Академический Документы

Профессиональный Документы

Культура Документы

6 X 8 1M Shade

Загружено:

amachmouchiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

6 X 8 1M Shade

Загружено:

amachmouchiАвторское право:

Доступные форматы

STRUCTURAL DESIGN CALCULATIONS

6.0 x 8.1 CAR PARKING SHADES - PROMER QATAR

STRUCTURAL DESIGN CALCULATIONS

25-Oct-09

Date

Revision

Description

REVISION HISTORY

Calc. by

Checkd. By

Appd. By

AL JAIDAH AND SONS

TENTS AND UMBRELLA TRADING CO

INDUSTRIAL LINE -18 DOOR -54 QATAR

6.0 x 8.1 CAR PARKING SHADES - PROMER QATAR

Checking of Fabric Sunshade

*** COMMERCIAL 95 PRE KNITTED SHADE CLOTH ***

3100

20

0

PROJECT :

0.43

COMMERCIAL 95 PRE

KNITTED SHADE CLOTH

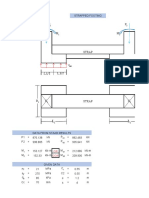

Y = C + SAG

S2 + C2 = Y2

S2 + C2 = ( C + 0.2 ) 2

S2 + C2 = C2 + 0.4 C + 0.04

S = ( 0.4 C + 0.04 )

X = C ln (( S + Y ) / C )

1.55 =C ln {( ( 0.4 C + 0.04 )) + ( C + 0.2 )} / C

BY TRIAL AND ERROR

TRY C = L2 / ( 8 * SAG )

C = 3.12 / ( 8 * 0.2 )

6m

1.55 =6 ln {( ( 0.4 * 6 + 0.04 )) + ( 6 + 0.2 )} / 6

1.55 1.54

OK

S = ( 0.4 * 6 + 0.04 )

S = 1.56

Y

6 + 0.2

6.2

FABRIC TENSILE FORCE PER LINEAR METER

T

0.43 * 6.2

2.66 kN/m

TENSILE STRENGTH OF FABRIC ( PRE CONTRAINT 1202S )

635 daN / 5 cm

6350 N / 50mm

127 kN/m

>

2.66 kN/m

OK

AL JAIDAH AND SONS

TENTS AND UMBRELLA TRADING CO

INDUSTRIAL LINE -18 DOOR -54 QATAR

PROJECT :

6.0 x 8.1 CAR PARKING SHADES - PROMER QATAR

*** 20mm DIA WIRE ROPE ***

50

0

8100

2.66

Y = C + SAG

S2 + C2 = Y2

S2 + C2 = ( C + 0.5 ) 2

S2 + C2 = C2 + 1.0 C + 0.25

S = ( 1.0 C + 0.25 )

X = C ln (( S + Y ) / C )

4.05 =C ln {( ( 1.0 C + 0.25 )) + ( C + 0.5 )} / C

BY TRIAL AND ERROR

TRY C = L2 / ( 8 * SAG )

C = 8.12 / ( 8 * 0.5 )

16.4 m

4.05 = 16.4 ln {( ( 1.0 *16.4 + 0.25 )) + ( 16.4 + 0.5 )} / 16.4

4.05 4.03

OK

S = ( 1.0 * 20.2 + 0.25 )

S = 4.08

Y

16.4 + 0.5

16.9

WIRE ROPE TENSILE FORCE

T

2.66 * 16.9

44.95 Kn

TENSILE STRENGTH OF 20mm dia WIRE ROPE

= 216 kN

>

44.95 kN

OK

AL JAIDAH AND SONS

TENTS AND UMBRELLA TRADING CO

INDUSTRIAL LINE -18 DOOR -54 QATAR

PROJECT :

6.0 x 8.1 CAR PARKING SHADES - PROMER QATAR

AL JAIDAH AND SONS

TENTS AND UMBRELLA TRADING CO

INDUSTRIAL LINE -18 DOOR -54 QATAR

PROJECT :

6.0 x 8.1 CAR PARKING SHADES - PROMER QATAR

DESIGN REFERENCE

BS 5950 part 1: 2000 Structural use of Steel (Code of Practice for Design - Rolled and Welded Section)

