Академический Документы

Профессиональный Документы

Культура Документы

Solids Handling

Загружено:

Sandra Enn BahintingИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Solids Handling

Загружено:

Sandra Enn BahintingАвторское право:

Доступные форматы

10/22/2015

ChE 132

Materials

Handling

Prepared by

Engr. Sandra Enn Bahinting

Section 21

Pages 21-4 to 21-27

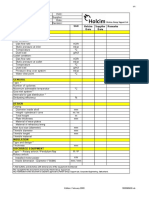

Tables

21-4 : Material Classes & Bulk Densities

21-5 & 21-6 : Screw Conveyor Capacities & Loading

Conditions

21-7 : Belt Conveyor Data

21-8 & 21-9 : Bucket Elevator Specifications

21-10 : Flight Conveyor Capacities

21-11 : Apron Conveyor Capacities

21-12 : Approximate Pneumatic Conveyor Costs

21- 13 : Air Velocities Needed to Convey Solids of

Various Bulk Densities

Figure 21-13 : Nomographs for Determining Conveyor

Design Parameters

10/22/2015

HANDLING OF SOLIDS

Handling

of Materials:

Deals with the transfer of materials over

relatively short distances.

-

Art and science involving the moving,

packaging and storing of substances in

any form

The creation of time and place utility in

material

Materials handling are broken down into

specific disciplines

Conveying deals with movement of bulk solids in fixed path

Feeding accurate control of material flow necessary for

effiecient conveying and processing

Unit handling deals with moving objects both in fixed and

nonfixed path

Packaging science of controlled portioning of bulk materials

and unit objects

Storing - accumulaionon and storage of large quantities of a bulk

solid

Warehousing -covers receiving, storing, shipping and scheduling

of unit loads

Carrier handling and transport concerns the loading, securing

and transporting and unloading of bulk materials and unit loads

10/22/2015

Bucket Elevators

Designed for the primary purpose of

elevating material

used for lifting (maximum incline of

10 degrees), and are composed of

a conveyor belt equipped with buckets and stretched vertically

between two pulleys

10/22/2015

Types of Bucket Elevators

Centrifugal discharge best suited for handling loose, freeflowing, fine, or small lump material.

Continuous bucket elevators - designed to handle friable,

fragile materials to minimize product degradation or damage.

They are also ideal for handling sluggish or abrasive materials.

Positive discharge - elevator design where the buckets are used

to elevate commodities such as popcorn, candy and potato

chips where the utmost concern is on gentle handling and

finished food grade applications.

Internal discharge - a type of continuous bucket elevator. The

difference being an internal discharge elevator is designed to

discharge material along the buckets' internal path

10/22/2015

Power Requirement for Bucket

Elevator

HP

2T Z

1000

HP

0 .4

0 . 00345 L

100

power required to

move the load

horizontally

T = material handled, tons/hr.

Z = increase in elevation of material, ft.

L is distance between conveyor centers, in f

Note: To allow for satisfactory loading of the bulk material, the elevator length

is usually increased by about 5 ft (1.5 m)

Example:

Choose a bucket elevator to handle 150 tons/h (136.1 tonnes/h)

of abrasive material weighing 50 lb/ft3 (800.5 kg/m3) through a

vertical distance of 75 ft (22.9 m) at a speed of 100 ft/min (30.5

m/min).

a. What horsepower input is required to drive the elevator?

b. The bucket elevator discharges onto a horizontal conveyor

which must transport the material 1400 ft (426.7 m).

i.

Determine the required power input needed to drive it.

ii.

Total hp input for the conveyor installation

The power input to a conveyor is composed of two portions:

(a)the power required to move the empty belt conveyor

(b) the power required to move the load horizontally.

10/22/2015

10/22/2015

Flight Conveyor

10/22/2015

Capacities of Flight Conveyors (at 80% Efficiency):

BDS b

6000

T= Capacity tons/hr

B= Width of flight, in.

D = Depth of flight, in.

S= Speed of Conveyor, fpm

b = Bulb density of material being

handled, lb/ft3

Screw

Conveyor

10/22/2015

SCREW CONVEYORS

Horsepower Requirements Of Screw Conveyors and

all Conveyors Operating with a Scraping Action.

