Академический Документы

Профессиональный Документы

Культура Документы

ASME and ANSI Standard Copper Water Tube and Solder-Joint Ends Valves and Fittings

Загружено:

aconibet90400 оценок0% нашли этот документ полезным (0 голосов)

152 просмотров1 страницаАвторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

152 просмотров1 страницаASME and ANSI Standard Copper Water Tube and Solder-Joint Ends Valves and Fittings

Загружено:

aconibet9040Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

ASME/ANSI STANDARD COPPER WATER TUBE

& SOLDER-JOINT ENDS - VALVES & FITTINGS

SERVICE RECOMMENDATIONS As steam installations, the successful application of

copper tube depends upon weight of tube and solder

ASME/ANSI STD COPPER WATER TUBE/SOLDER-JOINT ENDS

Seamless copper water tube is used for such services used when making joints. The solder must have a

as steam, water or air and oil, gas or similar fluids. melting point high enough to remain unaffected by the

temperature of the steam.

Type K Tube is especially recommended for under-

ground use and where service conditions are severe. It HARD COPPER TUBE: Hard copper tube is intended

is also recommended for general plumbing and heating primarily for use in straight lengths. Without proper

systems and is used for gas, oil and steam. bending equipment, its use is not recommended for

field bending.

Type L Tube is for interior use in general plumbing

and heating work. SOFT COPPER TUBE: This tube can be bent with-

out special bending equipment and is recommended

Type M Tube is for use for use when bends must be made in the field, as in

with solder-joint fittings concealed replacement work. Soft copper tubing may

only, for waste, vent and become flattened or distorted when being handled or

interior drainage lines while in transit. The ends of this tube should therefore

and other non-pressure be sized to assure a tight soldered joint.

applications.

Type K (hard and soft) and Type L (hard and soft) in

sizes 3/8" to 12" and Type M (hard) in sizes 21/2" to

12" conform to ANSI Standard for Copper Water

Tube, H23.1. Also conforms to Federal Specification

WW-T-799.

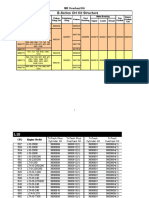

TUBE DIMENSIONS AND WEIGHTS

Nom- Actual Type K Tube Type L Tube Type M Tube

inal Out-

DIMENSIONS OF SOLDER-JOINT ENDS Size side Wall Wgt. Wall Wgt. Wall Wgt.

Standard A B of Diam. Thick- Per Thick- Per Thick- Per

Water Inside Diameter Depth Tube of Tube ness Foot ness Foot ness Foot

Tube In. In. In. Lbs. In. Lbs. In. Lbs.

Size Inches Min. Inches Max. Inches Min. Inches

1/4 3/8 .030 .126 –– ––

1/4 5/16

_______________________________________________________________________

–– ––

.377 .381

_________________________________________________________________ 3/8 1/2 .049 .269 .035 .198 –– ––

_______________________________________________________________________

3/8 .502 .506 3/8

_________________________________________________________________ 1/2 5/8 .049 .344 .040 .285 –– ––

_______________________________________________________________________

1/2 .627 .631 1/2 3/4 7/8

_________________________________________________________________ .065 .641 .045 .455 –– ––

_______________________________________________________________________

3/4 .877 .881 3/4 1 11/8 .065 .839 .050 .655 –– ––

_________________________________________________________________ _______________________________________________________________________

