Академический Документы

Профессиональный Документы

Культура Документы

Subsidence Control Measures in Coalmines - A Review

Загружено:

katta_sridharОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Subsidence Control Measures in Coalmines - A Review

Загружено:

katta_sridharАвторское право:

Доступные форматы

11/13/2015

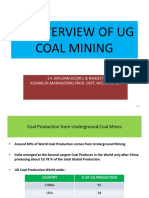

Subsidencecontrolmeasuresincoalmines:Areview

JournalofScientificandIndustrialResearch

Vol.64,May2005,pp.323332

Subsidencecontrolmeasuresincoalmines:Areview

RDLokhande,APrakash,KBSingh*andKKKSingh

CentralMiningResearchInstitute,Dhanbad826001

Received19October2004accepted24March2005

Thispaperreviewssubsidencecontrolapproachesadoptedinundergroundcoalmines.Subsidence,asuddendepressionof

theground,occursintwoforms,troughandpotholesubsidence.Thiscanbehazardoustolifeandpropertyasitoccurswithout

any prior indication. Subsidence can be controlled by using partial extraction methods, stowing etc. in working mines.

Backfillingandgroutingcanbeusedtostabilizeunapproachableabandonedundergroundmines.

Keywords:Coalmines,Subsidence,Partialextraction,Stowing,Grouting

IPCCode:E21C45/00

Introduction

Surface manifestation of underground coal extraction occurs in two forms, pothole and trough subsidence.

Potholesubsidenceisasuddendepressionofgroundsurfaceofsmallareaduetosuddencollapseofoverburden

intotheundergroundvoid.Troughsubsidenceisalargeareadepressionofthesurfaceterrain,whichiscommon

at greater depth. Pothole subsidence is hazardous to life, as it does not impart any prior indication before its

occurrence. Ground movements produce various forms of damage to different surface features and structures.

Damagetobuildingsresultfromtilting,curvatureandlineardeformationofthegroundbuiltonit.Compression

and extension of the surface alter the gradient of structural alignment, which ultimately causes their

deformation. Subsidence phenomena, which occurs in abandoned mines to a large extent, continues through

yearsaftermining1.Abandonedroomandpillarminingeventwocenturiesagomaystillbecausingsubsidence,

which results in heavy loss of life and property. This paper reviews various subsidence control approaches,

whicharebeingadoptedincollieriesforbothworkingandabandonedcoalmines.

SubsidenceControlinWorkingCoalmines

PlaneFittingMethod

_____________

*Authorforcorrespondence

Tel:913262203010/2203070Fax:913262202429

Email:kbsingh_cmri@yahoo.com

Conventional method of leveling house superstructure

subject to curvature and twisting makes it practically

almost impossible when the differential subsidence is

large 2, where any attempt to level the superstructure,

liftingitbylargeamount,caninvariablyleadtodamagethestructure.Toovercomethis,aPlaneFittingMethod

(PFM) was developed3. As curvature and twisting are caused by differential subsidence, PFM completely

eliminatesstrainonthesuperstructurecausedbycurvatureandtwisting.

Height adjustment devices (cribjack assembly) are installed under the superstructure for keeping the

superstructure in a time dependent incline plane. Number of cribjack assembly needed for superstructure is

obtainedas:

N=1.5W/J(1)

where,N=NumberofcribjackassemblyW=Weightofsuperstructure,tonsJ=Capacityofjack,tons.

Locations of cribjack assembly are selected carefully to cover all corners and area under the beam.

Maximum spacing of the cribjack assembly is limited to less than 3 m. Under heavy portion of the

superstructure,cribjackassemblyisdenselyplaced.

TrenchAroundHouse

Trenchingaroundhouseiseffectiveinreducingcompressivestressesonthefloorandwall.Thetrenchshould

be at least 0.3 m wide, 0.9 to 2.0 m from the exterior wall and should extend 0.15 m to 0.2 m below the

foundation4. Plain strain formulation was used to study stress reduction on the basement floor due to different

dimensionsoftrench(Fig.1).

http://www.niscair.res.in/sciencecommunication/researchjournals/rejour/Jsir/Fulltextsearch/2005/May%202005/jsir671%20Vol%2064%20May%202005

1/10

11/13/2015

Subsidencecontrolmeasuresincoalmines:Areview

Fig.1Finiteelementmodelforstudyingtheeffectoftrench

At the boundary nodal points on the ground surface,

known vertical and horizontal displacements were

assumed. Vertical displacement was selected such that it

imposedaconstantcurvatureof1.5105 1/mthroughout

the top of the ground surface. Horizontal displacement

waschosensuchthatitimposedacompressivestrainof3

104and7104mm/mthroughoutthegroundsurfaceof

the model. These imposed values of curvature and

horizontal compressive strain are some typical measured

values.

Fig. 2Relation between maximum subsidence and width/depth The interaction of basement floor and ground was

ratio

modeled by using Winklers sub grade reaction theory5.

Forimplementingthesubgradereactiontheory,thegroundmodelinplanestrainwasfirstrunalone(withoutthe

wallandfloor).Knowndisplacementsattheinterfacenodalpointsofthegroundandfloor,andgroundandwall

were imposed in the groundalone model all other boundary points of the ground alone model were fully

constrained.Byrunningthegroundalonefiniteelementmodel,reactionforcesattheinterfacenodalpointswere

determined.Afterthis,thecombinedground,floor,andwallmodelwasrunwithknownreactionforcesatthe

interfacenodalpointsandknowndisplacementsatallothersurfaceboundarynodalpoints.

Percentagereductioninmaximumcompressivestressonthefloorduetodiggingadeeperandwidertrench

wascalculatedwithrespecttonotrenchsituation.Alsothepercentagegaininreductionofcompressivestress

onthefloorduetodiggingalargedimensiontrenchwithrespecttotheprecedingsmallerdimensiontrenchwas

calculated.