Horsepower

Coefficien

t Capacity,

33,000

lb./min

Length,

ft

ft lbf

hp min

where: Coefficients = 4.0 (Ashes)

= 2.5 (Coal)

= 1.3 (grain)

Horsepower Required to Drive Flight Conveyors:

HP

a T

L b W L S 10

1000

where:

HP = Total horsepower of conveyor shaft

T = Material handled, tons/hr

L = Length of conveyor from center to center of sprocket, ft.

W = Total weight of chain and flights per foot of distance

between centers (both runs), lb. Usually equal to T max.

S = Speed, fpm

a = Constant for material

b = Constant for Conveyor

10/22/2015

Belt conveyors

Power Requirement for Belt Conveyors:

For empty belt conveyor (minimum value)

HP 1

0 . 03 WS

990

For material (not considering belt) conveyed horizontally.

HP 2

F L Lo

F ( L Lo ) T

For lifting material:

HP 3

990

TZ

990

10

10/22/2015

Total horsepower required:

F L L o T 0 . 03 WS

TZ

990

HP = horsepower required

F = friction factor, 0.05 for plain bearings; 0.03 for anti friction

bearing depending

upon the installation maintenance

L = length of conveyor between terminal pulleys, ft.

Lo = 100 for plain bearing; 150 for anti friction bearing

S = speed of belt, fpm.

T = material handled, tons/hr.

Z = increase in elevation of material, ft.

W = mass of moving parts, including belt and idlers per foot of

distance between

center of terminal pulleys (both/runs), lb.

Approximate Weights of Conveyors

Flight Conveyors:

4 x 10 to 6 x 18

use W = 0.5 lb/in of width per running foot

8 x 18 to 10 x 24

use W = 1.0 lb/in of width per running

foot

Belt Conveyors:

use W = 1.0 lb/in of width per running

foot

11

10/22/2015

Example:

A

belt conveyor is required to deliver crushed

limestone having a bulk density of 75 lb/cu ft

at the rate of 200 tons/hr. The conveyor is to

be 200 ft between centers of pulleys with a

rise of 25ft. The largest lumps are 4 in an and

constitute 15% of the total. The conveyor will

discharge over the end. For a belt speed of

200 fpm, what is the minimum width of belt

that can be used? Calculate the horsepower

for the drive motor. (F = 0.03 , Lo=150)

Example

What is the capacity of a fight conveyor of 12 by

24 in traveling at 100 fpm and handling the

crushed limestone. These materials are to be

moved horizontally a distance of 100 ft. Weight of

light conveyor is 1.0 lb/in of width per running foot

. 10 x 24 in flight conveyor calculate the h.p

required.

Constant for material = 0.6 " conveyor = 0.04 bulk

density of wheat = 75 lb /ft3

12

10/22/2015

Example:

A screw conveyors is to be installed to convey

800 bushels is of wheat per hour over a distance

of 80 ft.Determine the horsepower requirements

for the installation ( 1 bushel = 8 gallons, bulk

density of wheat = 48 lb/ft3 )

13

Вам также может понравиться

- Dense Medium SeparationДокумент37 страницDense Medium SeparationFelipe Goes Ribeiro BrideОценок пока нет

- Factoring PolynomialsДокумент2 страницыFactoring PolynomialsSandra Enn BahintingОценок пока нет

- Mechanical Operations Lab MCQДокумент21 страницаMechanical Operations Lab MCQRoyalОценок пока нет

- Design and Analysis of Screw Conveyor at Inlet of Ash/Dust ConditionerДокумент6 страницDesign and Analysis of Screw Conveyor at Inlet of Ash/Dust ConditionerMohd HafizzОценок пока нет

- Cyclone SeparatorДокумент1 страницаCyclone SeparatordadОценок пока нет

- Particle S: Size ReductionДокумент16 страницParticle S: Size Reductionnhalieza1067Оценок пока нет

- Chap TestДокумент114 страницChap TestLori Napolitano0% (1)

- Size Reduction: Department of Chemical Engineering University of Engineering & Technology PeshawarДокумент60 страницSize Reduction: Department of Chemical Engineering University of Engineering & Technology PeshawarRavid GhaniОценок пока нет

- Writing A Thesis ProposalДокумент4 страницыWriting A Thesis ProposalSandra Enn BahintingОценок пока нет

- Broadband TransformersДокумент6 страницBroadband Transformersflegias100% (1)

- 1.4 Material and Energy BalanceДокумент51 страница1.4 Material and Energy Balancesmith100% (1)

