Академический Документы

Профессиональный Документы

Культура Документы

Basics of PLA - Bioplastics MAGAZINE

Загружено:

Isadora HenriquesИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Basics of PLA - Bioplastics MAGAZINE

Загружено:

Isadora HenriquesАвторское право:

Доступные форматы

Basics

Basics of PLA

Article contributed* by

Dr. Rainer Hagen,

Vice President and Product Manager,

Uhde Inventa-Fischer GmbH,

Berlin, Germany

Industrial composting

Most attractive method of disposal based on public acceptance

No recovery of material and energy

Mechanical recycling

Loss of product properties cannot be recovered

Downcycling

Burning (energy recycling)

Competition between human food, industrial lactic acid

and PLA production is not to be expected: For example,

using PLA as substitute for 5% of the German packaging

plastics consumption requires only 0.5% (sugar beet)

to 1.25% (wheat) of the agricultural area available. At

the same time, approximately 30% of the available area

lies fallow mainly for economic reasons. Research is in

progress on processes and micro-organisms that produce

lactic acid from cellulose coming from agricultural

residues such as maize stalks or straw.

Figure 1: Methods of PLA Recycling

fossil raw material

Total Fossil Energy [GJ/ t plastic]

140

120

100

80

60

40

20

0

PA 6

HDPE

PET

PLA

Source: M. Patel, R. Narayan, in Natural Fibers, Biopolymers and Biocomposites, A.

Mohanty, M. Misra, L. Drzal, Taylor & Francis Group, 2005, Boca Raton.

Figure 2: Consumption of Fossil Resources by PLA vs.

Polymers from Fossil Feedstock - cradle to gate

38

bioplastics MAGAZINE [01/09] Vol. 4

At temperatures below its glass transition point (e.g.

55C, depending on comonomer content) PLA is as stable

as PET or PBT. Only in an industrial composting facility,

the high temperature (60C) and humidity required for the

hydrolysis are achieved. After hydrolysis, PLA is biologically

degradable by common micro-organisms. Lactic acid, the

monomer building block of PLA can frequently be found

in plants and animals as a by-product or intermediate

product of metabolism. Lactic acid is non-toxic.

Lactic acid can be industrially produced from a number

of starch or sugar containing agricultural products.

Back into polymerisation

Collecting and sorting to be solved yet

fossil fuel

Polylactide or Polylactic Acid (PLA) is a synthetic, aliphatic

polyester from lactic acid. For industrial applications, such

as fibres, films and bottles, the chain length n should be

between 700 and 1400. This is significantly higher than

with partially aromatic polyesters like PET and PBT where

n is between 100 and 200. Therefore, the requirements on

both raw material purity and technical effort are much

higher.

Non-depleting properties of PLA

Recovers green energy

Chemical recycling

Introduction

Several recycling methods can be applied to waste PLA

(Fig. 1). Composting allows only moderate benefits. In

future, sorting, purification of PLA waste and re-feeding

into the polymerisation plant seems to be the most

attractive way of recovery.

PLA like other biopolymers is often criticised for the

need of process energy from fossil resources. Even if this

is the case at present, 1 kg of PLA represents less energy

equivalents than 1 kg of polymers from petrochemical

Basics

feedstock (Fig. 2). Consequently, PLA producers can also

reap financial benefits by trading CO2 emission certificates

(Fig. 3).

Process Routes to PLA

Several Process Routes have been developed or are

practised on industrial scale: Ring Opening Polymerisation

(ROP), Direct Polycondensation in high boiling solvents

(DP S), and Direct Polymerisation in bulk followed by chain

extension with reactive additives.

ROP is the route which delivers by far the highest

proportion of PLA chips available on the market. The

other routes produce only minor amounts or did not get

past the pilot scale. Figure 4 depicts the steps of a ROP

process, starting from lactic acid. In the first part lactide

is formed, which after fine purification is converted by

ROP to PLA.

