Академический Документы

Профессиональный Документы

Культура Документы

Ameron Bondstrand 5000 Pipe and Fitting Specification

Загружено:

DGWАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ameron Bondstrand 5000 Pipe and Fitting Specification

Загружено:

DGWАвторское право:

Доступные форматы

Bondstrand Guide Specifications

FIBERGLASS - COMPOSITE PIPE GROUP

Bondstrand 5000

Pipe and Fittings

Vinylester reinforced thermosetting resin pipe

for plant piping fiberglass piping systems

Scope

This specification defines the reinforced thermosetting resin (RTR) piping system

to be used in those sections of Plant Piping General Services calling for fiberglass

piping systems.

References,

Quality Assurance

References are made to other standards and tests which are a part of this section.

Where conflict exists between the requirements of this specification and listed

references, the specification shall prevail.

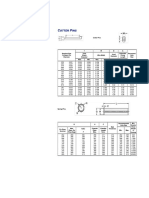

70F

170F

ASTM

Pipe Property

Units

21C

77C

Method

Physical and

Mechanical Properties

Nominal Pipe Size

Circumferential

Tensile stress at

weeping

Tensile modulus

Poissons ratio

Longitudinal

Tensile strength

Tensile modulus

Poissons ratio

Beam apparent

Elastic modulus

Hydrostatic design

basis (cyclic)

Thermal conductivity

Pipe wall

Thermal expansion

Linear

Flow coefficient

Absolute roughness

Specific gravity

Density

Performance

Requirements

ISO-9001

2-6

103 psi

MPa

106 psi

GPa

8-16

24.00 24.00

138.00 138.00

3.70

3.13

25.50 21.60

0.28

0.45

2-6

8-16

D1599

2.90 2.32

20.00 16.00

0.35 0.66 D2105

103 psi

MPa

106 psi

GPa

12.00

82.70

2.00

13.80

0.20

7.00

48.30

1.45

10.00

0.35

106 psi

GPa

1.70

11.70

1.40

9.65

103 psi

MPa

8.00

55.20

6.00

41.40

D2992

Btuin/(hrft2F)

W/mC

2.00

0.28

2.00

0.28

C177

10.00 10.00

18.00 18.00

150.00 150.00

17.40 17.40

5.30

5.30

1.80

1.80

0.07

0.07

D696

D792

10-6 in/in/F

10-6 mm/mmC

Hazen-Williams

10-6 ft

10-6 m

lb/in3

8.00 5.50 D2105

55.20 37.90

1.40 1.00 D2105

9.70 6.89

0.26 0.43 D2105

1.45

10.10

.44 D2925

3.00

The pipe shall be manufactured in accordance with ASTM D2996 Specification for

RTRP. When classified under ASTM D2310, the pipe shall meet Type I, Grade 2 and

Class E (RTRP-12ED) for 2 through 16 nominal pipe sizes.

Pipe shall be rated for a minimum internal pressure of 150 psig at 200F in sizes 1

through 16 and shall have full vacuum capability at 80F in sizes 1 through 10 when

installed above ground.

CERTIFICATED FIRM

FP706A (6/00)

Materials

Pipe Construction

Filament-wound fiberglass reinforced vinylester resin pipe shall be Bondstrand 5000 as

manufactured by Ameron International Fiberglass Pipe Group, or approved equal. The

pipe shall have an integral corrosion barrier, nominally 50 mils thick, constructed with

the same vinylester resin as the pipe structural wall. Non-reinforced liners or corrosion

barriers shall not be allowed due to potential for fracturing during lower temperature,

transportation, and installation.

Structural wall

The pipe shall have the following

nominal wall thickness:

Pipe Diameter Nominal Wall Thickness

inches

inches

mm

1

3.5

.140

1.5

3.5

.140

Pipe end preparation options

2

3.1

.123

The piping manufacturer will provide

3

3.2

.126

20 or 40 RL joints, if the contractor

4

3.8

.151

6

4.6

.181

requests them, in sizes 2" through

8

5.7

.226

6" to reduce field labor assembly

10

5.7

.226

12

5.7

.226

time in those sections of the system

14

6.4

.250

where longer joint lengths may be

16

6.8

.269

employed. In addition, the pipe

manufacturer will provide pipe joints with the spigot ends already prepared for

adhesive application to reduce field labor time on all pipe sizes (1-16) along with

factory installed bells or couplings.

