Академический Документы

Профессиональный Документы

Культура Документы

Company Profile

Загружено:

Tori SmallАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Company Profile

Загружено:

Tori SmallАвторское право:

Доступные форматы

Company Profile

constructive solutions

Dear Sirs,

We thank you for giving us the chance to present our selves, our products, and our services. This letter is

generated in an effort of putting Fosam Company Limited, and it's parent company JMH Fosroc International, into

perspective, and offer high value of products and services for the construction market.

Company Synopsis

JMH Group

The owners of the JMH Group are Dr James & Mrs Fitriani Hay. Dr Hay is a former BP senior executive, where he

worked for over 27 years. In 2002 Dr Hay decided to pursue his ambition to establish & manage his own company. The

opportunity arose in the shape of Fosroc, which BP was in the process of divesting. This company had arrived in BP as

part of the acquisition of Burmah Castrol. It was a good fit with the investment criteria set out by Dr Hay.

The target company had to have:

a strong brand in its sector

a reputable trading history

an international base covering Middle East and Asia

low capital expenditure

talented people who thrive under new ownership

excellent products

Fosroc therefore represented a good acquisition prospect, probably even more so as it had lacked any real strategic

direction for several years. The fit was good, timing perfect, and the deal was executed within three months. Fosroc

joined the JMH Group at the end of December 2002.

The Group is family owned, and operates in mainly the construction & chemicals sectors, with an annual turnover of

around $250m.

JMH Fosroc International

Fosroc has more than 70 years experience in servicing the construction market, it was previously owned by BP

(British Petroleum) and based in Tamworth - UK, before its purchase by JMH Fzco international, a privately owned

company that is based in Dubai in the United Arab Emirates with a world wide presence. As perceived from the

logo, Fosroc is all about constructive solutions, providing the right proposal, of the right product, backed up with

unrivaled technical support and onsite and office presence for contractors, applicators, and consultants alike to give

an integrated constructive solution to construction issues and problems. To achieve this, Fosroc always relied on

extensive research of the local conditions and characteristics of independent local construction markets,

development of high tech quality innovative products to suit these local conditions, and followed by highly

motivated technically competent staff to insure the proper implementation of these products.

Fosam Company Limited

Head Office

Post Box 11081

Jeddah 21453

Saudi Arabia

www.fosroc.com

Telephone: +966 2 637 5345

Fax: +966 2 637 5891

email: fosam@fosroc.com

Regional Offices

Jeddah Sales Office

Jeddah Showroom

Riyadh

Dammam

Khamis Mushayt

Tel:

Tel:

Tel:

Tel:

Tel:

(02)

(02)

(01)

(03)

(07)

6080999

665 0787

482 9303

847 2929

250 0469

Fax:

Fax:

Fax:

Fax:

Fax:

(02)

(02)

(01)

(03)

(07)

635 3330

667 4884

482 7562

847 1582

250 0469

Yanbu Tel:

Makkah Tel:

Medinah Tel:

Jubail Tel:

(04)

(02)

(04)

(03)

322 4280

542 0869

845 1767

362 3904

Registered Office: Industrial Area, Phase 4, Road No. 414, Street No. 407

Fax:

Fax:

Fax:

Fax:

(04)

(02)

(04)

(03)

391 2980

542 0869

846 3195

362 3875

Company Profile

constructive solutions

In pursuit of excellence, Fosroc cooperates with various universities around the world in research of new

technology that can be facilitated in producing its high quality products that undergo extreme quality control

measures. Fosroc has more than 20 operating manufacturing companies' world wide, with exports reaching an

additional 50 countries.

Fosam Company Limited

Fosam is a Saudi Arabian Based limited liability

company, It's shareholders are the heirs of the late

Sheikh Kamal Adham, Saudi Arabian Markets

Limited and JMH Fosroc International:

1) Heirs of H.E. (late) Sheikh Kamal Adham

(25%) whom are recognized as leading

businessmen in Saudi Arabia being well

known in both the Kingdom and overseas.

2) Saudi Arabian Markets Limited (25%) is one

of the oldest established companies

(established 1946) based in the Western

Province. It is owned by the Ashmawi family

and has branches throughout the Kingdom.

3) JMH Fosroc International (50%).

The Groups products and support services are aimed at improving customers efficiency and competitiveness

formulated to stringent standards of quality and reliability.

Fosroc pioneers new techniques in many of its markets, and strong emphasis is given to product innovation the

Groups 3 central research and development units (UK, India, Emirates) are international leaders in their fields.

Close links with the worlds universities and technical institutions help maintain this pace of development.

The Group has an international network of companies, most with their own manufacturing and technical support

facilities. Close liaison between these local operations and experienced central support teams ensure that Group

products, and their supply, match local needs. The ability to transfer technology and ideals across national and

industrial boundaries is a key to the Groups sustained growth.

FOSROC first started operation in Saudi Arabia in 1974 when they entered into a Distributor Agreement with Saudi

Arabian Market Limited.

Shortly after this agreement was signed it was decided that in order to serve better the market, a manufacturing

plant would have important advantages in terms of bringing new technology into the country in line with the policy of

the Kingdom. A joint venture agreement was then concluded between the two parties and H.E. Sheikh Kamal

Adham. After obtaining the necessary approvals for Commercial Registration, production began in September 1982

under the name of FOSAM.

