radiograph film length shall be 10" (254mm) minimum, or full length of weld if less than

10" (254mm).

(e)

The following imperfections, in addition to those specified in API 650, are unacceptable:

-

individual slag inclusions longer than " (6mm) or one-third of the plate

thickness, whichever is greater,

porosity with comet tails.

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

GES D.01

Page 21 of 25

Rev 0 1999

8.0

TESTING

8.1

Statutory Testing

8.1.1

The Vendor/Contractor shall conduct the hydraulic test on the tank in accordance with API 650

and this specification.

8.1.2

The tests shall be carried out in the presence of the Owner's Inspector and, if required, by the

Inspection Authority's representative.

8.1.3

The Vendor/Contractor shall submit his test procedure in writing to the Owner for approval.

8.2

Test Procedures

8.2.1

Prior to carrying out the hydrostatic test, all backing and reinforcement plates shall be leak tested

using air via a tell-tale hole with soap and water.

8.2.2

No type of preservative or paint shall be allowed to cover any joint, mechanical or welded, before

the test is complete.

8.2.3

The Vendor/Contractor shall be responsible for:

8.2.4

(a)

Hydrostatically testing the tank, including filling and emptying. If salt water is used for

testing and will remain in the tank for more than 30 days, an oxygen scavenger and a

corrosion inhibitor shall be added and maintained in concentration sufficient to prevent

any corrosion. After testing, the tank shall be drained and thoroughly rinsed with clean

fresh water.

(b)

Installing the covers of deck manholes in floating roofs, before filling.

(c)

Furnishing, laying and removing all lines required for testing from the water supply

point to the water disposal point.

(d)

Cleaning out any standing water, silt or other dirt, left in a tank after hydrostatic testing

so that the tank interior is clean and ready for operation.

(e)

Ensuring adequate venting arrangements during filling and draining.

The water filling rate for testing shall not exceed the following:

BOTTOM COURSE

THICKNESS

in

TANK PORTION

mm

FILLING RATE

in/hr

mm/hr

<_

22

Top course

Below top course

12

18

300

450

22

Top third

Middle third

Below Third

9

12

18

225

300

450

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

8.2.5

GES D.01

Page 22 of 25

Rev 0 1999

Settlement Measurements

For tanks greater than 50 ft (15m) diameter, the shell and bottom settlement

measurements shall be made by the Vendor/Contractor per the following:

(a)

Shell settlement measurements shall be made after tank erection, prior to

hydrostatic testing and during water filling at the , and full levels corresponding to the

maximum filling height of the tank. Settlement measurements shall be taken at equally

spaced intervals of approximately 30 ft (10 m) around the tank shell on well marked locations

on the annular plate or on clips welded to the shell. A record of the settlement measurements

and the results of the hydrostatic test including leakage rate shall be submitted for Owner's

approval.

(b)

Bottom internal measurements shall be made after hydrostatic testing.

Such measurements shall be made at 10 ft (3 m) spacing from the centre on the radius.

Tank Diameter

ft

m

Number of Diameter Axes

150

46

> 150 to 225

> 46 to 69

> 225 to 325

> 69 to 99

> 325

> 99

10

Additional measurements shall be made in the annular plate region at

approximately 30 ft (10 m) intervals around the tank shell. A set of at least 3 measurements shall

be made at each location commencing inward from the inside surface of the tank shell and

equally spaced on a radial line. A 100% visual examination shall be made of the tank bottom to

detect any localized depressions. The location and extent of depressions shall be indicated on the

tank bottom plate layout drawing.

8.3

Nameplates

8.3.1

A nameplate shall be provided on each tank in accordance with API 650, Section 8.0.

8.3.2

The nameplate shall be of stainless steel stamped or engraved with the required

information.

9.0

DOCUMENTATION

9.1

Introduction

9.1.1

9.2

This section covers the documentation requirements for design, materials, fabrication,

inspection and testing.

