Академический Документы

Профессиональный Документы

Культура Документы

Ijmet 06 10 009

Загружено:

IAEME PublicationОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ijmet 06 10 009

Загружено:

IAEME PublicationАвторское право:

Доступные форматы

International Journal of Mechanical Engineering and Technology (IJMET)

Volume 6, Issue 10, Oct 2015, pp. 66-77, Article ID: IJMET_06_10_009

Available online at

http://www.iaeme.com/IJMET/issues.asp?JType=IJMET&VType=6&IType=10

ISSN Print: 0976-6340 and ISSN Online: 0976-6359

IAEME Publication

ANALYSIS OF PERFORMANCE AND

EMISSION CHARACTERISTICS OF A

DIESEL ENGINE FUELLED WITH

BIODIESEL

R. Sundara Raman

Assistant Professor Mechanical Engineering,

Indian Naval Academy, Ezhimala- 670 310

Dr. G. Sankara Narayanan

Dean- PG Studies & Research,

Sree Sastha Institute of Engineering and Technology,

Chembarambakkam, Chennai

Dr. N. Manoharan

Director- Research, AMET University, Chennai

1. ABSTRACT

The rapid depletion in world petroleum reserves and uncertainty in

petroleum supply due to political and economical reasons along with the

sharp escalation in the petroleum prices have simulated the search for

alternatives to petroleum based fuels especially diesel and gasoline.

Moreover, bulks of petroleum fuels are being consumed by agriculture and

transport sector for which diesel engine happens to be the prime mover.

Though there are wide varieties of alternative fuels available the research has

not yet provided the right renewable fuel to replace diesel. Vegetable oil due

to their properties being close to diesel fuel may be a promising alternative for

diesel engines. Due to their high viscosity, they cannot be directly used in a

diesel engine. Transesterification is one method by which viscosity could be

drastically reduced and the fuel could be adopted for use in diesel engine.

Present investigation focuses on use of Rice Bran Oil in Diesel engine.

Performance and exhaust emission characteristics of the engine have been

evaluated. Esterified Rice Bran Oil has exhibited performance very close to

that of diesel fuel. In the present work it is observed that, the NOX and

unburned hydrocarbon emission decreases and carbon monoxide, particulate

emission and smoke intensity increases with the use of biodiesel in diesel

engine. When compared to non-esterified Rice Bran Oil, esterified Rice Bran

Oil emits less smoke and therefore be regarded as an environment friendly

fuel.

http://www.iaeme.com/IJMET/index.asp

66

editor@iaeme.com

R. Sundara Raman, Dr. G. Sankara Narayanan and Dr. N. Manoharan

Cite this Article: R. Sundara Raman, Dr. G. Sankara Narayanan and Dr. N.

Manoharan, Analysis of Performance and Emission Characteristics of A

Diesel Engine Fuelled with Biodiesel, International Journal of Mechanical

Engineering and Technology, 6(10), 2015, pp. 66-77.

http://www.iaeme.com/currentissue.asp?JType=IJMET&VType=6&IType=10

2. INTRODUCTION

Efficient use of natural resources is one of the fundamental requirements for any

country to become self sustainable. Both in organized and unorganized sectors

Internal Combustion Engine has become an indispensable prime mover. Fast

depletion of fossil fuels is demanding an urgent need to carry out research to find

viable alternative fuels.

Thermodynamic tests based on engine performance evaluations have established

the feasibility of using a variety of alternative fuels such as hydrogen, CNG, alcohols,

biogas, producer gas and a host of vegetable oils. To increase foreign exchequers and

contribute towards protection of earth from the threat of environmental degradation,

biofuels can be a good alternative for diesel in most of the developing countries. The

fuels of bioorigin may be alcohols, edible and non-edible vegetable oils, biomass,

biogas etc., Some of these fuels can be used directly while others need to be

formulated to bring the relevant properties close to conventional fuels.

3. VEGETABLE OILS

Vegetable oil based fuels can be utilised as diesel alternatives for Diesel engines.

Research work has revealed that the use of untreated vegetable oils in diesel engines

has created problems such as injector fouling, lubricating oil dilution and other kinds

of troubles. Vegetable oils are a mixture of organic compounds ranging from simple

straight chain compounds to complex structure of proteins and fat soluble vitamins.

Some inorganic compounds of heavy metals are also present. Vegetable oils have

perceptible amount of nitrogen and sulphur which may affect emission spectra. Most

of them are not only simple aromats containing hydrogen and carbon but also belong

to the turbine class.

The chain length of fatty acids is inversely proportional to the thermal efficiency

except at very small chain length. Proportion and the location of double bonds also

affect the cetane number. On a volume basis, heat content of vegetable oils is almost

comparable to diesel oil owing to greater densities it has. Heat value decreases with

increasing unsaturation as a result of fewer hydrogen atoms and decreases with

increasing saponification number.

Vegetable oils have the following advantages over diesel oil:

They are easily handled liquid fuels with properties close to those of diesel oil in

many respects

They are a renewable source of energy.

They mix easily with diesel oil. Hence they can be used in the blended form also.

They can be produced in rural areas by well known agriculture practices. The

extraction of the oil from the plant seeds is a relatively simple process which can also

be carried out in rural areas.