The Industrial License of FOSAM Company Limited enables it to manufacture a broad range of construction

chemicals including;

1)

2)

3)

4)

5)

6)

7)

8)

9)

10)

Admixtures.

Surface Treatment.

Grouts & Anchoring Products.

Repair Materials.

Industrial Flooring Materials.

Protective Coatings.

Sealants and Waterproofing.

Waterproofing materials and PVC waterstops.

Tile adhesives and grouts & miscellaneous ancillary products.

Patented Electro-Chemical Repair.

Page 2 of 2

Company Profile

constructive solutions

The factory is situated on the Jeddah Industrial Estate and also has a laboratory which is responsible for quality

control of all products manufacture, and assists with customer service and long term testing so as to ensure that

only products of the highest quality matching international standards are supplied to our customers.

FOSAM deploys a team of experienced sales engineers and specifiers who can demonstrate product application

and provide advice where and when required.

The Companys Head Office is based in Jeddah and branch offices are located in Makkah, Madinah, Jeddah,

Riyadh, Dammam, Jubail, Khamis Mushayat and Yanbu.

Fosam's Factory

Fosams manufacturing facility lays in Jeddah's industrial area,

phase 4, it is situated on an area of 25,000 m 2 That is ran by

professional local and international expertise. The factory is

equipped with state of the art machinery and incorporates the

following areas:

1)

2)

3)

4)

5)

6)

7)

8)

9)

10)

11)

12)

13)

14)

15)

Head offices building.

Factory offices and guidance center.

Fully equipped laboratories and research facilities.

Concrete Admixtures manufacturing plant.

Powder manufacturing plant.

PVC extrusion and manufacturing plant.

Resinous manufacturing plant.

Sealant and polymers processing and manufacturing

plant.

Aggregate plant.

Raw material warehouses.

Finished goods warehouses.

Various warehouses and training rooms.

Truck loading and unloading areas.

Press and media center.

Cafeteria.

The factory is also equipped with state of the art fire fighting

and safety systems. This comes out of the company's

management extreme concern of health and safety which was

singled out as the primary directive of all operations.

Fosam take pride in its ability to meet the demands of the continuously growing construction market that is hungry

for Fosam high performance products, the current Saudi Arabian Jeddah factory has a production capacity of the

following:

1) Concrete Admixtures

2) Resinous Products

3) Powdered Products

4) Sealants

5) PVC Water Stops

: 150,000

: 15,000

: 84,500

: 7500

: 2600

Liters / Day

Kilograms / Day

Kilograms / Day

Kilograms / Day

Kilograms / Day

Fosam also exports many of its specialty products to neighboring countries as well as Africa, and countries where

locality conditions such as weather, construction techniques,etc. matches those of Saudi Arabia including its

various regions.

Fosam's factory was a pioneer in environmental friendly practices, it does not dispose of industrial waste into the

existing sewer network, Fosam follow the international recommendations on industrial and hazardous disposal

practices.

Page 3 of 3

Company Profile

constructive solutions

Delivery Networks

Fosam grow on a single honest promise, which was "We deliver", weather it was physical delivery of products, or

information delivery such as proposals and technical assistance. This section will cover the actual physical delivery

of products, delivery routs, and frequency.

Fosam outside of Jeddah has two major branches and warehouses in the central and eastern provinces, the other

warehouses and offices are a bit smaller but still as important. Fosam is uses both internal owned vehicles for

delivery of inside-region deliveries, and external transport contracts with major transport companies for remote and

inter-regional deliveries.

Supply Routes:

Fosam factory supplies the two major regions (Central and Eastern) on daily basis, these two regions are then self

sustained, unless trailer deliveries are needed to remote regional areas. The routes are as follows:

Western

Region

Jeddah (City

Limits)

Makkah

Madinah

Khamis Mushait

Yanbu

Tabuk

Taif

Jizan

Hanakiya

Bisha

Baha

Rabigh

Furaish

Duba

Shoaiba

Transit Time

same day

delivery

same day

delivery

1 day

1 day

1 day

1 day

1 day

1 day

1 day

1 day

1 day

same day

delivery

1 day

1 day

same day

delivery

Direct Delivery From Factory

Central Region

Transit Time

Riyadh (City

Limits)

Al-Qasim

1 1/2 days

Al-Jouf

Hail

Hafr Al-Batin

Onayza

Al-Shaqra

Najran

1 1/2 days

1 Day

1 1/2 days

1 1/2 days

1 1/2 days

1 1/2 days

1 1/2 days

Page 4 of 4

Eastern Region

Transit Time

Dammam (City

Limits)

Hufouf

2 days

Haradh

Uthmaniya

Abqaiq

Khafji

Jubail

1 1/2 days

1 1/2 days

1 1/2 days

2 days

2 days

2 days

Company Profile

constructive solutions

Inter-Company & Export:

UAE

Qatar

Bahrain

Kuwait

Oman

Egypt

Jordan

Yemen

Libya

Sudan

Tunis

Bangladesh

Mauritius

Ethiopia

Brazil

Sri Lanka

Eritrea

United Kingdom

Philippines

Land Transport Time

3-4 Days

3-4 Days

2-3 Days

3-4 Days

6-8 Days

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Sea Transport Time

Air Transport Time

Depending on Freight

Schedule

Country

Depending on Freight

Schedule

Fosam supplies various countries with multiple products, this business includes sister companies as well as

distributors, and independent clients, by means of air, sea, land transportation. It goes as far as:

Health, Safety & Environment

Health and safety, as well as protection of the environment are main goals that JMH group of companies live by, the

statement by Chairman & CEO is:

"Commitment to Health, Safety and Environmental Performance (HSE)

Everybody who works for JMHfzco, anywhere, is responsible for getting HSE right. Good HSE performance and the

health, safety and security of everyone who works for us are critical to the success of our business.

