Академический Документы

Профессиональный Документы

Культура Документы

Me 0741 PS 991

Загружено:

Esteban Vanegas AlvarezОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Me 0741 PS 991

Загружено:

Esteban Vanegas AlvarezАвторское право:

Доступные форматы

ME-0741-PS-991-D

08-08

RG6/IS

SERIES 625

RING GATE NOZZLE

MACHINING &

INSTALLATION DATA

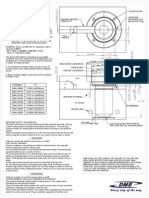

NOTE: Before installing a Ring Gate Nozzle, it is important to take the

nozzle's expansion factor into consideration. For best results, please

follow the information below

NOTE: Dimensions are shown in Inches.

+0.001

3.001 0.000

MANIFOLD LINE

0.125 MIN.

0.250 MIN.

2.12

0.03 X 45

CHAMFER

"A" + BE

30

+0.0005

0.080

1.0005 0.0000

To compensate for the nozzle's growth when heat is applied, the linear

expansion of the nozzle (BE) at a given temperature must be added

to the nominal "A" dimension. The formula below shows how to figure

boring depth (dimension "A" + BE). The tip of the nozzle will now be

flush with cavity line.

NOZZLE SUB-ASSEMBLY

CATALOG NUMBER

Formula for determining this expansion factor is as follows:

BE="A" dimension x 0.00000633 x(Nozzle set point temperature - 68 F).

EXAMPLE: Given a 3 inch "A" dimension, with a nozzle set point

temperature of 500 F:

BE = 3 x 0.00000633 x (500 - 68) = 0.008

Thus "A" + BE will be 3.008

Note: The above information is only given as an example. variations may occur

based on mold configurations and cooling factor. In some instances it may

be necessary to obtain an empirical factor.

"A" DIMENSION

FOR NOZZLE ASSEMBLY

EHA 0016

EHA 0017

EHA 0018

EHA 0019

EHA 0020

EHA 0021

EHA 0022

4.000

5.000

6.000

7.000

8.000

9.000

10.000

RING GATE TIP SUB-ASSEMBLY

CATALOG NUMBER

EHT 0040

NOTE: Nozzle Assembly requires Nozzle Sub-assembly and Tip-assembly.

ME-0741-PS-991-D

08-08

RG6/IS

SERIES 625

RING GATE NOZZLE

MACHINING &

INSTALLATION DATA

OPERATING & SERVICING INSTRUCTIONS

FOR NOZZLE SERIES 250, 375, & 625

All interchangeable nozzles are similar, and differ only in size and material flow

capacity. The information found below applies to the nozzle series 250, 375 & 625.

OPERATING PROCEDURE

The nozzles are supplied with a Square (Flat) Coil equipped with a

Type J Thermocouple.

It is recommended to use a D-M-E closed loop Temperature Controller for optimum

Temperature Control.

When starting the nozzle, set the temperature to 10% voltage if using in open loop

manual type or to 200 F if using closed loop automatic type. In either case this

procedure will allow the heater to dissipate any moisture.

Make sure you maintain this start-up setting for 15 minutes.

Controller equipped with Step Smart , Smart Step

or other heater warm-up circuitry will change automatically.

It is essential to use controllers with the proper voltage and wattage capabilities.

The voltage and wattage of each heater is clearly marked on the heater tag.

Step Smart , Smart Start and DME are all registered trademarks

of DME Company.

IMPORTANT SAFETY INFORMATION

A hot-runner system includes electrical elements and may contain molten

plastic at elevated temperature and pressure.To avoid injury, exercise

caution by reading these instructions before servicing or operating the

system.

These instructions must be passed on to the end user where they should

be read before using this product. Failure to do so can result in serious

injury or death.

DANGER

Failure to comply will result in serious injury or death:

ELECTRICAL HAZARDS

Improper voltages or grounding can result in electrical shock. Use only

with proper voltage and a proper earth ground.

To avoid electrical shock, do not operate product when wet.

Do not operate this equipment with covers or panels removed.

To avoid electrical shock, turn off main power disconnect and lockout /

tag out before servicing this device. Do not connect temperature sensors to

electrical power. It will damage the product and it could cause fire,

severe injuries or even death.

If green ground wire present wire must be connected to the ground.

Do not rebend rigid leads. Rebending leads might result in damage to circuit.

Product might absorb moisture when cool. Use low Voltage or power to drive

out residual moisture before applying full power. Failure to do so may cause

damage to this product.