TensionCable

Atensioncableisusedtoreducetwistingdamagetothestructure,whichhashighcompressivestrengthbut

low tensile strength, for example, concrete block masonry. For proper design, tension in the cable must be

determinedproperly2.

HydraulicSandStowing(HSS)

InIndiancoalmining,stowingplaysavitalroleforsubsidencecontrol.Amongdifferentmethodsofstowing,

HSSisveryeffectiveinIndianmining(Fig.2).ThemaximumsubsidenceinIndiancoalfieldswithHSSfilling

isonly5percentwhereasitis60percentincaseofcavingwithrespecttoextractionthicknessofasingleseam

extraction6.Thus,themaximumsubsidencecanbereduced12timesbyhydraulicfillingofvoidswithsandwith

respecttocaving.Insomestowedpanels,thevalueofsubsidenceishighduetodelayinstowingoroldstowed

room and pillar working in the overlying or underlying seam. The magnitude of maximum subsidence varies

between05and35percentoftheextractionthickness7.ThemaximumsubsidencewithHSSishighinforeign

http://www.niscair.res.in/sciencecommunication/researchjournals/rejour/Jsir/Fulltextsearch/2005/May%202005/jsir671%20Vol%2064%20May%202005

2/10

11/13/2015

Subsidencecontrolmeasuresincoalmines:Areview

coalminesincomparisontoIndiancoalmines(Table1)duetostrongoverlyingrockinIndiancoalmines.Thus,

HSSisveryeffectiveinIndiatoreducesubsidenceincomparisontoothercountries.

Table1Maximumsubsidencewithhydraulicsandstowing

Country

Maximumsubsidence

%

8

20

Ruhrcoalfield,Germany

12

UpperSilesia,Poland9

2535

North&Pasdecalaiscoalfield,France10

1520

Britishcoalfield11

19

Kuho(II)colliery,Japan12

05

Kampteecoalfield,India6

PartialExtractionMethods

Partialextractionmethodsusedtominimizesubsidence

as well as strain to protect different surface features and

structuresareasfollows:

NonEffectiveWidthofExtraction

Non Effective Width (NEW) of extraction (Fig. 3) is

theundergroundwidthofextraction,whichdoesnotcause

practically any movement on the surface. Whenever an

underground opening is made, the equilibrium of the

surrounding rock mass is disturbed. This causes stress

redistribution around the opening. A pressure arch is

formedfollowingtheredistributionofstress13.Theheight

of caved dome is controlled by: i) Strength of immediate

roof ii) Bulking properties of caved rock mass and iii)

Fig.3Noneffectivewidthofextraction

Dimensionoftheexcavation.

The presence of strong bed in the overlying rock mass

discourages upward collapse of the roof. With further increase in the width of excavation, the caved dome

moves upward and a stage comes when the surface movement starts. It appears that a certain width can be

extractedwithoutcausinganymovementonthesurface.ThiswidthistermedasNEWandexpressedinterms

ofdepth.InIndia,NEWvariesbetween0.3to1.17timesthedepthsofextraction.Iftheextractionwidthiskept

lessthanNEW,nosubsidenceoccursonthesurface.Thepercentageofextractioninsingleseamworkingwith

noneffective width of extraction is about 5014. Further, the percentage of extraction is reduced in multiseam

miningcondition.ThevalueofNEWincreaseswithincreasingsandstoneandRockQualityDesignation(RQD)

inthesuperincumbentstrata.

Inthismethod,row(s)ofpillarsareextractedinsuchawaythatthewidthofextractionisalwayskeptless

than the NEW and the row(s) of pillars left as barrier between adjacent extracted row(s) of coal pillars have

longtermstabilitywithsafetyfactorequaltoormorethan2.0.

SafetyFactor=Strengthofpillar(S)/Loadonpillar(P)

(2)

ThepillarstrengthestimatedusingCMRIpillarstrengthequation15:

S=(0.27ch0.36)+([H/250+1][We /h1])Mpa

(3)

where,c=Uniaxialcompressivestrengthof1inchcoalcube,Mpah=Workingheight,mH=Depthbelow

surface,mWe=Pillarwidth,m(forsquarepillar)=2w1w2/(w1+w2)(forrectangularpillar).

LoadonpillarisestimatedusingWilsonsformula 16asgivenbelow:

P=[0.025H/We2]*[(We+fH)(We+B)]Mpa

(4)

http://www.niscair.res.in/sciencecommunication/researchjournals/rejour/Jsir/Fulltextsearch/2005/May%202005/jsir671%20Vol%2064%20May%202005

3/10

11/13/2015

Subsidencecontrolmeasuresincoalmines:Areview

where,We=pillarwidth,mH=depthbelowsurface,mB=roadwaywidth,mf=0.3forcaving=0.2for

stowing.

ChessBoardMethod

WhenNEWextractionisnotpossible,ChessBoardmethodmaybeadopted.Inthismethod,everyalternate

pillarineveryrowisextractedsoastoleaveachessboardpattern(Fig.4).ThePercentageofextractioninthis

patterncomesto606517.

Thesafetyfactorofthepillarsleftoutmustbeatleast2.0forlongtermstabilitypointofview.Theformula 16

usedtocalculatetheloadonpillaris:

P=0.025[(We+B)/We]2[2H(We+B)/1.8]Mpa

(5)

ThestrengthofpillarisestimatedusingEq.3.

GoafPillarMethod

When NEW or chessboard method does not give good

recoveries, the Goaf Pillar method may be tried. This

method consists of leaving pillars systematically in the

goafsuchthatthewidthoftheextractedspanaroundany

suchpillarislessthanNEWandtheleftoutpillarshavea

longterm stability. The pattern will depend on seam

strength, extraction height, depth and pillar size 17. This

methodgivesthebestrecovery

(6070%)18amongallthepartialextractionmethods.