Vegetable oils cannot be a substitute for petrol because of their high viscosity and

poor volatility.

http://www.iaeme.com/IJMET/index.asp

67

editor@iaeme.com

Analysis of Performance and Emission Characteristics of A Diesel Engine Fuelled with

Biodiesel

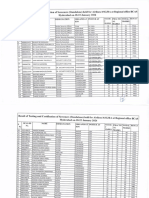

Some of the vegetable oil properties are given in the Table 1.1.

4. PROBLEMS WITH VEGETABLE OILS:

The problems encountered during engine tests with vegetable oils were studied and

classified into two groups.

Operation Problems

Durability Problems

The operation problems were carbon deposits on injector, carbon deposits on piston

and rings and also gum formation.

In order to reduce viscosity of vegetable oils, heating of oils has been tried out.

Heating the oils however, transfers its spray characteristics more like diesel oil.

Conversion of the vegetable oil to the simple esters of methyl and ethyl alcohols is

called as biodiesel (ester) and it is a possible way to overcome almost all the problems

associated with the vegetable oils, including the crank case polymerization problems.

Effect of injection pressure has been investigated to use of vegetable oil in diesel

engine and concluded that this injection pressure could improve the performance and

suggested that the endurance testing of the engine was essential with regards to the

checking of gum formation in the combustion chamber.

Table 1.1 Fuel Properties of Vegetable Oil

Sl.No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

Vegetable

Oil

Castor

Corn

Cotton Seed

Crambe

Linseed

Peanut

Rapeseed

Safflower

H.O.

Safflower

Sesame

Soyabean

Sunflower

#2 Diesel

Viscosity

at 38C

mm2/C

29.7

34.9

35.5

53.6

27.2

39.6

37.0

31.3

0.9537

0.9095

0.9148

0.9044

0.9236

0.9026

0.9115

0.9144

Flash

Point

C

260

277

234

274

241

241

246

260

Cloud

Point

C

-1.1

1.7

10.0

1.7

12.8

-3.9

18.3

Pour

Point

C

-31.7

-40.0

-15.0

-12.2

-15.0

-6.7

-31.7

-6.7

Carbon

Residue

% Wt.

0.22

0.24

0.24

0.23

0.22

0.24

0.30

0.25

39516

0.9021

293

-12.2

-20.6

0.24

39349

39623

39575

43000

0.9133

0.9138

0.9161

0.8400

260

254

274

52

-3.9

-3.9

7.2

-15.0

-9.4

-12.2

-15.0

-33.0

0.25

0.27

0.23

20.35

42.3

37.6

41.8

44.6

34.6

41.8

37.6

41.3

Calorific

Value

KJ/Kg

37274

39500

39468

40482

39307

39782

39709

39519

41.2

49.2

35.5

32.6

33.9

2.7

40.2

37.9

37.1

47

Cetane

No.

Density

Kg/L

5. BIO-DIESEL

Vegetable oil is converted into glycerol and ester of vegetable oil by method of

Transesterification. This vegetable ester is also called as Biodiesel. Its viscosity is

drastically reduced when compared with vegetable oil and its properties come down

comparable with diesel. In this present work Rice Bran Oil Ester (Biodiesel) has been

taken and used as fuel in diesel engine.

http://www.iaeme.com/IJMET/index.asp

68

editor@iaeme.com

R. Sundara Raman, Dr. G. Sankara Narayanan and Dr. N. Manoharan

6. TRANSESTERIFICATION

Ethyl esters of vegetable oils were obtained by Transesterification and found that

viscosities of esters were less when compared to pure vegetable oils and hence the

engine has performed better with little higher smoke emissions. It is suggested that

optimized injection timing could reduce the smoke emissions for esters.

Preparation of esterified vegetable oil was reported and observed that

esterification has the effect of increasing the volatility and decreasing the viscosity of

the oil, making it close to the characteristics of diesel fuel. Use of linseed oil esters

has been tried out in a Diesel Engine and was found that there was a substantial

decrease in exhaust smoke density for lower concentrations of ester in blends and

observed that the fuel itself acts as a lubricant and thus the chance of wearing out gets

substantially reduced.

7. EXPERIMENTAL SET-UP

The experimental setup consists of an engine, hydraulic dynamometer, measuring

equipments for emission like NOx analyzer, smoke meter, CO and HC analyzer,

tachometer for speed measurement, Nickel- Chromium thermocouple for temperature

measurement and noise level meter for noise measurement.

8. SCHEMATIC OF THE EXPERIMENTAL SET-UP

http://www.iaeme.com/IJMET/index.asp

69

editor@iaeme.com

Analysis of Performance and Emission Characteristics of A Diesel Engine Fuelled with

Biodiesel

1. Test Engine

2. Dynamometer

3. Dynamometer panel

4. Fuel Tank

5. Fuel Burette

6. Air Filter

7.NO Analyser

8.CO/HC Analyser

9.Silencer

10.Exhaust Gas Temperature Indicator

Smoke

12.Engine Test Bed

9. VISCOSITY REDUCTION TECHNIQUES:

High viscosity of vegetable oils has been reported by almost all researchers as the

major bottleneck in their use as fuel. To overcome this problem, various techniques

have been successfully tried and the advances in this area are summarised below.

9.1. PREHEATING

Since high viscosity is a major problem with vegetable oils, one possible solution is to

heat the oils in order to reduce their viscosity or to heat the intake air in order to

accelerate the evaporation of the vegetable oil in the engine.