- The Role of Ore Properties in Thickening ProcessДокумент12 страницThe Role of Ore Properties in Thickening ProcessJeromeОценок пока нет

- High Angle Conveyor Offers Mine Haulage SavingsДокумент20 страницHigh Angle Conveyor Offers Mine Haulage SavingsZiggy Gregory100% (1)

- 28Документ24 страницы28Rogelio Arellano LawayanОценок пока нет

- Week # 10 MR Chapter 8: - Tutorial #10Документ31 страницаWeek # 10 MR Chapter 8: - Tutorial #10Farras HanifОценок пока нет

- Mass BalanceДокумент16 страницMass BalanceDewi Juliyanti Silaen0% (2)

- Unique Conveyor Problems and SolutionsДокумент20 страницUnique Conveyor Problems and SolutionsPaul MaposaОценок пока нет

- ME 267: Advanced Thermodynamics I: Thermodynamic RelationsДокумент73 страницыME 267: Advanced Thermodynamics I: Thermodynamic Relationsluzviminda ramosОценок пока нет

- Mechanical Operations 1Документ6 страницMechanical Operations 1Aegis0413Оценок пока нет

- CIP CalculationДокумент2 страницыCIP Calculationdmars123100% (1)

- CHEE 220 Lecture Settling & Sedimentation 2021Документ39 страницCHEE 220 Lecture Settling & Sedimentation 2021BASEKI JANIОценок пока нет

- Goldstein Solution Ch-7Документ10 страницGoldstein Solution Ch-7shaukatkhattak67% (3)

- Cyclone DesignДокумент10 страницCyclone DesignOmar EzzatОценок пока нет

- Alternating Current FundamentalsДокумент49 страницAlternating Current Fundamentalsvontedj100% (2)

- High VM Coal With 3% SulphurДокумент1 страницаHigh VM Coal With 3% SulphurIrshad HussainОценок пока нет

- Materials HandlingДокумент27 страницMaterials HandlingPatricia de LeonОценок пока нет

- Size Reduction PDFДокумент53 страницыSize Reduction PDFJayant Swami40% (5)

- PartechДокумент21 страницаPartechwendel raguindinОценок пока нет

- DewateringДокумент18 страницDewateringAspectОценок пока нет

- Chemical Process IndustriesДокумент29 страницChemical Process IndustriesSandra Enn BahintingОценок пока нет

- Dryer DesignДокумент9 страницDryer DesignGohar AbbasОценок пока нет

- DSP-1 (Intro) (S)Документ77 страницDSP-1 (Intro) (S)karthik0433Оценок пока нет

- Plant Eng Part 2 - ConveyorsДокумент30 страницPlant Eng Part 2 - ConveyorsLehlohonoloОценок пока нет

- Communition Theory Reference and FormulasДокумент10 страницCommunition Theory Reference and Formulasharishkumar.ravichandranОценок пока нет

- The Mining Grinding Office: Other Power FormulasДокумент2 страницыThe Mining Grinding Office: Other Power Formulassempatik721Оценок пока нет

- Bag FiltersДокумент4 страницыBag FiltersDoaa Badarneh100% (1)

- EPW Baghouse 1 Ae6Документ57 страницEPW Baghouse 1 Ae6Alejandra Palma SolanoОценок пока нет

- Drying - 5 - 29 Oct 2020 PDFДокумент25 страницDrying - 5 - 29 Oct 2020 PDFshubhamОценок пока нет

- Convective Mass TransferДокумент46 страницConvective Mass TransferSandra Enn BahintingОценок пока нет

- (Cyclone Separator) PDFДокумент11 страниц(Cyclone Separator) PDFهاجر صالح جبارОценок пока нет

- FluidisationДокумент14 страницFluidisationJuno LowОценок пока нет

- Lecture 3: Design Consideration of DriersДокумент6 страницLecture 3: Design Consideration of DriersachalОценок пока нет

- Angle of Nip PDFДокумент11 страницAngle of Nip PDFanasabdullah100% (1)

- Latest Low NOx Combustion TechnologyДокумент7 страницLatest Low NOx Combustion Technology95113309Оценок пока нет

- Lecture 3 Process Engineering of Size ReductionДокумент31 страницаLecture 3 Process Engineering of Size ReductionKARABO EMMANUEL NCUBEОценок пока нет

- Ball Mill SizingДокумент10 страницBall Mill Sizingvvananth100% (1)