Processing of PLA

A major advantage of PLA is the possibility to process

the polymer on common process equipment. Especially

the converters of polyolefins do not require a change

to other process equipment. They only need to change

the handling of granulate. It is very important to dry the

polymer before processing otherwise it will degrade.

Water and high temperatures (up to 240C) facilitate fast

degradation.

7

6

[kg CO2 eq/kg]

If process energy is supplied by biomass, e.g. biogas,

the fossil energy required for 1 kg PLA can be cut by half,

thus duplicating the benefits from trading CO2 emission

certificates. Additionally, significant potential exists

for saving process energy by improving lactic acid and

polymerisation technologies.

5

4

3

2

1

0

PA 6

HDPE

PET

PLA

Source: M. Patel, R.N arayan, in Natural Fibers, Biopolymers and Biocomposites, A.

Mohanty , M. Misra , L. Drzal, Taylor & Francis Group, 2005, Boca Raton.

Figure 3: CO2 Emissions by PLA vs. polymers from fossil

feedstock - cradle to gate

Lactic Acid

Water to

Hydrolysis

Evaporation/Distillation

Water,

Lactic Acid

Concentrated Lactic Acid

Pre-condensation

Purge

Oligomers

Pre-polymer

Formation of Cyclic Dimer

Crude Lactide

see Fig. 5

Lactide Purification

Highly Purified Lactide

Ring Opening Polymerisation

Dilactide

Polylactide with Monomer

Demonomerisation/Stabilisation

PLA is a polymer which can be processed by:

injection moulding

sheet extrusion

extrusion blow moulding

thermoforming

Polylactide

Figure 4: Steps of a PLA Process with Ring

Opening Polymerisation

stretch blow moulding

injection stretch blow moulding

fibre spinning

non woven spinning, spun bonding

Properties of PLA

PLA is a crystal clear, transparent material when

amorphous that becomes the hazier the higher the

crystallinity. Crystallized material is opaque. When

producing lactide, meso-lactide is formed as a by-product.

It is difficult to separate the meso-lactide from the Llactide in the purification step. When polymerizing L-

Figure 5: Ring opening Polymerisation

bioplastics MAGAZINE [01/09] Vol. 4

39

Basics

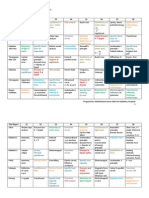

Table 1: Properties of PLA Types

Type

Tm

Tg

PLLA

PL / DLA

sc PLA

sbc PLA

160-180 C

55-65 C

55 C

60 C

55 C

45-55 Mpa 3-5 %

50-200 %

3-5 %

5-10 %

220-230 C

185-195 C

Tm - melting temperature

Tg - glass transition temperature

Eb - elongation at break

n - tensile strength at break

Eb

lactide with small contents of meso-lactide a co-polymer

is formed. Increasing meso-lactide leads to decreasing

crystallinity. With more than 10-15% meso-lactide the

polymer is amorphous.

By varying the amount of meso-lactide the properties of

the polymer can be adjusted for specific applications.

One of the reasons for the limited consumption of PLA

up to now is the low thermal resistance. The Tg (glass

transition temperature) is about 55C depending on

comonomer content to a small extent (Table 1).

Methods of improving thermal resistance are to prepare

a stereo complex (sc PLA) or a stereo-block copolymer

(sbc PLA). Melting point and heat distortion temperature

(HDT) will increase significantly.

Improving the thermal properties can extend the

applications of PLA considerably in the future.

There are also various additives that improve the

properties of PLA with respect to impact strength, melt

viscosity, HDT, crystallinity etc.

Perspective

PLA combines all prerequisites of sustainability with

important properties of well established polymers.

Applications have already been found in many niches of

packaging and textile products. Within those niches fast

growth of consumption is expected to continue depending

on the availability of PLA polymer.

High research activity is dedicated to overcome typical

weaknesses of PLA low impact strength and low heat

distortion temperature and to develop tailor-made

PLA grades in order to serve special applications. These

activities will conquer new niches for PLA and will help to

increase PLA consumption at high velocity.