1 1.128 1.132 29/32

_________________________________________________________________ 11/4 13/8 .065 1.04 .055 .884 .042 .68

_______________________________________________________________________

11/4 1.378 1.382 31/32

_________________________________________________________________ 11/2 15/8 .072 1.36 .060 1.14 .049 .94

_______________________________________________________________________

11/2 1.628 1.633 13/32 2 21/8 .083 2.06 .070 1.75 .058 1.46

_______________________________________________________________________

_________________________________________________________________

2 2.128 2.133 111/32 21/2 25/8 .095 2.93 .080 2.48 .065 2.03

_______________________________________________________________________

_________________________________________________________________

3 31/8 .109 4.00 .090 3.33 .072 2.68

_______________________________________________________________________

21/2 2.628 2.633 115/32

_________________________________________________________________

31/2 35/8 .120 5.12 .100 4.29 .083 3.58

_______________________________________________________________________

3 3.128 3.133 1 21/32

_________________________________________________________________ 4 41/8 .130 6.51 .110 5.38 .095 4.66

_______________________________________________________________________

31/2 3.628 3.633 129/32

_________________________________________________________________ 5 51/8 .160 9.67 .125 7.61 .109 6.66

_______________________________________________________________________

4 4.128 4.133 25/32

_________________________________________________________________ 6 61/8 .192 13.90 .140 10.20 .122 8.92

_______________________________________________________________________

5 5.128 5.133 221/32

_________________________________________________________________ 8 81/8 .271 25.90 .200 19.30 .170 16.50

_______________________________________________________________________

6 6.128 6.133 33/32

_________________________________________________________________ 10 101/8 .338 40.30 .250 30.10 .212 25.60

_______________________________________________________________________

8 8.128 8.133 331/32 12 121/8 .405 57.80 .280 40.40 .254 36.70

Data extracted from ASME/ANSI Standard 16.18–1984 (R1994) – Cast Copper Alloy Solder Joint

Pressure Fittings.

®

10750 CORPORATE DRIVE • STAFFORD, TEXAS BV-65

Вам также может понравиться

- UNT-PRC015-En - 062010 - High Rise Fan Coil Quick SelectДокумент14 страницUNT-PRC015-En - 062010 - High Rise Fan Coil Quick SelectyolepusaОценок пока нет

- MN 01005Документ20 страницMN 01005Ali AliОценок пока нет

- Jeppesen Fluid Lines and FittingsДокумент53 страницыJeppesen Fluid Lines and FittingsMarlou DyОценок пока нет

- Z843M1-RC MEZCLADORA PORTABALDEДокумент1 страницаZ843M1-RC MEZCLADORA PORTABALDEEdgar Manuel Morales MitmaОценок пока нет

- V4 SUBMERSIBLE PUMPSET - cUuTUtdДокумент8 страницV4 SUBMERSIBLE PUMPSET - cUuTUtdtayadeyadhneshОценок пока нет

- Culvert - Helcor Corrugated Steel Pipe (Armtec)Документ12 страницCulvert - Helcor Corrugated Steel Pipe (Armtec)didbeauОценок пока нет

- Quickvic Flexible Coupling For Steel: Carbon Steel Pipe - Grooved CouplingsДокумент4 страницыQuickvic Flexible Coupling For Steel: Carbon Steel Pipe - Grooved CouplingsMina MagdyОценок пока нет

- Series: Submersible Sewage PumpsДокумент9 страницSeries: Submersible Sewage PumpsJOHNNY CALEROОценок пока нет

- 107857.rawlplug - En.r-Ker-Ii Hybrid Resin Threaded RodsДокумент10 страниц107857.rawlplug - En.r-Ker-Ii Hybrid Resin Threaded RodsLouis BirОценок пока нет

- Product Catalog: Guiberson Quality Products and ServicesДокумент63 страницыProduct Catalog: Guiberson Quality Products and ServicesTitanBOPОценок пока нет

- Copper Tubes - ASTM B88Документ4 страницыCopper Tubes - ASTM B88Jacques SwartОценок пока нет

- Kuri CONQUERORДокумент16 страницKuri CONQUERORJosh WhiteОценок пока нет

- TECOtubeexpanders BROCHUREДокумент56 страницTECOtubeexpanders BROCHUREMontajes Industriales EOS, MIESAОценок пока нет

- 12 Column Pipe For Submersible PumpsДокумент4 страницы12 Column Pipe For Submersible PumpsEmac AutomationОценок пока нет

- Acople FlexibleДокумент4 страницыAcople Flexiblejhoger2012Оценок пока нет

- Y Strainer VictaulicДокумент4 страницыY Strainer VictaulicMohammed NiqrisОценок пока нет

- RC DetailingДокумент82 страницыRC DetailingkishoreОценок пока нет

- 300 LB CAST STEEL STRAINER SUBMITTALДокумент1 страница300 LB CAST STEEL STRAINER SUBMITTALanugrah_dimas5441Оценок пока нет

