Академический Документы

Профессиональный Документы

Культура Документы

Data Sheet

Загружено:

ΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Data Sheet

Загружено:

ΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣАвторское право:

Доступные форматы

Part No: CD-1206

Date: 8/21/2006

Description: magnetic buzzer

Page No: 1 of 5

Unit: mm

Specifications

Rated voltage

5 Vo-p

Operating voltage

Mean current

4.0 - 8.0 Vo-p

40 mA max.

Coil resistance

Sound output

47 7

Min. 85 (Typical 94) dBA

Rated frequency

Operating tempurature

Storage tempurature

Dimensions

Weight

Material

Terminal

RoHS

2,400 Hz

-30 ~ +70 C

-40 ~ +85 C

12 x H9 mm

1.6 g

PPS (Black)

SMD type (Au Plating)

yes

Applying rated voltage, 2400 Hz

square wave, duty

Distance at 10cm (A-weight free air).

Applying rated voltage of 2400 Hz, square

wave, duty.

See attached drawing

See attached drawing

Frequency Response Curve

Phone: 800.275.4899

Fax: 503.612.2381

www.cui.com

20050 SW 112th Ave.

Tualatin, OR 97062

Part No: CD-1206

Date: 8/21/2006

Description: magnetic buzzer

Page No: 2 of 5

Unit: mm

Appearance Drawing

Tolerance: 0.5

Measurement Method

Phone: 800.275.4899

Fax: 503.612.2381

www.cui.com

20050 SW 112th Ave.

Tualatin, OR 97062

Part No: CD-1206

Date: 8/21/2006

Description: magnetic buzzer

Page No: 3 of 5

Unit: mm

Mechanical Characteristics

Item

Solderability

Soldering Heat Resistance

Terminal Mechanical Strength

Vibration

Drop Test

Test Condition

Lead terminals are immersed in a solder bath

of +270 5C for 3 1 seconds.

Lead terminals are immersed in solder bath

of +260 5C for 3 1 seconds.

Lead pads should be soldered onto the PC

Board and then the force of 9.8 N (1.0 kg)

should be applied behind the part for

10 seconds.

The buzzer will be measured after applying

a vibration amplitude of 1.5 mm with 10 to

55 Hz band of vibration frequency to each of

the 3 perpendicular directions for 2 hours

The part should be dropped from a height of

75 cm onto a 40 mm thick wooden board 3

times in 3 axis (X, Y, Z) for a total of 9 drops.

Evaluation Standard

95% min. of lead terminals should

be covered with fresh solder.

Test Condition

The part will be subjected to +85C for

96 hours.

The part will be subjected to -40C for

96 hours

The part will be subjected to 10 cycles. One

cycle will consist of:

Evaluation Standard

No in interference in operation.

No damage or cutting off.

After the test, the part should

meet specifications without any

damage to the appearance and

the SPL should be within

10 dBA of the initial

measurement.

Environment Test

Item

High temp. test

Low temp. test

Thermal shock

Temp./Humidity cycle

Phone: 800.275.4899

The part shall be subjected to 10 cycles. One

cycle should last 24 hours and will consist of:

Fax: 503.612.2381

www.cui.com

After the test, the part should

meet specifications without any

damage to the appearance or

performance except SPL. After 4

hours at 25C, the SPL should be

80 dBA or more.

20050 SW 112th Ave.

Tualatin, OR 97062

Part No: CD-1206

Date: 8/21/2006

Description: magnetic buzzer

Page No: 4 of 5

Unit: mm

Reliability Tests

Item

Operating (Life Test)

Test Condition

1. Continuous life test:

The part will be subjected to 72 hours at 55C

with 5 V, 2400 Hz applied.

Evaluation Standard

2. Intermittent life test:

A duty cycle of 1 minute on, 1 minute off, a

minimum of 10,000 times at room temp.

(+25 10C) with 5 V, 2400 Hz applied.

After the test, the part should

meet specifications without any

damage to the appearance or

performance except SPL. After 4

hours at 25C, the SPL should be

80 dBA or more.