In the present work, the engine was operated with 100oC preheated fuel. The

tested vegetable oil was heated by electrical power.

The oil viscosity was determined by using a redwood viscometer and density of

the oil was calculated by a hydrometer.

9.2. DILUTION

Dilution refers to mixing of vegetable oil with other low viscosity fuels like diesel,

alcohol and others and it results in the reduction of the viscosity of the blends and in

the increase of the cetane number.

9.3. MICROEMULSIFICATION

Microemulsification is a system consisting of a liquid dispersed in an immiscible

liquid usually in droplets larger than colloidal size. The droplet size varying from 0.01

to 0.2 pm are generally considered as micro emulsions.

Micro emulsion conversion required no chemical reaction and tends to be rapid.

These are transparent and thermodynamically stable colloidal dispersions. Micro

emulsion formation depends upon interactions among molecules of constituents.

9.4. TRANSESTERIFICATION

It is the process of reacting a triglyceride with ethyl alcohol in the presence of a

catalyst like sodium hydroxide to produce glycerol and fatty acid esters. Temperature,

catalyst type and concentration ratio of alcohol to fuel and stirring rate influences the

esterification process to greater extent.

10. RESULTS AND DISCUSSION:

The performance of the engine and emission parameters of the engine with Diesel,

Raw Rice Bran Oil, Preheated Rice Bran Oil and Rice Bran Oil Ester (Biodiesel) are

presented and discussed below. The performance characteristics of the engine are

studied and compared with those obtained for the engine fitted with the particulate

trap and with an ordinary muffler.

http://www.iaeme.com/IJMET/index.asp

70

editor@iaeme.com

R. Sundara Raman, Dr. G. Sankara Narayanan and Dr. N. Manoharan

10.1. BRAKE SPECIFIC FUEL CONSUMPTION

The variation of brake specific fuel consumption with respect to brake power is

shown in Fig. 10.1 The specific fuel consumption of Rice Bran Oil ester is 0.357

kg/kW hr. at full load condition and 0.334 kg/kW hr. for diesel. The specific fuel

consumption of Rice Bran Oil Ester is higher compared to diesel but it is lower

compared to Raw Rice Bran Oil and Preheated Rice Bran Oil. This is probably due to

the low volatility, slightly higher viscosity and high density of the Rice Bran Oil Ester

which affects mixture formation of the fuel and thus leads to slow combustion.

102. BRAKE THERMAL EFFICIENCY

The variation of brake thermal efficiency with respect to brake power is shown in

10.2. The brake thermal efficiency of Rice Bran Oil Ester is slightly lower compared

to diesel operation. This is because of high viscosity, low volatility and high density

of the ester which affects atomization of the fuel and thus leads to poor combustion.

The maximum thermal efficiency of the Rice Bran Oil Ester is about 24.4%, where as

it is 20.44% for diesel. The Brake Thermal Efficiency of Raw Rice Bran Oil and

Preheated Rice Bran Oil are comparatively low with Rice Bran Oil Ester.

10.3. EXHAUST GAS TEMPERATURE

The variation of exhaust gas temperature with respect to brake power is shown in

Figure 10.3. Exhaust gas temperature is slightly higher when the load rises and it is

higher for ester than diesel at high loads. However, exhaust gas temperature of the

ester is lower compared to Raw Rice Bran Oil and Preheated Rice Bran Oil. Due to

incomplete combustion of the injected fuel and part of combustion extending into the

exhaust stroke there is a slight increase in exhaust gas temperature with Rice Bran Oil

and its ester compared to diesel operation. The maximum temperature of exhaust gas

at full load is 483oC for Rice Bran Oil Ester and 465oC for diesel.

10.4. CO EMISSION

The variation of CO emission with respect to brake power is shown in Fig. 10.4. The

CO emission of the Rice Bran Oil Ester is 0.62% volume at full load and 0.48%

volume for diesel. The CO emission of Rice Bran Oil Ester is high compared to diesel

operation. This is probably due to the use of richer mixture with ester due to lowered

thermal efficiency. At the same time CO emission of Raw Rice Bran Oil and

Preheated Rice Bran Oil is higher than ester.

10.5. HC EMISSION

Fig. 10.5 shows the variation of HC emission with respect to Brake power. Unburned

Hydrocarbon emission of Rice Bran Oil Ester is low compared to diesel and other

fuels. At full load condition, HC emission is 75 ppm for Rice Bran Oil Ester and 125

ppm for diesel.

10.6. NOX CONCENTRATION

The variation of NOx concentration with respect to brake power is shown in Fig. 10.6.

At full load condition NOx concentration is 330 ppm for biodiesel and 420 ppm for

diesel. The NOx concentration of Rice Bran Oil Ester, Raw Rice Bran Oil and

Preheated Rice Bran Oil are comparatively low to diesel operation. This is because

Rice Bran Oil and its ester gives a lower peak pressure compared to diesel operation.

Temperature is one of the major reasons for NOx formation.

http://www.iaeme.com/IJMET/index.asp

71

editor@iaeme.com

Analysis of Performance and Emission Characteristics of A Diesel Engine Fuelled with

Biodiesel

10.7. SMOKE INTENSITY

The variation of smoke intensity with respect to brake power is shown in Fig. 10.7.

