Академический Документы

Профессиональный Документы

Культура Документы

Foaming in Fractionation Columns

Загружено:

Anonymous v5uipHИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Foaming in Fractionation Columns

Загружено:

Anonymous v5uipHАвторское право:

Доступные форматы

Foaming in fractionation columns

By understanding the foaming process and its root causes, steps can be taken

to eliminate or minimise the formation of foaming

Mark Pilling Sulzer Chemtech USA

s long as there are fractionating columns, there

will be issues with foaming in some of the different

chemical applications. Foaming

in columns is problematic

because it hinders the hydraulic

processes (the vapour and

liquid flows within the tower).

This is especially true with

trayed internals where liquid

and vapour are meant to

contact intimately and then

physically separate within a

series

of

discrete

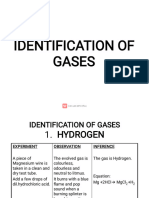

stages. Figure 1 Bubbles draining in foam

Conversely, packed columns

tend to be more forgiving in foaming When the wall of a bubble ruptures, the bubble

collapses, destabilising the foam. The main cause

applications.

Generally, there are two competing issues with of bubble rupture is thinning of the liquid wall.

foaming: first, the tendency for the process to Figure 1 shows how the liquid walls thin in the

generate foam (foaminess); and secondly, the upper section of the foam as the liquid drains

tendency for the process to destroy foam (foam downward.

Foams are stabilised when liquid viscosity and

stability). As with any dynamic balance, when

production (foaming) exceeds consumption surface tension oppose the natural drainage

(foam breakage), an excess occurs. When a frac- tendency of the bubble liquid. Liquid properties

tionating column generates stable foam, the play a central role in foaming. Liquid drainage

within foam is a natural phenomenon. Liquid

column capacity will decrease.

This article will briefly discuss the fundamen- always has a tendency to drain downward (or in

tals of foams and the different types of foam the direction of any centrifugal forces). As the

formations. The effect of foaming on various liquid drains from the bubbles, the liquid walls

internals will be discussed along with design and thin and weaken, eventually rupturing the

operating methods used to mitigate foaming bubbles and breaking the foam. Any condition

that stabilises the bubble wall thickness will

and/or the effects of foaming.

stabilise the foam.

Fundamentals of foams

Surface tension gradients within localised

Foaming is essentially the encapsulation of liquid create what is known as the Marangoni

vapour within a liquid cell. Foams can be formed effect, where liquids flow from lower to higher

with a variety of methods generally associated surface tension regions. Generally, foaming

with mechanical agitation or vapour formation. tendency is proportional to this gradient. This

www.digitalrefining.com/article/1001169

PTQ Q4 2015 1

key factor of foaming is

Without this effect, the evaporaexplained well by Zuiderweg

tion would have caused the bubble

and Harmans.1

film to thin and break. Figure 2

It is important to note that

shows wine tears produced as a

pure liquids will not produce

result of mass transfer. As the

a stable foam. However, when

alcohol evaporates from the wine

a surfactant is added to the

on the wall of the glass, the

system, stable foaming is then

surface tension increases and

possible.

Simply,

the

causes the liquid to form rivulets

surfactant concentration at

and droplets.

the liquid surface decreases

Foaming from solids/particulates

as the bubble size increases.

It is widely known that the presWhen this happens, the

ence of particulates tends to

higher surface tension in the

stabilise foam. When solids are

expansion area draws liquid

present in liquids, they increase

from the lower surface

the solution viscosity. Increased

tension region at the base of

viscosity inhibits the drainage of

the bubble. This heals the Figure 2 Marangoni effect in wine

foams and stabilises them. An

thinning bubble wall and

interesting study done by Kadoi4 looks at the

stabilises the foam.

influence of particulate composition, size, and

Types of foaming

shape on both viscosity and foaming in water.

Ross foams

Somewhat surprisingly, the increase in foam

As discussed by Ross2, a liquid solution with an stability was not always directly proportional to

incipient formation of a second liquid phase (for viscosity. Instead, particulate size, shape, and

instance, a hydrocarbon fluid with a high equi- composition seemed to play important parts in

librium amount of water or an aqueous fluid foam stability. It is also important to note that

with a small amount of hydrocarbon) will natu- the particulates did not transform a non-typical

rally be susceptible to foaming. Since this is an foaming system (water) into a foaming system.

equilibrium effect, Ross foams can sometimes be However, when a surfactant was added to the

overcome by changing the system temperature. water and foam was produced, the solids stabiA good example of this in practice is discussed lised the foam.

by Bolles.3 In his troubleshooting endeavour, he

Also important was the reinforcement of the

found that sections of the tower were approach- understanding that a smaller amount (weight) of

ing the incipient formation of a second liquid smaller size particulates creates more foam

phase, creating dramatic foaming within the stabilisation effects than a larger amount of

column. To further support this conclusion, he larger sized particles. This is an unfortunate

raised the temperature of the column, eliminat- truth for fractionation column applications

ing the incipient second liquid phase and the where the liquid solution is filtered to remove

foaming subsided.

particulates and the worst offenders (small particles) are the most difficult to remove.