BS 8110 part 1: 1997 Structural use of Concrete

CP3 chapter V : Loading, Part 2 : Wind loads

DESIGN CONSIDERATION

Compressive Strength, fc

30 N/mm2

Steel Yield Strength, fy

420 N/mm2

Soil Bearing Capacity

100 kPa ( Assumed; subject for soil investigation report )

Unit weight of concrete

24 kN/m3

Grade of Steel as per BS 5950 part 1 : 2000

S275

Grade 8.8 Bolt

8.1m

Loading Consideration

SHADENET + FRAMING

6

m

DEAD LOAD

=

0.05 kN/m2

Basic Wind Speed, V

45 m/s

Height of Structure

3.2 m

Topographical Factor, S1

1.0

( Ground roughness, Bldg size, Height

above ground , country with many

windbreak, ), S2

0.68

Statistical Factor, S3

1.0

Design Wind Speed, Vs

=

=

=

VS1S2S3

45 * 1 * 0.68 * 1

30.6 m/s

Dynamic Pressure, q

=

=

0.613 * 30.62 * 10-3

0.57 kN/m2

WIND LOAD

( table 3 of CP3 Chap V part 2)

For a duopitch canopy roofs with maximum roof angle of 14.5

Considering overall coefficient

=

=

+ 0.4

- 1.2

Reduction factor for free standing multibay canopy roofs (on second bay)

on Maximum ( + )

=

0.87

On Minimum ( - )

=

0.64

Canopy Wind Pressure,

=

=

0.57*0.4*0.87

0.57*1.2*0.64

4.0 mm x 2.5" dia pipe

Member Section

Rafter Pipe

=

=

0.19 kN/m2

0.43 kN/m2

8.1m

AL JAIDAH AND SONS

TENTS AND UMBRELLA TRADING CO

INDUSTRIAL LINE -18 DOOR -54 QATAR

PROJECT :

6.0 x 8.1 CAR PARKING SHADES - PROMER QATAR

DESIGN OF CANOPY ROOF

Total surface area

=

=

6 * 3.1 + (2+8.1)/2 * 3.1*2

49.91 m2

since the wind pressure coefficient on roof varies by zone total wind pressure reduce by 15% consider a 15% reduction of the total pressure on roof

( case 1 )

Upward force due to wind

=

=

=

( case 2 )

8.1m

6

m

3.

1

Downward force due to wind and weight of canopy roof

=

49.91 * 0.19 * 85% + 49.91 * 0.05

=

10.55 kN

2.0m

49.91 * 0.43

21.46 * 85%

-18.24 kN

=

=

( 3.052 + 32 )1/2

4.27 m

=

=

( 0.78 + 4.27 )

4.34 m

tan

=

=

0.78 / 4.27

10.3

0.78m

6m

2 1/2

RAFTER PIPE

Section property of 2.5" mm dia pipe 4.0 mm thick

Area

radius of gyration

=

=

=

=

0.785 * ( 63.52 -55.52 )

747 mm2

( 63.52 + 55.52 )0.5 / 4

21 mm

Considering case 1, force equally resisted by rafter pipe member ( compression )

=

=

(10.55 / 4) / sin 10.3

14.75 kN

Considering case 2, force equally resisted by rafter pipe member ( tension )

Slenderness ratio

From table 24 a, BS 5950

Compressive Strength, rc

Compression Resistance

Tension Resistance

=

=

(18.24 / 4) / sin 10.3

25.5 kN

=

=

4340 / 30

206

40 N/mm2

=

=

747 * 40 * 10-3

29.88 kN

> 14.75 kN

OK

=

=

747 * 275 * 10-3

205 kN

> 25.5 kN

OK

3.1

AL JAIDAH AND SONS

TENTS AND UMBRELLA TRADING CO

INDUSTRIAL LINE -18 DOOR -54 QATAR

PROJECT :

6.0 x 8.1 CAR PARKING SHADES - PROMER QATAR

AL JAIDAH AND SONS

TENTS AND UMBRELLA TRADING CO

INDUSTRIAL LINE -18 DOOR -54 QATAR

PROJECT :

6.0 x 8.1 CAR PARKING SHADES - PROMER QATAR

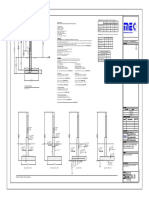

BASE CONNECTION

350 mm x 350 mm x 20 mm thk base plate with 4 nos of M25 Grade 8.8 Anchor Bolt with embedment length of 600 mm