The smoke intensity of Rice Bran Oil Ester is 4.2 BSU at full load and 3.5 BSU for

diesel. Rice Bran Oil Ester operation smoke intensity is increased at higher loads.

This may be due to the higher viscosity and density of the ester that leads to poor

vaporization and slow combustion of the injected fuel. When the highly viscous Rice

Bran Oil is injected, the atomization of fuel is poor leading to larger droplets and less

air entrainment resulting in inefficient combustion. This leads to higher smoke

emission with Rice Bran Oil Ester. However, Raw Rice Bran Oil smoke intensity is

higher compared to Rice Bran Oil Ester. This may be due to the higher viscosity and

density of the Raw Rice Bran Oil.

10.8. PARTICULATE EMISSION

The variation of particulate emission with brake power is shown in Fig. 10.8. The

particulate emission of the Rice Bran Oil Ester is higher compared to diesel operation.

This may be due to their incomplete combustion. At full load condition particulate

emission is 5.36 g/hr for Rice Bran Oil and 4.52 g/hr for diesel.

http://www.iaeme.com/IJMET/index.asp

72

editor@iaeme.com

R. Sundara Raman, Dr. G. Sankara Narayanan and Dr. N. Manoharan

http://www.iaeme.com/IJMET/index.asp

73

editor@iaeme.com

Analysis of Performance and Emission Characteristics of A Diesel Engine Fuelled with

Biodiesel

http://www.iaeme.com/IJMET/index.asp

74

editor@iaeme.com

R. Sundara Raman, Dr. G. Sankara Narayanan and Dr. N. Manoharan

http://www.iaeme.com/IJMET/index.asp

75

editor@iaeme.com

Analysis of Performance and Emission Characteristics of A Diesel Engine Fuelled with

Biodiesel

11. CONCLUSIONS

Experiments were conducted on a single cylinder, water cooled DI diesel engine using

Diesel, Raw Rice Bran Oil, Preheated Rice Bran Oil and Biodiesel (Rice Bran Oil

Ester) and the following conclusions are made based on the experimental results.

Engine works smoothly on biodiesel with performance comparable to diesel

operation.

Brake Specific Fuel Consumption of engine with biodiesel is increased by 6.44%

from that of diesel.

Break thermal efficiency of engine with biodiesel is reduced by 3.96% from that of

diesel.

The exhaust gas temperature with diesel is 465oC and for biodiesel it is increased to

483oC at full load conditions.

Unburned hydrocarbon emission is significantly reduced with biodiesel. The

percentage decrease in unburned hydrocarbon with biodiesel is 47% from that of

diesel.

Carbon monoxide emission with biodiesel is 0.62% by volume which is higher than

that of diesel whose Carbon monoxide emission is 0.48% by volume. When

compared to diesel, NOx emission is reduced by 16.6% with biodiesel.

The smoke emission of biodiesel is 15.3% higher than that of diesel.

In particulate emission, the biodiesel is inferior to diesel, the emission increases by

14.3%.

Of the whole it is concluded that the Rice Bran Oil Ester (Biodiesel) will be a

good alternative fuel for the diesel engine.

http://www.iaeme.com/IJMET/index.asp

76

editor@iaeme.com

R. Sundara Raman, Dr. G. Sankara Narayanan and Dr. N. Manoharan

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

John W. Goodrum, S. Edward Law (2012) Rheological properties of Peanut OilDiesel Fuel Blends, ASAE Transactions paper, p.p.897-900.

Goering C.E., A.W. Schwab, M.J. Daugherty, E.H.Pryde, A.J.Heakin (2013) Fuel

properties of Eleven Vegetable Oils, ASAE Transactions paper, p.p.1472-1483.

Bhattacharyaa S., C.S. Reddy (2014) Vegetable oils as fuels for Internal

Combustion Engines: A Review, Silsoe Research Institute Transaction paper,

p.p.157-165.

Prasad C.M.V., M.V.S.M. Krishna, C.P. Reddy and K.R. Mohan (2013)

Performance evaluation of non-edible vegetable oils as substitute fuels in low

heat rejection diesel engines, Proceedings of the Institution of Mechanical

Engineers, 214(D2), p.p.181-187.

Seppo A. Niemi, Petri E.Illikainen, Mika, L.K. Makinen, Vaino, O.K. Laiho

(2013) Performance and Exhaust Emissions of a Tractor Engine using Mustard

seed oil as fuel. SAE Transaction paper, p.p.21-32.

Kenton R. Kaufman, George L.Pratt, Mariusz Ziejewski Hans J. Goettler (2013)

Fuel injection anomalies observed during Long-term Engine Performance Tests

on Alternate Fuels, SAE Transaction paper, p.p.591-601.

Needham J.R. and D.M. Doyle (2013) the combustion and Ignition Quality of

Alternative Fuels in Light Duty Diesel Engine. SAE Transaction paper, p.p.651671.

Dennis L. Siebers. (2012) Ignition Delay characteristics of Alternative Diesel

Fuels: Implications on cetane number, SAE Transaction paper, p.p.673-686.

Bernard Freedman, Marvin O. Bagby, Timothy J. Callahan and Thomas W. Ryan

III (2014) Cetane Numbers of fatty esters, Fatty alcohols and Triglycerides

determined in a constant volume combustion Bomb, SAE Transaction paper,

p.p.153-161.

