Академический Документы

Профессиональный Документы

Культура Документы

Inter Aud Proc

Загружено:

Anonymous ycFeyuLAtАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Inter Aud Proc

Загружено:

Anonymous ycFeyuLAtАвторское право:

Доступные форматы

SAFETY MANAGEMENT MANUAL

SUNEITA

ISSUER: G.M.B INC

INTERNAL AUDIT PROCEDURES

APPROVEDBY:

PAGE: 1/ 3

DATE: 12/13

1. Purpose

The purpose of this procedure is to set forth guidelines for conducting Internal

Audits on the Safety Management System of the SUNEITA .

2. Scope

This procedure applies to all aspects of the Safety Management System.

3. Responsibility

The Designated Person is responsible for maintaining the Internal Audit schedule

and notifying auditors of their scheduled time to audit. The Safety Management

Representative will recommend the schedule to the Designated Person. Only

individuals who have been trained to conduct internal audits will be assigned.

Each auditor is responsible for following the procedure for auditing and providing

the proper reports. When more than one auditor is assigned, one will be

designated as the lead auditor. The lead auditor is responsible for the entire audit

report.

4. Procedure

A. Audit Scheduling

1. An audit schedule shall be maintained to ensure that an internal audit of

each unit (vessel or office) is conducted at least annually.

2. This schedule shall be developed by the Safety Management

Representative and approved by the Designated Person, and will indicate

the tentative date of the audit, what unit will be audited, what elements of

the ISM Code will be addressed, and the appointed auditor(s).

3. All auditors shall be independent of the area they are assigned to audit.

B. Audit Preparation

1. Prior to the audit, the auditor(s) shall review the pertinent sections of the

Safety Management Manual, Common Procedures, the Vessel

Procedures (if applicable), and any previous audit reports relevant to this

unit.

2. The review shall include any observations made during previous audits, a

follow up to ascertain if any previous nonconformities are still open and

any areas of emphasis set forth by the Designated Person through the

Safety Management Representative.

3. It is recommended that the auditor(s) prepare a list of questions on the

INTERNAL AUDIT CHECKLIST or similar document to

use as a guide to ensure coverage of the subjects to be audited. The

checklist should be kept to a minimum length in keeping with the

objectives and scope of the audit. The checklist may be filled in by hand

NUMBER: SMM 12.1

REVISION: 0

EFFECTIVE DATE:

12/13

PAGE:1/3

SAFETY MANAGEMENT MANUAL

Internal Audit Procedures

or electronically. These shall become a part of the audit record for future

audit guidance.

4. The Safety Management Representative shall coordinate the schedule for

the audit with the assigned auditor(s), with the D.P.A

for the office or with the Master of the vessel to be audited. This

coordination will ensure that the audit does not conflict with operational

commitments of the unit being audited.

5. Any revisions to the schedule shall be reported to and approved by the

Designated Person.

C. Audit Execution

1. After a brief meeting with the D.P.A or Master, the

auditor shall:

a. conduct an opening meeting to outline the scope and objectives of

the audit as well as the methods to be used for carrying out and

reporting the audit.

b. established a schedule for a representative to be available in each

area to be audited.

2. The audit shall be conducted with the minimum interruption of business.

The auditor shall take adequate notes so that findings and observations

may be accurately reported. The audit is intended to confirm the

implementation of the Safety Management System and its effectiveness.

Nonconformities and observations, and the evidence for them, shall be

communicated orally to the auditee as they are established.

3. The auditor(s) must take the time to properly document the findings

obtained during the audit. Notes made in the audit checklists should

support any observations or nonconformities determined.

4. Audit findings shall be recorded in PMS. The auditor shall complete

the nonconformity section in PMS and may complete

the NONCONFORMITY REPORT - CORRECTIVE ACTION

REQUEST (NCCAR) . This form is designed to assist the

internal auditor while conducting the audit. If the NCCAR is used, the

information still needs to be entered into PMS.

5. At the closing meeting, the auditor shall present all nonconformities and

observations to the Ship Operations Manager or Master as applicable,

who shall then sign a printout of each PMS nonconformity or

observation or the NCCAR. This signature is acknowledgment that the

nonconformity or observation has been identified by the auditor and is not

an admission of wrongdoing.

NUMBER: SMM 12.1

REVISION: 0

EFFECTIVE DATE:

12/13

PAGE:2/3

SAFETY MANAGEMENT MANUAL

Internal Audit Procedures

D. Audit Report

1. The audit report in the PMS system is the responsibility of the lead

auditor to enter. To assist in the preparation of the audit report, the

auditor may write a brief summary report on INTERNAL AUDIT REPORT

form

2. The audit report shall include:

a. The list of nonconformities by number with a brief summary

b. All observations noted by the auditor

i. All nonconformities and observations shall specifically refer to

the appropriate section of the ISM Code and/or SMM.

ii. All nonconformities and observations shall be number using the

following system:

NC# - ISM Section NC Letter

5. The completed audit checklist and nonconformity reports shall become the

supporting documentation for the Audit Report. It is considered an

important tool in the formulation of the next audit.