Bolts subjected to tension due to Moment

=

2 * T * 220* 10-3

115.6 kN

=

=

15.37 / 4

3.84 kN

total

119.4 kN

=

=

0.75 * * 252/4 * 450 * 10-3

165.5 kN

> 119.4 kN

OK

=

=

119.4 * 10 / ( * 25 * 0.5 *30 )

< 600 mm

555 mm

OK

=

=

119.4 * 2 * 0.04

9.55 kNm

=

=

9.55 * 106 / 275

34734 mm3

34.7 cm3

=

=

=

350 * 202 / 6

23333 mm3

23.3 cm3

<

34.73 cm3

50.89 * 106

Using 25 mm dia Grade 8.8 bolt

Capacity

Embedment length

Plate bending moment

Section Modulus Required

considering base plate

section modulus, Sx

not OK

Section property (section A - A) with 12 mm gusset plate

N. A. ( x )

126 mm

Sec. Moment of area, Ix

9606151 mm4

Section Modulus, Sx

=

=

405867mm3

40.5 cm3

12

150

>

34.73 cm3

OK

18

Welding Capacity of 10mm fillet weld

Capacity per 1mm

270

40

350

40

40

=

=

350

270

40

4 nos. 25mm dia

grade 8.8 bolt

10mm weld

350 x 350 x 20mm thk

STEEL PLATE

6.6" dia x 11mm thk

CHS COLUMN

12mm thk

STIFFENER PLATE

10 * 0.7 * 220

1540 N/mm

350

SECTION A-A

AL JAIDAH AND SONS

TENTS AND UMBRELLA TRADING CO

INDUSTRIAL LINE -18 DOOR -54 QATAR

PROJECT :

6.0 x 8.1 CAR PARKING SHADES - PROMER QATAR

Considering 1.6m x 1.6m x 1200mm thick Concrete Footing

Weight of Footing

=

=

1600

1.6 * 1.6 * 1.2 * 25

56.25 kN

1600

1200

5.27 kN

1600

5.27 kN

* Case 1 Due to Downward Load

6m

Moment

=

=

5.27 * 6

31.62 kNm

Maximum Pressure

=

=

( 76.8+ 5.27) / (1.6 * 1.6) + 6 * 31.62 / (1.6 * 1.62)

78.38 kN/m2

<

=

=

=

=

=

=

=

=

9.12 * 6

54.72 kNm

( 76.8 - 9.12 )* 0.8

54.15 kNm

3*18*0.9*1.6*.9/2*.9/3

10.49 kNm

(54.14+10.49) / 54.17

1.18

Soil Bearing Pressure Check

* Case 2 Due to Upward Load

Stability Check of Footing

Overturning Moment

Resisting Moment

due to passive pressure

F.S. Overturning

Reinforcement for 1200mm thk base for cracking

Minimum each face, As

Provided

=

0.13 * 250

=

325 mm2

T12 @ 150 ( 757 mm2 )

100

OK

9.12 kN

9.12 kN

6m

>

OK

AL JAIDAH AND SONS

TENTS AND UMBRELLA TRADING CO

INDUSTRIAL LINE -18 DOOR -54 QATAR

PROJECT :

6.0 x 8.1 CAR PARKING SHADES - PROMER QATAR

Вам также может понравиться

- SpreadsheetДокумент7 страницSpreadsheetChan Kin CheungОценок пока нет

- Post-Tensioned Concrete Column Supported Slab Design (Flat Plate System)Документ6 страницPost-Tensioned Concrete Column Supported Slab Design (Flat Plate System)Educadd AMEERPET HyderabadОценок пока нет

- Design of ColumnДокумент3 страницыDesign of ColumnHarini RameshОценок пока нет

- PILE FOUNDATION DESIGN Manual Cal - CommentsДокумент6 страницPILE FOUNDATION DESIGN Manual Cal - CommentsDilip PatelОценок пока нет

- Pile Cap Design - ColumnsДокумент7 страницPile Cap Design - ColumnsJule LobresОценок пока нет

- SHRT ColДокумент3 страницыSHRT ColashokОценок пока нет

- M3D - SampleProblemSet ACI PDFДокумент6 страницM3D - SampleProblemSet ACI PDFasaisenthilОценок пока нет