Chavan Dk, Maheshwari Sanchit, Patil Gaurav, Sawant Ajinkya and Wani

Paritosh, Design and Analysis of An Air Cooled Radiator For Diesel Engine with

Hydrostatic Transmission For A Special Purpose Vehicle, International Journal

of Mechanical Engineering and Technology, 5(4), 2014, pp. 138 - 146.

Mohd Muqeem and Dr. Manoj Kumar, Design of An Intercooler of A

Turbocharger Unit To Enhance The Volumetric Efficiency of Diesel Engine,

International Journal of Mechanical Engineering and Technology, 4(3), 2013,

pp. 1 - 10.

Rajinder Kumar Soni and Pranat Pal Dubey, Diesel Engine Air Swirl

Mesurements Using AVL Test RIG, International Journal of Mechanical

Engineering and Technology, 4(1), 2013, pp. 79 - 91.

http://www.iaeme.com/IJMET/index.asp

77

editor@iaeme.com

Вам также может понравиться

- 5 Ijmperddec20185Документ12 страниц5 Ijmperddec20185TJPRC PublicationsОценок пока нет

- Performance and Emission Characteristics of CI Engine With Methyl Esters of Palm Stearin Under Varying Compression Ratios and Fuel Injection PressuresДокумент9 страницPerformance and Emission Characteristics of CI Engine With Methyl Esters of Palm Stearin Under Varying Compression Ratios and Fuel Injection PressuresT Hari PrasadОценок пока нет

- 1 PDFДокумент10 страниц1 PDFSomnath SwamyОценок пока нет

- Performance and Emission Characteristics of A CI Engine Fueled With Diesel-Waste Fried Oil Blend With Dee As AdditiveДокумент21 страницаPerformance and Emission Characteristics of A CI Engine Fueled With Diesel-Waste Fried Oil Blend With Dee As AdditiveLOKESHОценок пока нет

- FileserveДокумент9 страницFileserveCao Đào NamОценок пока нет

- A Technical Seminar ON: "Bio Diesel and Its Importance"Документ18 страницA Technical Seminar ON: "Bio Diesel and Its Importance"Dhinesh GanesanОценок пока нет

- Experimental Studies On The Combustion and Emission Characteristics of A Diesel Engine Fuelled With Used Cooking Oil Methyl Ester and Its Diesel BlendsДокумент7 страницExperimental Studies On The Combustion and Emission Characteristics of A Diesel Engine Fuelled With Used Cooking Oil Methyl Ester and Its Diesel BlendsAshokОценок пока нет

- v4 2 11Документ7 страницv4 2 11api-19662887Оценок пока нет

- Venkatesh and BhaghaviДокумент10 страницVenkatesh and BhaghavilarryОценок пока нет

- Experimental Analysis of Engine Performance and Combustion Characteristics Using Dual Biodiesel BlendsДокумент7 страницExperimental Analysis of Engine Performance and Combustion Characteristics Using Dual Biodiesel BlendsMadhurjya SaikiaОценок пока нет

- 95-f30032بيرلوسس مهم جدااДокумент6 страниц95-f30032بيرلوسس مهم جدااmohamed aliОценок пока нет

- The Effect and Comparison of Biodiesel-Diesel Fuel On Crankcase Oil, Diesel Engine Performance and EmissionsДокумент7 страницThe Effect and Comparison of Biodiesel-Diesel Fuel On Crankcase Oil, Diesel Engine Performance and EmissionsMinim AllОценок пока нет

- Performance and Evaluation of Pongamia (Karanj) Oil As An Alternative Fuel For Surface TransportationДокумент7 страницPerformance and Evaluation of Pongamia (Karanj) Oil As An Alternative Fuel For Surface Transportationrahuldbajaj2011Оценок пока нет

- Diesel From Tyres Paper PDFДокумент17 страницDiesel From Tyres Paper PDFsatyjes7537Оценок пока нет

- Effect of Supercharging On Engine PerformanceДокумент13 страницEffect of Supercharging On Engine PerformanceanshurathoreОценок пока нет

- 13 Turbocharged Engine Paper - SCOPUSДокумент8 страниц13 Turbocharged Engine Paper - SCOPUSProf. Ravi ShankarОценок пока нет

- Experimental Investigation of Lubricating Properties of Engine OilДокумент4 страницыExperimental Investigation of Lubricating Properties of Engine OilAnthony CamarenaОценок пока нет

- IJERTV2IS90078Документ8 страницIJERTV2IS90078rvsrmechОценок пока нет

- Performance, Emission Chars BiodieselДокумент10 страницPerformance, Emission Chars BiodieselBragadish BragsОценок пока нет

- Performance and Emission Analysis of DI Diesel Engine Fuelled With Methyl Esters of Beef Tallow and Diesel BlendsДокумент17 страницPerformance and Emission Analysis of DI Diesel Engine Fuelled With Methyl Esters of Beef Tallow and Diesel BlendsM tejaswiniОценок пока нет

- Energies: Performance and Combustion Characteristics Analysis of Multi-Cylinder CI Engine Using Essential Oil BlendsДокумент15 страницEnergies: Performance and Combustion Characteristics Analysis of Multi-Cylinder CI Engine Using Essential Oil BlendsSuara Kabir AdewaleОценок пока нет