Our goals are simply stated - no accidents, no harm to people, and no damage to the environment.

Page 5 of 5

Company Profile

constructive solutions

We will continue to drive down the environmental and health impact of our operations by reducing waste, emissions

and discharges, and using energy efficiently. We will produce quality products that can be used safely by our

customers.

We will:

Consult, listen and respond openly to our customers, employees, neighbors, public interest groups and those

who work with us.

Work with others - our partners, suppliers, competitors and regulators - to raise the standards of our industry.

Openly report our performance, good and bad.

Recognize those who contribute to improved HSE performance.

Our business plans include measurable HSE targets. We are all committed to meeting them.

DR. J Hay

Chairman CEO"

In line with this statement the company has a complete tool box of health and safety standards and policies that can

be summarized as:

1. Level 1: Basics

a. Safety weeks.

b. Emergency evacuation & incidents / crisis

management.

c. Personal safety, house keeping, & hygiene.

d. Safe operating principles: production.

e. Safe operating principles: Maintinance.

f. Safety in Warehousing.

g. Safety of Sales, & technical staff on site.

h. Safety in offices.

i. Supervision of drivers, contractors, & visitors.

j. Fosroc golden safety rules.

2. Level 2: Basic Admin

a. Internal & external operating & legal permits.

b. Workplace education & training procedures (non emergency.

c. MSDS & labeling to international standards.

d. Health & safety monthly reporting.

e. Risk assessments.

3. Level 3: Advanced H&S approaches

a. HSE legislation

b. HAZOPS

c. OHSAS118001.

4. Incident reporting procedures and forms

a. Crisis Identification.

b. Incident / crisis management system framework.

c. Recordable case or not guidance flow chart.

d. Forms

e. Manuals, Activities, & Checklists.

Page 6 of 6

Company Profile

constructive solutions

Company Policies

Company policies are summarized by "The Rock", which is the foundation of all internal policies, the rock is:

" FOSROCS Foundation - Stronger than ROCK

The greatest constructions require solid foundations, the best being built on ROCK. Here is the foundation

that supports FOSROC.

PERFORMANCE

We will deliver the required returns to our shareholders and lenders, even at the worst market conditions, and

will maximise long-term shareholder value.

This performance will be distinctive versus our competitors and should attract further capital investment to

grow our company.

Employees will be encouraged and assisted to improve their skills to increase their individual performance

and that of the team.

We will understand fully our CUSTOMERS requirements and what is required to make FOSROC their

preferred choice and business partner.

We will provide our CUSTOMERS with quality products and services that meet their needs and where

appropriate exceed their expectations.

SAFETY

SAFETY will be a key FOSROC value; we will aim to operate with no accidents, no harm to people, and no

damage to the environment.

In all our operations, internal and external we will take every precaution and remove the potential for accident

occurrence. All in the company share the responsibility for safe working and shall, as a matter of duty, draw

immediate attention to any dangerous item of equipment or unsafe working practice.

RIGOUR

We will prepare detailed plans, setting out clear performance targets, milestones, and personal

accountabilities. These will be supported by excellent systems of planning, control, and, financial and risk

management.

INDIVIDUAL PERFORMANCE CONTRACTS will be key, representing the glue that binds us. Investments

and capital expenditure of whatever type will be properly evaluated and approved.

There will be VERIFICATION; through the INDIVIDUAL PERFORMANCE CONTRACTS to ensure that

promises are kept. The emphasis will be to identify areas where best practice is being achieved and can be

shared, or where help and support is required.

TRUST

There will be maximum delegation of authority to those who have demonstrated the experience and know

how, and who are in positions best able to exercise such authority.

There will be an environment in which all employees can freely ask questions and receive answers without

belittlement or censure. A No Blame culture will exist.

Employees will be encouraged to freely discuss their career objectives.

Page 7 of 7

Company Profile

constructive solutions

CONSENSUS

FOSROC has a diverse and experienced staff, and wherever possible decisions will be reached by

CONSENSUS thereby utilising the vast wealth of experience in the company.

However we have to be aware that business is always tough and our competitors want to take business from

us whenever they can. Therefore compromise will not be allowed to replace CONSENSUS.

When necessary tough decisions will be taken and implemented. These decisions will be justified and will be

for the overall long-term good of the business. Decisions made for individual gain or egotistic reasons will not

be tolerated.

RESPECT

Long term RELATIONSHIPS founded on creation of mutual advantage are vital to our success. We will

deliver what we promise.