Schedules/Reports

9.2.1

For each tank, the Vendor/Contractor shall supply with the tender, a schedule showing

submission of all documents for review and approval, proposed sub-contractors, material

procurement and a production/erection programme.

9.2.2

The Vendor/Contractor shall submit with the tender a Quality Control Plan for the

contract.

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

9.2.3

9.3

9.3.1

GES D.01

Page 23 of 25

Rev 0 1999

After Purchase Order/Contract award monthly reports on design, material procurement

and production progress shall be submitted to the Owner.

Data and Calculations

The documents shall be submitted for approval/review to the Owner and to the

Inspection Authority within the periods agreed between the Owner and the Vendor/Contractor.

It shall be the responsibility of the Vendor/Contractor to ensure that the production schedule of

the tank takes into account documentation submission periods, plus a three (3) week approval

review period by the Owner and/or the Inspection Authority.

The Vendor/Contractor shall be responsible for obtaining approvals from the

Inspection Authority.

For each tank, the Vendor/Contractor shall supply with his tender a completed

Tank Data Sheet containing all the relevant information necessary for appraisal of the mechanical

design by the Owner. Also included shall be any additional drawings, specifications, etc and a

list of any proposed subcontractors.

9.3.2

All calculations shall be carried out in a clear and logical manner. Where conditions

involve the use of formulae or methods not specified in the design code, the source of these

formulae or methods shall be clearly referenced.

Computer calculations will only be accepted if all input is shown, together with

calculated values of intermediate terms and factors and options chosen, as well as final calculated

dimensions, stresses or other values. The computer program shall be validated to the satisfaction

of the Owner.

9.4

Drawings

9.4.1

The following drawings and documents shall be sent by the Vendor/Contractor to the

Owner and/or the Inspection Authority for review and approval.

9.4.2

The plating drawings, shall as a minimum, show the position of all through thickness

welds, together with material thicknesses and specifications. In addition, it shall clearly indicate

the welding procedure specification which is applicable to each weld. The plating drawing may

be combined with the general arrangement drawing, provided that this drawing clearly indicates

the same information.

9.4.3

General arrangement drawings shall show the relative location and main dimensions of

all components including elevations and orientations of nozzles.

9.4.4

In addition, the following information shall be included on the assembly drawings:

-

nozzle schedule,

list of related drawings and procedures,

operating conditions,

design conditions,

corrosion allowance,

hydrotest,

NDE requirements,

design code and main standards/specifications,

weight, empty, operating, full of water,

painting requirements,

general notes covering specified requirements,

mechanical loading conditions (e.g. nozzle loads, wind, seismic etc).

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

GES D.01

Page 24 of 25

Rev 0 1999

9.4.5

Detail drawings, which may be included on the general arrangement, shall include

thicknesses and dimensions of all components, weld details, machining and surface finish

requirements, gasket and nameplate details.

9.4.6

'As-Built' drawings may be the general arrangement drawings marked-up with the actual

as-built dimensions.

9.4.7

Drawing sizes shall conform to ISO Standards A1 to A4. All drawings shall be suitable

for microfilming on 35 mm film mounted in aperture cards. Where drawings are CAD

generated, two (2) sets of copy disks shall be supplied.

9.5

Other Documents

9.5.1

Previously qualified weld procedures may be proposed by the Vendor/Contractor,

provided all welding and testing was witnessed by an independent third party and are

supported by evidence of successful previous application. Evidence shall be in the form of

quality records of previous applications.

9.5.2

NDE procedures shall include the general procedure to be utilised for each type of NDE

employed, together with detailed technique sheets for each applicable joint configuration

proposed for each vessel.

9.6

Manuals

9.6.1

Data Book

On completion of fabrication, the tank Vendor/Contractor shall submit to the

Owner, two (2) copies of the Tank Data Book which shall contain the following:

-

9.6.2

all drawings, including `As-Built' drawings,

all calculations,

NDE procedures,

hydrotest procedure and test certificate,

material test certificate,

radiography and other NDE records,

welding procedure/welder qualification certificates,

inspection certificates,

nameplate rubbing or photograph,

tank data sheets (as-built),

certificate of compliance as per API 650, Section 8.3.