- Ijmet 08 06 010 PDFДокумент11 страницIjmet 08 06 010 PDFLatifah HanumОценок пока нет

- Welcome To International Journal of Engineering Research and Development (IJERD)Документ13 страницWelcome To International Journal of Engineering Research and Development (IJERD)IJERDОценок пока нет

- Cottonseed Trimethylolpropane (TMP) Ester As Lubricant and Performance Characteristics For Diesel EngineДокумент8 страницCottonseed Trimethylolpropane (TMP) Ester As Lubricant and Performance Characteristics For Diesel Engineelias chernetОценок пока нет

- Performance Combustion and Emission Characteristics On DI Diesel Engine Using Bio AdditiveДокумент6 страницPerformance Combustion and Emission Characteristics On DI Diesel Engine Using Bio AdditiveSetiyo WibisonoОценок пока нет

- Conversão de Nergia 2Документ6 страницConversão de Nergia 2Ricardo PereiraОценок пока нет

- Performance Characteristics of A Low Heat Rejection Diesel Engine Operating With BiodieselДокумент7 страницPerformance Characteristics of A Low Heat Rejection Diesel Engine Operating With BiodieselbalakaleesОценок пока нет

- 12.PSEP-Elsevier - Recent Published ArticleДокумент9 страниц12.PSEP-Elsevier - Recent Published ArticleYUVARAJAN DОценок пока нет

- Deepak Agarwal2Документ10 страницDeepak Agarwal2Vaibhav MoonОценок пока нет

- A Comparative Study On Anchovy Fish Oil, Anchovy Fish Oil Methyl Ester and Diesel Fuels in A Diesel EngineДокумент11 страницA Comparative Study On Anchovy Fish Oil, Anchovy Fish Oil Methyl Ester and Diesel Fuels in A Diesel EngineNoah Cajurao IIОценок пока нет

- Investigations Into Emmission Charecterestics of LHR Engine Using Palm Stearn Methyl Ester Oil With A Modified Piston GeometryДокумент5 страницInvestigations Into Emmission Charecterestics of LHR Engine Using Palm Stearn Methyl Ester Oil With A Modified Piston GeometryInternational Journal of Application or Innovation in Engineering & ManagementОценок пока нет

- Ijmet 10 01 014Документ10 страницIjmet 10 01 014IAEME PUBLICATIONОценок пока нет

- The Performance and Emissions of A Diesel Engine Fueled With Biodiesel From Yellow Grease and Soybean OilДокумент17 страницThe Performance and Emissions of A Diesel Engine Fueled With Biodiesel From Yellow Grease and Soybean OilSmith SteinОценок пока нет

- Performance Evaluation of Rice Brawn Oil in Low Grade Low Heat Rejection Diesel EngineДокумент12 страницPerformance Evaluation of Rice Brawn Oil in Low Grade Low Heat Rejection Diesel EngineresearchinventyОценок пока нет

- Applied Energy: K. Muralidharan, D. VasudevanДокумент10 страницApplied Energy: K. Muralidharan, D. VasudevanSubhadip DasОценок пока нет

- Artificial Neural Network Optimization Modeling OnДокумент16 страницArtificial Neural Network Optimization Modeling OnWan NurdyanaОценок пока нет

- Energy Conservation Through Centrifugal Oil Cleaning System in Industrial ApplicationsДокумент5 страницEnergy Conservation Through Centrifugal Oil Cleaning System in Industrial Applicationssuraj dhulannavarОценок пока нет

- Evaluating The Influence of Cetane Improver Additives On The Outcomes of A Diesel Engine Characteristics Fueled With Peppermint Oil Diesel BlendДокумент15 страницEvaluating The Influence of Cetane Improver Additives On The Outcomes of A Diesel Engine Characteristics Fueled With Peppermint Oil Diesel BlendgurusamyОценок пока нет

- Using Cottonseed Oil: Performance Improvement of A Di Diesel EngineДокумент8 страницUsing Cottonseed Oil: Performance Improvement of A Di Diesel EngineARVINDОценок пока нет

- Aceite de Pino en Motor DieselДокумент8 страницAceite de Pino en Motor DieselPedro RodriguezОценок пока нет

- International Energy Journal PAPER Dual Biodiesel For Diesel EnginesДокумент14 страницInternational Energy Journal PAPER Dual Biodiesel For Diesel EnginesAnonymous TPwGA2SОценок пока нет

- Effects of Open Combustion Chamber Geometries On The Performance of PongamiaДокумент8 страницEffects of Open Combustion Chamber Geometries On The Performance of PongamiaVaibhav MoonОценок пока нет

- 1827 ApprovedpaperДокумент20 страниц1827 ApprovedpaperMahtab SajnaniОценок пока нет

- Dee CFPPДокумент16 страницDee CFPPNeha AntimonyОценок пока нет

- 138 Ijmperdfeb2018138Документ10 страниц138 Ijmperdfeb2018138TJPRC PublicationsОценок пока нет

- Sai Kishore ReddyДокумент16 страницSai Kishore Reddysatwik reddyОценок пока нет