- Chequered Plate DesignДокумент1 страницаChequered Plate DesignAsif AliОценок пока нет

- Analysis of Tenement 1Документ84 страницыAnalysis of Tenement 1IyswariyaОценок пока нет

- Union Contracting - Car Parking Rev02Документ47 страницUnion Contracting - Car Parking Rev02krvprasadОценок пока нет

- Analysis & Design of Combined Footing: Condition:1Документ3 страницыAnalysis & Design of Combined Footing: Condition:1Nikhil PoriyaОценок пока нет

- Isolated Footing (ACI)Документ4 страницыIsolated Footing (ACI)Boubakeur FerkousОценок пока нет

- SteelDesign Composite Fu NewДокумент16 страницSteelDesign Composite Fu Newpresentasi mankonОценок пока нет

- Hidden BeamДокумент1 страницаHidden BeamKulal SwapnilОценок пока нет

- Dimensional Solutions Mat3DДокумент69 страницDimensional Solutions Mat3DTimothy HancockОценок пока нет

- Filter Vessel Steel Structure DesignCalculation - Rev - AДокумент29 страницFilter Vessel Steel Structure DesignCalculation - Rev - AsridharОценок пока нет

- 2 PDFДокумент1 страница2 PDFSujit RasailyОценок пока нет

- Isoloated Footing DesignДокумент7 страницIsoloated Footing Designvijay moreОценок пока нет

- Wind Load Calculation Using EurocodeДокумент3 страницыWind Load Calculation Using EurocodeemmanuelОценок пока нет

- Design Isolated FootingДокумент4 страницыDesign Isolated FootingMaheshreddyОценок пока нет

- Calc of Steel UNP 150.75.9.12,5 CanopyДокумент11 страницCalc of Steel UNP 150.75.9.12,5 CanopyOecoep IteemОценок пока нет

- Paper For Bearing Capacity PDFДокумент4 страницыPaper For Bearing Capacity PDFernestnsabimana74Оценок пока нет

- Is 13849 PDFДокумент517 страницIs 13849 PDFsauravОценок пока нет

- Standard Calculation Sheet For R.C. DesignДокумент6 страницStandard Calculation Sheet For R.C. DesignsitehabОценок пока нет

- PostFoundation 1Документ1 страницаPostFoundation 1امين الزريقيОценок пока нет

- Maximum LoadsДокумент4 страницыMaximum LoadsНемања КараклајићОценок пока нет

- LOAD CALCULATION For PORTAL FRAMED SHED WITH WIND ASCE 7-10Документ10 страницLOAD CALCULATION For PORTAL FRAMED SHED WITH WIND ASCE 7-10Aboalmaail AlaminОценок пока нет

- Mxy Abs MX MX Mxy Abs My My Mxy Abs MX MX: Sample CalculationДокумент3 страницыMxy Abs MX MX Mxy Abs My My Mxy Abs MX MX: Sample CalculationUttam Kumar GhoshОценок пока нет

- Design For Lifting Pad EyeДокумент4 страницыDesign For Lifting Pad EyeAsaru DeenОценок пока нет

- Staad Pro Stainless Steel ReportДокумент29 страницStaad Pro Stainless Steel ReportRaviteja Girijala100% (1)

- S.0 Dike Wall DesignДокумент1 страницаS.0 Dike Wall Designraudelmoreno83100% (1)

- Ring Foundation As Per IS 110891984Документ4 страницыRing Foundation As Per IS 110891984Rajesh Gangwal0% (1)

- Isolated Footing Design Excel SheetДокумент2 страницыIsolated Footing Design Excel SheetAli ImranОценок пока нет

- Slab Manual DesignДокумент1 страницаSlab Manual DesignAtul ShrivastavaОценок пока нет

- Kerala State Pollution Control BoardДокумент34 страницыKerala State Pollution Control Boardprofessionalservices_infoОценок пока нет

- A&m BSR-2011Документ26 страницA&m BSR-2011Mukesh Jangid100% (1)

- Design of ColumnsДокумент7 страницDesign of Columnscarlo castanedaОценок пока нет

- Sign Board CalcsДокумент34 страницыSign Board CalcsMimi MoragnОценок пока нет

- Design of RC Pad With Single Column Footing: Dead Imposed WindДокумент22 страницыDesign of RC Pad With Single Column Footing: Dead Imposed Windsvrao4u100% (2)

