Академический Документы

Профессиональный Документы

Культура Документы

Clarificador Compacto

Загружено:

Aranza Tafur BorreroОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Clarificador Compacto

Загружено:

Aranza Tafur BorreroАвторское право:

Доступные форматы

MONROE

Compact Clarifier

Manufacturer of Industrial Filtration Systems

Non-clogging plate design

Simultaneously removes both

floatable and settleable

contaminants

Requires less space than typical

clarifiers

Filter media not required

Minimum maintenance

Capacities from 1 to 2,000

GPM

Customized to Meet

Your Needs

Monroe Compact Clarifiers are

specially sized for each application. Monroe Environmental

will evaluate your fluid effluent

and determine design parameters

for your particular installation.

Your Compact Clarifier will then be

constructed to provide the most

economical and efficient liquid

clarification to meet your needs.

Broad Range of Industrial

Capabilities

Oil Recovery Separated oils,

process fluids and other floatable

materials are guided to an accumulation area for easy removal and

reclamation. An adjustable overflow

weir or a Monroe Oil Recovery Unit

Ideally Suited for

Chemical processing

Coolant systems

Food processing

can be included to remove these

elements.

Foundry operations

Separated Solids Removal Where

the dirt load is heavy, a drag conveyor may be included to provide

continuous removal of settled solids

from the bottom of the clarifier.

Industrial waste management

Cone bottom construction is sometimes recommended for nondraggable solids.

Plastic manufacturing

Glass plant operations

Metal working

Oil refining

Paper making

Plating and coating processes

Steel processing

Storm water systems

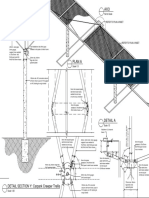

Clean Liquid

Outlet

Tramp Oil

Outlet

Modular Laminar

Plates

Inlet

Solids

Discharge

Optional

Drag Conveyor

Chemical Treatment The Monroe

Compact Clarifier can include a pretreatment process as an integral

part of the basic clarifier. This aids in

the separation of dissolved solids,

very fine particles and emulsified

oils that tend to remain suspended

in water or process fluids. A chemical treatment tank and/or flocculation chamber can be added to allow

MONROE Compact Clarifier

pH control and mixing of emulsion

breakers and coagulants into the

influent before the laminar flow

process

Laminar Flow Principle

The unique design of the Monroe

Compact Clarifier creates laminar

flow conditions and allows gravitational forces to separate the lighter

and heavier elements from the fluid.

Normally, industrial laminar flow

separation requires settling areas

beyond practical space availability in

typical manufacturing plants.

The Monroe Advantage

Unrestricted

Solids Flow

Special Features

Wide range of construction

materials. Mild steel, special

coatings, stainless steel, fiberglass,

plastics and other materials are

available to meet specific needs.

No moving parts in the clarifier

section reduces equipment cost

and practically eliminates

operating cost when compared

with a centrifuge separator.

Long

Laminar

Plates

Restricted

Solids Flow

Due to

Clogging

3'

to

10

Easily removable laminar plates.

The unique, modular design of

the Monroe Compact Clarifier

allows easy removal of individual

laminar plate modules from the

clarifier for inspection.

'

up

to

"

24

Modular

Laminar

Plates

Monroes design engineers, however, have eliminated this problem

through the unique capabilities of

the Compact Clarifier.

Particulate

Drop Off

The Monroe Compact Clarifier

Separated particles are required to

move only a few inches before

reaching an uninterrupted and

protected free fall or rise to

collection areas. Efficiency is

increased and build-up of collected

particles is prevented.

Particulate

Build-up

Complete electrical controls to

meet customer requirements are

available if required.

Typical Separators

Long laminar sections require

particles to travel as much as 10 feet

before free fall or rise to collection

areas, often causing clogging and

re-entrainment with other fluid

flow currents, reducing separation

efficiency.

Many Configurations Available

Monroe Compact Clarifier complete package systems are available including mixers,

chemical feed pumps, instrumentation and electrical controls.