The Vendor/Contractor shall supply the Owner one set of reproducible original

drawings.

10.0

PRIOR TO SHIPMENT

10.1

Painting and Coatings

10.1.1

Surface preparation, painting and painting materials shall be in accordance with GES X.01 and

GES X.02 and GES X.03.

10.1.2

Shop prefabricated plates intended for site welding shall be left with a 2" (50mm) margin,

unprimed.

10.1.3

Providing written agreement is obtained from the Owner, the unprimed margins may be

GENERAL ENGINEERING SPECIFICATION

ATMOSPHERIC STORAGE TANKS (API 650)

GES D.01

Page 25 of 25

Rev 0 1999

protected for transport, prior to site welding, by a special weld preparation coating or a weldable

prefabrication primer.

10.2

Spares

The Vendor/Contractor shall submit with his proposal a priced list of

recommended spares for start-up and two years normal operation.

10.3

Packing/Storage

10.3.1

This section describes the minimum requirement for the preservation and protection of the

equipment during transportation and storage, prior to unpacking.

10.3.2

The probable storage period will be specified in the Purchase Order/Contract and shall extend

from the time of despatch to the time of unpacking at site. If the storage period is not stated, a

minimum period of 24 months shall be assumed. All packing shall be suitable for sea freight.

10.3.3

The following preparation for shipment shall be a minimum requirement.

After mechanical completion at the works, the materials and equipment

shall be left in a clean dry condition.

The Vendor/Contractor shall be responsible for loading and anchoring

the items to prevent damage during shipment.

10.3.4

Any additional preservation/protection requirements for sea transport shall be advised by the

Vendor/Contractor.

10.3.5

Equipment preservation and protection shall be adequate to enable the equipment to be delivered

without suffering damage or deterioration.

10.3.6

Adequate supports and bracing shall be fitted to prevent distortion of tanks and parts of tanks

during shipment.

10.4

Shipping

10.4.1

All detailed arrangements are to be covered by the Vendor/Contractor and the Purchase

Order/Contract.

10.4.2

All relevant equipment and materials shall not leave the Vendor/Contractor's works for

shipment until the release has been approved by the Owner's Inspector.

10.5

Warranty

10.5.1

The Vendor/Contractor shall warrant the tank, specified materials and services supplied against

any defect for a period of 12 months after commissioning or 24 months from the date of delivery

to the site, whichever is the shorter period, or for the period stipulated in the Purchase

Order/Contract.

10.5.2

Should any item be found defective, the Vendor/Contractor shall be responsible for all costs

associated with restoring the tank and equipment to the standard specified by the Purchase

Order/Contract.

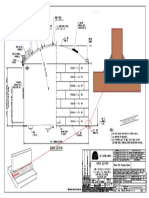

DATA SHEET No.

TANK

P.O. / CONTRACT No.

CLIENT

PLANT

LOCATION

SERVICE

SHEET

ITEM No.