- Exp - S6 - CrushersДокумент14 страницExp - S6 - CrushersAnuj SrivastavaОценок пока нет

- Gravity Conveyor With Air FluidizeДокумент3 страницыGravity Conveyor With Air Fluidizechem_taОценок пока нет

- Slides PPT - Chapter 5 - Pneumatic TransportДокумент33 страницыSlides PPT - Chapter 5 - Pneumatic TransportSaranya Devi100% (1)

- Material BalanceДокумент33 страницыMaterial BalanceJaynie Lee Villaran100% (1)

- CycloneДокумент25 страницCycloneAna Marie AllamОценок пока нет

- Eceboardlouie: Front BackДокумент7 страницEceboardlouie: Front BackJoaquin GonzalezОценок пока нет

- Fluid Flow Thru A Bed of Particles: Che 317E Particle TechnologyДокумент19 страницFluid Flow Thru A Bed of Particles: Che 317E Particle TechnologyJulie Anne Cristales100% (1)

- Chemical Engineering: Assistant Professor inДокумент12 страницChemical Engineering: Assistant Professor inChemical EngineerОценок пока нет

- Power Drawn by Grinding MediaДокумент5 страницPower Drawn by Grinding MediaanruloОценок пока нет

- FluidizationДокумент32 страницыFluidizationDylan Navarro LОценок пока нет

- Centrifugal Separation and SievingДокумент5 страницCentrifugal Separation and SievingVincent NguyenОценок пока нет

- Un1 MergedДокумент467 страницUn1 MergedHariHaran KОценок пока нет

- Storage PDFДокумент12 страницStorage PDFanasabdullahОценок пока нет

- Ball MillДокумент3 страницыBall MillHeeshanGunathilakaОценок пока нет

- A Simulation Model For An Air-Swept Ball Mill Grinding CoalДокумент12 страницA Simulation Model For An Air-Swept Ball Mill Grinding CoalAnonymous NxpnI6jCОценок пока нет

- Lab Manual For Trommel CitДокумент2 страницыLab Manual For Trommel CitRyle ArbonОценок пока нет

- Ball Mill Design - CompressДокумент6 страницBall Mill Design - CompressSuresh VedalaОценок пока нет

- Kinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583Документ19 страницKinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583nicolasОценок пока нет

- Fluid Coupling in Belt Conveyor DrivesДокумент12 страницFluid Coupling in Belt Conveyor Drivesnoelaroboi100% (2)

- PT - 241properties and Characteristics of ParticlesДокумент49 страницPT - 241properties and Characteristics of ParticlesAli HasSsan100% (1)

- MO UNIT - I PPT NotesДокумент81 страницаMO UNIT - I PPT NotesKrishnan DhanasekaranОценок пока нет

- Diameter of Roll CrusherДокумент1 страницаDiameter of Roll Crusherharishkumar.ravichandran0% (1)

- L/R MG/ (MV'/R) (V mn/30 Or, V 2zm/60)Документ5 страницL/R MG/ (MV'/R) (V mn/30 Or, V 2zm/60)Md Jakir HossainОценок пока нет

- Lecture 4 - QuadrilateralsДокумент29 страницLecture 4 - QuadrilateralsSandra Enn BahintingОценок пока нет

- Lectures 7 - Solids (V BH)Документ48 страницLectures 7 - Solids (V BH)Sandra Enn BahintingОценок пока нет

- Solids (V 1) 3bh) ConeДокумент13 страницSolids (V 1) 3bh) ConeSandra Enn Bahinting0% (1)

- Centrifugal Separation Processess: Prepared by Engr. Sandra Enn BahintingДокумент31 страницаCentrifugal Separation Processess: Prepared by Engr. Sandra Enn BahintingSandra Enn BahintingОценок пока нет

- Chemical Hazard: Industrial Process SafetyДокумент11 страницChemical Hazard: Industrial Process SafetySandra Enn BahintingОценок пока нет

- Shell Momentum BalanceДокумент13 страницShell Momentum BalanceSandra Enn BahintingОценок пока нет

- Homework 1Документ5 страницHomework 1Sandra Enn BahintingОценок пока нет

- The Set of Real Numbers and Its PropertiesДокумент29 страницThe Set of Real Numbers and Its PropertiesSandra Enn BahintingОценок пока нет

- Vsepr: Chemical Bonding II: Molecular GeometryДокумент16 страницVsepr: Chemical Bonding II: Molecular GeometrySandra Enn BahintingОценок пока нет

