Академический Документы

Профессиональный Документы

Культура Документы

Engineered Masonry Walls

Загружено:

Rm1262Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Engineered Masonry Walls

Загружено:

Rm1262Авторское право:

Доступные форматы

ENGINEERED

MASONRY WALLS

ENGINEERED MASONRY WALLS

Engineered masonry walls fall outside the empirical

design restrictions and provisions of the National

Building Regulations. Where the height, length, shape

or load-bearing capacities go beyond the empirical

tables a competent engineer must submit a suitable

design to the local authority for approval.

Engineered boundary walls - effective in commercial,

residential and industrial situations

Examples above and right are engineered walls which

form part of a private clinic in Panorama, Cape. The

broad-fluted tinted Split-Face masonry produced by

Columbia DCM meets architectural demands for

aesthetics, but at the same time has a practical and

functional use.

An important aspect of free-standing walls is their

ability to withstand the high wind loads that are

experienced in the Cape. This Columbia test sample

wall structure was designed by consulting engineer

Mike Arndt for walls 2.1m above ground level in 5m

panels of 140mm hollow concrete masonry. This

design has become standard.

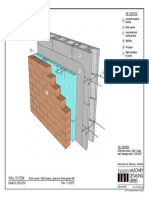

TYPICAL BOUNDARY WALL PANEL IN

HOLLOW DENSE CONCRETE MASONRY

TYPICAL BOUNDARY WALL PANEL IN

HOLLOW DENSE CONCRETE MASONRY

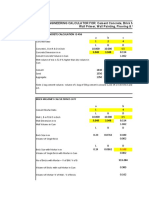

Calculate your own costs

1. Determine the total length of wall or walls

2. Divide it into 5m lengths or portions of 5m lengths

3. Determine the height (up to maximum permissible as shown on

4.

5.

6.

drawing)

Calculate the number of building block plus pilaster blocks (see

calculation plan or determine number of variationsof standard

module)

Phone an SABS supplier in your area for the price for the number

of bricks plus delivery to site

Information required:

Quantity of block

Colours: (grey or tinted)

Textures: (smooth or split face)

Reinforcing per panel

No

Mark

Diam

Length

Bending

Y12

1600

270 (700 cage)

Y12

1900

Straight

R10

1650

150 (620 cage)

TYPICAL BOUNDARY WALL PANEL IN

HOLLOW DENSE CONCRETE MASONRY

This plan is acceptable for submission to local

authorities. Simply submit this drawing with

your house plan to indicate the wall position.

Specifications

1. All joints to be 10mm

2. Max. length = 5190mm

3. Max. height above ground = 2100mm

Concrete mix (foundation 15MPa)

1 sack cement

2 barrows damp sand

30 litres water

3 barrows 26mm stone

Name

Address

Mortar

1 sack lime

NB: This panel is the maximum size

permissible for a freestanding wall under

normal urban and per-urban conditions.

1 sack cement

3 barrows sand

Post code

Concrete mix (pier core 15MPa)

Telephone

1 sack cement

2 barrows damp sand

35 litres water

2 barrows 13mm stone

Footings

30m 60m

100m 200m

Fax

ENGINEERED MASONRY WALLS

The up-market Marina da Gama housing estate required a

combination, the first 1m a retaining wall, and above that a

2.1m wall giving security and good road-noise reduction.

Reinforced 400 x 400mm pilaster blocks created the edge

support for the 5m long panels. For the soil retaining portion a

modular 190mm wide modular block was used and above that

a 140mm wide modular block was used and above that a

140mm wide unit. The wall has withstood the full force of

seasonal south-easter wind since early 1993.

An attractive residential security and road-noise screen wall

was constructed with modular 190mm blocks for walls and

piers.

The tallest vertical, fully reinforced retaining wall in

the Western Cape, designed by Liebenberg and

Stander circa 1985, forms a proud part of a

housing development in Higgovale, Cape Town.

The wall stands 5.2m high and is built with modular

190mm hollow masonry combined with 190mm

beam blocks every second course.

ENGINEERED MASONRY WALLS

Sturdy, closed-off yard areas are combined with attractive

open security fencing in Cape industrial areas, using

pilaster blocks and tubular steel fencing sections for

architectural effect.

Cover picture: At Ratanga Junction, Century City, this

engineered, reinforced boundary wall was erected using

hollow, dry stack units. The total length is 2.3km. The units

were manufactured by Columbia DBL, Cape.

Inset: Some of the steel placements.

Ilco Homes surrounded their "Summergreen"

economic housing development with tinted M140mm

block walls from Inca (Cape). The walls are 2m high

from ground level with wet-cast capping units

decoratively rounding off the columns.

Below: Clients in modern housing estates require

secure living with access control. Inca (Cape) supplied

many kilometres of 2m high decorative walling to meet

customer requirements.