Wide&StallMining

Under surface/subsurface structures, extraction of coal

seam at moderate depth cover faces problem of low

recovery.Conventionalmethodofminingforoptimalcoal

extractionundersuchgeominingconditionsissplittingof

originaldevelopedpillarsinwhichsmallsizedcoalpillars

(Stooks) are left out to protect the surface structure and

overlying coal seam(s). Formation of stook during the

Fig.4Chessboardmethodofmining

optimization of recovery causes considerable drop in

strength of the natural support, which is not desirable for

long term stability of the underground mining and surface structures19. In Indian geomining conditions,

conventionalsplittingandstookingmethoddoesnotprovidemorethan30percentcoal20,21 during optimization

from a developed thick seam under built up areas. In multisection seam, during the optimization of recovery,

pillar strength decreases due to increased height of extraction22, stability of parting and superimposition of

pillarsmakesthesituationmorecomplexfromproduction,productivityandsafetypointofview.

Matchingofgallerysizewiththestrengthofimmediateroofandstrengthimprovementofthenaturalsupport

by increasing width/height ratio of pillars are the two basic constituents of the Wide & Stall philosophy23.

Strength of ultimate pillars and stability of overlying exposed roof span play an important role for long term

stability of wide stall under shallow depth cover. The effective bearing capacity of a pillar is comparatively

more than a number of stook of the equivalent area. Widths of existing galleries are increased in a particular

configurationtoimprovecoalrecoveryleavingwidepillarincomparisontostookofintactcore.Wide&Stall

formationaccommodatesexistinggalleriesofadevelopedcoalseamaswellasimprovesrecovery(4065%)26

andsafetyoftheultimateminingstructureincomparisontotheconventionalmethod.Onthebasisofextensive

laboratory investigations on different simulated models, idea of Wide & Stall mining was conceived and first

time implemented in the field at East Bhuggatdih Colliery of the Jharia Coalfield24. Taking advantage of the

presence of massive sandstone roof and rapid increase of pillar strength with the increase of its widthheight

ratio25,splittingandstookingofthepillarwasreplacedbyWide&Stallformation(Fig.5).

SplittingofPillarwithStowing

http://www.niscair.res.in/sciencecommunication/researchjournals/rejour/Jsir/Fulltextsearch/2005/May%202005/jsir671%20Vol%2064%20May%202005

4/10

11/13/2015

Subsidencecontrolmeasuresincoalmines:Areview

The Directorate General of Mine Safety (DGMS) generally does not permit splitting of pillars by caving

undersurfacefeatures.Butthepillarscanbesplitwithstowing.Thewidthandnumberofsplitsaredecidedby

pillarstrengthconsiderations.Aminimumsafetyfactorof1issufficienttoensurelongtermstabilityofstooks

withcompletestowing.

SplittingofPillarwithSideBolting

If all the partial extraction methods could not be

practiced and also stowing material is not available then

thepillarcanbesplitwithsystematicfullcolumngrouted

side bolting. The bolted pillar should have longterm

stabilitytoensurezerosubsidenceatsurface.

It was found that the strength of pillar increases with

systematic side bolting and the augmented strength16 is

givenby:

Sb=S[1+{20As(q1)}/(ca2)]Mpa(6)

Fig.5Wide&stallmethodofmining

where,Sb=strengthofboltedpillars,MpaS=strengthof

unboltedpillarsdefinedbyeqn(3),MpaAs = anchorage

strength of each bolt, t q = triaxial strength factor

(average 3.5) c = Coal strength, t/m2 a = Spacing

betweenthebolt,m.

The load on the reduced pillars is estimated using

tributaryareaconcept27andisgivenas:

P=0.025H[L1L2/w1w2]Mpa(7)

Where,H=depthbelowsurface,mw1,w2=Pillarwidths,mL1,L2=Centretocentrepillarsize,m.

HarmonicMining

Extractionofapanelcausestensionalandcompressive

strainatthesurface.Theworkingintwoseamsshouldbe

so advanced simultaneously to cancel out the balance of

strain,causedbyonefacebythestraininducedbyanother

at a different level. This approach is known as harmonic

mining, which, however, is not simple as the mine has to

be preplanned, and also problems due to interaction

between faces in different seams have to be countered.

Another application of the principle is in protection of

buildings. The working was laid out so that the building

was at the centre of a panel of maximum width. In this,

thebuildingwassubjectedtoeffectsoftravelingstrains28.

To counter it, the face was split into two units, which

were advanced in steps with a fixed interval between

them such that strain induced by two faces cancel each

other(Fig.6).

Fig.6Harmonicmining

SubsidenceControlinAbandonedCoalmines

Abandoned coalmines also cause surface deformation

with time following both pothole and trough subsidence.

Two distinctly different subsidence control technologies have been developed for abandoned coalmine 29,30: i)

Pointsupportmethodandii)Arealbackfilling.

PointSupportMethod

ThecostofPointSupportmethodinvolvesalargenumberofboreholesandtheuseofexpensivematerialin

relativelysmallquantities.ThisexistsseveraldozenPointSupportmethod,whichoperateeithertosupportthe

undergroundcavities,controllingsubsidence,ortoisolatethestructurefromtheeffectofsubsidenceifitshould

occur. The method usually involves deep foundation through the mine opening supporting the structure on the

http://www.niscair.res.in/sciencecommunication/researchjournals/rejour/Jsir/Fulltextsearch/2005/May%202005/jsir671%20Vol%2064%20May%202005

5/10

11/13/2015

Subsidencecontrolmeasuresincoalmines:Areview

underlying strata. On the principle of Point Support methods, some other methods are: i) Gravel Column and

AssociatedMethodii)FlyashGroutInjectionandiii)FabricFormedConcrete.

GravelColumn

Gravel column usually placed in the mine opening.

Borehole is drilled through the mine strata, and gravel

poureddowntheboreholetoformapileontheminefloor.