Fittings

It is important to maintain compatibility of fittings, piping and adhesives to ensure that

the system performs as specified. Pipe, fittings and adhesive shall be supplied by the

same manufacturer.

Filament-wound fittings

Fittings in 1 through 16 nominal sizes shall be filament-wound with a reinforced resinrich liner of equal or greater thickness than the pipe liner and shall be manufactured with

the same resin type as the pipe.

Compression Molded Fittings

Compression molded fittings in sizes 2" through 6 nominal sizes may be used in

services at or below 150F. Where fast closure of valves may produce surges (water

hammer), filament wound fittings will be used.

Contact molded, spray up or hand lay-up fittings shall not be allowed.

Testing

Inspection and testing of the piping will be performed in accordance with the requirements of ANSI B31.1. Hydrostatic testing of all installed piping shall be performed with

water at 11 2 times the design pressure of the lowest rated piping system component.

Test and repair procedures

The RTRP manufacturer will provide test and repair procedures in the event field repairs

are required.

Installation

Installation procedures and techniques as well as system design criteria including

burial, anchoring, guiding and supporting the pipe shall be in accordance with

manufacturers recommendations.

Piping system installers and fitters will be trained by a direct factory employee of the

piping system manufacturer and certified by the trainer prior to system assembly in

the field.

Important Notice

This literature and the information and recommendations it contains are based on data reasonably believed

to be reliable. However, such factors as variations in environment, application or installation, changes in

operating procedures, or extrapolation of data may cause different results. Ameron makes no representation or warranty, express or implied, including warranties of merchantability or fitness for purpose, as to

the accuracy, adequacy or completeness of the recommendations or information contained herein. Ameron

assumes no liability whatsoever in connection with this literature or the information or recommendations it

contains. Product specifications are subject to change.

FIBERGLASS - COMPOSITE PIPE GROUP - HEADQUARTERS

P.O. Box 801148 Houston, TX 77280 Tel: (713) 690-7777 Fax: (713) 690-2842 http://www.ameron.com

Asia

Ameron (Pte) Ltd.

No. 7A, Tuas Avenue 3

Singapore 639407

Tel: 65 861 6118

Fax: 65 862 1302/861 7834

Europe

Ameron B.V.

J.F. Kennedylaan 7

4191 MZ Geldermalsen

The Netherlands

Tel:

+31 345 587 587

Fax:

+31 345 587 561

Americas

P.O. Box 878

Burkburnett, TX 76354

Tel: (940) 569-1471

Fax: (940) 569-2764

Composites

P.O. Box 71370

11 McBride Street

Newnan, Georgia 30263

Tel: (770) 253-2000

Fax: (770) 253-9234

Centron International

P.O. Box 490

600 FM 1195 South

Mineral Wells, Texas 76068

Tel: (940) 325-1341

Fax: (940) 325-9681

1996 Ameron FP706A (6/00) supercedes FP706 (9/96) Printed in USA 5M[472]

Вам также может понравиться

- JFD 100Документ1 страницаJFD 100ecsuperalОценок пока нет

- Hydro Forming of T-JOINTДокумент12 страницHydro Forming of T-JOINTSenthamilselvi RamachandranОценок пока нет

- Compliance Statement for 4 Residential Building ProjectДокумент1 страницаCompliance Statement for 4 Residential Building ProjectAhmed HelmyОценок пока нет

- Bond Strand 5000 eДокумент8 страницBond Strand 5000 eUmar KidaОценок пока нет

- HVAC and Chilled Water SystemsДокумент1 страницаHVAC and Chilled Water Systemssonianchal233Оценок пока нет

- Erection Manual For Class 800 Counterflow Cooling TowerДокумент17 страницErection Manual For Class 800 Counterflow Cooling TowerEdy SuprayitnoОценок пока нет

- Cooling WaterДокумент4 страницыCooling WaterChristian SusantoОценок пока нет

- Kitz Butterfly Valve Catalog PDFДокумент28 страницKitz Butterfly Valve Catalog PDFlyguyenquocduyОценок пока нет