Concrete Manufacturers Association - Membership List (Masonry) 2001/2002

Head Office

PO Box 168 Halfway House 1685

Tel: +27118056742

Fax: +27113154683

Email: cma@cis.co.za

Website:http://www.cma.org.za

Western Cape Regional Office:

GR Koch

PO Box 7231, Roggebaai,

Cape Town 8012

Tel:/Fax: +27214612511

Cell: 0824547657

Email: imes@mweb.co.za

Cape Brick

(021)5112006

Morula Brick & Sand (Pty) Ltd*

(012)5491727

Concor Technicrete (Pty) Ltd *

(011)4952200

Neat Contech cc*

(046)6481359

Corobrik (Pty) Ltd*

(031)5603911

Precast Concrete Industries

(Namibia)

(09264)612804103

Columbia DBL (Pty) Ltd*

(021)9051665

Stanger Brick & Tile (Pty) Ltd*

(032)4570237

Deranco Blocks (Pty) Ltd*

(041)4633338

Watson Concrete*

(011)7400910

(011)8733949

False Bay Bricks (Cape)*

(021)9041620

Western Granite Bricks (Pty)

Ltd*

(021)9041620

Inca Masonry Products (Pty) Ltd*

(043)7451215

White River Cement Bricks

(013)7501271

Infraset*

(012)6520000

Lategans Cement Works*

(021)8731154

*Companies which hold the SABS mark

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Standard Productivity of MachineryДокумент7 страницStandard Productivity of MachineryAtther Javeed90% (42)

- Arup Scheme Design Guide 2006Документ139 страницArup Scheme Design Guide 2006Boris Escubio100% (1)

- Case Study of Sri-Lankan HousingДокумент56 страницCase Study of Sri-Lankan HousingdixitprabidhiОценок пока нет

- Crane Runway Installation Tolerances-BechtelДокумент1 страницаCrane Runway Installation Tolerances-BechtelRm1262Оценок пока нет

- Construction of Poultry Shed: Janpad Panchayat Balrampur Distt.-BalrampurДокумент6 страницConstruction of Poultry Shed: Janpad Panchayat Balrampur Distt.-BalrampurUpendra kumarОценок пока нет

- Structural Scheme Design Guide by ArupДокумент129 страницStructural Scheme Design Guide by ArupNatalie Sullivan100% (15)

- The Concrete Society - Fire DamageДокумент6 страницThe Concrete Society - Fire DamageRm1262Оценок пока нет

- Henderson, Johnson & Wood 2002 Enhancing The Whole Life Structural Performance of Multi-Storey Car ParksДокумент50 страницHenderson, Johnson & Wood 2002 Enhancing The Whole Life Structural Performance of Multi-Storey Car ParksRm1262Оценок пока нет

- Concrete Design Guide No. 3: Lateral Loads and Other FactorsДокумент6 страницConcrete Design Guide No. 3: Lateral Loads and Other Factorsspid003Оценок пока нет

- BT4 SpecificationsДокумент8 страницBT4 SpecificationsJet BlackОценок пока нет

- Cranerunwaybeams 4ed bk180 PDFДокумент13 страницCranerunwaybeams 4ed bk180 PDFMacОценок пока нет

- Building Construction Damp ProofingДокумент120 страницBuilding Construction Damp Proofingइंजि कौस्तुभ पवारОценок пока нет

- BCA Publication "Making Good & Finishing"Документ14 страницBCA Publication "Making Good & Finishing"MisterphylОценок пока нет

- STEEL CONFERENCE EXPANSION JOINTSДокумент4 страницыSTEEL CONFERENCE EXPANSION JOINTSCharles Orebola OresanwoОценок пока нет

- How Silos FailДокумент14 страницHow Silos FailMedhat Hasanain100% (2)

- Labor Man HourДокумент7 страницLabor Man HourAwit123456Оценок пока нет

- Pm-5104-Pc-Fm-Final Project-30-12-2021Документ18 страницPm-5104-Pc-Fm-Final Project-30-12-2021sunainaОценок пока нет

- Cutting Edge Masonry Codes and StandardsДокумент70 страницCutting Edge Masonry Codes and StandardsMuhammad MurtazaОценок пока нет

- BK Series Kilcher Bearing StripsДокумент6 страницBK Series Kilcher Bearing Stripsforbeska100% (1)

- Russell PHD 2015 Progressive Collapse of Reinforced Concrete Flat Slab StructuresДокумент238 страницRussell PHD 2015 Progressive Collapse of Reinforced Concrete Flat Slab StructuresRm1262Оценок пока нет

- Reinforcement of Concrete StructuresДокумент13 страницReinforcement of Concrete StructurestevredeОценок пока нет

- Technoslide Elastomeric-Plain-Sliding-Bearings-For-Bridges-Structures-BrochureДокумент13 страницTechnoslide Elastomeric-Plain-Sliding-Bearings-For-Bridges-Structures-BrochureRm1262Оценок пока нет

- Extend Abstract - 67792 - Joao GeadaДокумент10 страницExtend Abstract - 67792 - Joao GeadaRm1262Оценок пока нет

- Electric Rolling Bridge, Scientific American 24 August 1889 p120Документ2 страницыElectric Rolling Bridge, Scientific American 24 August 1889 p120Rm1262Оценок пока нет

