Академический Документы

Профессиональный Документы

Культура Документы

CFRP Strips On Punching Shear Strength Development of Bubble Deck Slab

Загружено:

IJARTETИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CFRP Strips On Punching Shear Strength Development of Bubble Deck Slab

Загружено:

IJARTETАвторское право:

Доступные форматы

ISSN 2394-3777 (Print)

ISSN 2394-3785 (Online)

Available online at www.ijartet.com

International Journal of Advanced Research Trends in Engineering and Technology (IJARTET)

Vol. 2, Issue 9, September 2015

CFRP Strips on Punching Shear Strength

Development of Bubble Deck Slab

Reshma Mathew1, Binu .P2

M.tech.Student, Department of CE, Sree Narayana Gurukulam College of Engineering, Kolenchery, India 1

Associate Professor, Department of CE, Sree Narayana Gurukulam College of Engineering, Kolenchery, India 2

Abstract: Bubble deck slab is a revolutionary biaxial concrete floor system, it eliminate concrete in centre of slab which is

not performing any structural action. In slabs, thickness of compressed concrete is only a small proportion of the slab depth

and this means it involves only the concrete between the surface and ball. So there is no sensible difference between the

behaviour of a solid slab and Bubble Deck. But weight of bubble deck slab is low compared to solid slab, so punching shear

capacity of bubble deck is very low. This study deals with what will be the effect of strengthening system such as CFRP to

improve the load carrying capacity of bubble deck slab. Finite element software ANSYS 14.5 is used for nonlinear analysis

of bubble deck slab.

Keywords: Bubble deck slab, Punching shear, CFRP, Finite element modelling, ANSYS 14.5

I.

INTRODUCTION

The bubble deck slab is a revolutionary biaxial

concrete floor system developed in Europe. High-density

polyethylene hollow spheres replace the ineffective concrete

in the centre of the slab, thus decreasing the dead weight and

increasing the efficiency of the floor. For the construction of

bubble deck slab it requires three main materials. They are

steel, plastic spheres and concrete. This slab have many

advantages over a normal solid slab such as lower total cost,

reduced material use, improve structural efficiency,

construction time decreased, and is a green technology. When

the load is act on a structure compressive force is fully taken

by concrete above neutral axis and tensile force is taken by

steel in tension zone, so there is no sensible difference

between flexural strength of solid slab and bubble deck slab.

But punching shear capacity of bubble deck slab is a crucial

problem. Bubble deck slab have low weight compared to solid

slab. Thus punching shear capacity of bubble deck slab is low.

Punching shear is a type of failure in flat slabs due to localized

forces. In flat slab this occurs at column support points. The

failure occurs due to shear. It is a catastrophic failure because

no visible signs are shown prior to failure. FRP is a composite

material, composed of fibres and polymer matrix. FRP has

wide range of applicability in civil engineering and other

fields. Nowadays FRP is most commonly used material to

increase

Load carrying capacity, stiffness reduce Deflection etc., one

of the promising properties of FRP is its light weight and

Reduced cost compared to other strengthening systems. Most

commonly used fibres are CFRP and GFRP. In this study

bubble deck slab is strengthened with CFRP in different

schemes. Compared to GFRP, CFRP have more tensile

strength. ANSYS 14.5 is used for modelling and analysis of

bubble deck slab.

II.

SCOPE OF THE STUDY

Construction of solid slab is a crucial problem, it

require large quantity of money, materials and labours.

Bubble deck slab is a light weight structure. Production of one

cubic meter of concrete causes CO2 emission close to 300 kg.

But bubble deck slab have less material consumption hence it

reduces emission of CO2 into atmosphere. Thus we can

achieve green construction .But studies related to FRP

strengthened bubble deck is limited. This study investigates

effect of CFRP strips to increase punching shear capacity of

bubble deck slab.

III.