6. The Audit Report and supporting documents shall be filed in the Safety

Management System files maintained in the Port Office.

7. A formal audit report shall be submitted through PMS within two weeks

of the audit completion. This is the official record and must be completed.

E. Follow-Up Action

1. All Nonconformities documented as a result of an Internal Audit shall be

subject to tracking and follow-up activities in accordance with SMM .

5. RECORDS

The audit checklists and audit reports are considered Safety Management

System records and shall be retained and readily available for future audits.

NUMBER: SMM 12.1

REVISION: 0

EFFECTIVE DATE 12/13

PAGE:3/3

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- A Piece of Blue SkyДокумент508 страницA Piece of Blue Skymadhusri002100% (1)

- ISO Audit ChecklistДокумент21 страницаISO Audit Checklistghostghost12380% (5)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- HCOPL 650307-1RB Suppressive Acts Suppression of Scientology and ScientologistsДокумент15 страницHCOPL 650307-1RB Suppressive Acts Suppression of Scientology and ScientologistsClassIVauditorОценок пока нет

- Atack, Jon - A Piece of Blue Sky - Scientology, Dianetics and L. Ron Hubbard ExposedДокумент472 страницыAtack, Jon - A Piece of Blue Sky - Scientology, Dianetics and L. Ron Hubbard ExposedAmmo Alamo100% (1)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- How To Perform An Internal Audit Using ISO 19011 ENДокумент11 страницHow To Perform An Internal Audit Using ISO 19011 ENIslam Way100% (5)

- Audit Handbook 01-Dec-09 Doc MCДокумент47 страницAudit Handbook 01-Dec-09 Doc MCAgus Mulyadi100% (1)

- Catholic HymnalДокумент226 страницCatholic HymnalAnonymous ycFeyuLAt100% (3)

- Catholic HymnalДокумент226 страницCatholic HymnalAnonymous ycFeyuLAt100% (3)

- Hydrostatic ParticularsДокумент16 страницHydrostatic ParticularsAnonymous ycFeyuLAtОценок пока нет

- Good Maintenance On Board Ships E2017Документ94 страницыGood Maintenance On Board Ships E2017criОценок пока нет

- Workers Compensation Audit ChecklistДокумент2 страницыWorkers Compensation Audit Checklistapi-504443207Оценок пока нет

- Barge Insurance FormДокумент12 страницBarge Insurance FormAnonymous ycFeyuLAtОценок пока нет

- ISO 13485 Implementation: Project Manager's GuideДокумент19 страницISO 13485 Implementation: Project Manager's GuideCarlos LucioОценок пока нет

- Cyber Security Plan TemplateДокумент58 страницCyber Security Plan TemplateAnonymous ycFeyuLAtОценок пока нет

- International Scientology News 27 (17-27) PDFДокумент12 страницInternational Scientology News 27 (17-27) PDFCaroline Letkeman100% (1)

- Planned Maintainece System For ShipsДокумент22 страницыPlanned Maintainece System For ShipsHarshad TallurОценок пока нет

- The Road To Xenu: A Narrative Account of Life in ScientologyДокумент93 страницыThe Road To Xenu: A Narrative Account of Life in ScientologyHura OptymizmОценок пока нет

- Tug Insurance Survey FormДокумент15 страницTug Insurance Survey FormAnonymous ycFeyuLAtОценок пока нет

- CISA Combined PDFДокумент264 страницыCISA Combined PDFshakti9667100% (1)

- Sea Trial ProceduresДокумент24 страницыSea Trial ProceduresAnonymous ycFeyuLAtОценок пока нет

- Iso IATF 16949 Upgrade Planner and Delta ChecklistДокумент14 страницIso IATF 16949 Upgrade Planner and Delta ChecklistHomero Januncio100% (1)

- Cargo Ship Safety Construction Certificate NewДокумент6 страницCargo Ship Safety Construction Certificate NewAnonymous ycFeyuLAtОценок пока нет

- Ballast Water Management ManualДокумент226 страницBallast Water Management ManualAnonymous ycFeyuLAtОценок пока нет

- 12.2 ISM Internal AuditingДокумент3 страницы12.2 ISM Internal Auditingsimon_midjajaОценок пока нет

- Meteorology: Background ConceptsДокумент98 страницMeteorology: Background ConceptsPuja Kadam Ghadi100% (1)

- Sop-Ad-01 - Internal AuditДокумент6 страницSop-Ad-01 - Internal Auditapi-278193171Оценок пока нет

- Fast Wil Declaration of OwnershipДокумент1 страницаFast Wil Declaration of OwnershipAnonymous ycFeyuLAtОценок пока нет

- CERTДокумент1 страницаCERTAnonymous ycFeyuLAtОценок пока нет

- Load Line Certificate Guyana: BSL B#2Документ4 страницыLoad Line Certificate Guyana: BSL B#2Anonymous ycFeyuLAtОценок пока нет