Marangoni foams

All things considered, it is clear that particuFoaming can occur with or without the presence lates are generally detrimental additions to a

of mass transfer. Foams stabilised by surface foaming system. The potential for the presence

tension gradients due to mass transfer are of particulates should always be accounted

referred to as Marangoni foams. In applications for during the column engineering design stage.

where the higher volatility component has a In less serious cases, the equipment can be

lower surface tension, Marangoni foaming can sized to account for the foaming. Ideally,

be a problem. When a bubble forms in these the particles need to be removed from

systems, the lighter component evaporates from the system with filtration or totally prevented

the liquid and the surface tension of the remain- from forming in the process or entering the

ing liquid increases and stabilises the bubble. column.

2 PTQ Q4 2015

www.digitalrefining.com/article/1001169

Processes and applications

that are susceptible to foam

Amine contacting and regenerating systems are notorious for

foaming tendencies, with about

half of the reported industrial

column foaming cases coming

from acid gas treating units.5

Acidic amines, such as MEA,

DEA, and MDEA in their pure Figure 3 Vapour and liquid flows on trays

state, are essentially non-foaming. However, amine systems

tend to have a variety of potential contaminants such as:

Liquid hydrocarbons: Ross

foams

Oil field chemical contaminants:

Ross

foams

and

surfactants

Corrosion products (such as

iron

sulphide):

particulate

Figure 4 Vapour and liquid flows in structured packing

foaming

Amine degradation products:

increases the froth height and causes entrainsurfactants.

ment. Also, the foam fills up the downcomer and

Some other known foaming processes are:

Refinery preflash towers and long residue eventually backs onto the tray and hydraulically

stripping sections are also known to be suscepti- floods it. In either case, foaming can substanble to foaming.6 Studies show that different tially limit tray capacity.

crude types have different foaming potential.

Packings operate with vapour and liquid flowOther contaminants and suspended particulates ing past each other, with the vapour remaining

also affect foaming in these systems

in the continuous phases and liquid rivulets and

Refinery alkylation isostrippers also can foam droplets being in the dispersed phase. With this

near the feed. This is a Ross foam condition operation, the packings are much less likely to

where aqueous hydrofluoric acid is present in generate bubbles and foaming. This is why packthe hydrocarbon.

ings are preferred in foaming applications.

However, when the liquid rate in a packed

Difference between trays, random packings,

column is high enough to bridge gaps within the

and structured packings

packed bed, the vapour will flow upward through

A wide variety of research has been done on the the liquid and form bubbles.

topic of foaming with different column internals.

Reviewing random versus structured packing,

Generally, it is accepted that packings perform we see an interesting set of counter principles.

better in foaming processes than trays do. This First, due to its streamline structure, structured

is essentially due to the nature of the devices packing has a very high capacity and efficiency

(see Figures 3 and 4). In most trayed applica- relative to random packing in high vapour rate

tions, the vapour flows upward through a applications. However, the more laterally open

continuous liquid layer on the tray deck and structure of random packings allows them to

creates bubbles. In most systems, the bubbles process high liquid rates more effectively. With

break quickly. However, in systems where the foaming systems, foam acts as a volumetric

bubbles are stabilised, foaming is an issue.

liquid flow multiplier.

When trays do foam, a foam layer develops on

In cases where the liquid rates are low and the

top of the liquid on the tray deck and then flows foaming tendency is moderate, the effective

into the downcomer. The foam on the tray deck liquid volumetric flow rate is low to moderate.

www.digitalrefining.com/article/1001169

PTQ Q4 2015 3

In these cases, the inherent hydraulic advantages

of structured packing ensure that it performs

well. However, in higher liquid rate and/or

highly foaming systems where the effective

liquid volumetric flow rate is higher, the

random packings ability to handle more liquid

tends to overcome the vapour handling capabilities of the structured packing, making random

packing the better choice. This effect is shown in

a study by Thiele.7

What internals to use in foaming

applications?

Since trays are the most susceptible column

internal to foaming, they are typically only used

in applications where they are needed for

specific purposes. For example, trays are used

quite often in amine contactors, a known foaming application. They are used mainly because

some amine reactions are slow and additional

residence time is desired. Trays are also used in

sour water strippers, another known foaming

process. This is because these services are often

dirty and trays provide a more robust solution.

In these cases, a foam factor is used that

derates the capacity of the device, sometimes by

as much as 50%. With this derating factor, the

column diameters are larger so that the vapour

flows are lower through the column and the tray

downcomers are larger to have more residence

time and lower liquid velocities.