We will RESPECT the needs and aspirations of our customers, partners and suppliers and develop mutually

beneficial relationships with them.

All staff will be treated fairly and with RESPECT. They will understand the requirements of their job and how

this contributes to the overall company. They will have constructive appraisals of their performance, training to

improve their skills, and be competitively rewarded for their performance.

We will be tolerant of peoples religions, culture and personal beliefs. Racism and verbal abuse will not be

tolerated under any circumstances.

Career development will be based on merit and will seek to be inclusive and draw on all the diversity in the

company. This will be supported by professional HR processes and development plans. Training will be a key

performance area.

Company performance, plans, and issues will be communicated regularly to all staff.

Company Managers will lead by example they will ensure that a high performance team culture will be the

norm. There will be no place for internal politics or one up-man-ship.

Decision-making should be fast but not rushed and based on fact not opinion. We should recognise when the

wrong decision has been made and take corrective action to correct the situation.

STRATEGY

The company will have a clear vision of where it is going. STRATEGY will be the basis of that vision.

We will understand fully what makes us successful we will use that knowledge in conjunction with the

experience and expertise of our people to develop, WINNING STRATEGIES, which deliver shareholder

value, employee value and desired market share.

STRATEGY will be delivered through meticulous and rigorous planning and implementation. As a result

PLANNING will complement MARKETING as a core competency in the company. "

The company has a complete manual based on the rock, as well as complying with the local regulations of

the kingdom of Saudi Arabia.

Page 8 of 8

Company Profile

constructive solutions

Quality Control Systems

As Fosam Company Limited manufactures and market over 200 standard products, and other 200 specialized

products for the constructing industry; quality control of raw materials and finished goods starts early at the

purchase phase of raw materials. With a detailed specification outlining the chemical, physical and

mechanical properties of the products to be purchased, and the variety of suppliers as well as potential ones,

random samples are passed to the laboratory from each purchase, and then tested in accordance to these

detailed specs.

After more than 70 years in the industry (30 of which in the local market of Saudi

Arabia), we were able to draw up a list of approved suppliers of which critical raw

materials are provided through, these suppliers gained trust and reputation through

continuous testing of their materials.

When raw materials arrive at our factory, it is tested by QC department for

compliance with our original specification, and then a number is allocated based on

its raw material coding, supplier and batch. This number will be referred to for stock

control and production until it is finally incorporated in a finished product, thus

material can be traced at all times.

Random samples of manufactured products then go through a series of tests to

ensure compliancy to original formulation, and designated product performance, no

products get released from the factory unless QC signs the batch card of which

materials has been manufactured according to.

The production process is based on a batch card under supervision from the works

supervisor and a member of the quality control department, if the material being

manufactured is a multi-component and/or undergoes a multi-stage process, then at

pre-determined points QC hand pick random samples and test it for compliance, and

if there is a need, necessary corrections are made prior to completion of process.

Manuals for both production specification, QC testing, and compliancy are available

with operations, technical, and QC departments.

Once manufactured products are approved, packaging into appropriate specified containers, drums, tins,

bags, boxes,etc., is performed and additional samples are taken to the QC warehouses, these samples are

retained for two years as reference samples if there was a need for re-testing.

Each batch number is stamped on packing and tallies with the batch card number and the quality control

retained sample reference. Each test, intermediate, and final are recorded against the batch number.

The above is necessarily general since we use over 550 different raw materials covering such differing

chemicals, and more than 40 partially processed materials, and these are all for the standard products. In

addition to the foregoing procedures, we are backed up with our parent FOSROC company technology, at

their laboratories in Tamworth, England, all materials have in depth analysis and performance testing carried

out to ensure worldwide uniformity of standards. However, local variations are permitted to meet local

conditions, but approval must be obtained from Central FOSROC Technology Laboratories and Centres of

Excellence.

Page 9 of 9

Company Profile

constructive solutions

Recent Notable Achievements in the Industrial Sector

Grouts

Recently Pumps and compressors (on an Aramco site) up to 5 m width and 15

m long were successfully gravity grouted using Fosams Conbextra Epoxy

Grouts using standard methods only (chaining was not necessary - at

temperatures of 50 OC and above), without site modification or manipulation of

grout proportions. The flow of 5m horizontally was achieved within 30 minutes

repeatedly. The rotating equipment (pumps and Compressors) supported by

this grout on the foundations are known to be the largest in the world

presently. Aramco have acknowledged that the methods which we have

developed (and their consultants and contractors have adopted) have proved

to be highly successful, ensuring that the operation of epoxy grouting at

elevated temperatures in summer are easily met within the pot life of the

epoxy grout. Our designed methods of application, along with the free flowing

grouts have ensured that construction programs are met and tight schedules

are maintained. A complimentory letter from the project management group is

freely available for perusal, confirming the performance of our grouts.

Repairs

Renderoc repair mortars has been extensively applied by many

methods (and rigorously tested for performance) and Fosam have been

provided with letters of achievement and thanks from Aramco

consultants as well as leading universities who have come to appreciate

the performance of Fosroc repair materials that we provide to our

Clients. It has been categorically proven in comparative tests (against

leading international brands of products) that Fosam concrete repair

mortars exceed equivalent competitor performance, even exceeding the

properties described in the data sheets, providing stress transfer through

the cementitious mortars without creep development.