- M8456 2 TrusealДокумент3 страницыM8456 2 Trusealk_tevenОценок пока нет

- Bending The RulesДокумент2 страницыBending The RuleskikiuОценок пока нет

- General Notes On Instrumentation Cable: Non-Fire Propagating CablesДокумент5 страницGeneral Notes On Instrumentation Cable: Non-Fire Propagating CablesCharu ChhabraОценок пока нет

- Reinforcing Detailing of R.C.C Members - K.kaviTHAДокумент47 страницReinforcing Detailing of R.C.C Members - K.kaviTHAGurupriyaОценок пока нет

- John Lysaght Country Service Manual 1948Документ222 страницыJohn Lysaght Country Service Manual 1948allan3692Оценок пока нет

- B3097 CatalogДокумент22 страницыB3097 CatalogSIBIN GRzОценок пока нет

- Reinforcing Detailing of R.C.C MembersДокумент47 страницReinforcing Detailing of R.C.C MembersAmey ShettiОценок пока нет

- Tsurumi Options: Submersible Sewage PumpsДокумент5 страницTsurumi Options: Submersible Sewage PumpsTài AnhОценок пока нет

- Strainer - Cono de BrujasДокумент2 страницыStrainer - Cono de BrujasAlfredoОценок пока нет

- Cortador Hidraulico de TuberíaДокумент1 страницаCortador Hidraulico de TuberíaSahara BolivarОценок пока нет

- TERA Joint BrochureДокумент16 страницTERA Joint BrochureraigoukiОценок пока нет

- Tubing DataДокумент8 страницTubing DataGunawan AdeОценок пока нет

- Reinforcing Detailing of R.C.C MembersДокумент47 страницReinforcing Detailing of R.C.C Membersmanumeet100% (2)

- Conduiting WorkДокумент24 страницыConduiting Worknaam9Оценок пока нет

- Chemrite Steel FibreДокумент3 страницыChemrite Steel FibreICPL-RWPОценок пока нет

- Sheet Piling BrochureДокумент4 страницыSheet Piling BrochurethinagaraОценок пока нет

- Petroleum Production Engineering-I: Third Year Second TermДокумент46 страницPetroleum Production Engineering-I: Third Year Second Termsarfraz hussain100% (1)

- SSAB - Water Mains - Pipes and Fittings - ENДокумент22 страницыSSAB - Water Mains - Pipes and Fittings - ENservice techniqueОценок пока нет

- Reinforcement DetailingДокумент47 страницReinforcement DetailingMuhammad Saqib Abrar94% (16)

- TMCX ConnectorsДокумент5 страницTMCX ConnectorsGregory StewartОценок пока нет

- US Seal MFG Catalog 2012Документ236 страницUS Seal MFG Catalog 2012hufuents-1Оценок пока нет

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesОт EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesОценок пока нет

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversОт EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversРейтинг: 5 из 5 звезд5/5 (2)

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesОт EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesОценок пока нет

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyОт EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyОценок пока нет

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersОт EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersРейтинг: 3.5 из 5 звезд3.5/5 (2)

- Rock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesОт EverandRock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesОценок пока нет

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!От EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Рейтинг: 5 из 5 звезд5/5 (2)

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsОт EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsРейтинг: 4 из 5 звезд4/5 (1)

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkОт EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkОценок пока нет

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Cylindrical Compression Helix Springs For Suspension SystemsОт EverandCylindrical Compression Helix Springs For Suspension SystemsОценок пока нет

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Sexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicОт EverandSexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicОценок пока нет

- Water TreatmentgdfgdfgДокумент1 страницаWater Treatmentgdfgdfgaconibet9040Оценок пока нет

- Ball MillДокумент1 страницаBall Millaconibet9040Оценок пока нет

- Microsoft Project - Guided Tour - StartДокумент1 страницаMicrosoft Project - Guided Tour - Startaconibet9040Оценок пока нет

- Microsoft Project - Simple Tracking - StartДокумент2 страницыMicrosoft Project - Simple Tracking - Startaconibet9040Оценок пока нет

- Microsoft Project - Simple Resources - StartДокумент1 страницаMicrosoft Project - Simple Resources - Startaconibet9040Оценок пока нет

- Microsoft Project - Guided Tour - StartДокумент1 страницаMicrosoft Project - Guided Tour - Startaconibet9040Оценок пока нет