SPECIMEN MODELLING

3.1 Element type and material properties

All Rights Reserved 2015 IJARTET

ISSN 2394-3777 (Print)

ISSN 2394-3785 (Online)

Available online at www.ijartet.com

International Journal of Advanced Research Trends in Engineering and Technology (IJARTET)

Vol. 2, Issue 9, September 2015

Element type used for modelling of bubble deck slab

are solid 65 for concrete, link 180 for steel and shell 181

CFRP strips

for FRP and HDPE balls. ANSYS 14.5 software was used

3

SHELL

EX

259GPa

for modelling of bubble deck slab and dimension of slab

181

PRXY

0.35

specimen was 2500 x 2500 x 230 mm. Dimension of

Column stub used was 300 x300 mm. Thickness of HDPE

GFRP strips

ball is 1 mm. In order to save time only quarter of slab is

EX

20.23GPa

modelled and symmetrical boundary condition were

PRXY

0.223

applied to create full geometry. Load is applied through

column as nodal load. Boundary condition used for slab 3.2. Modelling of solid slab and bubble deck slab

was fixity. In which all degree of freedom were

constrained. Material properties and element type used for

Solid slab and bubble deck slab were modelled using

modelling is shown in Table 3.1

ANSYS 14.5. 8 mm diameter steel reinforcement bars was

used and no shear reinforcement is provided. Fig 3.1 shows

Modelling of solid slab and bubble deck slab. Difference

TABLE 3.1

between solid and bubble deck slab is that in bubble deck slab

ELEMENT TYPE AND MATERIAL PROPERTIES FOR THE

concrete in the centre portion is removed and replace with 180

MODELING OF BUBBLE DECK SLAB

mm diameter HDPE balls were used.

Si

Element Type

Material Properties

no:

Used

for

modelling

concrete

EX

25000MPa

PRXY

0.2

Open Shear

Transfer

0.2

Coefficient

1 SOLID 65

Closed

Shear

0.8

Transfer

Coefficient

Uniaxial

3.5 MPa

Figure 3.1.Meshed model of solid and bubble deck slab

Cracking

stress

Uniaxial

-1

Crushing

Stress

Steel

EX

200000 MPa

PRXY

0.3

2

LINK180

Yield Stress

415

Tangent

0

Modulus

Figure 3.2 Meshed model of HDPE balls

HDPE balls

EX

1030MPa

PRXY

0.4

3.3 Modelling of Bubble deck slab with CFRP

All Rights Reserved 2015 IJARTET

ISSN 2394-3777 (Print)

ISSN 2394-3785 (Online)

Available online at www.ijartet.com

International Journal of Advanced Research Trends in Engineering and Technology (IJARTET)

Vol. 2, Issue 9, September 2015

Load carrying capacity of bubble deck slab is low

. In order to improve the load carrying capacity of bubble

de k slab it is strengthned with CFRP. CFRP arranged in

different schemes.figure shows bubble deck slab with

different schemes of FRP. Dimensions of FRP used in this

study as shown in Table 3.2

TABLE 3.2

DIMENSIONS OF CFRP

CFRP

Length

of FRP

(mm)

Breadth

of FRP

(mm)

2100

200

Thickness

of FRP

(mm)

2

Figure 3.4. Bottom view of one fourth model of bubble deck slab

with CFRP scheme 3

IV.

RESULTS AND DISCUSSION

4.1. Solid and bubble deck slab

This section deals with result obtained from

ANSY 14.5 which include load carrying capacity

and displacement diagram of bubble deck slab.

Figure 3.3.Bottom view of one fourth model of bubble deck slab with

CFRP scheme 1

Figure 4.1. Displacement diagram of solid slab

Figure 3.4. Bottom view of one fourth model of bubble deck slab with

CFRP scheme 2.

All Rights Reserved 2015 IJARTET

ISSN 2394-3777 (Print)

ISSN 2394-3785 (Online)

Available online at www.ijartet.com

International Journal of Advanced Research Trends in Engineering and Technology (IJARTET)

Vol. 2, Issue 9, September 2015

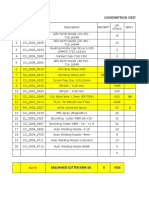

TABLE 4.1

COMPARISON OF SOLID AND BUBLE DECK SLAB

load

carrying

capacity of slab

(kN)

Percentage

decreased

compared to solid

slab

Solid

slab

351.256

Bubble deck

slab

240.105

70 %

4.2. Bubble deck slab strengthened with CFRP

Figure 4.2. Displacement diagram of bubble deck slab

Figure 4.5,4.6,4.7 shows stess diagram of bubble

deck slab with CFRP scheme 1,scheme 2,scheme3

Figure 4.3. Stress diagram of bubble deck slab

Figure 4.5.Stress diagram of bubble deck slab with CFRP scheme 1

Figure 4.4. stress diagram of HDPE balls

Figure 4.6. Stress diagram of bubble deck slab with CFRP scheme 2

All Rights Reserved 2015 IJARTET

ISSN 2394-3777 (Print)

ISSN 2394-3785 (Online)

Available online at www.ijartet.com

International Journal of Advanced Research Trends in Engineering and Technology (IJARTET)

Vol. 2, Issue 9, September 2015

Figure 4.8. Comparison of solid slab ,bubble deck slab and bubble deck

slab with different schemes.