Nitomortar range of epoxy and hybrid mortar repair systems did prove

their performance in various industrial and repair projects, The ministry

of water and electricity did specify and use these mortars extensively for

repairs where a high degree of chemical and abrasion resistance is

required, and where resinous systems has been specified for use.

These mortars enjoy a similar reputation of the cementitious repair

systems of Fosam, their ease of use, and reliability among contractors

and consultants alike presented them as the leading products in the

market.

Coatings

High performance Flexguard elastomeric coatings (Flexguard 500 & Flexguard PU) are being acclaimed as

outperforming the alternatives on the market, while maintaining the simplicity in application (in the extremes of the

Middle East heat) for which Fosroc is renown. Presently Flexguard Products are the leading epoxy and

polyurethane performers in concrete coatings in the Middle East, particularly in Saudi Arabia where they are

successfully applied for Aramco, Saudi Electric Company and Sabic. International Consultants from Houston Texas

for a multi billion dollar Petrochemical project are presently being more and more favorably impressed with our

coatings ease-of-application in high summer, resilience, continued elastomeric performance and UV/IR weathering

resistance in the KSA, ensuring that their level of confidence with our local products are growing exponentially.

Page 10 of 10

Company Profile

constructive solutions

Fosams Coal Tar Epoxy coatings have proved themselves successful in meeting the demands of application in

local environments successfully, as is evidenced by the continued extra ordinary demand for Nitocote ET401 by

both Aramco and SABIC projects on Jubail sites proving ease of application.

Fosams Acid and Alkali protective coatings are extremely high performance. Nitocote EN901 is designed for

protecting concrete structures against extremes in pH in local temperatures. It has been proven to be successful in

protecting against 98% Sulphuric Acids, and 36.7% HCL conditions.

New Generation Joint Sealants

Fosroc have developed a new range of Joint sealant out of the tried and tested Silyl terminated Polyethers MS

Polymer now termed MS sealants. These next generation sealants have the astounding property of being tolerant

to damp surfaces, while being one-part and primerless. Our full range of sealants are used as building sealants

(taking over from acrylic sealants) in the form of Nitoseal MS50, also being low modulus, (taking over from Silicon

sealants) for high movement, non staining applications in high temperatures like Saudi Arabia on Marble, stone,

granite etc. The range extends into Civil Engineering providing high performance sealants used under water, and in

exposed conditions.

Waterproofing

New developments in Fosrocs Waterproofing stable are ensuring that Waterproofing membranes (Proofex

Engage) are now physically bonded to the concrete substrate during the casting process, once more ensuring a

simple operation during construction, eliminating curing of subgrade concrete surfaces and delays for overcoating

Page 11 of 11

Company Profile

constructive solutions

with Epoxy waterproofing coatings. The additional time gained accelerates the construction program by ensuring

immediate backfilling after casting which ensures superstructures can be accelerated, unhindered by open

excavation. Proofex Engage is capable of withstanding 7bar pressure against the positive face (focused on a

deliberate cut in the membrane) without tracking (or migrating) further than 120 sq mm at the bond line. There is no

chemical bond or heat developed bond to break down under pressure.

In conclusion it has become evident that the performance of Fosams products is becoming increasingly obvious to

the Saudi Arabian Industrys international project teams, particularly in Jubail. Our range of products are developed

for the Middle East market in a tropical grade where pot life is at risk, and are fit -for-purpose when related to the

many speciality environments in the Petrochemical Industry. It goes without saying that the supply of products from

Fosam (being native to Saudi Arabia) will be timeously delivered (generally within 3 days for ex-stock items) to site,

the products are cost-effective and cost-competitive, while the technical support will be immediate. Aramco have

judged Fosam Company as A-grade supplier/vendors as has Fluor Arabia.

Waterproofing Examples

Page 12 of 12

Вам также может понравиться

- Summer Training Repor1Документ60 страницSummer Training Repor1abcgabcgОценок пока нет

- SEM-4 GCSR Company ReportДокумент30 страницSEM-4 GCSR Company ReportHNSMBA 2016Оценок пока нет

- 5K Car CareДокумент11 страниц5K Car Carekarthik sОценок пока нет

- Working Capital ReportДокумент60 страницWorking Capital ReportRavi JoshiОценок пока нет

- Sources of Data Method of Data CollectionДокумент76 страницSources of Data Method of Data CollectionHaripriya VijayОценок пока нет

- Winter Project ReportДокумент23 страницыWinter Project ReportSARAVANANОценок пока нет

- IB Case BoeingДокумент1 страницаIB Case BoeingvinayakbelwadeОценок пока нет

- Finance Project in Indian Cotton TextileДокумент109 страницFinance Project in Indian Cotton TextileRoyal ProjectsОценок пока нет

- Prikshit Report of Marketing Strategies of TATAmotorsДокумент54 страницыPrikshit Report of Marketing Strategies of TATAmotorsPrikshit SharmaОценок пока нет

- Voltas 1Документ85 страницVoltas 1Kuldeep Batra100% (1)

- MRF Organizational Study: India's Leading Tyre ManufacturerДокумент79 страницMRF Organizational Study: India's Leading Tyre ManufacturerBikash PattnayakОценок пока нет