- SET IdentitiesДокумент21 страницаSET IdentitiesSandra Enn BahintingОценок пока нет

- Equation Solution and Solution SetsДокумент17 страницEquation Solution and Solution SetsSandra Enn BahintingОценок пока нет

- Mindanao State University-Iligan Institute of Technology Department of Chemical Engineering College of EngineeringДокумент7 страницMindanao State University-Iligan Institute of Technology Department of Chemical Engineering College of EngineeringSandra Enn BahintingОценок пока нет

- Transient Response of Simple Control SystemsДокумент8 страницTransient Response of Simple Control SystemsSandra Enn BahintingОценок пока нет

- Lab ReportДокумент16 страницLab ReportSandra Enn Bahinting100% (1)

- PhysicsBowl 2013Документ11 страницPhysicsBowl 2013Ajay NegiОценок пока нет

- Effects of Moisture Content On The Foundry Properties of Yola Natural SandДокумент12 страницEffects of Moisture Content On The Foundry Properties of Yola Natural SandatikОценок пока нет

- Wire Calculations in Helical Undergoing: Stress Strands BendingДокумент8 страницWire Calculations in Helical Undergoing: Stress Strands BendingHoàng LongОценок пока нет

- Peperiksaan Percubaan SPM 2004Документ29 страницPeperiksaan Percubaan SPM 2004Carolyn Chang Boon ChuiОценок пока нет

- CLS Aipmt 17 18 XI Phy Study Package 1 SET 2 Chapter 4Документ42 страницыCLS Aipmt 17 18 XI Phy Study Package 1 SET 2 Chapter 4Monisha50% (2)

- PHYSICSДокумент24 страницыPHYSICS21SO204 AnvithaОценок пока нет

- Lawrence M. Hull - Mach Reflection of Spherical Detonation WavesДокумент10 страницLawrence M. Hull - Mach Reflection of Spherical Detonation WavesGhoree23456100% (1)

- Operations On Matrices - Linear AlgebraДокумент35 страницOperations On Matrices - Linear AlgebradocsdownforfreeОценок пока нет

- Cebu Institute of Technology University: ECE 162 W1Документ8 страницCebu Institute of Technology University: ECE 162 W1meshin yuОценок пока нет

- HPSC AP Physics 2016Документ27 страницHPSC AP Physics 2016SAHIN InspireОценок пока нет

- Answer Key Chapter 7Документ4 страницыAnswer Key Chapter 7linОценок пока нет

- Chemistry 12 PDFДокумент83 страницыChemistry 12 PDFAnonymous 8V2iHxBОценок пока нет

- 3.optical DetectorsДокумент36 страниц3.optical DetectorsSourav SasidharanОценок пока нет

- Physics Assignment 3 PDFДокумент24 страницыPhysics Assignment 3 PDFVISMAYA K100% (1)

- Hydraulic Calculations Safe RainДокумент21 страницаHydraulic Calculations Safe RaingonleoОценок пока нет

- Study of Zero Chromatic Dispersion in PCF Using Different MaterialДокумент3 страницыStudy of Zero Chromatic Dispersion in PCF Using Different MaterialerpublicationОценок пока нет

- Buckling Lengths of Columns Rigorous ApproachДокумент8 страницBuckling Lengths of Columns Rigorous ApproachBobaru MariusОценок пока нет

- 2017 Chen3009 Chapter 1 Compressible Flow-StudentДокумент38 страниц2017 Chen3009 Chapter 1 Compressible Flow-StudentApple EmiratessОценок пока нет

- Static Force AnalysisДокумент19 страницStatic Force Analysiskreddy260100% (1)

- Electromagnetic Levitation System: Mathematical ModelДокумент9 страницElectromagnetic Levitation System: Mathematical ModelMervin RodrigoОценок пока нет

- Ch5-Coherence and Fringe Localization-Part AДокумент38 страницCh5-Coherence and Fringe Localization-Part ACristopher RolandoОценок пока нет

- Chapter 1 Introduction To Engineering EconomyДокумент8 страницChapter 1 Introduction To Engineering EconomyJason AdiaОценок пока нет

- Unit 4Документ76 страницUnit 4Hemant TulsaniОценок пока нет

- S o M - Definitions CompleteДокумент25 страницS o M - Definitions CompleteHema SubramanianОценок пока нет