When the tip of pile contacts the mine roof, it is rodded

downtospreadthepileandpermitsadditionalgraveltobe

placed (Fig. 7). The objective is to place as much gravel

as possible in the mine opening and to achieve firm

contact with the mine roof. The filling of a significant

fraction of the open mine volume reduced the amount of

potentialsubsidencesimplybykillingopenvolumewithin

mine. In effect, the extraction ratio has been reduced by

introducing the volume of gravel. The toe of the gravel

pile abuts against nearby pillar, providing lateral support

andprotectionagainstdeterioration,ineffecttheheightof

Fig.7Groutedcolumntosupporttheoverburden

thepillarhasbeenslightlyreducedbyburyingtheirlower

portions. Finally, some direct support is provided to the

roofstrata,reducingtheroofspanandenhancingthestability.

Themethodmaybeusedinavarietyofapplicationsandwithmaterialotherthangravele.g.,gravelcolumns

maybeplacedinacloselinearoundtheperimeterofthebuildingtoformacontinuousgravelwall.Theinterior

ofthesitemaybecompletelyfilledwithslurryorothermaterial.Alternatively,aleanconcretemaybeusedin

placeofgravel,sothatthepilesachievesignificantstructuralcapacity.

FlyashGroutInjection

In a partially subsided mine, it may be difficult to build gravel columns. A highly fluid injection material is

desiredthatwillfillsmallvoidsandcrevices,yetisexpensiveenoughtouseinsuchlargeopeningsasmaystill

existinthemine.Itiscarriedtoboreholebypipeandhose,andpoureddowntheboreholeinfreefall.Inlarge

opening,thevalueofgroutinjectedineachshiftissufficienttocreateadiskperhaps10mindiamand10cm

tall by next day, this disk will have set, and another disk will be placed on the top by each days injection.

Eventually,thecolumnofgroutwillcontactthemineroof,theboreholewillbefilledwithgrout,andanystrata

separationsinthemineroofwillbegrouted.

FabricFormedConcrete

Aboreholeisdrilledfromthesurfacethroughthemineopeningandashortdistanceintotheminefloor.The

fabric tube is then placed around a grout pipe, and the assembly lowered into the borehole. Concrete is then

pumpedfromthegroutpipetoinflatethefabrictubefromthebottomup.Creatingaconcretecolumnkeyedinto

theminefloorandroof28.Oftenthegroutpipeisleftinplacetoprovidesomereinforcement.Thefinisheddiam

of the column depends upon the tensile strength of the fabric and the depth of mine opening. Since the fabric

mustresistburstingunderthehydrostaticpressureofthefluidconcrete.

Inthedesignofasubsidencecontrolsystemsuchasfabricformedconcrete,theinteractionamongthemine

floor,columnandmineroofelementsmustbeconsidered.Itisdifficulttoobtaincompletecontact.Theconcrete

columnistypicallystiffandstrongincomparisontothemineroofandfloor,sothatmaximumloadislimitedby

bearingstrengthoffloorratherthanthestrengthoftheconcretecolumn.

ArealBackfilling

ArealBackfillinginvolvesthefillingofminevoidstoprovidegeneralprotectiontourbanareasthatmaybe

measuredinsqkm.Itinvolvedthelargequantitiesofmaterialssuchascoalminerefuseorflyash,whichare

available locally at low cost. Such materials are not desired on the surface, and backfilling provides an

environmentally sound method for their disposal in addition to controlling subsidence. In contrast to the point

supportsystem,whichistypicallygravityfeedmethod,ArealBackfillingusuallyinvolvespressureinjection.On

the principle of Areal Backfilling, some other methods are: i) Pumped Slurry Injection ii) Fly ash Slurry

Injectionandiii)PneumaticFlyashInjection

PumpedSlurryInjection

Pumped Slurry Injection4,31 method (Fig. 8) is used in

dryorwetmines,butismoresuccessfulwhenthemineis

http://www.niscair.res.in/sciencecommunication/researchjournals/rejour/Jsir/Fulltextsearch/2005/May%202005/jsir671%20Vol%2064%20May%202005

6/10

11/13/2015

Subsidencecontrolmeasuresincoalmines:Areview

inundated. It offers more effective overburden support

than other flushing methods. The objective of using fill

materialforgroundcontrolistoeithereliminateorreduce

groundmovementsthatcanresultinsurfacesubsidence.

From the practical standpoint, fill rarely occupies the

entireminedoutareaandgenerallydoesnotcontactwith

the roof. Furthermore, a certain delay exists between

miningandtheplacementofthefillconsequently,support

pillarsarealreadyloadedandinitialroofconvergencehas

occurred prior to fill placement. The fill material acts

initially as a passive support, and being to take on load

only when additional deformation of the roof or pillars

takesplace.

The functions of fills as ground control measures are:

(i) To reduce the effective void, thus limiting the

propagation of roof caving (ii) To increase the residual

strength, post failure stiffness and to a lesser extent, the

effective peak strength of support pillar and (iii) To

providedirectroofsupport29. The geotechnical properties

ofthefillmaterialunderwetconditionsareverycriticalin

meetingthedesignobjectives.Consequently,fillmaterials

Fig.8Sectionalviewthroughafloodedmineroomatthepointof must be fully characterized to determine their adequacy

slurry injection showing measurement of particles and growth of foruseasbackfill32.

deposit

Coalminerefuseiscrushedandloadedintotruckatthe

mine refuse pile, and traveled several kilometers to a

mixingpumpingfacility.Mixingwaterisusuallyobtainedfromadeepwellpumpdrawingwaterdirectlyfrom

flooded mine. Coalmine refuse and water are mixed, and pumped through slurry pipeline as much as several

kilometerstotheinjectionboreholescurrentlyinuse.Fromasinglemixinglocation,slurrypipelinesmayberun

to a large numbers of boreholes, each of which is backfilled in turn. In locations where multiple seams were

mined,lowermostseamisbackfilledfirst,andtheremainingseamsinsequencefromthebottomup.