- It S All About ImagineeringДокумент31 страницаIt S All About ImagineeringLakshya KarnaniОценок пока нет

- K.D.ketcHENWARES PVT - Ltd. Project Report-Prince DudhatraДокумент78 страницK.D.ketcHENWARES PVT - Ltd. Project Report-Prince DudhatrapRiNcE DuDhAtRaОценок пока нет

- Internship ReportДокумент44 страницыInternship ReportPower King Samar Baba100% (1)

- Parth ProjectДокумент69 страницParth ProjectParth TrivediОценок пока нет

- Working Capital & Ratio Analysis of Hindustan National GlassДокумент78 страницWorking Capital & Ratio Analysis of Hindustan National GlassPratik Gaikwad100% (1)

- Project Report On Ford Motor Company PDFДокумент15 страницProject Report On Ford Motor Company PDFHargun VirkОценок пока нет

- MRFДокумент19 страницMRFUmesh GadeОценок пока нет

- Project Report On: Larsen & Toubro Limited (L&T)Документ40 страницProject Report On: Larsen & Toubro Limited (L&T)Rohit D GhuleОценок пока нет

- Summer Traning Project Report ON: Tata MotorsДокумент56 страницSummer Traning Project Report ON: Tata MotorsAbhishek KumarОценок пока нет

- Mba Sumer ProjectsДокумент66 страницMba Sumer ProjectsSheikh ZuhaibОценок пока нет

- Leather IndustryДокумент7 страницLeather IndustrySumit ChandraОценок пока нет

- Summer Industrialtraining Report On Honda CarДокумент36 страницSummer Industrialtraining Report On Honda CarBanwari Lal Prajapat100% (1)

- Farida Shoes Private Limited: No.17, Jalal Road, Mootukullai, Ambur, TAMIL NUDU 635804 Email Id: Fspladmin@farida - Co.inДокумент58 страницFarida Shoes Private Limited: No.17, Jalal Road, Mootukullai, Ambur, TAMIL NUDU 635804 Email Id: Fspladmin@farida - Co.inVicky100% (4)

- Siya RamДокумент62 страницыSiya RamNeeraj SoniОценок пока нет

- Summer InternДокумент10 страницSummer InternHIMANI GERAОценок пока нет

- Executive Summary PROJECT REPORT ON SEZДокумент1 страницаExecutive Summary PROJECT REPORT ON SEZasandilyaОценок пока нет

- CREYATE: Arvind's Omni Channel AvatarДокумент13 страницCREYATE: Arvind's Omni Channel AvatarAtul GuptaОценок пока нет

- Bharat Electronics LimitedДокумент36 страницBharat Electronics LimiteddipanshuОценок пока нет

- Kadvani Project Report-Prince DudhatraДокумент69 страницKadvani Project Report-Prince DudhatrapRiNcE DuDhAtRa100% (1)

- CHEMEXIL - Chemical Exports From India (Report)Документ37 страницCHEMEXIL - Chemical Exports From India (Report)Mayank GuptaОценок пока нет

- Customer Feedback at Big BazaarДокумент77 страницCustomer Feedback at Big BazaarSheetal ChekeОценок пока нет

- MRFДокумент42 страницыMRFfaraz_005Оценок пока нет

- Ultratech Final Report Submission Final 2010Документ93 страницыUltratech Final Report Submission Final 2010Kumar Pratik0% (1)

- Shahbaaz KhanДокумент86 страницShahbaaz KhanChandan SrivastavaОценок пока нет

- Ashok Leyland HRДокумент25 страницAshok Leyland HRkunal100% (1)

- Ongc ProjectДокумент36 страницOngc ProjectdsgoudОценок пока нет

- Ganesh ProjectДокумент61 страницаGanesh ProjectLakhan SharmaОценок пока нет

- Textile Internship Report SummaryДокумент43 страницыTextile Internship Report SummaryZaighum AliОценок пока нет

- Escorts Industrial TrainingДокумент21 страницаEscorts Industrial TrainingNitish BhardwajОценок пока нет

- Project On AccLimitedДокумент47 страницProject On AccLimitedBrijesh Patel100% (4)

- Operation Management HCL NewДокумент103 страницыOperation Management HCL Newdeepak GuptaОценок пока нет

- Dairy Project ReportДокумент30 страницDairy Project Reportmib225657% (7)

- Advertising Effectiveness of TATA MotorsДокумент72 страницыAdvertising Effectiveness of TATA MotorsAmit0% (1)

- Introduction - Wipro LTD: Wipro As A Company Going GlobalДокумент62 страницыIntroduction - Wipro LTD: Wipro As A Company Going GlobalMakdoom MullaniОценок пока нет

- Oil and Natural Gas Corporation LTD ProjectДокумент15 страницOil and Natural Gas Corporation LTD ProjectManoj NagОценок пока нет

- Velkast Foundries Internship ReportДокумент24 страницыVelkast Foundries Internship ReportZabiulla NОценок пока нет

- JK InventoryДокумент118 страницJK Inventorygouri khanduallОценок пока нет

- Ashok Leyland Project ReportДокумент40 страницAshok Leyland Project ReportMukesh kannan MahiОценок пока нет