When trays are not mandatory in a foaming

service, packings will be the first choice. The

selection between random versus structured

packing should be based on previous experience,

the liquid flow rate, and the expected severity of

foaming. For very low liquid flux rates (<10 m3/

m2-hr) and low to moderate foaming, structured

packings will be the natural choice. For very

high liquid rates (>50 m3/m2-hr) and moderate

to high foaming, random packings will be the

preferred choice.

The difficulty comes where the effective liquid

flux rates are between these extremes. In the

testing from Thiele, above a liquid rate of 20 m3/

m2-hr, structured packing with a surface area of

350 m2/m3 with a 45 corrugation angle showed

a significant increase in pressure drop due to

foaming. However, it should be noted that a

lower surface area packing (for example, the

standard 250 m2/m3 size) with a more vertical

60 corrugation angle would be much more

4 PTQ Q4 2015

resistant to foaming.

From these studies, it would seem that a

reasonable rule of thumb would be that structured packings in moderate foaming systems are

typically safe at liquid flux rates below 25 m3/

m2-hr. As a first pass, this is probably a useful

value for an initial review, but it must be kept in

mind that the degree of foaminess and the packing geometry will have a major effect in the

proper packing choice. It is important to note

that structured packings with appropriate corrugation angle and hydraulic diameter have been

successfully used in hundreds of gas sweetening

units, which are considered to be foaming

systems. Liquid loads in these applications are

typically high, with some structured packing

units working properly at flux rates over 100 m3/

m2-hr.

Similar to trays, random packings typically are

also derated using a foam factor. Since they can

handle foaming more effectively than trays, the

foam factor for a random packed column is typically less conservative than for those used with

trays. Structured packings may or may not use a

foam factor.

How to avoid foaming in the process

As mentioned previously, there are a variety of

contaminants that can cause excessive foaming

in a fractionation process. Preventing these

contaminants from entering the system is nearly

always the most effective method to prevent

foaming, but often not the most cost effective

method. Upstream contaminants (particularly

from oil fields) need to be carefully monitored

and removed. Oils, liquid hydrocarbons and

greases need to be avoided. In amine systems,

the amine quality must be checked and continually cleaned. Degradation products, solids, and

corrosion products must be minimised.

If the contaminant cannot be removed from

the feed, the next best option is to remove the

contaminant in the process itself. This is

commonly done with particulates or other chemical contaminants by using a recycle stream and

a mechanical filter or an activated carbon bed.

Although this seldom removes all the contaminants, it does serve to maintain them at an

acceptable level. One thing to note is that if

carbon beds are used in conjunction with antifoams that the carbon beds may actually remove

the anti-foam and mitigate its benefit.

www.digitalrefining.com/article/1001169

How to deal with foaming in

the process

changes possible. First, the feed

Anti-foams are commonly used

distribution should not create

to reduce the foaming tendency

foaming. With a total liquid

of the process. They generally

phase feed, this should not be

serve to assure a uniform surface

an issue other than to ensure

tension on the liquid portion of

that the feed momentum is

the foam. This removes the

minimised and that the liquid

surface tension gradient that

feed is submerged in the normal

stabilises the foams.

distributor liquid. With a two

The use of anti-foam can be

phase feed, care needs to be

costly and is often empirical,

taken that the vapour and liquid

with the proper formulation

separate without generating

being dependent upon the

foam. If it is suspected that the

actual foam causing contamiincoming feed is foaming then a

nants. Different types of

good solution is to use a feed

anti-foams work well in some

device with centrifugal separasystems and work poorly, or

tors (such as a Sulzer GIRZ and

even promote foaming, in other

HiPer inlet cyclone).

systems. The same can be said Figure 5 Sulzer GIRZ feed device

One example of a GIRZ applifor dosage rates. While the

cation is for a US West Coast

correct dosage of the proper anti-foam can work refiner in the preflash tower. The refiner was

very well, the improper rate of the same chemi- having issues with foaming when running differcal can even produce a detrimental effect.

ent crude slates. Sulzer recommended the

As mentioned earlier, temperature variations installation of a GIRZ in the tower feed to mitican control incipient second liquid phases. In this gate foaming. The unit is now on-line and the

case, the process components and conditions refiner can run multiple crude slates with no

must be understood and correct temperature issues in the column, thus increasing their flexiadjustments need to be made as possible.

bility and profitability.

Directionally, as the system temperature

With random packing, you can mitigate foamincreases, more liquid vaporises, vapour velocity ing by using a larger size packing that is further

increases, the liquid rate decreases, and the away from flood. This is essentially just designliquid viscosity decreases. All of these occur- ing with a foam factor.

rences tend to inhibit foaming. A decrease in

With structured packing, a more vertical crimp

column pressure should have a similar effect.

angle can be used, such as a 60 (X Style) packFor mass transfer Marangoni positive systems ing corrugation. This will allow the liquid to flow

that promote foaming, this can generally be more easily down the corrugations without

predicted with a review of the physical proper- bridging and creating a foaming opportunity.

ties of the components in the process simulation. Also, using a larger crimp size (lower surface

If there is a surface tension decrease of more area packing) creates larger channels for fluid

than 1 dyne/cm per theoretical stage moving up flow. This will also delay bridging due to higher

the column, this process can be expected to have relative liquid flux rates. Finally, using a high

foaming issues. In this case, the internals need performance packing with an S shape (such as

to be designed beforehand to allow for this. MellapakPlus) to minimise liquid hold-up at the

Conversely, if the system is Marangoni negative packing layer interface will also delay the onset

(increasing surface tension as you move up the of foaming in the bed. The smooth vertical trancolumn), foaming is not expected.

sition between the packing layers can be seen in

Figure 6.