- Microsoft Project - Guided Tour - StartДокумент1 страницаMicrosoft Project - Guided Tour - Startaconibet9040Оценок пока нет

- Microsoft Project - Advanced Resources - StartДокумент3 страницыMicrosoft Project - Advanced Resources - Startaconibet9040Оценок пока нет

- Microsoft Project - Advanced Tasks AДокумент3 страницыMicrosoft Project - Advanced Tasks Aaconibet9040Оценок пока нет

- Microsoft Project - Advanced Tasks AДокумент3 страницыMicrosoft Project - Advanced Tasks Aaconibet9040Оценок пока нет

- Microsoft Project - Simple Resources - StartДокумент1 страницаMicrosoft Project - Simple Resources - Startaconibet9040Оценок пока нет

- Microsoft Project - Advanced Plan - StartДокумент18 страницMicrosoft Project - Advanced Plan - Startaconibet9040Оценок пока нет

- Microsoft Project - Guided Tour - StartДокумент1 страницаMicrosoft Project - Guided Tour - Startaconibet9040Оценок пока нет

- Microsoft Project - Simple Formatting - StartДокумент1 страницаMicrosoft Project - Simple Formatting - Startaconibet9040Оценок пока нет

- Book Launch Project ScheduleДокумент4 страницыBook Launch Project Scheduleaconibet9040Оценок пока нет

- Microsoft Project - Simple Resources - StartДокумент1 страницаMicrosoft Project - Simple Resources - Startaconibet9040Оценок пока нет

- Microsoft Project - Advanced Tracking C - Start PDFДокумент90 страницMicrosoft Project - Advanced Tracking C - Start PDFaconibet9040Оценок пока нет

- Microsoft Project - Advanced Tasks A - StartДокумент18 страницMicrosoft Project - Advanced Tasks A - Startaconibet9040Оценок пока нет

- Microsoft Project - Advanced Tracking A - StartДокумент18 страницMicrosoft Project - Advanced Tracking A - Startaconibet9040Оценок пока нет

- Microsoft Project - Advanced Assignments B - Start PDFДокумент18 страницMicrosoft Project - Advanced Assignments B - Start PDFaconibet9040Оценок пока нет

- Microsoft Project - Advanced Tracking B - StartДокумент24 страницыMicrosoft Project - Advanced Tracking B - Startaconibet9040Оценок пока нет

- Microsoft Project - Advanced Assignments A - StartДокумент18 страницMicrosoft Project - Advanced Assignments A - Startaconibet9040Оценок пока нет

- Microsoft Project - Simple Tracking - StartДокумент2 страницыMicrosoft Project - Simple Tracking - Startaconibet9040Оценок пока нет

- Microsoft Project - Advanced Assignments A - StartДокумент18 страницMicrosoft Project - Advanced Assignments A - Startaconibet9040Оценок пока нет

- Microsoft Project - Simple Assignments - StartДокумент4 страницыMicrosoft Project - Simple Assignments - Startaconibet9040Оценок пока нет

- Microsoft Project - Advanced Tasks B - StartДокумент18 страницMicrosoft Project - Advanced Tasks B - Startaconibet9040Оценок пока нет

- Book Launch Project ScheduleДокумент4 страницыBook Launch Project Scheduleaconibet9040Оценок пока нет

- Microsoft Project - Simple Assignments - StartДокумент4 страницыMicrosoft Project - Simple Assignments - Startaconibet9040Оценок пока нет

- Microsoft Project - Simple Assignments - StartДокумент4 страницыMicrosoft Project - Simple Assignments - Startaconibet9040Оценок пока нет

- 455zx - Brochure PDFДокумент16 страниц455zx - Brochure PDFDhru Ti100% (1)

- Plate Mill ProcessДокумент2 страницыPlate Mill ProcessVinay RajputОценок пока нет

- Kinematics and Kinetics of RigidbodiesДокумент190 страницKinematics and Kinetics of RigidbodiesmadhurivelpulaОценок пока нет

- Explo - Lirika OTC PDFДокумент6 страницExplo - Lirika OTC PDFMariusz PawlasОценок пока нет