of

No. of UNITS

OPERATING AND DESIGN DATA

1 Vendor / Contractor

2

3 Location

4 Fluid Stored

5 Operating Press/Temp

psig/F

6 SG of Liquid

7 Design Liquid Head

ft

8 Design Code

9 Internal Design Pressure

Tank

in wg

Coil

psig

10 External Design Pressure

Tank

in wg

Coil

psig

11 Design Metal Temp

Tank

12 Min. Mechanical Design Temp.

Coil

F

13 Tank Dia

ft

14 Pumping Rate

In / Out

15 Breathing Rate

In / Out

ft

Out

ft/h

16 Corrosion Allowance

17 Inert Blanket

Tank Height

In

at

usgpm

bar

and

in

Yes/No

18 Hazard Considerations

19

20 Uniform Live Load

lb/ft

21 Foundation Type

22 Wind Design Code

23 Earthquake Design Code/ Zone

/Zone 2

Special Roof Load

lb/ft

Maximum Rainfall

in/hr

Wind Velocity

mph

Earthquake Factor

24

25

MATERIALS

26

27 Shell

Roof

28 Bottom

Reinforcement

29 Nozzle Flanges

Nozzle Necks

30 Fittings

31 Structurals

32 Fixed Internals

Removable Internals

33 External Attachments

34 Internal Bolting / Nuts

External Bolting/Nuts

35 Gaskets

36 Floating Roof Seal

37 Internal Lining/Coating

38 Heating Coil & Nozzles

39

PAINTING

40

41

42

43

44

45

Revision No./Date

Prepared by/Date

Authorised by/Date

Purpose

(C) 1999 NATIONAL OIL CORPORATION. The information on this sheet may be used only for the purpose for which it is supplied by NOC.

K:\nocspecs\SPECIFICATIONS\d-series\d-01\Dd0101r0.xls Sheet1

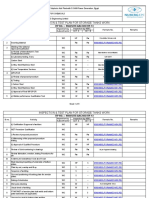

DATA SHEET No.

TANK

P.O. / CONTRACT No.

CLIENT

PLANT

LOCATION

SERVICE

SHEET

ITEM No.

of

No. of UNITS

CONSTRUCTION

1 Vendor / Contractor

2

3 Roof Type

Supported

Self Supported

4 Roof Slope or Radius:

5 Roof Plate Seams:

Floating

Covered Floating

Roof to Shell Details:

Lap

Butt

8 Anchor Bolts:

Yes

No

9 Insulation:

Yes/No

Bottom Plate Seams:

6 Bottom Plate Slope:

7 Intermediate Wind Girder

Top Girder Used as Walkway

Thickness

mm

10 Weight Empty:

lb

11 Weight Full of Operating Fluid

lb

12 Weight Full of Water

lb

13 Nominal Capacity

ft

14 Max. Overturning Moment at Base

lb.ft

15 Maximum Shear at Base

lb

Yes/No

Density

lb/ft

16

17 Hydrostatic Test

Full of Water

18 Weld Examination

Radiography

19

Supplementary Ultrasonic

20

Sectioning

21 Leak Testing

Bottom

22

Shell

23

Roof

24 Mill Test Report

Required / Not Required

25

TANK ATTACHMENTS

26

27

28 Stairway Type:

Circular

Straight

Ladder

Landings

29 Stairway Supplied By:

Handrailing

30 Walkway Width:

31 Draw Off Sump:

ft

Standard

Yes/No

Scaffold Hitch

Yes/No

Special

Yes/No

32 Internal Pipe

Swingline

Suction Nozzle

33 Heating Coil

Yes/No

Surface Area

ft

34 Roof Drain

Hose

Jointed

Syphon

35

36 Breather Valve:

Yes/No

Type:

37 Flame Arrestor

Yes/No

Type:

By:

By:

38 Level Indicator

Yes/No

Type:

By:

39 Dip Hatch

Yes/No

Type:

By:

40 Insulation Supports

Yes/No

Type:

Supplied By:

41 E STANDARDS

42

43

44

45

Revision No./Date

Prepared by/Date

Authorised by/Date

Purpose

(C) 1999 NATIONAL OIL CORPORATION. The information on this sheet may be used only for the purpose for which it is supplied by NOC.

K:\nocspecs\SPECIFICATIONS\d-series\d-01\Dd0101r0.xls Sheet2

DATA SHEET No.

TANK

P.O. / CONTRACT No.

CLIENT

PLANT

SERVICE

LOCATION

ITEM No.

SHEET

of

No. of UNITS

SKETCH

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

Revision No./Date

Prepared by/Date

Authorised by/Date

Purpose

(C) 1999 NATIONAL OIL CORPORATION. The information on this sheet may be used only for the purpose for which it is supplied by NOC.

K:\nocspecs\SPECIFICATIONS\d-series\d-01\Dd0101r0.xls Sheet3

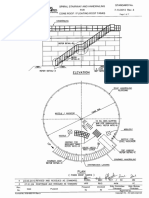

DATA SHEET No.