- Installation of Chilled Water Piping SystemДокумент1 страницаInstallation of Chilled Water Piping SystemYoga PristlinОценок пока нет

- PCW-DSF OpcДокумент25 страницPCW-DSF OpcDavid SilvaОценок пока нет

- OJT2 Vertical (Orchard Residences)Документ89 страницOJT2 Vertical (Orchard Residences)Jansen Paul Sanidad Arista100% (1)

- ST2 ChilledWaterAppДокумент3 страницыST2 ChilledWaterAppYersonJuarezОценок пока нет

- Weld Restoration of Disk - Example of Elliott Repair TechnologyДокумент49 страницWeld Restoration of Disk - Example of Elliott Repair TechnologyMachineryengОценок пока нет

- ET Subsea Ball ValvesДокумент9 страницET Subsea Ball ValvesAndrew BaileyОценок пока нет

- NEPROPLAST FlowGuard PipesДокумент12 страницNEPROPLAST FlowGuard PipesperezismaelОценок пока нет

- Specification FOR Piping Fabrication and InstallationДокумент27 страницSpecification FOR Piping Fabrication and Installationgc_panchaОценок пока нет

- u-PVC InchДокумент46 страницu-PVC Inchegemen7404612Оценок пока нет

- Samsung VRF Installation Trend For BuildingДокумент55 страницSamsung VRF Installation Trend For BuildingNaseemОценок пока нет

- Aluminium Alloy 3003 Data SheetДокумент1 страницаAluminium Alloy 3003 Data SheetShyamKhatriОценок пока нет

- Check List For: Screed Works: Subcontractor Contractor Section of Work: Civil LOCATION: Parcel 18, Plot 405 LevelДокумент6 страницCheck List For: Screed Works: Subcontractor Contractor Section of Work: Civil LOCATION: Parcel 18, Plot 405 LevelAminovic PlusОценок пока нет

- Grounding - 1501479512Документ74 страницыGrounding - 1501479512zaheer2931Оценок пока нет

- 02 Samss 006Документ17 страниц02 Samss 006inatt101Оценок пока нет

- uPVC Fittings: For Drainage ApplicationsДокумент24 страницыuPVC Fittings: For Drainage ApplicationsMiguel GualdaОценок пока нет

- Sulphate Resisting Cement ManufactureДокумент3 страницыSulphate Resisting Cement ManufactureshaayashanmugaОценок пока нет

- Short List of Applied Piping Standard PDFДокумент3 страницыShort List of Applied Piping Standard PDFmohamad3010Оценок пока нет

- Ra Eg C Oo Ecur' Yfachtties: Document Submitta!Документ64 страницыRa Eg C Oo Ecur' Yfachtties: Document Submitta!721917114 47Оценок пока нет

- FP - EHSP-02-F1 KTS Risk Assessment Form REV D 21102020Документ85 страницFP - EHSP-02-F1 KTS Risk Assessment Form REV D 21102020Arjel SagadОценок пока нет

- Therminol vp1Документ10 страницTherminol vp1karthik1amarОценок пока нет

- Brazing and Jointing of Copper PipesДокумент3 страницыBrazing and Jointing of Copper Pipessunny_84t100% (1)

- Standard Dimension Ratio (SDR) : HDPE Pressure Pipes According To EN 12201, EN 13244 and DIN 8074/75Документ1 страницаStandard Dimension Ratio (SDR) : HDPE Pressure Pipes According To EN 12201, EN 13244 and DIN 8074/75Arunprasad MurugesanОценок пока нет

- Butterfly ValveДокумент4 страницыButterfly ValveghjtyuОценок пока нет

- 67CF Series Installation Sheet PDFДокумент4 страницы67CF Series Installation Sheet PDFARMANDOОценок пока нет

- GRP Puddle Pipe SpecificationДокумент1 страницаGRP Puddle Pipe SpecificationIshwar AltОценок пока нет

- Subsea Pipeline Technology: Radial Flow TeeДокумент1 страницаSubsea Pipeline Technology: Radial Flow TeeJuan Roberto López BetanzosОценок пока нет

- Buried Pipes and Fittings Painting SpecДокумент5 страницBuried Pipes and Fittings Painting SpecRohan Sharma50% (2)