- Doors PDFДокумент34 страницыDoors PDFoz23Оценок пока нет

- P1276 Parts ManualДокумент146 страницP1276 Parts ManualNilsОценок пока нет

- Somar Integra Executive Summary.r2Документ3 страницыSomar Integra Executive Summary.r2vanessa_corneliaОценок пока нет

- Lect5 Detachable Fastener Bolt Nut Locking FoundationДокумент36 страницLect5 Detachable Fastener Bolt Nut Locking FoundationPramodVermaОценок пока нет

- Steel Sheet Pile CatalogueДокумент80 страницSteel Sheet Pile CatalogueBrian TanОценок пока нет

- DS PM0217 en Co 3755Документ2 страницыDS PM0217 en Co 3755prasad336Оценок пока нет

- CPL Cross Reference - Overhaul KitsДокумент13 страницCPL Cross Reference - Overhaul KitsAugusto NuñezОценок пока нет

- Remover e Instalar Camisas de CilindrosДокумент4 страницыRemover e Instalar Camisas de CilindrosAlejandro ValenzuelaОценок пока нет

- Oil Free Compressor Manual 132 KWДокумент33 страницыOil Free Compressor Manual 132 KWrubiodegoОценок пока нет

- Dynapac f1800w En-20220822.134322Документ2 страницыDynapac f1800w En-20220822.134322Fredrik ÅkessonОценок пока нет

- Exterior Dimensions Uc1A - : JANUARY 2009Документ20 страницExterior Dimensions Uc1A - : JANUARY 2009wayne mcmurrayОценок пока нет

- Weld Defect Code Acceptance CriteriaДокумент17 страницWeld Defect Code Acceptance CriteriaNavanitheeshwaran Sivasubramaniyam100% (3)

- Kobelco 70SR: The Most Awesome 7-Ton Excavator Under 40 CharactersДокумент16 страницKobelco 70SR: The Most Awesome 7-Ton Excavator Under 40 Charactershaiccdk6Оценок пока нет

- TIMBER BEAM DESIGNДокумент144 страницыTIMBER BEAM DESIGNweng paraleОценок пока нет

- Electro-Hydraulic Actuators For Valves SKB32.. SKB82.. SKB62.. SKB60Документ16 страницElectro-Hydraulic Actuators For Valves SKB32.. SKB82.. SKB62.. SKB60Avotech DubaiОценок пока нет

- Conservation of Energy Worksheet #1 - 1Документ3 страницыConservation of Energy Worksheet #1 - 1Alyssa ColeОценок пока нет

- Mechanics of Material Lab ManualДокумент64 страницыMechanics of Material Lab ManualMOAZОценок пока нет

- SM-McCormick ZTX230 ZTX260 ZTX280 TRACTOR Service Repair ManualДокумент66 страницSM-McCormick ZTX230 ZTX260 ZTX280 TRACTOR Service Repair ManualRiahi Rezeg20% (5)

- Chung2006 PDFДокумент9 страницChung2006 PDFNguyen Tran HieuОценок пока нет

- Date: Drawn Trac. Scale Checked Apprd.: Replacement: Replaced By: DWG: Rev.Документ1 страницаDate: Drawn Trac. Scale Checked Apprd.: Replacement: Replaced By: DWG: Rev.Deepak DasОценок пока нет

- Conversion of Wet Flow Rate To Dry Flow Rate Bruce Burton, Research and Development Manager 10-15-1999Документ3 страницыConversion of Wet Flow Rate To Dry Flow Rate Bruce Burton, Research and Development Manager 10-15-1999Victor VazquezОценок пока нет

- PC W130B 02 EUДокумент100 страницPC W130B 02 EUОблачноОценок пока нет

- System Head in Metric UnitsДокумент7 страницSystem Head in Metric UnitsrammysiОценок пока нет

- EEBDДокумент8 страницEEBDChan DanОценок пока нет

- Tetra Pak CIP Unit PДокумент2 страницыTetra Pak CIP Unit PNaglaa FathyОценок пока нет

- 1602 (Fuel Injection Nozzles and Lines) - ST609885: Parts ListДокумент6 страниц1602 (Fuel Injection Nozzles and Lines) - ST609885: Parts ListLe Anh DangОценок пока нет