Manufacturer of Industrial Filtration Systems

Registered ISO 9001 Ford Q1

Monroe Environmental is a

QS/TE 9000 Company

11 Port Avenue, P.O. Box 806

Monroe, Michigan 48161 USA

Phone: 1-800-992-7707 or 734-242-7654

Fax: 734-242-5275

www.monroeenvironmental.com

2000 Monroe Environmental Corporation

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Practical Cs Xii Mysql 2022-23 FinalДокумент9 страницPractical Cs Xii Mysql 2022-23 FinalHimanshu GuptaОценок пока нет

- TrellisДокумент1 страницаTrellisCayenne LightenОценок пока нет

- ICD10WHO2007 TnI4Документ1 656 страницICD10WHO2007 TnI4Kanok SongprapaiОценок пока нет

- 2a Unani Medicine in India - An OverviewДокумент123 страницы2a Unani Medicine in India - An OverviewGautam NatrajanОценок пока нет

- Grade9 January Periodical ExamsДокумент3 страницыGrade9 January Periodical ExamsJose JeramieОценок пока нет

- A Junk Project - An Income Generating ProjectДокумент2 страницыA Junk Project - An Income Generating ProjectHercules Verdeflor ValenzuelaОценок пока нет

- Aquaculture - Set BДокумент13 страницAquaculture - Set BJenny VillamorОценок пока нет

- Answer Key To World English 3 Workbook Reading and Crossword Puzzle ExercisesДокумент3 страницыAnswer Key To World English 3 Workbook Reading and Crossword Puzzle Exercisesjuanma2014375% (12)

- Bài Tập Từ Loại Ta10Документ52 страницыBài Tập Từ Loại Ta10Trinh TrầnОценок пока нет

- Ae - Centuries Before 1400 Are Listed As Browsable DirectoriesДокумент3 страницыAe - Centuries Before 1400 Are Listed As Browsable DirectoriesPolNeimanОценок пока нет

- Technical Data Sheet TR24-3-T USДокумент2 страницыTechnical Data Sheet TR24-3-T USDiogo CОценок пока нет

- Paramount Healthcare Management Private Limited: First Reminder Letter Without PrejudiceДокумент1 страницаParamount Healthcare Management Private Limited: First Reminder Letter Without PrejudiceSwapnil TiwariОценок пока нет

- Resume NetezaДокумент5 страницResume Netezahi4149Оценок пока нет

- Mark Magazine#65Документ196 страницMark Magazine#65AndrewKanischevОценок пока нет

- Personal Finance Kapoor 11th Edition Solutions ManualДокумент26 страницPersonal Finance Kapoor 11th Edition Solutions Manualsiennamurielhlhk100% (28)

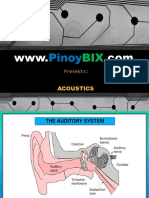

- AcousticsДокумент122 страницыAcousticsEclipse YuОценок пока нет

- Particle BoardДокумент1 страницаParticle BoardNamrata RamahОценок пока нет

- Neelima A Kulkarni ResumeДокумент3 страницыNeelima A Kulkarni ResumeAcademics LecturenotesОценок пока нет

- Settlement Report - 14feb17Документ10 страницSettlement Report - 14feb17Abdul SalamОценок пока нет

- Buildingawinningsalesforce WP DdiДокумент14 страницBuildingawinningsalesforce WP DdiMawaheb ContractingОценок пока нет

- Lec. 2Документ22 страницыLec. 2محمدОценок пока нет

- Eu Schengen Catalogue enДокумент54 страницыEu Schengen Catalogue enSorin din ConstanțaОценок пока нет

- Endometab Exam 2018Документ8 страницEndometab Exam 2018teabagmanОценок пока нет

- Properties of LiquidsДокумент26 страницProperties of LiquidsRhodora Carias LabaneroОценок пока нет

- Specialty Coffee Association of Indonesia Cupping Form (ARABICA)Документ1 страницаSpecialty Coffee Association of Indonesia Cupping Form (ARABICA)Saiffullah RaisОценок пока нет

- Bigbazaar PDFДокумент14 страницBigbazaar PDFazhagu sundaramОценок пока нет

- LicencesДокумент5 страницLicencesstopnaggingmeОценок пока нет

- En 50124 1 2001Документ62 страницыEn 50124 1 2001Vivek Kumar BhandariОценок пока нет

- Pest of Field Crops and Management PracticalДокумент44 страницыPest of Field Crops and Management PracticalNirmala RameshОценок пока нет

- HemoptysisДокумент30 страницHemoptysisMarshall ThompsonОценок пока нет