Test Conditions

Standard Test Condition

Judgement Test Condition

a) Tempurature: +5 ~ +35C

a) Tempurature: +252C

b) Humidity: 45 - 85%

b) Humidity: 60 - 70%

c) Pressure: 860 - 1060 mbar

c) Pressure: 860 - 1060 mbar

Recommended Temperature Profile for Reflow Oven

Recommended Land Pattern

Phone: 800.275.4899

Fax: 503.612.2381

www.cui.com

20050 SW 112th Ave.

Tualatin, OR 97062

Part No: CD-1206

Date: 8/21/2006

Description: magnetic buzzer

Page No: 5 of 5

Unit: mm

Packaging

Phone: 800.275.4899

Fax: 503.612.2381

www.cui.com

20050 SW 112th Ave.

Tualatin, OR 97062

Вам также может понравиться

- High-Frequency, High-Power, High-Voltage Chips With Nonmagnetic OptionДокумент9 страницHigh-Frequency, High-Power, High-Voltage Chips With Nonmagnetic OptionΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- Data SheetДокумент16 страницData SheetΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- 3.3 V Ecl/Pecl/Hstl/Lvds: ÷2/4, ÷4/5/6 Clock Generation ChipДокумент12 страниц3.3 V Ecl/Pecl/Hstl/Lvds: ÷2/4, ÷4/5/6 Clock Generation ChipΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- Data Sheet 1Документ17 страницData Sheet 1ΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

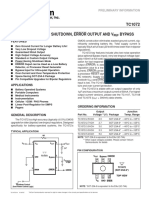

- TC1072 50ma Cmos Ldo With Shutdown, Error Output and V BypassДокумент12 страницTC1072 50ma Cmos Ldo With Shutdown, Error Output and V BypassΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- Axial Leads/Spinguard: General DescriptionДокумент6 страницAxial Leads/Spinguard: General DescriptionΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- 54ACT283 4-Bit Binary Full Adder With Fast Carry: General Description FeaturesДокумент8 страниц54ACT283 4-Bit Binary Full Adder With Fast Carry: General Description FeaturesΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- AX97 Series: SMD Power InductorsДокумент3 страницыAX97 Series: SMD Power InductorsΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- Patented : SM6S10 Thru SM6S36AДокумент5 страницPatented : SM6S10 Thru SM6S36AΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- Data SheetДокумент6 страницData SheetΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- VRLA Rechargeable Battery: Application FeaturesДокумент1 страницаVRLA Rechargeable Battery: Application FeaturesΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- Data SheetДокумент14 страницData SheetΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- Wall Plug - Ins: Electrical Specifications (@25C)Документ1 страницаWall Plug - Ins: Electrical Specifications (@25C)ΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- VN0610LL FET Transistor: N Channel - EnhancementДокумент4 страницыVN0610LL FET Transistor: N Channel - EnhancementΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- 8K Microwire Compatible Serial EEPROM: 93AA76A/B/C, 93LC76A/B/C, 93C76A/B/CДокумент26 страниц8K Microwire Compatible Serial EEPROM: 93AA76A/B/C, 93LC76A/B/C, 93C76A/B/CΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣ100% (1)

- Data Sheet: BZW03 SeriesДокумент9 страницData Sheet: BZW03 SeriesΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- BTA204S Series B and C: 1. Product ProfileДокумент13 страницBTA204S Series B and C: 1. Product ProfileΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- VRLA Rechargeable Battery: Features ApplicationДокумент1 страницаVRLA Rechargeable Battery: Features ApplicationΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- VRLA Rechargeable Battery: Application FeaturesДокумент1 страницаVRLA Rechargeable Battery: Application FeaturesΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- Data SheetДокумент2 страницыData SheetΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- RFR D H - Am-H RK: Eceiver Ecoder Ybrid IДокумент4 страницыRFR D H - Am-H RK: Eceiver Ecoder Ybrid IΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

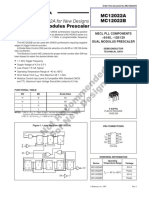

- Mc12022A Mc12022B Consider Mc12052A For New Designs 1.1Ghz Dual Modulus PrescalerДокумент8 страницMc12022A Mc12022B Consider Mc12052A For New Designs 1.1Ghz Dual Modulus PrescalerΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- Mc12022A Mc12022B Consider Mc12052A For New Designs 1.1Ghz Dual Modulus PrescalerДокумент8 страницMc12022A Mc12022B Consider Mc12052A For New Designs 1.1Ghz Dual Modulus PrescalerΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Molecular Chemical Bonding NotesДокумент2 страницыMolecular Chemical Bonding NotesMeera KumarОценок пока нет