FlyashSlurryInjection

Flyashslurryisinjectedinabandonedmineusingapumpingsystem.Becauseofitsgreaterfluidity,flyash

slurry(5060%solid)ishighlypumpableandtravelsundergroundalongdistance.Atonelocation,flyashslurry

wasdepositedmorethanakilometerfromitsinjectionpoint,clearly,largeareasmaybebackfilledfromeach

injectionborehole,butdifficultymaybeencounteredindeterminingwheretheflyashistraveled.

PneumaticFlyashInjection

Some use has been made of pneumatic injection of dry fly ash in dry mines. The process simply involved

carryingtheflyashindryproducttankersdirectlytotheinjectionborehole,andusingthetankersonboardair

compressortoblowtheflyashintothemineopening.Suchsystemshavenotbeendevelopedtothesamedegree

ashaveeffectivepumpedslurrymethods,butcertainlycouldbeeffectiveindrymineswherelittlesubsidence

hastakenplaceandgoodconnectivitybetweenminesentriesexists.Inanisolatedmineentry,backpressurecan

rapidlybuildup,defeatingthepneumatictransportmechanism.

Intheinjectionhead(Fig.9),theinnerpipecarriescompressedair,whichimpingesonthecurvedeflection

plate at the bottom of the casing, spraying the wet coal mine refuse horizontally. In open air, the mine refuse

wouldtravelupto15minaflattrajectory.Inamineopening,theminerefusewouldtendtodepositinacircle

aroundtheinjectionhead.Asthedepositscomeneartosealingthemineroof,airvelocitythroughthenarrow

openingremainingisexpectedtoformapipethroughwhichslurrywouldbecarriedinapneumatictransportto

bedepositedatgreaterdistances.Asconceived,thesystemdoesnothavecertainobviousfaults,norhasitbeen

inoperationlongenoughforthisfaulttobecorrected.

FillingofCracks

Soil and sandcement mixture above alluvium and

rocks, must be filled in cracks formed due to ground

movements respectively. However, cracks, developed in

riverorrivuletbeds,shouldbeinfilledbyconcrete.This

restrictsthepenetrationofsurfacewaterthroughcracksor

http://www.niscair.res.in/sciencecommunication/researchjournals/rejour/Jsir/Fulltextsearch/2005/May%202005/jsir671%20Vol%2064%20May%202005

7/10

11/13/2015

Subsidencecontrolmeasuresincoalmines:Areview

faults and thereby reduces the erosion of the overburden,

thusreducingthepossibilityofpotholeformation33.

Discussion

Importantsubsidencecontrolmeasuresincoalminesare

summarizedasfollows:

Methods

Minescondition

Remarks

PlaneFitting

Workingmine

TrenchAround

House

TensionCable

Workingmine

Stowing

Workingmine

NonEffective

Width

Workingmine

Protectsthesuperstructure

byeliminatingstrain.

Trenchingaroundahouse

absorbscompressivestrain.

Itiseffectiveinreducing

damagetoconcreteblock

masonrybasement.

Hydraulicstowingisvery

mucheffectiveinIndiaasit

reducesmaximum

subsidenceby1/12timesin

comparisontocaving.

Thismethodusedto

controlsubsidence

completely.Thepercentage

ofcoalrecoveryisabout

ChessBoard

Workingmine

Workingmine

Fig.9Pneumaticassistedslurryinjection

GoafPillar

Workingmine

WideandStall

Workingmine

SplittingofPillar

withstowing

Workingmine

Splittingofpillar

withsidebolting

Workingmine

5014insingleseam

conditionasisfurther

reducedinmultiseam

extraction.

Thismethodisusedfor

completesubsidence

controlwith6065%coal

recovery17.

Usedwheredifficultto

workbyNEWandChess

Boardmethods.Itgivebest

recoveryamongallpartial

extractionmethods.The

extractionpercentage

comesto607018.

Usedwherecoveris

shallowforcomplete

subsidencecontrol.The

extractionpercentageis40

6526.

Splitedpillars(stooks)with

stowingmusthaveatleast

1safetyfactortosupport

theoverburden.

Fullcolumngroutedside

boltingincreasethe

strengthofsplitedpillarsto

withstandoverburdenfor

completesubsidence

control.

http://www.niscair.res.in/sciencecommunication/researchjournals/rejour/Jsir/Fulltextsearch/2005/May%202005/jsir671%20Vol%2064%20May%202005

8/10

11/13/2015

Subsidencecontrolmeasuresincoalmines:Areview

Fig.10Differentmethodsforsubsidencecontrol

HarmonicMining

Workingmine

GravelColumn

Abandonedmine

FlyashGrout

Injection

Abandonedmine

FabricFormed

Cement

Abandonedmine

PumpedSlurry

Injection

Abandonedmine

FlyashSlurry

Injection

Abandonedmine

PneumaticFlyash

Injection

Abandonedmine

Almoststrainfreeminingto

controldeformationon

surface.

Gravelgivesafirmcontact

totheroofandeliminatesthe

groundmovement.

Flyashgroutinjectionis

effectiveinpartially

subsidedareatofillsmall

voidsandcrevices.

Groutedconcretessupport

theoverburdentoavoid

subsidencemovement.

Usefulindryandwet

condition.Offersmore

effectiveoverburdensupport

thanotherflushingmethods.

Italsoincreasestheresidual

strengthandpostfailure

stiffness31.

Aflyashstowingwith50

60percentsolidstravelsa

greatdistancetosupporta

largeareaofoverburden.

Effectiveindrymineswhere

lesssubsidencehastaken

placeandgoodconnectivity

betweenminesentries

exists.