How to minimise the effects of foaming with

equipment design

Packing

With packings, there are only a few design

www.digitalrefining.com/article/1001169

Trays

For tray designs, it is accepted that trays operating in the froth regime are clearly more

PTQ Q4 2015 5

susceptible to foaming than

In froth regime applications,

those operating in the spray

there is too much liquid on the

regime. This is due to the

tray deck to allow a practical

balance between foam generatransition to a spray regime and

tion and foam destruction. In

destroy the foam. As an examthe froth regime, vapour bubbles

ple, froth and foam height

through the liquid pool create

studies were conducted at the

foaming opportunities. In the

University of Texas with a weir

spray regime, vapour is in the

load of 55 m3/m-hr.9 At these

rates, it was found that higher

continuous phase and the liquid

vapour rates created more foam.

on the tray deck is blown into

However, column designs can

droplets above the deck, likely

still be altered to control

destroying any small bubbles

Figure 6 Sulzer MellapakPlus

foaming.

that may be formed.

The vapour side dry pressure

Unfortunately in foaming packing

drop of a tray is a common

applications, most trays are

designed to operate in a froth regime. It is quite calculation that represents vapour momentum

difficult to force operation in the spray regime entering a tray. For trays operating in the froth

when high liquid rates are present. Methods to regime, dry drop is a good indicator of foaming

shift a trays operation from froth to spray susceptibility. In amine columns where liquid

regime include lowering the effective liquid rates are high, the following guidelines are

depth on the tray deck, increasing the vapour proposed by Shiveler:10

velocity through the deck orifices, and using For dry drops:

larger deck orifices. The most effective way to <40mm H2O (vapour hole velocity of 4.2 m/s),

lower the liquid depth on a tray is to increase foaming tendency is low

the number of liquid passes. Shell HiFi multi- 40-50mm H2O, (vapour hole velocity of

pass trays (shown in Figure 7) are often used for 4.2-4.8 m/s), low to moderate tendency

Tray downcomer design is also important for

this purpose. Another helpful modification can

be to increase the trays spacing, allowing the foaming applications. It is recommended that

tray to more easily accommodate the foam the downcomer be large enough so that the clear

build-up prior to flooding. A successful case liquid velocity does not exceed 0.10 m/s.

study using these techniques is discussed by Another more conservative recommendation is

for a limit of 0.06 m/s.11 Generally, it is seen that

Resetarits.8

increased downcomer residence time is less

beneficial than decreased downcomer velocity.6 This would

indicate that large downcomers

with a slope from top to bottom

would be preferred.

Conclusions

Figure 7 Shell HiFi Plus Trays

6 PTQ Q4 2015

Foaming in susceptible fractionation columns is a phenomenon

that is essentially unavoidable.

However, by understanding the

foaming process and the root

cause of the foaming, steps can

be taken to eliminate and/or

minimise the formation of

foaming. When foaming cannot

be avoided, process and equipment modifications can be

www.digitalrefining.com/article/1001169

made to successfully deal with the foaming to

maintain a properly operating column with efficient operation.

GIRZ, HiPer, and MellapakPlus are trademarks of Sulzer

Chemtech AG. Shell HiFi and Shell HiFi Plus are trademarks of

Shell.

References

1 Zuiderweg F J, Harmens A, The influence of surface

phenomena on the performance of distillation columns, Chem.

Eng. Sci., Vol 9, 1958, 89-108.

2 Ross S, Nishioka G, Foaminess of binary and ternary

solutions, The Journal of Physical Chemistry, Vol. 79, No. 15,

1975, 1561-1565.

3 Bolles W L, The solution of a foam problem, Chem Eng Prog,

Sept 1967, 48-52.

4 Kadoi K, Nakae H, Relationship between foam stabilization

and physical properties of particles on aluminum foam

production, Materials Transactions, Vol. 52, No. 10, 2011,

1912-1919.

5 Kister H Z, What caused tower malfunctions in the last 50

years, Trans. IChemE, 81 Part A, Jan 2003, 5.

6 Barber A D, Wijn E F, Foaming in crude distillation units, I

ChemE, Symposium Series No.156, 3.1/15-35.

7 Thiele R, Wiehler H, Repke J U, Wozny G, Hydrodynamics of

foaming systems in packed towers, 2004 AIChE Annual Meeting.