TANK

P.O. / CONTRACT No.

CLIENT

PLANT

LOCATION

SERVICE

FLANGES

REF

SHEET

ITEM No.

SIZE

No.

CLASS

DISTANCE

ANSI B16.5

NOZZ

STAND

from

API 605

SCH

OUT

REF. T.L.

(L)

(E)

TYPE

FACE

RAD

ANGLE

of

No. of UNITS

SERVICE

NOZZLE

REINFORCING

ATTACH

PADS

-MENTS

(R)

(A)

O/D

THK

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Revision No./Date

Prepared by/Date

Authorised by/Date

Purpose

(C) 1999 NATIONAL OIL CORPORATION. The information on this sheet may be used only for the purpose for which it is supplied by NOC.

K:\nocspecs\SPECIFICATIONS\d-series\d-01\Dd0101r0.xls Sheet4

Вам также может понравиться

- C. Specifications For Cone Roof TKДокумент21 страницаC. Specifications For Cone Roof TKFajar Sidiq AliwiyonoОценок пока нет

- 32 Samss 006Документ22 страницы32 Samss 006Vajid MadathilОценок пока нет

- 32 Samss 005Документ33 страницы32 Samss 005naruto256100% (1)

- 2015 References Terminals EДокумент59 страниц2015 References Terminals EAllyson JohnsonОценок пока нет

- Name Designation JOB Job Description Crew NoДокумент52 страницыName Designation JOB Job Description Crew NoattaullaОценок пока нет

- DSF-1101901-0568-SPC-MEC-179 Rev 4 PDFДокумент6 страницDSF-1101901-0568-SPC-MEC-179 Rev 4 PDFanon_102608277Оценок пока нет

- KOC-P-002 Part 2 Rev 7Документ56 страницKOC-P-002 Part 2 Rev 7Hari Krishnan0% (1)

- Engineering Design Guide For Storage TanksДокумент107 страницEngineering Design Guide For Storage Tankssonng.engОценок пока нет

- Lifting Eye Fir TanksДокумент1 страницаLifting Eye Fir TanksSarfarazОценок пока нет

- VP 3209 e 031a 02 0013 Rev.dДокумент254 страницыVP 3209 e 031a 02 0013 Rev.dSuryaprakashОценок пока нет

- API 650 Part 9 - 2001 Welded TanksДокумент20 страницAPI 650 Part 9 - 2001 Welded TanksHassan Ali SadiqОценок пока нет

- Datasheet Floating Roof Tanks Spill Prevention Level Switch SXRLTX A Series1 EnglishДокумент4 страницыDatasheet Floating Roof Tanks Spill Prevention Level Switch SXRLTX A Series1 EnglishDylan RamasamyОценок пока нет

- IONE-AA00-PE-QA-0021 UT Procedure - Rev - 0Документ29 страницIONE-AA00-PE-QA-0021 UT Procedure - Rev - 0Firas AlbaweiОценок пока нет

- Seismic LoadДокумент1 страницаSeismic LoadJae Kyoung LimОценок пока нет

- Development of SA-738 Gr. B High Strength Steel Plate With Excellent Toughness For Power Generating PlantsДокумент6 страницDevelopment of SA-738 Gr. B High Strength Steel Plate With Excellent Toughness For Power Generating PlantsKK SinghОценок пока нет

- 653 150Rev2PubДокумент10 страниц653 150Rev2PubMuhammad HannanОценок пока нет

- Qot BD 1 22 Me SPC 10147 00Документ18 страницQot BD 1 22 Me SPC 10147 00Hamid MansouriОценок пока нет

- PV Elite Örnek PDFДокумент223 страницыPV Elite Örnek PDFakın ersözОценок пока нет

- A307 6545 104 Enq Rev0Документ283 страницыA307 6545 104 Enq Rev0Yogi YuganОценок пока нет

- Inspection and Repair of Storage Tanks 1710346228Документ113 страницInspection and Repair of Storage Tanks 1710346228Jayapal BhukyaОценок пока нет