Other growth factors are the availability and prices of

crude oil, agricultural products and production plants and

technology.

Within the foreseeable future PLA will not become a

commodity polymer like PE, PP, PS this is considered to

be an advantage both for PLA producers and converters.

However, this could change in the long term.

www.thyssenkrupp.com

*: The article is based on a contribution to a book, submitted

for publication in T. Haas, M. Kircher, T. Khler, G. Wich, U.

Schrken, R. Hagen, White Biotechnology, in R. Hfer, Ed.,

Sustainable solutions for modern economies, The Royal

Society of Chemistry, Cambridge, forthcoming 2009, ISBN

9781847559050.

40

bioplastics MAGAZINE [01/09] Vol. 4

Вам также может понравиться

- Modified Polymers, Their Preparation and Properties: Main Lectures Presented at the Fourth Bratislava Conference on Polymers, Bratislava, Czechoslovakia, 1-4 July 1975От EverandModified Polymers, Their Preparation and Properties: Main Lectures Presented at the Fourth Bratislava Conference on Polymers, Bratislava, Czechoslovakia, 1-4 July 1975A. RomanovРейтинг: 5 из 5 звезд5/5 (1)

- Biodegradation of PLAДокумент7 страницBiodegradation of PLArahmihytОценок пока нет

- Wood-Filled Plastics - They Need The Right Additives For Strength, Good Looks, and Long Life - Plastics TechnologyДокумент5 страницWood-Filled Plastics - They Need The Right Additives For Strength, Good Looks, and Long Life - Plastics TechnologyParas PatelОценок пока нет

- Surface Properties and Optical Properties Modifiers: - Anjanah Ganapathy G S S 2016303005Документ16 страницSurface Properties and Optical Properties Modifiers: - Anjanah Ganapathy G S S 2016303005BubbleОценок пока нет

- Polypropylene Composites With Natural Fibers and Wood - General Mechanical Property ProfilesДокумент8 страницPolypropylene Composites With Natural Fibers and Wood - General Mechanical Property ProfilesCarlos SoaresОценок пока нет

- ADEKA India. ADEKA GlobalДокумент7 страницADEKA India. ADEKA GlobalNga VuОценок пока нет

- Additif PolimerДокумент32 страницыAdditif PolimerAndinОценок пока нет

- Monoesters For Transformer Insulating LiquidДокумент9 страницMonoesters For Transformer Insulating LiquidTELKOMNIKAОценок пока нет

- Wood Plasticcomposite2019Документ9 страницWood Plasticcomposite2019Bayron Rubiano LadinoОценок пока нет

- Polymers: Rheological Basics For Modeling of Extrusion Process of Wood Polymer CompositesДокумент16 страницPolymers: Rheological Basics For Modeling of Extrusion Process of Wood Polymer CompositesMuhammad IlyasОценок пока нет

- 94 Aaa 320576041 DДокумент16 страниц94 Aaa 320576041 Drp.qscplОценок пока нет

- Characterization of Wax Esters, Free Fatty Alcohols and Free Fatty AcidsДокумент6 страницCharacterization of Wax Esters, Free Fatty Alcohols and Free Fatty AcidsTravis KirinОценок пока нет

- MWF BrochureДокумент6 страницMWF BrochurejohnsopranaОценок пока нет

- Wood Polymer Composites: of and Review PaperДокумент10 страницWood Polymer Composites: of and Review PaperPhạm MiềuОценок пока нет

- Pod66 Tang PDFДокумент9 страницPod66 Tang PDFM Jodi AlfayedОценок пока нет

- Chemicalsguide ADEKAДокумент24 страницыChemicalsguide ADEKAAgenk VambudyОценок пока нет

- Crodamide Slip Adds For Film ExtrusionДокумент4 страницыCrodamide Slip Adds For Film ExtrusionGabriel CamposОценок пока нет

- Kent2003 ReferenceWorkEntry SoapSoapFattyAcidsFattyAcidsAnДокумент43 страницыKent2003 ReferenceWorkEntry SoapSoapFattyAcidsFattyAcidsAnAhmed KhaledОценок пока нет