- Thread Types and UsesДокумент1 страницаThread Types and UsesJDPNetoОценок пока нет

- Bar / Wire Wrapped Steel Cylinder Pipes With Mortar Lining and Coating (Including Specials) - SpecificationДокумент22 страницыBar / Wire Wrapped Steel Cylinder Pipes With Mortar Lining and Coating (Including Specials) - SpecificationPratik KharmateОценок пока нет

- QCS 2014 - 3.7 Roller Shutter FIre DoorsДокумент3 страницыQCS 2014 - 3.7 Roller Shutter FIre DoorsthomsonОценок пока нет

- 200622-Fcu & Refrigerant Pipe & Insulation SizeДокумент1 страница200622-Fcu & Refrigerant Pipe & Insulation Sizegukan rajОценок пока нет

- Wavin PE Pressure Pipes Data SheetДокумент2 страницыWavin PE Pressure Pipes Data SheetConspiracy_PTОценок пока нет

- Catalog Swivel Joints PDFДокумент24 страницыCatalog Swivel Joints PDFluiggi19970530Оценок пока нет

- 17.25 Victaulic Style 489 Stainless Steel Rigid CouplingДокумент4 страницы17.25 Victaulic Style 489 Stainless Steel Rigid Couplingguita riefОценок пока нет

- Flexible Sprinkler Hose Installation GuideДокумент7 страницFlexible Sprinkler Hose Installation GuideSopi LabuОценок пока нет

- Systech Duct FactoryДокумент14 страницSystech Duct Factoryمحمد عبداللهОценок пока нет

- SPEC For Chilled Water Pipework and FittingsДокумент4 страницыSPEC For Chilled Water Pipework and FittingsonspsnonsОценок пока нет

- P-193 - Pipeline Pump Station and Terminal Valves in Crude Oil Service (API 6D Valves)Документ34 страницыP-193 - Pipeline Pump Station and Terminal Valves in Crude Oil Service (API 6D Valves)MatteoОценок пока нет

- A 1 KДокумент5 страницA 1 KSumantrra ChattopadhyayОценок пока нет

- E25NAFLON Expansion BellowsДокумент22 страницыE25NAFLON Expansion BellowsRezza Octova GochirОценок пока нет

- Cabinet Features and Specs for Fire Hose Reel and Layflat ModelsДокумент4 страницыCabinet Features and Specs for Fire Hose Reel and Layflat Modelsmain mydriveОценок пока нет

- Almona PP R Catalog Full PDFДокумент29 страницAlmona PP R Catalog Full PDFFirst LastОценок пока нет

- 05 WMS - CHWP InstallationДокумент15 страниц05 WMS - CHWP InstallationHimanshu Niveriya100% (1)

- Catalogo SchulzДокумент61 страницаCatalogo SchulzIsabel PulidoОценок пока нет

- Profile Minh PhucДокумент25 страницProfile Minh PhucThomas C. LaneОценок пока нет

- Integraheader: The Long-Term Chlorine Header SolutionДокумент8 страницIntegraheader: The Long-Term Chlorine Header Solutionmanuel.ape6263Оценок пока нет

- XYLEM - Type XA ModulesДокумент62 страницыXYLEM - Type XA Modulessindalisindi100% (2)

- Install HVAC Ductwork EfficientlyДокумент5 страницInstall HVAC Ductwork EfficientlyBuraq Aircondition Cont & Gen Maint LLC BuraqОценок пока нет

- Info On HDPE PipesДокумент49 страницInfo On HDPE PipesH.V. Patil100% (1)

- Underground Sea Water Piping SpecsДокумент12 страницUnderground Sea Water Piping SpecsSuhas NatuОценок пока нет

- SpearsДокумент96 страницSpearsatnkpr_vn9368Оценок пока нет

- 2 Specification For GRP PipingДокумент4 страницы2 Specification For GRP Pipinggc_panchaОценок пока нет

- He130 - Driveway Asphalt Coating: Physical PropertiesДокумент2 страницыHe130 - Driveway Asphalt Coating: Physical PropertiesDGWОценок пока нет

- Overkote Asphalt Pavement Coating: DescriptionДокумент1 страницаOverkote Asphalt Pavement Coating: DescriptionDGWОценок пока нет