8 Resetarits M L, Navarre J L, Monkelbaan D R, Hangx G W

www.digitalrefining.com/article/1001169

A, van den Akker R M A, Trays inhibit foaming, Hydrocarbon

Processing, Mar 1992.

9 Redwine D A, Flint E M, Van Winkle M, Froth and foam height

studies, I & EC Process Design and Development, Oct 1967,

525-532.

10

Shiveler G H, Wandke H, Steps for trouble-shooting

amine sweetening plants, 2015 AIChE Spring Meeting, Kister

Distillation Symposium.

11 Thomas W J, Ogboja O, Hydraulic studies in sieve tray

columns, Ind. Eng. Chem. Process Des. Dev., 17 (4), 429-443,

1978.

Mark Pilling is Manager of Technology with Sulzer Chemtech

USA where he oversees the development of mass transfer

equipment and specialises in applications for various process

technologies. He holds a BS degree in chemical engineering

from the University of Oklahoma.

LINKS

More articles from: Sulzer Chemtech USA

More articles from the following categories:

Corrosion/Fouling Control

Mass Transfer & Separation

PTQ Q4 2015 7

Вам также может понравиться

- Advanced Distillation Technologies: Design, Control and ApplicationsОт EverandAdvanced Distillation Technologies: Design, Control and ApplicationsОценок пока нет

- Flooded CondensersДокумент13 страницFlooded Condensersstreamt100% (1)

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationОт EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationОценок пока нет

- An Investigation of Premature Flooding in A Distillation ColumnДокумент11 страницAn Investigation of Premature Flooding in A Distillation ColumnBramJanssen76Оценок пока нет

- Fluid Catalytic Cracking: Science and TechnologyОт EverandFluid Catalytic Cracking: Science and TechnologyРейтинг: 5 из 5 звезд5/5 (1)

- To Foul or Not To FoulДокумент8 страницTo Foul or Not To FoulkcdeguzmanОценок пока нет

- Distillation Column Troubleshooting Part IДокумент8 страницDistillation Column Troubleshooting Part INishat M PatilОценок пока нет

- Acetone MSDSДокумент9 страницAcetone MSDSCeline TheeОценок пока нет

- Amine Unit Management of ContaminantsДокумент6 страницAmine Unit Management of ContaminantsRicardo Bec100% (3)

- Analysis of FoamingДокумент16 страницAnalysis of Foamingjafo_211Оценок пока нет

- PSV For Distillation GuidelinesДокумент3 страницыPSV For Distillation GuidelinesMubarik AliОценок пока нет

- Damping of Process TowersДокумент4 страницыDamping of Process TowersJerry DsouzaОценок пока нет

- DistillationДокумент7 страницDistillationAbdus Saboor KhalidОценок пока нет

- Salt Fouling FCCДокумент6 страницSalt Fouling FCCVenkatesh Kumar RamanujamОценок пока нет

- 2012-07 Overpressure Protection + Working With The CSB After An Accident - Selected PapersДокумент8 страниц2012-07 Overpressure Protection + Working With The CSB After An Accident - Selected PaperssourcemenuОценок пока нет

- Making Plastics From Monomer To Polymer CEP Sep 2015Документ6 страницMaking Plastics From Monomer To Polymer CEP Sep 2015Juan Sebastian SánchezОценок пока нет

- Tray Distillation ColumnsДокумент27 страницTray Distillation ColumnsRajeshkumar Elango0% (1)

- Reboilerand Condenser Operating ProblemsДокумент6 страницReboilerand Condenser Operating Problemsbalu928100% (1)

- Crude Overhead DesignДокумент5 страницCrude Overhead DesignDaniele CirinaОценок пока нет

- Control of Foaming in Amine Systems - Brimstone 07 Rev A-2-2 PDFДокумент13 страницControl of Foaming in Amine Systems - Brimstone 07 Rev A-2-2 PDFscm996100% (1)

- Distillation Tray Types Operation TRBSHTДокумент38 страницDistillation Tray Types Operation TRBSHTGary JonesОценок пока нет

- IFP Materials PDFДокумент65 страницIFP Materials PDFProcess EngineerОценок пока нет

- 10 - Distillation Revamp Pitfalls To AvoidДокумент8 страниц10 - Distillation Revamp Pitfalls To AvoidRenato GilbonioОценок пока нет

- Kister - Troubleshoot Packing Maldistribution Upset Part 1, Temperature Surveys and Gamma ScansДокумент8 страницKister - Troubleshoot Packing Maldistribution Upset Part 1, Temperature Surveys and Gamma ScansgonzalezpcjОценок пока нет

- Catalyst Circulation in Pressure BalanceДокумент2 страницыCatalyst Circulation in Pressure Balancesaleh4060Оценок пока нет

- IFP Materials PDFДокумент38 страницIFP Materials PDFProcess EngineerОценок пока нет

- Combining The Use of Rupture Discs With Relief ValvesДокумент6 страницCombining The Use of Rupture Discs With Relief Valveskronaf100% (1)