- Adk Cizer Adk Stab: Polymer AdditivesДокумент10 страницAdk Cizer Adk Stab: Polymer AdditivesEliton S. MedeirosОценок пока нет

- Additive Specialties and High Performance ConcentratesДокумент11 страницAdditive Specialties and High Performance ConcentratesXuân Giang NguyễnОценок пока нет

- Industry OverviewДокумент26 страницIndustry OverviewNajihah Ramli100% (1)

- Oleochemical Industry Future Through Biotechnology: ReviewДокумент10 страницOleochemical Industry Future Through Biotechnology: ReviewAmanda SartikaОценок пока нет

- Bayer MaterialScienceДокумент3 страницыBayer MaterialScienceaelshazlОценок пока нет

- CEPE Inventory ListДокумент153 страницыCEPE Inventory Listjai soniОценок пока нет

- Type of AdmixturesДокумент6 страницType of AdmixturesRV VimalОценок пока нет

- Experimental Comparison of Vegetable and Petroleum Base Oils Inmetalworking Fluids Using The Tapping Torque Test PDFДокумент6 страницExperimental Comparison of Vegetable and Petroleum Base Oils Inmetalworking Fluids Using The Tapping Torque Test PDFRajОценок пока нет

- Brochure - Specialty Effects For Polymer ProcessingДокумент6 страницBrochure - Specialty Effects For Polymer ProcessingXuân Giang NguyễnОценок пока нет

- Pripol Dimer Acids: Flexibility and HydrophobicityДокумент4 страницыPripol Dimer Acids: Flexibility and Hydrophobicitymaged_abdnaghoОценок пока нет

- Polylactic Acid (PLA) Production-64832 PDFДокумент63 страницыPolylactic Acid (PLA) Production-64832 PDFzackОценок пока нет

- Biodegradation of Synthetic and Natural Plastic byДокумент12 страницBiodegradation of Synthetic and Natural Plastic byselly agustinaОценок пока нет

- Palm OilДокумент2 страницыPalm OilSunday OluwanisolaОценок пока нет

- European Polymer Journal: Marina P. Arrieta, Juan López, Alberto Hernández, Emilio RayónДокумент16 страницEuropean Polymer Journal: Marina P. Arrieta, Juan López, Alberto Hernández, Emilio RayónORGEX TMОценок пока нет

- Ion-Exchange and Adsorbent Resins For Food IndustryДокумент28 страницIon-Exchange and Adsorbent Resins For Food IndustryMario Darío Gatto0% (1)

- Biopolymers: Sindhu Reka.R 14BBT047Документ14 страницBiopolymers: Sindhu Reka.R 14BBT047aminsuhadiОценок пока нет

- Updated 4326660 Poster PresentationДокумент1 страницаUpdated 4326660 Poster Presentationhephlin thamОценок пока нет

- Plasticizer Presentation March 2010Документ58 страницPlasticizer Presentation March 2010Kaushal KothariОценок пока нет

- Polymer Additives and PlasticizersДокумент25 страницPolymer Additives and PlasticizersDeva Raj100% (1)

- Biofibres Biodegradable Polymers and Biocomposites An OverviewДокумент24 страницыBiofibres Biodegradable Polymers and Biocomposites An OverviewAbdul BasitОценок пока нет

- Processing Technologies For Poly (Lactic Acid)Документ33 страницыProcessing Technologies For Poly (Lactic Acid)Aero Fortia NaturaОценок пока нет

- Databook 2013Документ309 страницDatabook 2013Jan ZawiszaОценок пока нет

- Vegetal Vs Mineral OilsДокумент6 страницVegetal Vs Mineral OilsDark CenobiteОценок пока нет

- Brochure MosselmanДокумент12 страницBrochure Mosselmanvcoranm100% (1)