V.

CONCLUSION

Punching shear capacity of bubble deck slab is

low.compared to solid slab bubble deck can achieve only 70

% load carrying capacity.Strengthening bubble deck slab

using CFRP is an effective method for improving load

carriying capacity. Bubble deck with CFRP scheme 3 can

achieve more than 25 % load carrying capacity compared to

bubble deck slab without strengthening system.

Figure 4.7. Stress diagram of bubble deck slab with CFRP scheme 3

TABLE 4.2

COMPARISON OF RESULTS

Soli

d

slab

Bubble

deck

slab

without

strength

ening

Bubble

deck

with

schem

e1

Buble

deck

with

schem

e2

Bubble

deck

with

schem

e3

ACKNOWLEDGMENT

The author acknowledges Binu .P (guide ),all staffs

of SNGCE college ,friends and parents for their valuable

support and guidance to carry out this study.

REFERENCES

[1]. J.G. Tenga, S.Y. Caob, Behaviour of GFRP-strengthened RC

cantilever slabs journal of Construction and Building

Materials vol 15 ,2001 .

Load

carry

ing

capa 351 240.105 265.63 275.91 298.82

city

.25

3

8

5

of

6

slab

Percentage increase in load carrying capacity (%)

[2]. Martina Schnellenbach-Held Punching behaviour of biaxial

hollow slab Journal of cement and concrete composites vol

24 ,2002 .

CFR

P

[5]. Ahmed Sabry Experimental and analytical study on on

punching strength of two-way slabs strengthened externally

with CFRP sheets , International Journal of Research in

Engineering and Technology, vol 03 , 2014 pp113-120

10

15

400

SS -solid slab

350 351.256

SS

300

298.825

275.918

265.633

250

240.105

200

BD

150

100

50

BD + CFRP +

0

SCHEME 1

25

[3]. Prabhu Teja Structural behaviour of bubble deck slab.

International Conference On Advances In Engineering,

Science And Management ,vol 30 ,2012

[4]. S.J. Kim Strengthening of one-way spanning RC slabs with

cutouts using FRP composites, Journal of construction and

building materials ,SCIENCE DIRECTvol 23 ,2009

[6]. www.bubble deck.com

BD + CFRP +

SCHEME 2

All Rights Reserved 2015 IJARTET

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Check List For HDPE BUTT Weld JointingДокумент2 страницыCheck List For HDPE BUTT Weld JointingAnil Kumar100% (9)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Wireless Notice Board With Wide RangeДокумент5 страницWireless Notice Board With Wide RangeIJARTETОценок пока нет

- Ready To Travel ApplicationsДокумент4 страницыReady To Travel ApplicationsIJARTETОценок пока нет

- Smart Water Management System Using IoTДокумент4 страницыSmart Water Management System Using IoTIJARTETОценок пока нет

- Privacy Preservation of Fraud DocumentДокумент4 страницыPrivacy Preservation of Fraud DocumentIJARTETОценок пока нет

- Non Invasive Blood Glucose Monitoring ForДокумент4 страницыNon Invasive Blood Glucose Monitoring ForIJARTETОценок пока нет

- Complaint Box Mobile ApplicationДокумент4 страницыComplaint Box Mobile ApplicationIJARTETОценок пока нет

- Power Transformer Explained PracticallyДокумент4 страницыPower Transformer Explained PracticallyIJARTETОценок пока нет

- Smart Door Using Raspberry PiДокумент4 страницыSmart Door Using Raspberry PiIJARTETОценок пока нет

- Insect Detection Using Image Processing and IoTДокумент4 страницыInsect Detection Using Image Processing and IoTIJARTETОценок пока нет

- Fire Detection and Alert System Using Convolutional Neural NetworkДокумент6 страницFire Detection and Alert System Using Convolutional Neural NetworkIJARTETОценок пока нет

- Review On Recycled Aluminium Dross and It's Utility in Hot Weather ConcretingДокумент3 страницыReview On Recycled Aluminium Dross and It's Utility in Hot Weather ConcretingIJARTETОценок пока нет