Conclusions

Winningofcoalisveryimportantbyusingsuitablemethod,whichgivesmaximumrecoveryandsafetytolife

andtheproperty.GoafPillarmethodofpartialextractionisbestsuitableforrecoveryandsafetypointofview

http://www.niscair.res.in/sciencecommunication/researchjournals/rejour/Jsir/Fulltextsearch/2005/May%202005/jsir671%20Vol%2064%20May%202005

9/10

11/13/2015

Subsidencecontrolmeasuresincoalmines:Areview

as this method consists of leaving pillars systematically in the goaf such that the width of the extracted span

aroundanysuchpillarislessthanNEWandtheleftoutpillarhavealongtermstability.Harmonicminingcan

be practiced surface structure as it neutralizes the strains without compromising coal recovery. Among all the

methods of abandoned mine, Pumped Slurry Injection method is best suitable as this method gives maximum

area coverage to support different overlying surface feature and structure and reaches maximum area of mine

wheretheothermethodsfailtodoit.

Acknowledgements

AuthorsthankDirector,CMRI,Dhanbad,forpermissiontopublishthispaper.ThanksarealsoduetoShriS

NRajakfordraftingthefigures.

References

1LittlejohnGS,Surfacestabilityinareasunderlainbyoldcoalworkings,GroundEngineering,England,12(2)(1979)2230.

2LuoY,PenghSS&DuttaD,Somemitigativemeasuresforprotectionofsurfacestructureaffectedbygroundsubsidence,ProcThird

WorkshoponSubsidenceduetoUndergroundMining,Morgantown,WV,1992,129138.

3LuoY&PenghSS,ProtectingasubsidenceaffectedhouseAcasestudy,Proc,VIIICongInternatSocMineSurvey,editedbyR

WillimDevore,Kentucky,1991,297300.

4PenghSS,SurfaceSubsidenceEngineering(SMEAIME,Littleton,Co),May1992,161.

5AttewellPB,YeatsJ&SelbyAR,SoilMovementsInducedbyTunnelingandtheirEffectsonPipelinesandStructures,(Chapmanand

Hall,NewYork)1986,321.

6S&TProjectReport,SurfaceSubsidenceinMiningAreas(CentralMiningResearchInstitute,Dhanbad)1991.

7SinghKB&SinghTN,Groundmovementoverlongwallworkingsinkampteecoalfield,India,EnggGeolInternatJ,50(1998)125

139.

8KratzschH,MiningSubsidenceEngineering(SpringerVerlag,Berlin),1983,441500.

9KnotheS,Rateofadvanceandgrounddeformation,Bergakademie,5(1953)513518.

10GrardC,Miningsubsidenceandthemeansofpermittinglimitationoftheeffectsonthesurface,Rev1IndustrieMin,51(1969)3570.

11WhittakerBN&ReddishDJ,Subsidencebehaviorofrockstructures,ComprehenRockEng,4(1993)751780.

12HiramastuY,OkamuraH,&SugawaraK,Surfacesubsidenceandhorizontaldisplacementcausedbymininginclinedcoalseams,Proc

4thCongInternatSocRockMechanics,Montreux,VolI,AABalkema,Rotterdam,1979,665670.

13WhittakerBN&ReddishDJ,Subsidence:Occurrence,PredictionandControl(Elsevier)1989,528.

14SinghKB,SinghSK,SheoreyPR,&SamantaS,NoneffectivewidthofextractionforsubsidencecontrolAcriticalapproach,

ProcNatSympEmergingMiningandGroundControlTechnologies,BanarasHinduUniversity,Varanasi,1994,126136.

15SheoreyPR,PillarStrength,CoalMinTechnolManage(CMTM)2000,617.

16WilsonAH,Researchintothedeterminationofpillarsize,MinEng,131(1972)409416.

17SinghSK,SinghKB&SheoreyPR,Explorationofcoalseamforcompletesubsidencecontrol,Minetech,15(4)(1994)2936.

18 PartialextractionofBograandSatgramseamsbelowbuiltupareaatJKNagarcolliery,EasternCoalfieldLimited(ECL)(Central

MiningResearchInstitute,Dhanbad)1995,14.

19SinghTN,PrasadD,&RafiquiMA,WidestallminingAmethodforpartialextractionofthickseamunderneathsurfacestructure,

ProcInternatSymponThickSeamMining(CentralMiningResearchInstitute,Dhanbad)1992,367380.

20SinhaPK,VermaRK&JainDK,ResearchanddevelopmenteffortsinthickseamminingPresentandfuturescenario,ProcInternat

SymponThickSeamMining(CentralMiningResearchInstitute,Dhanbad)1992,471492.

21FieldtrailofwideandstallminingofVII/VIIIseamunderbuiltupareaatEastBhuggatdihcolliery(CentralMiningResearchInstitute,

Dhanbad)1993,64.

22SalamonMDG&MunroAH,Studyofthestrengthofcoalpillars,JSouthAfricInstitMinandMetallur,68(1967)5567.

23SheoreyPR,DasMN,BaratD,PrasadRK&SinghB,Coalpillarstrengthestimationfromfailedandstablecases.InternatJRock

Mecha,24(1987)347355.

24 Singh R, Mondal P K, Singh A K, Wide Stall Mining: A method to optimise coal recovery from a seam under surface features,

Minetech,21(2000)1017.

25DasMN,Influenceofwidthheightratioonpostfailurebehaviorofcoal.InternatJMinGeolEng,4(1986)7987.

26SinghKB&SinghTN,Subsidencecontrolsinundergroundmine,Minetech,19(5)(1998)1720.

27BieniawskiZT,Designofminepillar(Integrateddesign),RockmechanicsinMining&Tunneling,(1984)183216.

28NCB,Principlesofsubsidenceengineering,NationalCoalBoard,ProductionDepartment,InformBullet,61/240,(1963)27.

29KarfakisMarioG,ResidualSubsidenceoverabandonedcoalmines,ComprehenRockEng,5(1993)451476.