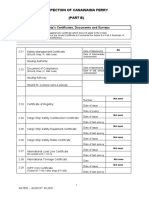

- Inspection of Canawaima Ferry (Part B) : 2.0 Ship's Certificates, Documents and SurveysДокумент23 страницыInspection of Canawaima Ferry (Part B) : 2.0 Ship's Certificates, Documents and SurveysAnonymous ycFeyuLAtОценок пока нет

- Guyana Tonnage Certificate Guyana: BSL B #2Документ2 страницыGuyana Tonnage Certificate Guyana: BSL B #2Anonymous ycFeyuLAtОценок пока нет

- Certificate of Test and Examination of Derricks and CranesДокумент2 страницыCertificate of Test and Examination of Derricks and CranesAnonymous ycFeyuLAtОценок пока нет

- Boatmaster's SyllabusДокумент15 страницBoatmaster's SyllabusAnonymous ycFeyuLAtОценок пока нет

- Cargo Ship Safety CertДокумент12 страницCargo Ship Safety CertAnonymous ycFeyuLAtОценок пока нет

- SCV Code July 2017Документ181 страницаSCV Code July 2017Knowledge CityОценок пока нет

- Lady Chandra Conditional Survey ReportДокумент2 страницыLady Chandra Conditional Survey ReportAnonymous ycFeyuLAtОценок пока нет

- Cargo Fule Calculation P6Документ2 страницыCargo Fule Calculation P6Anonymous ycFeyuLAtОценок пока нет

- Aroiama 11 ReportДокумент5 страницAroiama 11 ReportAnonymous ycFeyuLAtОценок пока нет

- Holy Week PDFДокумент15 страницHoly Week PDFAnonymous ycFeyuLAtОценок пока нет

- Cargo Ship Safety CertДокумент12 страницCargo Ship Safety CertAnonymous ycFeyuLAtОценок пока нет

- Sudden ListДокумент23 страницыSudden ListnishadyadavОценок пока нет

- Fire Booklt PT 1Документ36 страницFire Booklt PT 1Anonymous ycFeyuLAtОценок пока нет

- Engine Room Fire PlanДокумент1 страницаEngine Room Fire PlanAnonymous ycFeyuLAtОценок пока нет

- Canawaima ReportДокумент13 страницCanawaima ReportAnonymous ycFeyuLAtОценок пока нет

- Am 03Документ54 страницыAm 03WilsonОценок пока нет

- BRC Global Standard For Food Safety - Audit Duration CalculatorДокумент5 страницBRC Global Standard For Food Safety - Audit Duration CalculatorDavidHernandezОценок пока нет

- Prozess Gegen Scientology in Belgien - Artikel 1 Bis 35 Von Jonny JacobsenДокумент157 страницProzess Gegen Scientology in Belgien - Artikel 1 Bis 35 Von Jonny JacobsenWilfried Handl100% (1)

- Tesco PIU Guidelines On The Audit Process For Sites Supplying TescoДокумент7 страницTesco PIU Guidelines On The Audit Process For Sites Supplying TescoGourav TailorОценок пока нет

- Nasa GB A301Документ18 страницNasa GB A301watziznehmОценок пока нет

- Audit HH Australia PDFДокумент63 страницыAudit HH Australia PDFppiОценок пока нет

- The Social Psychology of IT Security Auditing From The Auditee's Vantage Point: Avoiding Cognitive DissonanceДокумент4 страницыThe Social Psychology of IT Security Auditing From The Auditee's Vantage Point: Avoiding Cognitive DissonancejbascribdОценок пока нет

- AuditPracticeManual CleanДокумент467 страницAuditPracticeManual Cleanghulam hussainОценок пока нет

- IMEC Program Order 375, An LRH ED 339R ImplementatiДокумент52 страницыIMEC Program Order 375, An LRH ED 339R ImplementatiFlibberdygibberОценок пока нет

- Risk-Based Auditing, Strategic Prompts and Auditor Sensitivity To The Strategic Risk of FraudДокумент56 страницRisk-Based Auditing, Strategic Prompts and Auditor Sensitivity To The Strategic Risk of FraudJuliana MaisyaraОценок пока нет

- Codigo de Conducta CostcoДокумент3 страницыCodigo de Conducta CostcoElmer Fernando Poma CanoОценок пока нет

- SM 17 NewДокумент40 страницSM 17 NewthenikkitrОценок пока нет

- Iso 9001 Internal Auditor TrainingДокумент2 страницыIso 9001 Internal Auditor TrainingMohamed ShabirОценок пока нет

- Scientology: Inside The "Flag Building"Документ2 страницыScientology: Inside The "Flag Building"Research GuyОценок пока нет

- At 5907 Pre EngagementДокумент5 страницAt 5907 Pre EngagementTyrelle Dela CruzОценок пока нет

- 0B Implemenation GuideДокумент71 страница0B Implemenation GuideSHAURYA TIWARIОценок пока нет