- Better Feed Entry For DebutanizerДокумент5 страницBetter Feed Entry For DebutanizerM Scott GreenОценок пока нет

- Distillation Column Troubleshooting Part IIДокумент8 страницDistillation Column Troubleshooting Part IINishat M PatilОценок пока нет

- The Hazards of Fired Heater Flooding, Dig. Ref Q4-2020 JZinkHCДокумент6 страницThe Hazards of Fired Heater Flooding, Dig. Ref Q4-2020 JZinkHCEsteban De Jesús Camargo100% (1)

- CEeNews2 04Документ6 страницCEeNews2 04Antonio MezzopreteОценок пока нет

- Inspecting Fractionation TowersДокумент11 страницInspecting Fractionation Towersjafo_211100% (1)

- CEP - Modeling Reactive AbsorptionДокумент9 страницCEP - Modeling Reactive Absorptionnp484Оценок пока нет

- Optimize Capacity and Efficiency For An Amine Unit - Gas Processing MagazineДокумент12 страницOptimize Capacity and Efficiency For An Amine Unit - Gas Processing MagazineMuhammad ImranОценок пока нет

- Design of Shell-And-Tube Heat Exchangers When The Fouling Depends On Local Temperature and Velocity PDFДокумент13 страницDesign of Shell-And-Tube Heat Exchangers When The Fouling Depends On Local Temperature and Velocity PDFIgorToporskyОценок пока нет

- Gulfpub HP 201811Документ93 страницыGulfpub HP 201811avinashpatil2408Оценок пока нет

- Flare SystemsДокумент10 страницFlare SystemsMahboob Ur-RahmanОценок пока нет

- De Ethanizer ColumnДокумент24 страницыDe Ethanizer Columnrohit agrawalОценок пока нет

- Troubleshooting Vacuum Unit Revamp - TДокумент6 страницTroubleshooting Vacuum Unit Revamp - TRafeek Emad AbdElkaderОценок пока нет

- Vessel Sizing and Level InstrumentationДокумент5 страницVessel Sizing and Level InstrumentationAlexanderОценок пока нет

- Pilot-Operated Safety Relief Valves A Simple, Effective Plant Upgrade - HP - Nov 2011 PDFДокумент5 страницPilot-Operated Safety Relief Valves A Simple, Effective Plant Upgrade - HP - Nov 2011 PDFonizuka-t2263Оценок пока нет

- CEcover904 p2Документ4 страницыCEcover904 p2Antonio MezzopreteОценок пока нет

- Refinery FractionatorsДокумент7 страницRefinery FractionatorsHuzefa CalcuttawalaОценок пока нет

- Achieve Optimal Heat Recovery in A Kettle ExchangerДокумент2 страницыAchieve Optimal Heat Recovery in A Kettle ExchangerbehnamhfОценок пока нет

- CH 4 - How Trays Work - DumpingДокумент10 страницCH 4 - How Trays Work - DumpingGissmo100% (1)

- Technip Separations PDFДокумент1 страницаTechnip Separations PDFProcess EngineerОценок пока нет

- September 2011 PDFДокумент86 страницSeptember 2011 PDFKimberly ConleyОценок пока нет

- Revamping of Process Plant - S MukherjeeДокумент6 страницRevamping of Process Plant - S Mukherjeesriman1234Оценок пока нет

- Distillation - Diagnosing Instabilities in The Column OverheadДокумент4 страницыDistillation - Diagnosing Instabilities in The Column OverheadRafaelОценок пока нет

- Inune Exchangers: M I N E Exchanger (After Brown Fintube Koch International)Документ30 страницInune Exchangers: M I N E Exchanger (After Brown Fintube Koch International)Process EngineerОценок пока нет

- Flare Line Failure CaseДокумент20 страницFlare Line Failure CaseHitesh PanchalОценок пока нет

- Vertical Thermosyphon Re Boilers. Maximum Heat Flux and Separation EfficiencyДокумент9 страницVertical Thermosyphon Re Boilers. Maximum Heat Flux and Separation EfficiencyPuskar GuptaОценок пока нет

- Debottlenecking A Distillation ColumnДокумент12 страницDebottlenecking A Distillation Columnrasik.kirane100% (1)

- What Caused Tower Malfunctions in The Last 50 Years-Henry KisterДокумент22 страницыWhat Caused Tower Malfunctions in The Last 50 Years-Henry KisterrakeshОценок пока нет

- Optimal Process FlowДокумент8 страницOptimal Process Flowazharump100% (1)

- Carbonyl Sulfide (COS) Removal From Propane GPAДокумент53 страницыCarbonyl Sulfide (COS) Removal From Propane GPAshitals_18100% (1)

- HCP - December 2019Документ135 страницHCP - December 2019kishna00950% (2)

- Design of ReboilersДокумент24 страницыDesign of ReboilersKrishanu SahaОценок пока нет