ASSEMBLY PROCEDURE - "ALL PARTS MUST BE CLEAN"

1. Apply an anti-seize compound on both the heater cover and tip threads.

2. Install the heater using a Square Coil Heater wrench (Wrench included

with replacement heater). After the heater is installed, it should cover the

entire length of the nozzle body - stretch the heater by hand if necessary.

3. Firmly screw the tip sub-assembly into the shank of the nozzle body.

Tighten and untighten two or three times making sure there is a good

contact between the tip and the shank. Torque to approximately 30 ft-lbs.

WARNING

Failure to comply can result in serious injury or death:

STORED ENERGY AND HIGH TEMPERATURE HAZARDS

This product maintains molten plastic at high pressure. Use caution when

operating and servicing the system.

Physical contact with molten plastic may result in severe burns. Proper

protective equipment, including eye protection, must be worn.

This product has heated surfaces. Use caution when operating and servicing

the system to avoid severe burns. Proper protective equipment should be worn.

DISASSEMBLY PROCEDURE

WIRING INFORMATION

1. Place the nozzle in a vice using "V" Block, then secure it firmly at the nozzle head.

Square Coil Heaters are supplied with 2" prestripped

36" long leads. Heaters are 240 VAC.

2 power leads are Multi Color.

1 ground lead is GREEN.

Thermocouple is "J" Type.

Thermocouple is supplied with 36" leads.

1 T/C lead is WHITE and negative (-)

constantan (non-magnetic).

1 T/C lead is BLACK and positive (+)

iron (magnetic).

2. For removal of tip from nozzle, a six point deep well socket is recommended. The

nozzle must be at processing temperature and the heater should be turned off

when removing tip counter-clockwise from the nozzle. If nozzle is still in the mold,

the nozzle must be "keyed" to prevent wire damages.

3. Tip must be cleaned of any material before reassembling.

4. Remove the heater using a Square Coil Heater wrench (Wrench is included with

replacement heater).

5. Cast-in heater may be removed if failure occurs and replaced with a Square Coil

Heater. Follow assembly procedures for Square Coil Heater.

D-M-E COMPANY

29111 STEPHENSON HIGHWAY

MADISON HEIGHTS

MICHIGAN 48071 USA

US 800-656-6653

CANADA 800-387-6600

www.dme.net

Вам также может понравиться

- Mold SaverDMEsav-msds 1Документ7 страницMold SaverDMEsav-msds 1Esteban Vanegas Alvarez100% (1)

- Jumbo Gate-Mate Nozzle Assemblies Installation Data: ME-0739-PS-051-C Gmn-PsДокумент2 страницыJumbo Gate-Mate Nozzle Assemblies Installation Data: ME-0739-PS-051-C Gmn-PsEsteban Vanegas AlvarezОценок пока нет

- American Standard Mold Base QRFДокумент4 страницыAmerican Standard Mold Base QRFEsteban Vanegas AlvarezОценок пока нет

- DME Single Zone Timer TCM-03-024DДокумент1 страницаDME Single Zone Timer TCM-03-024DEsteban Vanegas AlvarezОценок пока нет

- Distibutor Tubes: Important Safety InformationДокумент2 страницыDistibutor Tubes: Important Safety InformationEsteban Vanegas AlvarezОценок пока нет

- PR Oc Ess Contr OlsДокумент8 страницPR Oc Ess Contr OlsEsteban Vanegas AlvarezОценок пока нет

- Abrasive Stones - General Purpose Type E and MDMEabstonestypeem-msds PDFДокумент6 страницAbrasive Stones - General Purpose Type E and MDMEabstonestypeem-msds PDFEsteban Vanegas AlvarezОценок пока нет

- SDS271 Diamond CompoundДокумент7 страницSDS271 Diamond CompoundEsteban Vanegas AlvarezОценок пока нет

- Cut Off WheelDMEcutoffwh-msdsДокумент4 страницыCut Off WheelDMEcutoffwh-msdsEsteban Vanegas AlvarezОценок пока нет

- D-M-E In2 Innovative Interlocks: Mold Base MachiningДокумент2 страницыD-M-E In2 Innovative Interlocks: Mold Base MachiningEsteban Vanegas AlvarezОценок пока нет

- Abrasive Stones - General Purpose Type A and BDMEabstonesab-msdsДокумент6 страницAbrasive Stones - General Purpose Type A and BDMEabstonesab-msdsEsteban Vanegas AlvarezОценок пока нет