- Asset Tracking Using Low Power BluetoothДокумент6 страницAsset Tracking Using Low Power BluetoothIJARTETОценок пока нет

- MAR 20 2Q15:: Department of Public Works and HighwaysДокумент6 страницMAR 20 2Q15:: Department of Public Works and HighwaysFaustino AbadОценок пока нет

- VNT Brochure NewДокумент5 страницVNT Brochure Newda vin ciОценок пока нет

- White Cement - ReportДокумент15 страницWhite Cement - ReportSai PujithОценок пока нет

- Inconel 625 PDFДокумент16 страницInconel 625 PDFErick OlavarriaОценок пока нет

- Anchors Fundamentals - Hilti PDFДокумент24 страницыAnchors Fundamentals - Hilti PDFIho1Оценок пока нет

- QIPP-MPN012-M00-2001 Rev0 Painting Specification (Including Painting Coating Procedure)Документ18 страницQIPP-MPN012-M00-2001 Rev0 Painting Specification (Including Painting Coating Procedure)hetpinОценок пока нет

- ETA 19 0601 HIT HY 200 A R V3 Anchoring Jun 2023 Approval Document ASSET DOC 11504013Документ213 страницETA 19 0601 HIT HY 200 A R V3 Anchoring Jun 2023 Approval Document ASSET DOC 11504013gundeskОценок пока нет

- X ENP Data Sheet Technical Information ASSET DOC 2591592Документ9 страницX ENP Data Sheet Technical Information ASSET DOC 2591592Milos VukobratОценок пока нет

- Aquagenie 10L, 15L & 25L - 8Документ7 страницAquagenie 10L, 15L & 25L - 8Ravi GuptaОценок пока нет

- Consumables Consumption Daily Update SheetДокумент2 страницыConsumables Consumption Daily Update SheetAnilkumar G NairОценок пока нет

- Hygrothermal Performance of Hempcrete For Ontario (Canada) BuildingsДокумент10 страницHygrothermal Performance of Hempcrete For Ontario (Canada) BuildingsLIZETH ACОценок пока нет

- Column & Footing Marking PlanДокумент1 страницаColumn & Footing Marking PlanBIGG BOSSОценок пока нет

- Bladder Accumulators HYDACДокумент8 страницBladder Accumulators HYDACMaciej KostenckiОценок пока нет

- Toll PlazaДокумент13 страницToll PlazaNARAYAN DASОценок пока нет

- Stainless SteelsДокумент16 страницStainless SteelsMohdAizie MudaОценок пока нет

- Steps of Concrete Mix Design BSДокумент11 страницSteps of Concrete Mix Design BSrahul.frnds1448100% (1)

- Materials and Processes-NdtДокумент40 страницMaterials and Processes-NdtJhalbert BelmonteОценок пока нет

- Carbide Roll MaterialДокумент10 страницCarbide Roll MaterialziadОценок пока нет

- 2 Construction WorkДокумент53 страницы2 Construction WorkShuvam AdhikariОценок пока нет

- S. No. Construction Work Details CoefficientДокумент2 страницыS. No. Construction Work Details CoefficientRitesh kumarОценок пока нет

- Unit - 4Документ113 страницUnit - 4devabrijith2Оценок пока нет

- Adaptadores - BSP - NPTДокумент1 страницаAdaptadores - BSP - NPTJean DiasОценок пока нет

- Dhoraji Nagarpalika - Dhoraji: District:-RajkotДокумент15 страницDhoraji Nagarpalika - Dhoraji: District:-RajkotwapcosrajkotОценок пока нет

- ASTM G1 Standard Practice-1Документ8 страницASTM G1 Standard Practice-1bmalinovicОценок пока нет

- Presentation - Tilottoma - Anup MitraДокумент80 страницPresentation - Tilottoma - Anup MitraAnup Kumar MitraОценок пока нет

- Steel PipesДокумент16 страницSteel PipesAdam GordonОценок пока нет

- 2191 Teile0160-Probojci PDFДокумент60 страниц2191 Teile0160-Probojci PDFalex94kgОценок пока нет

- BTT EB Specification Double Wall 08-07Документ13 страницBTT EB Specification Double Wall 08-07Alonso VillaОценок пока нет

- Annular Cutter Feeds and SpeedsДокумент1 страницаAnnular Cutter Feeds and SpeedsAnonymous JzEb8CXErОценок пока нет