- Catalyst Passivation For Safer, More Efficient TurnaroundsДокумент4 страницыCatalyst Passivation For Safer, More Efficient TurnaroundsAltif AboodОценок пока нет

- Foaming in Fractionation ColumnsДокумент7 страницFoaming in Fractionation ColumnsmehdiОценок пока нет

- Minimum Requirements For The Basic Design of Winterization SystemsДокумент7 страницMinimum Requirements For The Basic Design of Winterization SystemsAnonymous v5uipHОценок пока нет

- Ghid RO2019 RO WebДокумент6 страницGhid RO2019 RO WebAnonymous v5uipHОценок пока нет

- Calibration Essentials Managing Your Program PDFДокумент24 страницыCalibration Essentials Managing Your Program PDFAnonymous v5uipHОценок пока нет

- Mean Temperature Differences in Multipass Heat Exchangers PDFДокумент6 страницMean Temperature Differences in Multipass Heat Exchangers PDFAnonymous v5uipH0% (1)

- Ijct 1 (5) 305-307Документ46 страницIjct 1 (5) 305-307Anonymous v5uipHОценок пока нет

- Ijct 1 (5) 305-307 PDFДокумент3 страницыIjct 1 (5) 305-307 PDFAnonymous v5uipHОценок пока нет

- DCS Hazardous AreasДокумент8 страницDCS Hazardous AreasAnonymous v5uipHОценок пока нет

- Thermal Degassing Fundamentals R4i1 enДокумент6 страницThermal Degassing Fundamentals R4i1 enAnonymous v5uipHОценок пока нет

- NT42 Calculation Heat Transfer of Storage Tank Rail TankДокумент2 страницыNT42 Calculation Heat Transfer of Storage Tank Rail TankAnonymous v5uipHОценок пока нет

- Butterfly Valve Installation Guide PDFДокумент3 страницыButterfly Valve Installation Guide PDFAnonymous v5uipHОценок пока нет

- Steam Traps Solve Sticky Railcar Heating ProblemДокумент2 страницыSteam Traps Solve Sticky Railcar Heating ProblemAnonymous v5uipHОценок пока нет

- Heat Exchanger Anti-VibrationДокумент6 страницHeat Exchanger Anti-VibrationAnonymous v5uipH100% (1)

- Amine AbsorberДокумент4 страницыAmine AbsorberAnonymous v5uipHОценок пока нет

- Plastics Engineering: Process Equipment and Piping Systems For Optimum Reliability and Cost-EffectivenessДокумент9 страницPlastics Engineering: Process Equipment and Piping Systems For Optimum Reliability and Cost-EffectivenesskoushkiОценок пока нет

- Exercise - IV: Subjective Level-IIДокумент2 страницыExercise - IV: Subjective Level-IIAmudala HemashviniОценок пока нет

- Density Estimation For Fatty Acids and Vegetable OilsДокумент6 страницDensity Estimation For Fatty Acids and Vegetable OilscymyОценок пока нет

- J.J.E. Herrera Velázquez Et Al - Instability Suppression by Sheared Flow in Dense Z-Pinch DevicesДокумент8 страницJ.J.E. Herrera Velázquez Et Al - Instability Suppression by Sheared Flow in Dense Z-Pinch DevicesImsaa4Оценок пока нет

- Polyethylene Terephthalate Plant CostДокумент2 страницыPolyethylene Terephthalate Plant CostIntratec SolutionsОценок пока нет

- Msds Loctite 401 Idh 231472Документ9 страницMsds Loctite 401 Idh 231472edwin cОценок пока нет

- Cell Adaptation, Injury and DeathДокумент91 страницаCell Adaptation, Injury and DeathAmera ElsayedОценок пока нет

- Recent Mineral Processing Publications PDFДокумент8 страницRecent Mineral Processing Publications PDFMonica Ulloa LamasОценок пока нет

- Ai TS 1 - Class XII - SET AДокумент18 страницAi TS 1 - Class XII - SET ASantryuОценок пока нет

- Ned-1501 Finian C01 (BT) PDFДокумент3 страницыNed-1501 Finian C01 (BT) PDFAm EОценок пока нет

- Molecular BiologyДокумент26 страницMolecular BiologyShadma KhanОценок пока нет

- LARE Section 2 Study Guide 2.0Документ4 страницыLARE Section 2 Study Guide 2.0chrisОценок пока нет

- Phytoplankton Culture For Aquaculture Feed: S R A CДокумент16 страницPhytoplankton Culture For Aquaculture Feed: S R A CFen TZОценок пока нет

- Notes For Chemistry PracticalsДокумент32 страницыNotes For Chemistry Practicalsj0ntj2ivjyОценок пока нет

- Quantum Mechanics II - Homework Assignment 5: Alejandro G Omez Espinosa March 23, 2013Документ5 страницQuantum Mechanics II - Homework Assignment 5: Alejandro G Omez Espinosa March 23, 2013Ale GomezОценок пока нет