- Nord-Lock Washers: The Original Wedge-Locking SolutionДокумент16 страницNord-Lock Washers: The Original Wedge-Locking SolutionDGWОценок пока нет

- Standard Pipe Sizes ME303-4.1.1Документ5 страницStandard Pipe Sizes ME303-4.1.1manashbdОценок пока нет

- Lee Spring CatalogДокумент391 страницаLee Spring CatalogDGWОценок пока нет

- D-01 7041 Flange-ANSI 125,150-RevlДокумент4 страницыD-01 7041 Flange-ANSI 125,150-RevlJohanna RojasОценок пока нет

- Wood Finishing Basics: Application Techniques & Product SelectionДокумент13 страницWood Finishing Basics: Application Techniques & Product SelectionDGWОценок пока нет

- What Is Sealcoating - Asphalt Sealcoating - Seal CoatДокумент2 страницыWhat Is Sealcoating - Asphalt Sealcoating - Seal CoatDGWОценок пока нет

- Masonry, Stucco & Brick Paints: Z - Xghiiify06991Tz)Документ2 страницыMasonry, Stucco & Brick Paints: Z - Xghiiify06991Tz)DGWОценок пока нет

- 01 04tocДокумент428 страниц01 04tocFaltooОценок пока нет

- Standard Pipe Sizes ME303-4.1.1Документ5 страницStandard Pipe Sizes ME303-4.1.1manashbdОценок пока нет

- Flat Washer and FastenersДокумент49 страницFlat Washer and FastenersDGWОценок пока нет

- Technical Note 812 - : MJ Adapter Connections Performance Pipe MJ AdaptersДокумент2 страницыTechnical Note 812 - : MJ Adapter Connections Performance Pipe MJ AdaptersDGWОценок пока нет

- Schedule 80 Pipe Dimensions & Pressure RatingsДокумент1 страницаSchedule 80 Pipe Dimensions & Pressure RatingsDGWОценок пока нет

- CAD-012854 - ROMAC 612 PIPE RESTRAINT FOR C905 PVCДокумент1 страницаCAD-012854 - ROMAC 612 PIPE RESTRAINT FOR C905 PVCDGWОценок пока нет

- PVC Gravity Sewer PipeДокумент1 страницаPVC Gravity Sewer PipeDGWОценок пока нет

- Rubber Expansion JointsДокумент9 страницRubber Expansion JointsDGWОценок пока нет

- Pipe Chart PDFДокумент2 страницыPipe Chart PDFCarlos Rivera0% (1)

- The First Hillside Washer That Eliminated Back-Up Plates!Документ1 страницаThe First Hillside Washer That Eliminated Back-Up Plates!DGWОценок пока нет

- Threaded Rod AccessoriesДокумент1 страницаThreaded Rod AccessoriesDGWОценок пока нет

- Tap Drill DataДокумент1 страницаTap Drill DataDGWОценок пока нет

- Thrust Restraint For Expansion JointДокумент2 страницыThrust Restraint For Expansion JointDGWОценок пока нет

- Steel Rebar SizesДокумент1 страницаSteel Rebar SizesDGWОценок пока нет

- Countersinking Drill Bit ReamerДокумент1 страницаCountersinking Drill Bit ReamerDGWОценок пока нет

- Tap Drill ChartДокумент2 страницыTap Drill ChartDGWОценок пока нет

- Screw Threads DesignДокумент1 страницаScrew Threads DesignDGWОценок пока нет

- JLRQQB JLRQQ - JLRQJRLL JLRQQK JLRQQC JLRQMQ JLRQMM JLRQMJ JLRQMRДокумент2 страницыJLRQQB JLRQQ - JLRQJRLL JLRQQK JLRQQC JLRQMQ JLRQMM JLRQMJ JLRQMRDGWОценок пока нет

- Bolt - Astm A449Документ2 страницыBolt - Astm A449DGWОценок пока нет

- Cotter Pins and Spring PinsДокумент1 страницаCotter Pins and Spring PinsDGWОценок пока нет

- Standard Pipe Schedules and Sizes ChartДокумент1 страницаStandard Pipe Schedules and Sizes ChartDGWОценок пока нет