- Aayush Leather IndustryДокумент50 страницAayush Leather IndustryRahul JaiswalОценок пока нет

- Granolite Vitrified Tiles Pvt. LTD Project Report-Prince DudhatraДокумент59 страницGranolite Vitrified Tiles Pvt. LTD Project Report-Prince DudhatrapRiNcE DuDhAtRaОценок пока нет

- Comparative Marketing Strategies of Maruti Suzuki and HyundaiДокумент82 страницыComparative Marketing Strategies of Maruti Suzuki and Hyundaidiwakar0000000Оценок пока нет

- Cost Effective Techniques-2Документ63 страницыCost Effective Techniques-2anon_265371938Оценок пока нет

- Gravity Project Report-Prince DudhatraДокумент29 страницGravity Project Report-Prince DudhatrapRiNcE DuDhAtRaОценок пока нет

- Grasim Industries LimitedДокумент46 страницGrasim Industries Limitedanurag6866Оценок пока нет

- RIL's Global StrategyДокумент5 страницRIL's Global StrategyAjay Singh TalyanОценок пока нет

- Fosroc Nitocote EP405 Technical SubmittalДокумент114 страницFosroc Nitocote EP405 Technical SubmittalErdal CanОценок пока нет

- ProfileДокумент256 страницProfileNishu SharmaОценок пока нет

- Ford AssignmentДокумент31 страницаFord AssignmentNauman AkramОценок пока нет

- Item Quantities of Phase-1Документ4 страницыItem Quantities of Phase-1Tori SmallОценок пока нет

- JYM Project - Schedule (Rev-3, 11.09.2015)Документ15 страницJYM Project - Schedule (Rev-3, 11.09.2015)Tori SmallОценок пока нет

- Course Book 6Документ19 страницCourse Book 6Tori SmallОценок пока нет

- Assets List for File #23352 Alfanar Construction CoДокумент1 страницаAssets List for File #23352 Alfanar Construction CoTori SmallОценок пока нет

- 7-2-c Form - Gen Consultant PQ Summary Rev-0Документ4 страницы7-2-c Form - Gen Consultant PQ Summary Rev-0Tori SmallОценок пока нет

- 5-Star Element Hemraj InjuryДокумент7 страниц5-Star Element Hemraj InjuryTori SmallОценок пока нет

- Project: JUAYMAH380/230KV BSP: SL No AДокумент4 страницыProject: JUAYMAH380/230KV BSP: SL No ATori SmallОценок пока нет

- SVC Safaniyah (BSP) Punch List (4) XLSX 1Документ52 страницыSVC Safaniyah (BSP) Punch List (4) XLSX 1Tori SmallОценок пока нет

- 380kv BSP project civil works schedule Juaymah substationДокумент2 страницы380kv BSP project civil works schedule Juaymah substationTori SmallОценок пока нет

- 5-Star Element Hemraj InjuryДокумент7 страниц5-Star Element Hemraj InjuryTori SmallОценок пока нет

- I Site Progress Civil Works: A 380 KV GIS BuildingДокумент3 страницыI Site Progress Civil Works: A 380 KV GIS BuildingTori SmallОценок пока нет

- Assets List for File #23352 Alfanar Construction CoДокумент1 страницаAssets List for File #23352 Alfanar Construction CoTori SmallОценок пока нет

- SI No 02 For Erection of Steel Structure For MarjanДокумент3 страницыSI No 02 For Erection of Steel Structure For MarjanTori SmallОценок пока нет

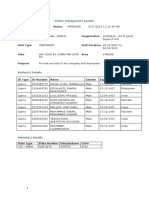

- Request# Status: Visitor Management SystemДокумент1 страницаRequest# Status: Visitor Management SystemTori SmallОценок пока нет

- Assets List Against File # 17920: Alfanar ConstructionДокумент1 страницаAssets List Against File # 17920: Alfanar ConstructionTori SmallОценок пока нет

- Expense Sheet TitleДокумент4 страницыExpense Sheet TitleTori SmallОценок пока нет

- 230kv Ohtl Sub - 10 Cut Over Plan Updated 29.2.16Документ10 страниц230kv Ohtl Sub - 10 Cut Over Plan Updated 29.2.16Tori SmallОценок пока нет

- Drawing2 - GIBДокумент1 страницаDrawing2 - GIBTori SmallОценок пока нет

- BSP AccessДокумент14 страницBSP AccessTori SmallОценок пока нет

- DPR - 22!12!2015 Safaniyah BSP, SVC and Sub-10Документ12 страницDPR - 22!12!2015 Safaniyah BSP, SVC and Sub-10Tori SmallОценок пока нет

- Details of Company Car Expenses (01.12.15)Документ266 страницDetails of Company Car Expenses (01.12.15)Tori SmallОценок пока нет

- Online job application for Prism Engineering ConsultantsДокумент2 страницыOnline job application for Prism Engineering ConsultantsTori SmallОценок пока нет

- Current & Previous Reading For Brake Pad Change (June 2015)Документ2 страницыCurrent & Previous Reading For Brake Pad Change (June 2015)Tori SmallОценок пока нет

- Acomplishment Chart 380kVДокумент8 страницAcomplishment Chart 380kVTori Small100% (1)