- Performance and Emission Characteristics of A CI Engine Fueled With Diesel-Waste Fried Oil Blend With Dee As AdditiveДокумент26 страницPerformance and Emission Characteristics of A CI Engine Fueled With Diesel-Waste Fried Oil Blend With Dee As AdditivePankaj KumarОценок пока нет

- Ijmet: ©iaemeДокумент11 страницIjmet: ©iaemeIAEME PublicationОценок пока нет

- Published File 2015 12 22 13 55 39Документ3 страницыPublished File 2015 12 22 13 55 39Alghazee Abo-jlalОценок пока нет

- Paper 2Документ5 страницPaper 2balakaleesОценок пока нет

- Agarwal2009 PDFДокумент13 страницAgarwal2009 PDFroberto gomezОценок пока нет

- Experimental Study On D I Diesel Engine Performance and Emission Characteristics (No) With Come - Diesel BlendsДокумент3 страницыExperimental Study On D I Diesel Engine Performance and Emission Characteristics (No) With Come - Diesel Blendsnidhul07Оценок пока нет

- V. Arul Mozhi Selvan Et. Al (2014). Effect of Cerium Oxide Nanoparticles and Carbon Nanotubes as Fuel-borne Additives in Diesterol Blends on the Performance, Combustion and Emission Characteristics of a Variable ComДокумент8 страницV. Arul Mozhi Selvan Et. Al (2014). Effect of Cerium Oxide Nanoparticles and Carbon Nanotubes as Fuel-borne Additives in Diesterol Blends on the Performance, Combustion and Emission Characteristics of a Variable ComwhutecompressorОценок пока нет

- JournalNX-Biodiesel Engine PropertiesДокумент7 страницJournalNX-Biodiesel Engine PropertiesJournalNX - a Multidisciplinary Peer Reviewed JournalОценок пока нет

- Ijmet: ©iaemeДокумент11 страницIjmet: ©iaemeIAEME PublicationОценок пока нет

- Production Methods of Biodiesel: January 2016Документ5 страницProduction Methods of Biodiesel: January 2016Anaya ChaudhryОценок пока нет

- 01 - Review Suresh2018Документ12 страниц01 - Review Suresh2018Chirag PatidarОценок пока нет

- A Production of Biodiesel From Waste Cotton Seed Oil and Testing On Small Capacity Diesel EngineДокумент8 страницA Production of Biodiesel From Waste Cotton Seed Oil and Testing On Small Capacity Diesel EngineYeabsira WorkagegnehuОценок пока нет

- Performance and Emission Characteristics of A Diesel Engine With Castor OilДокумент7 страницPerformance and Emission Characteristics of A Diesel Engine With Castor OilArati SakhalkarОценок пока нет

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityОт EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityРейтинг: 3 из 5 звезд3/5 (4)

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesДокумент10 страницImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationОценок пока нет

- A Study On The Reasons For Transgender To Become EntrepreneursДокумент7 страницA Study On The Reasons For Transgender To Become EntrepreneursIAEME PublicationОценок пока нет

- Broad Unexposed Skills of Transgender EntrepreneursДокумент8 страницBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationОценок пока нет

- Analyse The User Predilection On Gpay and Phonepe For Digital TransactionsДокумент7 страницAnalyse The User Predilection On Gpay and Phonepe For Digital TransactionsIAEME PublicationОценок пока нет

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyДокумент14 страницModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationОценок пока нет

- Determinants Affecting The User's Intention To Use Mobile Banking ApplicationsДокумент8 страницDeterminants Affecting The User's Intention To Use Mobile Banking ApplicationsIAEME PublicationОценок пока нет

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesДокумент15 страницAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationОценок пока нет

- Gandhi On Non-Violent PoliceДокумент8 страницGandhi On Non-Violent PoliceIAEME PublicationОценок пока нет

- Voice Based Atm For Visually Impaired Using ArduinoДокумент7 страницVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationОценок пока нет

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiДокумент16 страницInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationОценок пока нет

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurДокумент7 страницA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationОценок пока нет

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelДокумент9 страницFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationОценок пока нет

- Visualising Aging Parents & Their Close Carers Life Journey in Aging EconomyДокумент4 страницыVisualising Aging Parents & Their Close Carers Life Journey in Aging EconomyIAEME PublicationОценок пока нет

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaДокумент9 страницA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationОценок пока нет

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksДокумент10 страницA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationОценок пока нет

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesДокумент18 страницRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationОценок пока нет

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiДокумент16 страницA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationОценок пока нет

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDДокумент19 страницApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationОценок пока нет

- Various Fuzzy Numbers and Their Various Ranking ApproachesДокумент10 страницVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationОценок пока нет

- A Multiple - Channel Queuing Models On Fuzzy EnvironmentДокумент13 страницA Multiple - Channel Queuing Models On Fuzzy EnvironmentIAEME PublicationОценок пока нет

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsДокумент8 страницDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationОценок пока нет

- Analysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsДокумент13 страницAnalysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsIAEME PublicationОценок пока нет

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentДокумент8 страницKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationОценок пока нет

- EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESДокумент9 страницEXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESIAEME PublicationОценок пока нет

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsДокумент13 страницOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationОценок пока нет

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceДокумент7 страницQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationОценок пока нет

- Moderating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorДокумент7 страницModerating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorIAEME PublicationОценок пока нет