- Chemistry TextДокумент45 страницChemistry Textariel yana morgaОценок пока нет

- Technical Data Sheet: Ptfe + 20% PeekДокумент1 страницаTechnical Data Sheet: Ptfe + 20% PeekRohan KulkarniОценок пока нет

- Using psychrometric charts to analyze HVAC systemsДокумент18 страницUsing psychrometric charts to analyze HVAC systemsRockydel MontesОценок пока нет

- Case Studies of The EntrepreneursДокумент14 страницCase Studies of The EntrepreneursSneha DobariaОценок пока нет

- BSC 6yh Sem Kuk SyllabusДокумент8 страницBSC 6yh Sem Kuk SyllabusVicky ChaharОценок пока нет

- International PharmacopeiaДокумент389 страницInternational PharmacopeiaClau Cisternas Araya100% (3)

- Journal 9 PDFДокумент45 страницJournal 9 PDFRuzengulalebih ZEta's-ListikОценок пока нет

- Histamine, Serotonin, and Their Antagonists: Classification and Clinical UseДокумент47 страницHistamine, Serotonin, and Their Antagonists: Classification and Clinical Usebangkit99Оценок пока нет

- Experiment 9Документ6 страницExperiment 9venkatalakshmi civilОценок пока нет

- Carbomer 940: Information SheetДокумент3 страницыCarbomer 940: Information SheetrendyОценок пока нет

- SHS Physical Science Q1 SLM - 3Документ25 страницSHS Physical Science Q1 SLM - 3Adalee ColleenОценок пока нет

- Msds FFFP 3% UlДокумент4 страницыMsds FFFP 3% UlOtto JamesОценок пока нет

- Building electricity vocabularyДокумент9 страницBuilding electricity vocabularyChan PhakkdeyОценок пока нет

- Bomba Dosificadora Iwaki PDFДокумент29 страницBomba Dosificadora Iwaki PDFMaykolth BarrantesОценок пока нет

- Pressure Gauges With Syphon PDFДокумент2 страницыPressure Gauges With Syphon PDFhussamengОценок пока нет

- Effect of Phytochemical Constituents of Argemone Mexicana Leaf ExtractДокумент6 страницEffect of Phytochemical Constituents of Argemone Mexicana Leaf ExtractIJRASETPublicationsОценок пока нет

- MSDS Mindray M-30 LyseДокумент2 страницыMSDS Mindray M-30 LyseSandra HubayaОценок пока нет

- Toksikologi PDFДокумент134 страницыToksikologi PDFPurwani Ni NyomanОценок пока нет

- 3. Materials and MethodsДокумент42 страницы3. Materials and MethodsAli Akand AsifОценок пока нет

- Copy of Pharmacognosy-and-Plant-ChemistryДокумент25 страницCopy of Pharmacognosy-and-Plant-ChemistryDecemae FuentesОценок пока нет

- Himani Bansal Jayant Negi Ritesh Kumar Uday PratapДокумент7 страницHimani Bansal Jayant Negi Ritesh Kumar Uday PratapJayant NegiОценок пока нет

- Noble Gases 20 Aug 2022Документ2 страницыNoble Gases 20 Aug 2022PLABAN DASОценок пока нет

- USCG Cargo Compatibility Chart For Chemical TankersДокумент19 страницUSCG Cargo Compatibility Chart For Chemical TankersRodcyn YumangОценок пока нет

- Finish Powerball (1999)Документ4 страницыFinish Powerball (1999)Jim SmithОценок пока нет

- Storage ProteinДокумент3 страницыStorage ProteinprincessicyjulietОценок пока нет

- Activity Models in HYSISДокумент226 страницActivity Models in HYSISMbeygi1357Оценок пока нет

- Biology Cells Graphic OrganizerДокумент1 страницаBiology Cells Graphic OrganizerMaci StackhouseОценок пока нет

- NIH Public Access: Introduction To Peptide SynthesisДокумент17 страницNIH Public Access: Introduction To Peptide SynthesisStella AguirreОценок пока нет

- Astm b680-1980Документ2 страницыAstm b680-1980Yavuz Solmaz100% (1)

- COA CrosscarmДокумент1 страницаCOA CrosscarmSouheila MniОценок пока нет