- D-M-E Mold Straps: Important Safety InformationДокумент1 страницаD-M-E Mold Straps: Important Safety InformationEsteban Vanegas AlvarezОценок пока нет

- Abrasive Stones - General Purpose Type E and MDMEabstonestypeem-msds PDFДокумент6 страницAbrasive Stones - General Purpose Type E and MDMEabstonestypeem-msds PDFEsteban Vanegas AlvarezОценок пока нет

- Abrasive Sheets - ABW TypeDME ABW Abrasive SheetsДокумент6 страницAbrasive Sheets - ABW TypeDME ABW Abrasive SheetsEsteban Vanegas AlvarezОценок пока нет

- Me M741 PS 999 PDFДокумент2 страницыMe M741 PS 999 PDFEsteban Vanegas AlvarezОценок пока нет

- J Type Therm StandardsДокумент1 страницаJ Type Therm StandardsEsteban Vanegas AlvarezОценок пока нет

- Me 0508 PS 059Документ5 страницMe 0508 PS 059Esteban Vanegas AlvarezОценок пока нет

- Jumbo Gate-Mate Nozzle Assemblies Installation Data: ME-0739-PS-051-C Gmn-PsДокумент2 страницыJumbo Gate-Mate Nozzle Assemblies Installation Data: ME-0739-PS-051-C Gmn-PsEsteban Vanegas AlvarezОценок пока нет

- Me 0508 PS 057Документ3 страницыMe 0508 PS 057Esteban Vanegas AlvarezОценок пока нет

- Me 0508 PS 058 PDFДокумент3 страницыMe 0508 PS 058 PDFEsteban Vanegas AlvarezОценок пока нет

- Heater Replacement Instructions For Point Gate and Thru Hole TipsДокумент2 страницыHeater Replacement Instructions For Point Gate and Thru Hole TipsEsteban Vanegas AlvarezОценок пока нет

- Me 0708 PS 014Документ2 страницыMe 0708 PS 014Esteban Vanegas AlvarezОценок пока нет

- Me 0508 PS 059Документ5 страницMe 0508 PS 059Esteban Vanegas AlvarezОценок пока нет

- Thinswitch Installation InstructionsДокумент2 страницыThinswitch Installation InstructionsEsteban Vanegas AlvarezОценок пока нет

- S-Series Straight-Shot T-Series Straight-ShotДокумент2 страницыS-Series Straight-Shot T-Series Straight-ShotEsteban Vanegas AlvarezОценок пока нет

- Me 0704 PS 069Документ2 страницыMe 0704 PS 069Esteban Vanegas AlvarezОценок пока нет

- Drum Heater Installation English Sept 2015Документ1 страницаDrum Heater Installation English Sept 2015Esteban Vanegas AlvarezОценок пока нет

- Me 100005 0827Документ2 страницыMe 100005 0827Esteban Vanegas AlvarezОценок пока нет

- DMEInternalLatchLock DKL CAMFingerRemoval InstallationДокумент5 страницDMEInternalLatchLock DKL CAMFingerRemoval InstallationEsteban Vanegas AlvarezОценок пока нет

- High Performance Hot Sprue Bushing Installation DataДокумент2 страницыHigh Performance Hot Sprue Bushing Installation DataEsteban Vanegas AlvarezОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Paz-Soldan AtomClockДокумент84 страницыPaz-Soldan AtomClockdarrelОценок пока нет

- Ak Dimax Hf-10 PDB 042312Документ12 страницAk Dimax Hf-10 PDB 042312human bodyОценок пока нет

- Transformer ProtectionДокумент115 страницTransformer Protectionchiranjeevi raju100% (1)

- Cable CapacitanceДокумент1 страницаCable Capacitancegerrzen64Оценок пока нет

- Experiment.4. Load Characteristics of D.C Series GeneratorДокумент2 страницыExperiment.4. Load Characteristics of D.C Series Generatorمحمد الحديОценок пока нет

- What Is Piezoelectric Sensor - Construction, Working & ApplicationsДокумент4 страницыWhat Is Piezoelectric Sensor - Construction, Working & ApplicationsSam BelloОценок пока нет

- LS 400 Series: Incremental Linear Encoders With Slimline Scale Housing - For Limited Installation SpaceДокумент2 страницыLS 400 Series: Incremental Linear Encoders With Slimline Scale Housing - For Limited Installation SpaceНиколайОценок пока нет