- Vertical Equation Foundation-Spread Sheet PDFДокумент6 страницVertical Equation Foundation-Spread Sheet PDFmassive85Оценок пока нет

- Specification For Rhomboidal Steel Wire Rope Net Panels For Rock Fall Protection 1) ScopeДокумент5 страницSpecification For Rhomboidal Steel Wire Rope Net Panels For Rock Fall Protection 1) ScopeSOMNATH JANAОценок пока нет

- Car ShelterДокумент29 страницCar ShelterMochammad Shokeh100% (1)

- 32.0 M Dia Roof Design ReportДокумент124 страницы32.0 M Dia Roof Design ReportsndpinОценок пока нет

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Документ4 страницыF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Mohammed ElemamОценок пока нет

- Comparative Study of Supporting System of Elevated Billboard (Hoarding) Structures Having Different ConfigurationДокумент5 страницComparative Study of Supporting System of Elevated Billboard (Hoarding) Structures Having Different ConfigurationBhavin JoshiОценок пока нет

- Design of Equipment Fdns.Документ3 страницыDesign of Equipment Fdns.Gaurav Kumar SinghОценок пока нет

- Snow Load As Weight Per MM Calculation 330Документ1 страницаSnow Load As Weight Per MM Calculation 330Anonymous Iev5ggSRОценок пока нет

- Check Detailing For 160 Mva Fire WallДокумент12 страницCheck Detailing For 160 Mva Fire WallAnindit MajumderОценок пока нет

- Mapro - Strucure Stability Report Down Shed AreaДокумент26 страницMapro - Strucure Stability Report Down Shed AreaJaydeep PatelОценок пока нет

- Wind Load Calculation For Multiple Framed Open Structures Design Wind PressureДокумент2 страницыWind Load Calculation For Multiple Framed Open Structures Design Wind Pressurechirag01020% (1)

- Pile Capacity Comp./UpliftДокумент2 страницыPile Capacity Comp./UpliftPankaj Sherwal100% (1)

- Final Strap Design (Max Mu)Документ42 страницыFinal Strap Design (Max Mu)xyzzy blankОценок пока нет

- Calculations by Yg Plot 55 & 56 01.02.23Документ63 страницыCalculations by Yg Plot 55 & 56 01.02.23Shanil BussooaОценок пока нет

- Design of An Industrial BuildingДокумент7 страницDesign of An Industrial BuildingAbhishek KaushikОценок пока нет

- Staad Mezzanine DesignДокумент15 страницStaad Mezzanine Designmbhanusagar.keynesОценок пока нет

- Pad Foundation With Two Columns ExampleДокумент10 страницPad Foundation With Two Columns ExampleakankwasaОценок пока нет

- Axial Load Capacity For Deep Foundations Piles: Sand Input ResultsДокумент8 страницAxial Load Capacity For Deep Foundations Piles: Sand Input Resultsacidrisamuel2656Оценок пока нет

- 6 X 8.1M ShadeДокумент7 страниц6 X 8.1M ShadeehikmatОценок пока нет

- 6.0 X 8.1 Car Parking Shades - Promer Qatar Structural Design CalculationsДокумент11 страниц6.0 X 8.1 Car Parking Shades - Promer Qatar Structural Design Calculationssehikmat67% (3)

- Grade Slab ACI-150thkДокумент7 страницGrade Slab ACI-150thkMUTHUKKUMARAM100% (1)

- Abus Overhead Cranes InfoДокумент12 страницAbus Overhead Cranes Infoamachmouchi100% (1)

- This Is To Calculate The Input Values For Crane Software: 1,769 KG 6,580 KGДокумент1 страницаThis Is To Calculate The Input Values For Crane Software: 1,769 KG 6,580 KGamachmouchiОценок пока нет

- Stair Calculator: Calculate Approx Number of Steps Calculate Approx Number of StepsДокумент2 страницыStair Calculator: Calculate Approx Number of Steps Calculate Approx Number of StepstannuОценок пока нет

- Ebsl Quote Request Form / Work Order Form Page 1 of 1: Arjun Bhise West WestДокумент2 страницыEbsl Quote Request Form / Work Order Form Page 1 of 1: Arjun Bhise West WestamachmouchiОценок пока нет

- Welders Visual Inspection Handbook 2013 WEB New PDFДокумент77 страницWelders Visual Inspection Handbook 2013 WEB New PDFamachmouchiОценок пока нет