- Pluronic PeДокумент16 страницPluronic PeTrev GlasbeyОценок пока нет

- Market SurveyДокумент3 страницыMarket SurveyNurbaity IsmailОценок пока нет

- Kinetics of Propylene Glycol HydrochlorinationДокумент4 страницыKinetics of Propylene Glycol HydrochlorinationWidya Isti AriantiОценок пока нет

- EOДокумент26 страницEOdieego001100% (1)

- Propylene Glycol Usp-EpДокумент4 страницыPropylene Glycol Usp-Epvanhung68Оценок пока нет

- Polyethylene Terephthalate Waste Recycling and AppДокумент10 страницPolyethylene Terephthalate Waste Recycling and AppJohn David LunaОценок пока нет

- Polylactic Acid (PLA) Research, Development and IndustrializationДокумент12 страницPolylactic Acid (PLA) Research, Development and IndustrializationΘεανώ ΚαρώνηОценок пока нет

- Industrial Biotech J ProjectДокумент39 страницIndustrial Biotech J Projectchelsea charlesОценок пока нет

- Synthesis and Biomedical Applictions of Polylactic AcidДокумент5 страницSynthesis and Biomedical Applictions of Polylactic AcidYaliОценок пока нет

- Complete Report On Formation of Poly Lac PDFДокумент119 страницComplete Report On Formation of Poly Lac PDFMadhukar Scribd0% (1)

- Conversion of Plastic Wastes in To FuelsДокумент6 страницConversion of Plastic Wastes in To FuelsannuunakiОценок пока нет

- CSNL An Environment Friendly Alternative PDFДокумент15 страницCSNL An Environment Friendly Alternative PDFDonald_12Оценок пока нет

- Brochure Antifoams Defoamers Tego AntifoamДокумент8 страницBrochure Antifoams Defoamers Tego AntifoamJuan CubasОценок пока нет

- Study of Bio-Plastics As Green & Sustainable Alternative To PlasticsДокумент8 страницStudy of Bio-Plastics As Green & Sustainable Alternative To PlasticsAndehОценок пока нет

- Alternatives Routes To MEGДокумент22 страницыAlternatives Routes To MEGYan LaksanaОценок пока нет

- Silica Gel Production Report PDFДокумент8 страницSilica Gel Production Report PDFChoice Organo0% (1)

- Brosch - Biokunststoffe Web v01 - 1 PDFДокумент68 страницBrosch - Biokunststoffe Web v01 - 1 PDFMike AndersonОценок пока нет

- Lankem E-Brochure 2023Документ16 страницLankem E-Brochure 2023Alfredo MéndezОценок пока нет

- Chemistry and Technology of Epoxy Resins - B. Ellis (1993) PDFДокумент342 страницыChemistry and Technology of Epoxy Resins - B. Ellis (1993) PDFIsadora HenriquesОценок пока нет

- ISO 6721 - Part 2Документ19 страницISO 6721 - Part 2Isadora HenriquesОценок пока нет

- Mechanical Response of Polymers - W. RajagopalДокумент162 страницыMechanical Response of Polymers - W. RajagopalIsadora HenriquesОценок пока нет

- Mechanical Response of Polymers Wineman RajagopalДокумент162 страницыMechanical Response of Polymers Wineman RajagopalIsadora Henriques100% (2)

- Operationalization of Regenerative Design Indicators An Integrated Framework of Design and AnalysisДокумент10 страницOperationalization of Regenerative Design Indicators An Integrated Framework of Design and AnalysisVera MarinОценок пока нет

- C 13Документ5 страницC 13مصطفي الغنيمى0% (1)

- Eaton Busure (En)Документ16 страницEaton Busure (En)Danish NasimОценок пока нет

- Crude TBP Country Nigeria Distillation: Akpo BlendДокумент2 страницыCrude TBP Country Nigeria Distillation: Akpo Blendeke23Оценок пока нет

- Lugs and Ferrules Technical Information PDFДокумент2 страницыLugs and Ferrules Technical Information PDFkwagga125Оценок пока нет

- Temperature MeasuremenntДокумент25 страницTemperature MeasuremenntJan Edward L. SuarezОценок пока нет