- Analysis On Machine Cell Recognition and Detaching From Neural SystemsДокумент9 страницAnalysis On Machine Cell Recognition and Detaching From Neural SystemsIAEME PublicationОценок пока нет

- Prediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsДокумент13 страницPrediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsIAEME PublicationОценок пока нет

- A Review of Particle Swarm Optimization (Pso) AlgorithmДокумент26 страницA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationОценок пока нет

- Reading Task CardsДокумент2 страницыReading Task CardscatnappleОценок пока нет

- EE FlowchartДокумент1 страницаEE Flowchartgoogley71Оценок пока нет

- Longley Rice PropagationДокумент11 страницLongley Rice Propagationy_m_algbaliОценок пока нет

- Remote SensingДокумент30 страницRemote SensingVijay RajОценок пока нет

- O-CNN: Octree-Based Convolutional Neural Networks For 3D Shape AnalysisДокумент11 страницO-CNN: Octree-Based Convolutional Neural Networks For 3D Shape AnalysisJose Angel Duarte MartinezОценок пока нет

- HyderabadДокумент3 страницыHyderabadChristoОценок пока нет

- Sahara International Petrochemical Company (SIPCHEM)Документ2 страницыSahara International Petrochemical Company (SIPCHEM)shahbaz1979Оценок пока нет

- VKC Group of Companies Industry ProfileДокумент5 страницVKC Group of Companies Industry ProfilePavithraPramodОценок пока нет

- Inductive Grammar Chart (Unit 2, Page 16)Документ2 страницыInductive Grammar Chart (Unit 2, Page 16)Michael ZavalaОценок пока нет

- COMMUNICATIONS Formulas and ConceptsДокумент24 страницыCOMMUNICATIONS Formulas and ConceptsAllan Paul Lorenzo Abando76% (17)

- Guide To Networking Essentials Fifth Edition: Making Networks WorkДокумент33 страницыGuide To Networking Essentials Fifth Edition: Making Networks WorkKhamis SeifОценок пока нет

- Item No. 6 Diary No 6856 2024 ConsolidatedДокумент223 страницыItem No. 6 Diary No 6856 2024 Consolidatedisha NagpalОценок пока нет

- You Wouldnt Want To Sail On A 19th-Century Whaling Ship 33 Grisly EnglishareДокумент36 страницYou Wouldnt Want To Sail On A 19th-Century Whaling Ship 33 Grisly EnglishareDušan MićovićОценок пока нет

- AW-NB037H-SPEC - Pegatron Lucid V1.3 - BT3.0+HS Control Pin Separated - PIN5 - Pin20Документ8 страницAW-NB037H-SPEC - Pegatron Lucid V1.3 - BT3.0+HS Control Pin Separated - PIN5 - Pin20eldi_yeОценок пока нет

- Management and Entrepreneurship Important QuestionsДокумент1 страницаManagement and Entrepreneurship Important QuestionslambazОценок пока нет

- Median FilteringДокумент30 страницMedian FilteringK.R.RaguramОценок пока нет

- 819-5917-April 2021-Domestic Warranty Policy ManualДокумент46 страниц819-5917-April 2021-Domestic Warranty Policy ManualDean KershnerОценок пока нет

- Kudla Vs PolandДокумент4 страницыKudla Vs PolandTony TopacioОценок пока нет

- LG LCD TV 32lp1dc - Al-04ca Service ManualДокумент47 страницLG LCD TV 32lp1dc - Al-04ca Service ManualJavin GallardoОценок пока нет

- Aug 2020 Builders Line Tamil MonthlyДокумент48 страницAug 2020 Builders Line Tamil MonthlyBuildersLineMonthlyОценок пока нет

- User Custom PP Install74Документ2 страницыUser Custom PP Install74Zixi FongОценок пока нет

- Pa 28 151 161 - mmv1995 PDFДокумент585 страницPa 28 151 161 - mmv1995 PDFJonatan JonatanBernalОценок пока нет

- Biotechnology WebquestДокумент2 страницыBiotechnology Webquestapi-353567032Оценок пока нет

- Eastern Bank Limited: Name: ID: American International University of Bangladesh Course Name: Faculty Name: Due DateДокумент6 страницEastern Bank Limited: Name: ID: American International University of Bangladesh Course Name: Faculty Name: Due DateTasheen MahabubОценок пока нет

- Basics Stats Ti NspireДокумент7 страницBasics Stats Ti NspirePanagiotis SotiropoulosОценок пока нет

- Aircraft MaintenanceДокумент32 страницыAircraft MaintenanceTateОценок пока нет

- "Laughter Is Part of The Human Survival Kit. : David NathanДокумент4 страницы"Laughter Is Part of The Human Survival Kit. : David NathanTrang NhungОценок пока нет

- Saarthi Education Jija Mata Colony, Near Paithan Gate A Bad. Cont: 8694947070 / 5050Документ8 страницSaarthi Education Jija Mata Colony, Near Paithan Gate A Bad. Cont: 8694947070 / 5050Roshan KumarОценок пока нет

- Ins200 Assignment Hazardous PlaceДокумент10 страницIns200 Assignment Hazardous PlaceNur Syafatin Natasya86% (7)

- 2023 Reso-01Документ3 страницы2023 Reso-01John Mark Mercado JubelagОценок пока нет