- Concrete ChaklistДокумент1 страницаConcrete ChaklistTori SmallОценок пока нет

- Imam Hussain Sermon at MinaДокумент15 страницImam Hussain Sermon at MinaTori SmallОценок пока нет

- Car Wash Dec 14 (New)Документ2 страницыCar Wash Dec 14 (New)Tori SmallОценок пока нет

- Tuhaf Al UqulДокумент840 страницTuhaf Al Uqulapi-3738883Оценок пока нет

- Main Lab: FT-A-21226 29Y Female SelfДокумент1 страницаMain Lab: FT-A-21226 29Y Female SelfTori SmallОценок пока нет

- Shahrour FreedomДокумент14 страницShahrour FreedomTori SmallОценок пока нет

- Overbased Calcium Sulfonate 400 TBN TDSДокумент2 страницыOverbased Calcium Sulfonate 400 TBN TDSMohamad Reza JahanbakhshОценок пока нет

- Ngts - 3 24 10Документ41 страницаNgts - 3 24 10akmezimОценок пока нет

- Gojo BOQ 2013 ManualДокумент40 страницGojo BOQ 2013 ManualAbel BerhanemeskelОценок пока нет

- 006 131112 Cousins & Cousins Brochure SMДокумент56 страниц006 131112 Cousins & Cousins Brochure SMcousinscousinsОценок пока нет

- Project On Powder Dispensing System of Sand 3d PrintingДокумент101 страницаProject On Powder Dispensing System of Sand 3d PrintingSameer MandaogadeОценок пока нет

- Primer On Optimal Control BOOK SpeyerДокумент321 страницаPrimer On Optimal Control BOOK SpeyerRaul Rojas Peña50% (2)

- Circ Seam: Run Time Time Required For L/Seam or C/Seam (LS/CS) CsДокумент5 страницCirc Seam: Run Time Time Required For L/Seam or C/Seam (LS/CS) CsMina RemonОценок пока нет

- FENIXGSM Precios Boxs Unlock Argentina Precios ACTUALIZADOSДокумент2 страницыFENIXGSM Precios Boxs Unlock Argentina Precios ACTUALIZADOS✔Fenix GSM Oficial - Boxs Unlock en ArgentinaОценок пока нет

- Company Profile PT. Depriwangga EngДокумент12 страницCompany Profile PT. Depriwangga EngIrchamОценок пока нет

- GILKESДокумент25 страницGILKESJohnny CcanchiОценок пока нет

- Exam 70 461 Microsoft SQL ServerДокумент10 страницExam 70 461 Microsoft SQL Serverjimmy_sam001Оценок пока нет

- Victoria ChemicalДокумент10 страницVictoria ChemicalBobYu0% (1)

- PROJECT HSE PLAN REVIEWДокумент21 страницаPROJECT HSE PLAN REVIEWFaldiОценок пока нет

- DB KAF 4.3 en WebДокумент14 страницDB KAF 4.3 en WebnawajhaОценок пока нет

- Academic Task 3 Simulation QuestionsДокумент9 страницAcademic Task 3 Simulation QuestionsAnshulОценок пока нет

- Key Performance Indicators in Public-Private PartnershipsДокумент124 страницыKey Performance Indicators in Public-Private PartnershipsgrandmanituОценок пока нет

- Inspection and Test PlanДокумент6 страницInspection and Test PlanReduddboy100% (1)

- Wilderness 1500 X Study Plans Complete A 4Документ29 страницWilderness 1500 X Study Plans Complete A 4Anonymous eiCiKcVkОценок пока нет

- Industrial Profile of Bhavnagar DistrictДокумент19 страницIndustrial Profile of Bhavnagar Districtsiddharth singhОценок пока нет

- Engineering: ManualДокумент85 страницEngineering: Manualsabinum100% (3)

- Lean Manufacturing Transformation for ShipyardsДокумент12 страницLean Manufacturing Transformation for ShipyardsLukman Tarigan SumatraОценок пока нет

- Chapter 6 Layout Planning Model and Design Final FinalДокумент28 страницChapter 6 Layout Planning Model and Design Final Finaluser 123Оценок пока нет

- Gcaug PDFДокумент174 страницыGcaug PDFThi NguyenОценок пока нет

- Industry-Company MatrixДокумент66 страницIndustry-Company Matrixanon_981731217Оценок пока нет

- THS 2001 - Brochur of All Articles PresentedДокумент239 страницTHS 2001 - Brochur of All Articles Presentedramkumar31Оценок пока нет

- Characteristics of A Good Management Information SystemДокумент6 страницCharacteristics of A Good Management Information SystemSahil AhujaОценок пока нет

- Underpinning: TypesДокумент5 страницUnderpinning: TypesEnggUsmanZafarОценок пока нет

- BSNL Project Organization BehaviourДокумент32 страницыBSNL Project Organization BehaviourPrashantqmarОценок пока нет

- Resume Ben Ott (05-11-10)Документ1 страницаResume Ben Ott (05-11-10)aialosangelesОценок пока нет

- WCBasicAdminGuide 168952Документ402 страницыWCBasicAdminGuide 168952sreesamkumar_2931979Оценок пока нет