- Adiabatic Technique FOR Low Power VlsiДокумент16 страницAdiabatic Technique FOR Low Power VlsiAnamika PancholiОценок пока нет

- Analisis Soalan Fizik Kertas 2 BHG A Trial SPM 2010Документ3 страницыAnalisis Soalan Fizik Kertas 2 BHG A Trial SPM 2010Norhazami HashimОценок пока нет

- Development of A Network and Gas Lift Allocation Model For Production Optimization in The Ras Budran FieldДокумент14 страницDevelopment of A Network and Gas Lift Allocation Model For Production Optimization in The Ras Budran FieldTaiwo Adenike BashorunОценок пока нет

- Naman Mehta Sustainable VIIIДокумент13 страницNaman Mehta Sustainable VIIInaman mehtaОценок пока нет

- Basic Electronic For Marine EngineersДокумент45 страницBasic Electronic For Marine EngineersŞansal DikmenerОценок пока нет

- A GCE Physics B 2865 01 January 2006 Question PaperДокумент24 страницыA GCE Physics B 2865 01 January 2006 Question PaperMitul KaziОценок пока нет

- 0-2103471 Introduction To Engine DesignДокумент85 страниц0-2103471 Introduction To Engine DesignJulian DavidОценок пока нет

- New Generation PlanningДокумент3 страницыNew Generation PlanningSyed ArifОценок пока нет

- E510 Startup Installation ManualДокумент147 страницE510 Startup Installation Manualpermitha sariОценок пока нет

- Autometers Alliance Limited - 'Pegasus' (Powertronix Spa, Italy) Online UpsДокумент7 страницAutometers Alliance Limited - 'Pegasus' (Powertronix Spa, Italy) Online UpsItscrap ItscrapОценок пока нет

- High Temperature Primary Batteries For Venus Surface MissionsДокумент24 страницыHigh Temperature Primary Batteries For Venus Surface MissionsEsau Hernandez CalosОценок пока нет

- Remote Activity Iv - Phy 241/243 Work-Energy Theorem: Theory and ExplanationДокумент5 страницRemote Activity Iv - Phy 241/243 Work-Energy Theorem: Theory and ExplanationGhulam MahyyudinОценок пока нет

- Produced Water Re-InjectionДокумент171 страницаProduced Water Re-InjectionrfarajzadehОценок пока нет

- Thermoelectric Fan Powered by A CandleДокумент4 страницыThermoelectric Fan Powered by A CandleMohd Farihan Bin JamaludinОценок пока нет

- Processes Affecting Changes in PropertiesДокумент13 страницProcesses Affecting Changes in PropertiesMark julius garciaОценок пока нет

- Fallsem2016-17 1286 RM001 27-Jul-2016 Mee1003 THДокумент74 страницыFallsem2016-17 1286 RM001 27-Jul-2016 Mee1003 THaman agarwalОценок пока нет

- Cam Price List (Philips)Документ36 страницCam Price List (Philips)dave6522Оценок пока нет

- SKF TIH 240 Heater Instruction ManualДокумент134 страницыSKF TIH 240 Heater Instruction ManualWei Leng tehОценок пока нет

- Axpert MKS IV Off-Grid Inverter Selection GuideДокумент1 страницаAxpert MKS IV Off-Grid Inverter Selection GuideMax Hernandez RОценок пока нет

- A C M V: PsychrometryДокумент31 страницаA C M V: PsychrometryMessi CakeОценок пока нет

- OCTG Piping Inspection MethodsДокумент26 страницOCTG Piping Inspection MethodsAli HashimОценок пока нет

- Adina CFD FsiДокумент481 страницаAdina CFD FsiDaniel GasparinОценок пока нет

- Unit Merinyu Elektrik: Application For Certificate of CompetencyДокумент4 страницыUnit Merinyu Elektrik: Application For Certificate of CompetencySaff MdОценок пока нет

- Abstract-Piezoelectric Energy HarvestingДокумент2 страницыAbstract-Piezoelectric Energy HarvestingGanesh Venugopal100% (5)