30HuckJPeter,ChughPYoginder&JenningsM,Subsidencecontrolinabandonedcoalmines:USPractices,GroundControlinRoom

andPillarMining,editedbyYPChugh(SMEAIME,Littleton,Co)1982,151154.

31WaiteRH&AllenAS,Pumpedslurrybackfillingofinaccessiblemineworkingforsubsidencecontrol,USBurMines,Information

Circular8667,(1975).

32SwanG&BoardM,Fillinducedpostpeakpillarstability,inInnovationsinMiningBackfillTechnology,editedbyFPHassani,MJ

Scoble&TRYu(Balkema,Rotterdam)1989,8187.

33SinghKB,CausesandRemedialmeasuresofpotholesubsidenceduetocoalmining,JSciIndRes,59(2000)280285.

http://www.niscair.res.in/sciencecommunication/researchjournals/rejour/Jsir/Fulltextsearch/2005/May%202005/jsir671%20Vol%2064%20May%20200

10/10

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Charles2004 - Settlement and Tilt of Low-Rise BuildingsДокумент11 страницCharles2004 - Settlement and Tilt of Low-Rise BuildingsAbd100% (1)

- Behaviors of Overlying Strata in Extra Thick Coal Seams Using Top Coal Caving Method 2016 Journal of Rock Mechanics and Geotechnical EngineeringДокумент10 страницBehaviors of Overlying Strata in Extra Thick Coal Seams Using Top Coal Caving Method 2016 Journal of Rock Mechanics and Geotechnical Engineeringkatta_sridharОценок пока нет

- Is 1904Документ20 страницIs 1904chandra chandu100% (2)

- Mining Subsidence Engineering - Helmut KratzschДокумент551 страницаMining Subsidence Engineering - Helmut Kratzschferry verali100% (2)

- Geomorphology For EngineersДокумент874 страницыGeomorphology For EngineersAlexander Yulius Purnama100% (1)

- 2016 Chapter 3 Geotechnical Investigation and SamplingДокумент23 страницы2016 Chapter 3 Geotechnical Investigation and SamplingPm889096Оценок пока нет

- bd10 - 97 Highway Structures - General Design PDFДокумент31 страницаbd10 - 97 Highway Structures - General Design PDFSuheil BagasrawalaОценок пока нет

- MGB - Hazard Information PDFДокумент74 страницыMGB - Hazard Information PDFKyla MatiasОценок пока нет

- 14EE MiningTechnology-CavingSlopeInteractionModellingДокумент9 страниц14EE MiningTechnology-CavingSlopeInteractionModellingMezamMohammedCherifОценок пока нет

- Pressure Arch Theory (Longwall) : Prepared by P. Vinay CharyДокумент23 страницыPressure Arch Theory (Longwall) : Prepared by P. Vinay Charykatta_sridharОценок пока нет

- Bridges & StructuresДокумент24 страницыBridges & Structureskatta_sridharОценок пока нет

- Permeability of Sandstone and Coal Samples Subjected To ConfiningДокумент101 страницаPermeability of Sandstone and Coal Samples Subjected To Confiningkatta_sridharОценок пока нет

- 25th International Conference On Ground Control in MiningДокумент6 страниц25th International Conference On Ground Control in Miningkatta_sridharОценок пока нет

- A Study of The Behaviour of Overlying Strata in Longwall Mining and Its Application To Strata Contro 141111171916 Conversion Gate02Документ5 страницA Study of The Behaviour of Overlying Strata in Longwall Mining and Its Application To Strata Contro 141111171916 Conversion Gate02katta_sridharОценок пока нет

- Mine-Scale Numerical Modelling of Longwall OperationsДокумент11 страницMine-Scale Numerical Modelling of Longwall Operationskatta_sridharОценок пока нет

- WATER PROBLEMS ASSOCIATED With Undersea LWДокумент20 страницWATER PROBLEMS ASSOCIATED With Undersea LWkatta_sridharОценок пока нет

- Export - 2015-09-03 09-05-55Документ1 страницаExport - 2015-09-03 09-05-55katta_sridharОценок пока нет

- 15.production and Productivity Improvement Measures at MOIL-MOILДокумент8 страниц15.production and Productivity Improvement Measures at MOIL-MOILkatta_sridharОценок пока нет

- Investigation of Rib Pillar Stability at Ömerler Underground Mine byДокумент8 страницInvestigation of Rib Pillar Stability at Ömerler Underground Mine bykatta_sridharОценок пока нет

- Automation in LongwallДокумент116 страницAutomation in Longwallkatta_sridharОценок пока нет

- LW Face Supports in Germal Coal Mining CompanyДокумент24 страницыLW Face Supports in Germal Coal Mining Companykatta_sridharОценок пока нет

- NUMERICAL MODELLING OF SURFACE SUBSIDENCE Due To LWДокумент12 страницNUMERICAL MODELLING OF SURFACE SUBSIDENCE Due To LWkatta_sridharОценок пока нет

- Experience in Longwall Mining at Coalbrook CollieriesДокумент15 страницExperience in Longwall Mining at Coalbrook Collierieskatta_sridharОценок пока нет

- Design of Rib Pillars in LW MiningДокумент16 страницDesign of Rib Pillars in LW Miningkatta_sridharОценок пока нет

- Pillar in Coal MinesДокумент8 страницPillar in Coal MinesSujit KumarОценок пока нет

- The Ground Control Management Plan of A Mine Ovacık Gold MineДокумент8 страницThe Ground Control Management Plan of A Mine Ovacık Gold Minekatta_sridharОценок пока нет

- Thick Seam Longwall MiningДокумент10 страницThick Seam Longwall Miningkatta_sridharОценок пока нет

- 12.challenges in UG Coal mining-CMPDI RanchiДокумент7 страниц12.challenges in UG Coal mining-CMPDI Ranchikatta_sridharОценок пока нет