- ADA441347Документ17 страницADA441347habibur Rahman KhanОценок пока нет

- Exhibit 5f - Concept - Design - Submission 100-119Документ20 страницExhibit 5f - Concept - Design - Submission 100-119NasserZakiОценок пока нет

- Retrofitting and Rehabilitation of Fire PDFДокумент134 страницыRetrofitting and Rehabilitation of Fire PDFVarun TyagiОценок пока нет

- Ijsrp p46106 PDFДокумент14 страницIjsrp p46106 PDFKannan JaganОценок пока нет

- Mera DilДокумент12 страницMera DilIqbal AhmadОценок пока нет

- Annerel & Taerwe 2008 Diagnosis of The State of Concrete Structures After FireДокумент6 страницAnnerel & Taerwe 2008 Diagnosis of The State of Concrete Structures After FireRm1262Оценок пока нет

- IMIESA April 2021Документ60 страницIMIESA April 2021Rm1262Оценок пока нет

- Annerel & Taerwe 2008 Diagnosis of The State of Concrete Structures After FireДокумент6 страницAnnerel & Taerwe 2008 Diagnosis of The State of Concrete Structures After FireRm1262Оценок пока нет

- UJ Postgraduate Engineering ManagementДокумент4 страницыUJ Postgraduate Engineering ManagementRm12620% (1)

- Flange BendingДокумент2 страницыFlange BendingMotoro AkinwoleОценок пока нет

- Arup DesignYearbook 2010Документ39 страницArup DesignYearbook 2010Si MonaОценок пока нет

- Swing Jib CranesДокумент2 страницыSwing Jib CranesRm1262Оценок пока нет

- BinsДокумент17 страницBinsRm1262Оценок пока нет

- Guide To Lifting Equipment Testing Inspections 2015Документ8 страницGuide To Lifting Equipment Testing Inspections 2015Rm1262Оценок пока нет

- A Challenge For Designers of Steel Silos PDFДокумент6 страницA Challenge For Designers of Steel Silos PDFRm1262Оценок пока нет

- Narayangharh-Mugling HighwayДокумент85 страницNarayangharh-Mugling HighwayRm1262Оценок пока нет

- Investigating how cement mixtures gain strength over timeДокумент14 страницInvestigating how cement mixtures gain strength over timeSIDDHANTОценок пока нет

- 05 General Report May 2012Документ133 страницы05 General Report May 2012kim kanhaОценок пока нет

- MasterKey Masonry DesignДокумент14 страницMasterKey Masonry Designsegun ajibolaОценок пока нет

- Civil Engg Work Qty Calculator 1 Sept 21Документ8 страницCivil Engg Work Qty Calculator 1 Sept 21Tahseen KhanОценок пока нет

- 01 030 02013 PDFДокумент1 страница01 030 02013 PDFMyo Min ThuОценок пока нет

- Wattle and Daub Construction Technique ExplainedДокумент8 страницWattle and Daub Construction Technique ExplainedkovarasanОценок пока нет

- Cherry Hill 0321Документ20 страницCherry Hill 0321elauwitОценок пока нет

- CompleteДокумент150 страницCompleteIoannis KapageridisОценок пока нет

- SEMEN INDONESIA CERTIFICATE FOR 250 KG/CM2 CONCRETEДокумент1 страницаSEMEN INDONESIA CERTIFICATE FOR 250 KG/CM2 CONCRETEAnnas AchoОценок пока нет

- BFC10502 Past YearДокумент12 страницBFC10502 Past Yearaoi_chiepОценок пока нет

- Eurocode 6: Design of Masonry StructuresДокумент39 страницEurocode 6: Design of Masonry StructuresjerryОценок пока нет

- Canal FallsДокумент20 страницCanal FallsRajesh KhadkaОценок пока нет

- BOQ for Civil Works of GD Phase I at The Lawrence SchoolДокумент35 страницBOQ for Civil Works of GD Phase I at The Lawrence SchoolHead Development ProjectОценок пока нет

- Remaining Concreting Works of CCBДокумент1 страницаRemaining Concreting Works of CCBkollol02cebuetОценок пока нет

- Cement IndiaДокумент16 страницCement IndiaRigОценок пока нет

- Concrete Block Partition WallДокумент25 страницConcrete Block Partition WallKripa PanjariОценок пока нет

- Rural Water Supply SR Kalaburagi Circle 2019-20.Документ338 страницRural Water Supply SR Kalaburagi Circle 2019-20.AEE Sub Div 1878% (9)

- Lab+Flyer NABL NaviMum+R4+-+PДокумент4 страницыLab+Flyer NABL NaviMum+R4+-+Pganesh.pg. GaniОценок пока нет

- T Proc Notices Notices 040 K Notice Doc 35291 396040301Документ135 страницT Proc Notices Notices 040 K Notice Doc 35291 396040301Engr Nissar KakarОценок пока нет

- Medical Lab ProjectДокумент48 страницMedical Lab ProjectDERRICK OCHIENGОценок пока нет