- Tank Erection Itp Org ChartДокумент34 страницыTank Erection Itp Org Chartvasantha kumar100% (1)

- Double DeckДокумент4 страницыDouble DeckJose CarlosОценок пока нет

- Plumbness Inspection ReportДокумент3 страницыPlumbness Inspection ReportDoris DorisОценок пока нет

- Tank GAДокумент1 страницаTank GASubramanian100% (1)

- DC S3-1301 REV.0 OriginalДокумент93 страницыDC S3-1301 REV.0 OriginalPeja JusohОценок пока нет

- Gis 42-102Документ38 страницGis 42-102Felix JaimesОценок пока нет

- Karmatech Brochure 2Документ8 страницKarmatech Brochure 2Anonymous 3akQhQFJSL100% (1)

- Welded Steel Tanks For Oil Storage - RPS 968 (Floating Roof)Документ7 страницWelded Steel Tanks For Oil Storage - RPS 968 (Floating Roof)YusufОценок пока нет

- 3191-CS-01 Rev A-009-011Документ3 страницы3191-CS-01 Rev A-009-011Syed Zain AliОценок пока нет

- A-1-10-Specification For FRP Vessels and TanksДокумент17 страницA-1-10-Specification For FRP Vessels and TanksbecemОценок пока нет

- Project HSE Requirements ManualДокумент14 страницProject HSE Requirements ManualHamid MansouriОценок пока нет

- 116Z TRHT SP MS 0000001 C Pressure Vessel SpecДокумент27 страниц116Z TRHT SP MS 0000001 C Pressure Vessel SpecMurli ramchandranОценок пока нет

- Erg (1) T 01 378 07Документ58 страницErg (1) T 01 378 07nazar750Оценок пока нет

- A.1) Verification Statement For Pvelite Calculations, As Per Asme Section Viii Div.1 2018Документ6 страницA.1) Verification Statement For Pvelite Calculations, As Per Asme Section Viii Div.1 2018ToniОценок пока нет

- CMGPP-FD-EL-SPE-0001 Specification For AC Induction Motor - Rev.0Документ14 страницCMGPP-FD-EL-SPE-0001 Specification For AC Induction Motor - Rev.0PHAM THANH TUОценок пока нет

- ITP F TK-4101 & TK-4201 A/B: Persian Gulf Star Gas Condensate Refinery-Kal Station Booster PumpДокумент20 страницITP F TK-4101 & TK-4201 A/B: Persian Gulf Star Gas Condensate Refinery-Kal Station Booster PumpHamid MansouriОценок пока нет

- EGP3-10.00 Storage TanksДокумент53 страницыEGP3-10.00 Storage TanksMathias OnosemuodeОценок пока нет

- Is 1893 Evaluation For VesselДокумент8 страницIs 1893 Evaluation For Vessellalitlbw91Оценок пока нет

- What Is The Low Temperature TankДокумент64 страницыWhat Is The Low Temperature TankAhmed ELmlahy100% (2)

- Desalinated Water TankДокумент34 страницыDesalinated Water Tankhgagselim2012Оценок пока нет

- Chattopadhyay - Material-Selection-For-A-Pressure-Vessel PDFДокумент10 страницChattopadhyay - Material-Selection-For-A-Pressure-Vessel PDFRenan Gustavo PazОценок пока нет

- Floating Roof Seal Selection GuidelinesДокумент3 страницыFloating Roof Seal Selection GuidelinesRoshin99100% (2)

- Inspection & Test Plan For Storage Tanks Work: ITP NO.:-9560/SITE/QAC/022/ITP-13Документ6 страницInspection & Test Plan For Storage Tanks Work: ITP NO.:-9560/SITE/QAC/022/ITP-13Shubham ShuklaОценок пока нет

- 8-12 X 3000 M Spherical LPG Storage TankДокумент1 страница8-12 X 3000 M Spherical LPG Storage Tankevrim77100% (1)