- Gutter CalculationДокумент5 страницGutter CalculationamachmouchiОценок пока нет

- Pds Hempathane Hs 55610 En-GbДокумент2 страницыPds Hempathane Hs 55610 En-GbThines KumarОценок пока нет

- Design of Steel I Section BS5950Документ6 страницDesign of Steel I Section BS5950amachmouchi100% (1)

- Calculation of Beam/Column Splice: HB-300x300x10x15Документ5 страницCalculation of Beam/Column Splice: HB-300x300x10x15amachmouchiОценок пока нет

- Commercial Vehicles BrochureДокумент20 страницCommercial Vehicles Brochurebinhtb14Оценок пока нет

- InfoWorks ICM Overview 60 Mins PDFДокумент31 страницаInfoWorks ICM Overview 60 Mins PDFAnonymous lyVIwA60% (2)

- AM3KA539 Combined Depth/Tension Measurement Device: With Low Voltage Tension AmplifierДокумент27 страницAM3KA539 Combined Depth/Tension Measurement Device: With Low Voltage Tension AmplifierDiego CorderoОценок пока нет

- 27U RackДокумент6 страниц27U Racknitin lagejuОценок пока нет

- PQ070XF02SZH: Features Outline DimensionsДокумент4 страницыPQ070XF02SZH: Features Outline DimensionsJulio Cesar CastilloОценок пока нет

- Project Report JamiaДокумент76 страницProject Report JamiaShoaibОценок пока нет

- Simple Free-Energy InformationДокумент11 страницSimple Free-Energy InformationDrago MelovОценок пока нет

- Solar Storage System Comp GUIDEGTM 2 1Документ10 страницSolar Storage System Comp GUIDEGTM 2 1harosalesvОценок пока нет

- SearchBot Results For Touchstone 1Документ6 страницSearchBot Results For Touchstone 1CОценок пока нет

- Heat ConductionДокумент11 страницHeat ConductionAlex Samuel SilvaОценок пока нет

- A Practical Guide To Machine Vision Lighting - Part IIIДокумент4 страницыA Practical Guide To Machine Vision Lighting - Part IIIChai Jien WeiОценок пока нет

- Cummins ECM Reference NotesДокумент11 страницCummins ECM Reference NotesjuanОценок пока нет

- ID 2051814.1 Oracle Support Sample SetupДокумент9 страницID 2051814.1 Oracle Support Sample SetupFerasHamdanОценок пока нет

- Pressure Flow and Temperature SwitchesДокумент16 страницPressure Flow and Temperature SwitchesMD SAMANОценок пока нет

- Email Id of Controllers PDFДокумент10 страницEmail Id of Controllers PDFAbhishek KumarОценок пока нет

- CCR Equipment ListДокумент1 страницаCCR Equipment Listbehzad parsiОценок пока нет

- Sanjay ProjectДокумент41 страницаSanjay ProjectPrynka RawatОценок пока нет

- 015 VT PumpsДокумент32 страницы015 VT PumpsZainul Abdin100% (1)

- MclogitДокумент19 страницMclogitkyotopinheiroОценок пока нет

- 3.14. TR-069 WAN Management...Документ6 страниц3.14. TR-069 WAN Management...duculeteОценок пока нет

- TA125Документ4 страницыTA125WaqasjamОценок пока нет

- NFC Reader LibrarayДокумент63 страницыNFC Reader Libraraysekhar479Оценок пока нет

- Vogt Valves: Catalog & Application ManualДокумент161 страницаVogt Valves: Catalog & Application ManualAngelique DeanОценок пока нет

- Make A Project of Calculator in Visual BasicДокумент9 страницMake A Project of Calculator in Visual BasicCHITRA MINI96% (23)

- Fis-Opf Ach PaymentsДокумент5 страницFis-Opf Ach PaymentscrazytrainОценок пока нет

- Noise Control in BuildingsДокумент36 страницNoise Control in BuildingsEmily Ong100% (1)

- Em 59717521644Документ68 страницEm 59717521644Mostafa MirbaghriОценок пока нет

- SMДокумент36 страницSMharan2000Оценок пока нет

- LG W4320S Service ManualДокумент24 страницыLG W4320S Service ManualeleandrorobertoОценок пока нет