- AOC F013 SeriesДокумент2 страницыAOC F013 SeriesYap HSОценок пока нет

- Microbiology Fundamentals2 PDFДокумент260 страницMicrobiology Fundamentals2 PDFJai MurugeshОценок пока нет

- Property of Polyfelt TS Nonwoven GeotextilesДокумент1 страницаProperty of Polyfelt TS Nonwoven GeotextilesAgis Satryo Falck100% (1)

- Chem 31.1 - FR2 CastroДокумент4 страницыChem 31.1 - FR2 CastroMatthew Rei De LeonОценок пока нет

- MSDS H2oДокумент5 страницMSDS H2oWilanda Tama50% (2)

- Lesson Plan Class VIIДокумент4 страницыLesson Plan Class VIIPushpa Kumari100% (1)

- Strain Gauges PPT-2Документ30 страницStrain Gauges PPT-2Shreyas shreyuОценок пока нет

- Elements and Compounds: Science 1 Grade 7 Cavite State University Naic Laboratory Science High SchoolДокумент39 страницElements and Compounds: Science 1 Grade 7 Cavite State University Naic Laboratory Science High SchoolBabbie Lorio100% (2)

- Indonesia Webinar 3 (JCOAL) - 1Документ17 страницIndonesia Webinar 3 (JCOAL) - 1Budi Setyawan100% (1)

- Theories of Aging PDFДокумент47 страницTheories of Aging PDFBenedict LumabiОценок пока нет

- SPH Bearing Draft (09.06.11)Документ38 страницSPH Bearing Draft (09.06.11)rchandra2473Оценок пока нет

- Lab 13 Gas LawsДокумент15 страницLab 13 Gas Lawsjohn linОценок пока нет

- Grinding MIL STD 866Документ11 страницGrinding MIL STD 866Dimitris GrimanelisОценок пока нет

- Ucrete General v1 Jac 2Документ52 страницыUcrete General v1 Jac 2DeepmalaJayeshОценок пока нет

- Indian Institute of Welding - ANB Refresher Course - Module 07Документ55 страницIndian Institute of Welding - ANB Refresher Course - Module 07dayalram0% (1)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyОт EverandSodium Bicarbonate: Nature's Unique First Aid RemedyРейтинг: 5 из 5 звезд5/5 (21)

- Piping Engineering Leadership for Process Plant ProjectsОт EverandPiping Engineering Leadership for Process Plant ProjectsРейтинг: 5 из 5 звезд5/5 (1)

- Process Plant Equipment: Operation, Control, and ReliabilityОт EverandProcess Plant Equipment: Operation, Control, and ReliabilityРейтинг: 5 из 5 звезд5/5 (1)

- Well Control for Completions and InterventionsОт EverandWell Control for Completions and InterventionsРейтинг: 4 из 5 звезд4/5 (10)

- An Applied Guide to Water and Effluent Treatment Plant DesignОт EverandAn Applied Guide to Water and Effluent Treatment Plant DesignРейтинг: 5 из 5 звезд5/5 (4)

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesОт EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesРейтинг: 1 из 5 звезд1/5 (2)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОт EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОценок пока нет

- Handbook of Cosmetic Science: An Introduction to Principles and ApplicationsОт EverandHandbook of Cosmetic Science: An Introduction to Principles and ApplicationsH. W. HibbottРейтинг: 4 из 5 звезд4/5 (6)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlОт EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlРейтинг: 4 из 5 звезд4/5 (4)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОт EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОценок пока нет

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksОт EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksРейтинг: 5 из 5 звезд5/5 (1)

- A New Approach to HAZOP of Complex Chemical ProcessesОт EverandA New Approach to HAZOP of Complex Chemical ProcessesОценок пока нет

- Guidelines for Chemical Process Quantitative Risk AnalysisОт EverandGuidelines for Chemical Process Quantitative Risk AnalysisРейтинг: 5 из 5 звезд5/5 (1)

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersОт EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsОт EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsОценок пока нет

- Piping and Instrumentation Diagram DevelopmentОт EverandPiping and Instrumentation Diagram DevelopmentРейтинг: 3.5 из 5 звезд3.5/5 (3)

- The Perfumed Pages of History: A Textbook on Fragrance CreationОт EverandThe Perfumed Pages of History: A Textbook on Fragrance CreationРейтинг: 4 из 5 звезд4/5 (1)

- Bioinspired Materials Science and EngineeringОт EverandBioinspired Materials Science and EngineeringGuang YangОценок пока нет

- Guidelines for the Management of Change for Process SafetyОт EverandGuidelines for the Management of Change for Process SafetyОценок пока нет

- The Periodic Table of Elements - Halogens, Noble Gases and Lanthanides and Actinides | Children's Chemistry BookОт EverandThe Periodic Table of Elements - Halogens, Noble Gases and Lanthanides and Actinides | Children's Chemistry BookОценок пока нет