- Respaldo Lab 3 - Constante de Planck ExcelДокумент4 страницыRespaldo Lab 3 - Constante de Planck ExcelmaryОценок пока нет

- Guide To Wireless Communications 3rd Edition Olenewa Test BankДокумент8 страницGuide To Wireless Communications 3rd Edition Olenewa Test BankJohnDeckerfrgam100% (16)

- Product Data Sheet: Relayaux - Three Phase Trip Circuit Supervision Relay - 2 C/O - 220 V DCДокумент2 страницыProduct Data Sheet: Relayaux - Three Phase Trip Circuit Supervision Relay - 2 C/O - 220 V DCN_LocusОценок пока нет

- Colorimeter: V Dinesh, Ap/Ece, Sce TrichyДокумент35 страницColorimeter: V Dinesh, Ap/Ece, Sce TrichykadaОценок пока нет

- 1hu3102 0ad01 Z 9f66312301001imb5 DC Servomotor Siemens ManualДокумент62 страницы1hu3102 0ad01 Z 9f66312301001imb5 DC Servomotor Siemens ManualJack ReacherОценок пока нет

- Price List PL-02/2013 01-09-2013: Type Ratings Icu Icu Unit RateДокумент7 страницPrice List PL-02/2013 01-09-2013: Type Ratings Icu Icu Unit RatepogisimpatikoОценок пока нет

- Harmony XB4 - XB4BD25Документ5 страницHarmony XB4 - XB4BD25asygafОценок пока нет

- Understanding Electricity: A Guide to Electrical Concepts and ComponentsДокумент55 страницUnderstanding Electricity: A Guide to Electrical Concepts and ComponentsPrudz100% (1)

- Installing and Commissioning MotorsДокумент4 страницыInstalling and Commissioning MotorsCraig PretoriusОценок пока нет

- May 22 P1 MSДокумент20 страницMay 22 P1 MSManeeha RamizОценок пока нет

- 6 9C-EnergyFormsConversionsДокумент5 страниц6 9C-EnergyFormsConversionsTracy Nicole MaurilloОценок пока нет

- High Voltage Ceramic Disc Capacitors (Low Loss Type) KGE/Char. SL/GP, 1 To 6 KVDC KBP/Char. B/Y5P, 1 To 3 KVDC KRP/Char. R/Y5R, 1 To 3 KVDCДокумент16 страницHigh Voltage Ceramic Disc Capacitors (Low Loss Type) KGE/Char. SL/GP, 1 To 6 KVDC KBP/Char. B/Y5P, 1 To 3 KVDC KRP/Char. R/Y5R, 1 To 3 KVDCKiritosaoОценок пока нет

- June 2021 (v3) QP - Paper 4 CIE Physics IGCSEДокумент16 страницJune 2021 (v3) QP - Paper 4 CIE Physics IGCSEManya PunjabiОценок пока нет

- Nortronics Headcare ManualДокумент15 страницNortronics Headcare ManualpsychpostersОценок пока нет

- KMS Physics Xii 2Документ10 страницKMS Physics Xii 2Lian M ShineОценок пока нет

- Solenoide FANДокумент2 страницыSolenoide FANGerardo Jesus Sanchez CañizalesОценок пока нет

- Chemistry: DPP - Daily Practice ProblemsДокумент7 страницChemistry: DPP - Daily Practice ProblemsAdityaОценок пока нет

- Cable Silicoando Tipo Vulcanizao-SihfДокумент1 страницаCable Silicoando Tipo Vulcanizao-SihfErick MüllerОценок пока нет

- Applied Thermodynamics by Eastop & Mcconkey Part 5 of 6Документ70 страницApplied Thermodynamics by Eastop & Mcconkey Part 5 of 6mechanicalengineers100% (1)

- Michel P Introduction To Laserplasma InteractionsДокумент423 страницыMichel P Introduction To Laserplasma InteractionsStrahinja DonicОценок пока нет

- 02 Principles of Gyroscopic InstrumentsДокумент18 страниц02 Principles of Gyroscopic InstrumentsFurkan DuruОценок пока нет

- Thermal History of Our UniverseДокумент2 страницыThermal History of Our Universesuraj devadas shankarОценок пока нет

- Fortinet Antenna Portfolio: Indoor and Outdoor AntennasДокумент11 страницFortinet Antenna Portfolio: Indoor and Outdoor AntennasOrientОценок пока нет