- Stress Evolution and Induced Accidents Mechanism in Shallow Coal Seam in Proximity Underlying The Room Mining Residual PillarsДокумент7 страницStress Evolution and Induced Accidents Mechanism in Shallow Coal Seam in Proximity Underlying The Room Mining Residual Pillarskatta_sridharОценок пока нет

- WATER PROBLEMS ASSOCIATED With Undersea LWДокумент20 страницWATER PROBLEMS ASSOCIATED With Undersea LWkatta_sridharОценок пока нет

- 16.shortwall Mining-D M Gokhale, WCLДокумент6 страниц16.shortwall Mining-D M Gokhale, WCLkatta_sridharОценок пока нет

- Deformation Failure and Permeability of Coal Bearing Strata During Longwall Mining 2016 Engineering GeologyДокумент12 страницDeformation Failure and Permeability of Coal Bearing Strata During Longwall Mining 2016 Engineering Geologykatta_sridharОценок пока нет

- Caving Mechanisms of Loose Top Coal in Longwall Top Coal Caving Mining Method 2014 International Journal of Rock Mechanics and Mining SciencesДокумент11 страницCaving Mechanisms of Loose Top Coal in Longwall Top Coal Caving Mining Method 2014 International Journal of Rock Mechanics and Mining Scienceskatta_sridharОценок пока нет

- 14.an Overview of Ug Coal mining-WCL HQДокумент30 страниц14.an Overview of Ug Coal mining-WCL HQkatta_sridharОценок пока нет

- 13.hydraulic Mining With Automation - Suresh D. Gharde, WCL HQДокумент6 страниц13.hydraulic Mining With Automation - Suresh D. Gharde, WCL HQkatta_sridharОценок пока нет

- Tiwari InnovationДокумент1 страницаTiwari Innovationkatta_sridharОценок пока нет

- 19 Ratnesh Mine ClosureДокумент12 страниц19 Ratnesh Mine Closurekatta_sridharОценок пока нет

- 09.roof SupportsДокумент22 страницы09.roof SupportsLavudiya RajkumarОценок пока нет

- Geotechnical Hazards Associated With DesertДокумент15 страницGeotechnical Hazards Associated With DesertSalam LabadiОценок пока нет

- 2012 GSI Roads Conference Paper 5 Investigation, Design and Construction in Karst by Peter Rutty and Paul Jennings PDFДокумент52 страницы2012 GSI Roads Conference Paper 5 Investigation, Design and Construction in Karst by Peter Rutty and Paul Jennings PDFNovia SetyaОценок пока нет

- MAR Laying Maintenance-ENДокумент32 страницыMAR Laying Maintenance-ENPatriciaMariaОценок пока нет

- Journal of Cleaner Production: Zhanjie Feng, Zhenqi Hu, Gensheng Li, Yuhang Zhang, Xi Zhang, Hao ZhangДокумент15 страницJournal of Cleaner Production: Zhanjie Feng, Zhenqi Hu, Gensheng Li, Yuhang Zhang, Xi Zhang, Hao ZhangCarlos Saldaña ParedesОценок пока нет

- SDPSДокумент350 страницSDPSDacianMОценок пока нет

- The Environmental Impact of Mining and Its CountermeasuresДокумент7 страницThe Environmental Impact of Mining and Its CountermeasuresAlejandro Guerrero LaverdeОценок пока нет

- Land Subsidence in JakartaДокумент10 страницLand Subsidence in JakartaNovi MustikasariОценок пока нет

- Ground Subsidence: Legal DefinitionДокумент10 страницGround Subsidence: Legal DefinitionAlyssa Mae BobitaОценок пока нет

- Lot - 60 - FCI ReportДокумент13 страницLot - 60 - FCI ReportMohit SharmaОценок пока нет

- Effects of Groundwater Development On The EnvironmentДокумент14 страницEffects of Groundwater Development On The EnvironmentRuel B. Ramos Jr.Оценок пока нет

- Makalah - Tonggotua Sormin-Restu Glorya Simangunsong - SMAN 2 Lintongnihuta - G - Nas2022Документ8 страницMakalah - Tonggotua Sormin-Restu Glorya Simangunsong - SMAN 2 Lintongnihuta - G - Nas2022ivn strssdОценок пока нет

- Usace Settlement AnalysisДокумент205 страницUsace Settlement AnalysisjjahaddinОценок пока нет

- Exner EquationДокумент8 страницExner Equationlomas3Оценок пока нет

- 3 - MPOB's Guidelines For Oil Palm On Peat (Tarmizi)Документ28 страниц3 - MPOB's Guidelines For Oil Palm On Peat (Tarmizi)Martin SigarОценок пока нет

- Educ265-Maed279 - Maribojoc - Powerpoint 1 PresentationДокумент37 страницEduc265-Maed279 - Maribojoc - Powerpoint 1 PresentationHarold MaribojocОценок пока нет

- Geotechnical Design of Shallow FoundationsДокумент35 страницGeotechnical Design of Shallow FoundationsAndré OliveiraОценок пока нет

- Terzaghi - 1951Документ7 страницTerzaghi - 1951Alexey NagibinОценок пока нет

- 1997 Berger GeoindicadoresДокумент9 страниц1997 Berger GeoindicadoresHeloisa AquinoОценок пока нет

- Soil Settlement-SubsidenceДокумент2 страницыSoil Settlement-SubsidenceAnonymous EFhRBnx50% (1)

- Hydrogeology - A Global Perspective by Gholam A. KazemiДокумент231 страницаHydrogeology - A Global Perspective by Gholam A. KazemiJohann Alvarez PerezОценок пока нет

- 1999 - 02 - Foundations in Limestone Areas of Peninsular MalaysiaДокумент12 страниц1999 - 02 - Foundations in Limestone Areas of Peninsular MalaysiafreezefreezeОценок пока нет

- Paper - SubsidenciaДокумент221 страницаPaper - SubsidenciaFernando Raúl Pastor ReañoОценок пока нет