- 3 OEE 3 144 Mechanical Design Check ListsДокумент13 страниц3 OEE 3 144 Mechanical Design Check ListsAnonymous HDlK5cXc8Оценок пока нет

- Ammonia Gas Spherical Storage Tank SS-101: Technological Institute of The PhilippinesДокумент16 страницAmmonia Gas Spherical Storage Tank SS-101: Technological Institute of The PhilippinesVaanОценок пока нет

- 13.2015 Development and Validation of A Leak Before Break Criterion For Cylindrical Pressure VesselsДокумент12 страниц13.2015 Development and Validation of A Leak Before Break Criterion For Cylindrical Pressure VesselsArun KumarОценок пока нет

- Pressure Vessel PlateДокумент4 страницыPressure Vessel PlateYetkin ErdoğanОценок пока нет

- Inigneers India Lltvilteid: ElevationДокумент7 страницInigneers India Lltvilteid: ElevationSandip SurОценок пока нет

- AST - Tank Shell DesignДокумент17 страницAST - Tank Shell DesignAntony Bruno GenewinОценок пока нет

- Sodium Leak Through Pin HolesДокумент9 страницSodium Leak Through Pin HolesAvinash ChittellaОценок пока нет

- Engineering Encyclopedia: Determining Acceptability of Materials For Storage TanksДокумент25 страницEngineering Encyclopedia: Determining Acceptability of Materials For Storage TanksAfzaalUmairОценок пока нет

- Storage Tank Alumnuim Roof - LatestДокумент22 страницыStorage Tank Alumnuim Roof - LatesthgagОценок пока нет

- ES-20.02 Quality Requirements PTT Public Co., LTD OF 23 For Pressure Vessel Engineering Standard REV: 01Документ23 страницыES-20.02 Quality Requirements PTT Public Co., LTD OF 23 For Pressure Vessel Engineering Standard REV: 01Nikki RobertsОценок пока нет

- 16 B 06 HДокумент20 страниц16 B 06 HVaibhav Bhoir0% (1)

- Stratification OT 3536-22 ScrubberДокумент31 страницаStratification OT 3536-22 ScrubberbecemОценок пока нет

- DJM-MBA-PCS-CA-018 LPG On-Spec Storage REV-BДокумент3 страницыDJM-MBA-PCS-CA-018 LPG On-Spec Storage REV-BDIANTOROОценок пока нет

- 338033-4604-45ES-0005-07 (Carbon Steel Vessels - Technical Specification) PDFДокумент9 страниц338033-4604-45ES-0005-07 (Carbon Steel Vessels - Technical Specification) PDFjdgh1986Оценок пока нет

- 20052015KGP8PLATEIAREPORTДокумент249 страниц20052015KGP8PLATEIAREPORTmizabОценок пока нет

- C5000 16 G28 B V04 B02 PDFДокумент321 страницаC5000 16 G28 B V04 B02 PDFAhmed OmarОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент14 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент37 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент13 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент29 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент14 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент37 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент38 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- P 09Документ34 страницыP 09Rochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент23 страницыNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент15 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент22 страницыNational Oil Corporation: Rev Date Description Checked ApprovedRochdi Sahli100% (1)

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент18 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент23 страницыNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- J 19Документ14 страницJ 19Rochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент37 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- J 15Документ15 страницJ 15Rochdi SahliОценок пока нет

- J 16Документ29 страницJ 16Rochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент11 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент16 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент13 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент13 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент12 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент28 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- J 05Документ20 страницJ 05Rochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент40 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент28 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент17 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент26 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент12 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент21 страницаNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- BVP651 Led530-4s 830 Psu DX10 Alu SRG10 PDFДокумент3 страницыBVP651 Led530-4s 830 Psu DX10 Alu SRG10 PDFRiska Putri AmirОценок пока нет

- Pulsating Heat Pipe ReportДокумент65 страницPulsating Heat Pipe ReportIdul Azharul HoqueОценок пока нет