- Aerial Robotics Lecture 2C - 3 Principal Axes and Principal Moments of InertiaДокумент3 страницыAerial Robotics Lecture 2C - 3 Principal Axes and Principal Moments of InertiaIain McCullochОценок пока нет

- KP KCДокумент11 страницKP KCHussain AbbasОценок пока нет

- Final Exam Cheat SheetДокумент1 страницаFinal Exam Cheat SheetDanielle GuindonОценок пока нет

- EMBO 2013 HandoutDeuterationДокумент54 страницыEMBO 2013 HandoutDeuterationRigel_TОценок пока нет

- Chapter21 - Fundamental of MachiningДокумент63 страницыChapter21 - Fundamental of Machining叭叭叭2Оценок пока нет

- 4 - 21 Mar Design - of - BreakwaterДокумент21 страница4 - 21 Mar Design - of - BreakwaterAhmad Aki Muhaimin100% (2)

- MAAE 3202 Mid Term Assignment 2014Документ11 страницMAAE 3202 Mid Term Assignment 2014Moustafa SohdyОценок пока нет

- Transport Phenomena ProblemsДокумент26 страницTransport Phenomena ProblemsCamilo SierraОценок пока нет

- Mechanical and Thermal Behavior of Kaolin Rice-Husk Ash Matrix CompositesДокумент6 страницMechanical and Thermal Behavior of Kaolin Rice-Husk Ash Matrix CompositesNaiane StocheroОценок пока нет

- Syllabus FE 2018 19Документ69 страницSyllabus FE 2018 19fuckyouОценок пока нет

- 4 - Rate Laws and Stoichiometry - StuДокумент62 страницы4 - Rate Laws and Stoichiometry - StuTiệp MatícОценок пока нет

- MRI Lecture NotesДокумент33 страницыMRI Lecture NotesArungoud PoshalaОценок пока нет

- Instruction ManualДокумент140 страницInstruction ManualJerryChenОценок пока нет

- Definition of ChemistryДокумент4 страницыDefinition of ChemistryGemlyn de CastroОценок пока нет

- CHEM10003 - Mock Exam 1Документ17 страницCHEM10003 - Mock Exam 1Sunny XiaОценок пока нет

- 06 Train Track Dynamics June 08Документ21 страница06 Train Track Dynamics June 08Charles KohОценок пока нет

- SEAM-Maths1-1.2 SD-Trigonometric Functions 28-8-19 SPCEДокумент13 страницSEAM-Maths1-1.2 SD-Trigonometric Functions 28-8-19 SPCESatish BarotОценок пока нет

- BC YES Calculator MCДокумент10 страницBC YES Calculator MCbingfang wuОценок пока нет

- Lecture 1-2 PDFДокумент49 страницLecture 1-2 PDFASHISH MEENAОценок пока нет

- Parts of Single Point Cutting ToolДокумент8 страницParts of Single Point Cutting ToolMukesh sutharОценок пока нет

- The Language of Our Dna Scalar EnergyДокумент5 страницThe Language of Our Dna Scalar EnergyNat Silva100% (1)

- AngularДокумент57 страницAngularThomas Edoche EdocheОценок пока нет

- Different Magnetic Interaction MechanismsДокумент5 страницDifferent Magnetic Interaction MechanismsJoshuaОценок пока нет

- Design of Electrical Apparatus Solved ProblemsДокумент14 страницDesign of Electrical Apparatus Solved ProblemsRichard RegidorОценок пока нет

- Boundary Conditions in Fluid MechanicsДокумент6 страницBoundary Conditions in Fluid MechanicsnickolasnaimОценок пока нет

- 신소재과학 시험문제모음Документ9 страниц신소재과학 시험문제모음Hanjin SeoОценок пока нет

- Answer Key: 13 VXY (Date: 12-02-2012) Review Test-7 Paper-2Документ18 страницAnswer Key: 13 VXY (Date: 12-02-2012) Review Test-7 Paper-2vishal110085Оценок пока нет

- Geometric Shapes and TransformationsДокумент10 страницGeometric Shapes and TransformationsisidroОценок пока нет