Академический Документы

Профессиональный Документы

Культура Документы

Moisture in Oil

Загружено:

JAY PARIKH0 оценок0% нашли этот документ полезным (0 голосов)

88 просмотров2 страницыmoisture in oil

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документmoisture in oil

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

88 просмотров2 страницыMoisture in Oil

Загружено:

JAY PARIKHmoisture in oil

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

project opportunity

Moisture Assessment, Ranking, and Optimal Dry-Out of

Power Transformers

The moisture condition of power

transformers is a critical parameter for safe

and reliable operation. Proper assessment

of moisture in paper is essential for an

effective life extension program

A classification chart for ranking power transformers by

moisture content

BACKGROUND Power transformers are critical, capitalintensive assets for the utility industry. Although

transformers are extremely reliable, many in use today

have exceeded their design life. Critical to the strategy

of extending the useful life of power transformers is an

effective method of assessing the condition of power

transformers, including the degree of moisture in

transformer insulation.

While it is generally accepted that water is bad for power

transformers, the specific effects of moisture are complex

and not widely understood. In addition to the long-term

damage associated with accelerated paper aging, the

evolution of vapor bubbles or free water from paper

insulation can cause short-term failure. Increasingly

stringent dryness criteria have evolved over the years with

improved factory and field dry-out processes, particularly

for transformers with high voltage and capacity ratings.

The present method of determining the dryness of

transformer insulation is to measure the moisture content

of an oil sample and use the well-established moisture

equilibrium characteristics between oil and paper insulation.

However, the dynamics of moisture movement between the

paper and the oil during temperature cycling is significant

and, unless taken into consideration, can cause significant

errors in moisture assessment. In addition, the actual

determination of the moisture content of the oil is fraught

with uncertainties. Although the Karl Fischer method is the

de facto standard for measuring the water content of oil,

human error and a number of uncertainties associated with

the oil sampling procedure reduce the reliability of

measurements and could lead to incorrect conclusions.

Transmission Substations

Transformer insulation systems comprise several different

grades and thickness of cellulose insulation. The type,

grade, and physical condition of oils vary considerably

from one unit to another. Even without these complications,

moisture migration between cellulose and oil is a complex,

temperature-dependent process: time constants for the

exchange of moisture between cellulose and oil are different

in each direction; moisture in the cellulose is not evenly

distributed; and not all of the moisture in the cellulose is

available for transfer to the oil. In addition, dissolved

moisture in oil can form precipitate during rapid cool-down

periods and become free water, which may not re-dissolve.

Therefore, any method of moisture determination based on

a single measurement without regard to these confounding

factors may provide a false indication of the insulations

integrity, especially for transformers with cyclical

load profiles.

EPRI projects have resulted in extended knowledge and

expertise on moisture dynamics in power transformers and

culminated in the design of a software package, called the

Transformer Moisture Monitor (TMM), incorporating

moisture-in-paper algorithms. Based on EPRI technology,

TMM uses fuzzy-logic computing to evaluate the relative

saturation of transformer oil from the output of a moisture

sensor, and to assess the water content in paper (WCP).

TMM alerts the operator when the insulation condition

requires attention and provides a confidence level for

the WCP.

PROJECT SUMMARY This project will disseminate critical

knowledge gained during EPRI efforts and apply this

knowledge at utility sites. Depending on the chosen level of

participation, EPRI will perform any or all of the following

activities for funding companies:

Conduct on-site seminars on the most effective

moisture assessment and ranking techniques.

August 2003

Provide hands-on training on efficient methods of

assessing the moisture condition of a population of

transformers, supervise participant testing of selected

transformers, and help participants rank them in terms

of moisture content.

Apply an on-line monitoring system (including the beta

version of TMM) to selected transformers.

Dry out one or more transformers while monitoring

their moisture condition.

DELIVERABLES A range of deliverables is available

for this project. Participating companies may choose the

combination of the following deliverables that best meet

their needs:

On-site seminar. EPRI will hold a seminar at the

participants site designed to familiarize them with

correct procedures and common pitfalls in moisture

assessment, resulting in guidelines for on-line moisture

monitoring. Topics will include sources of water

contamination; methods and instrumentation for

moisture assessment; effects of moisture on transformer

insulation and loading; distribution of moisture in

transformers; selection of moisture sensors and

transducers; and existing methods for transformer dryout. The seminar will also discuss determination of the

most suitable location(s) for moisture sensors, the

accuracy of moisture sensor performance, and the

factors affecting the quality of diagnoses, such as

moisture-in-oil solubility, temperature variation,

oil viscosity, and flow rate. In addition, the seminar

will cover an improved procedure for sampling oil

from operating transformers and evaluating the oil

samples moisture content by means of the Karl

Fischer apparatus.

Customized transformer moisture assessment

and ranking program. EPRI will provide

detailed procedures for accurate oil sample testing,

classification, and ranking of a specified transformer

population, and will supervise on-site testing.

Installation of online monitoring software. EPRI

will customize and install moisture sensors, a data

acquisition system, and TMM online monitoring

software, for a specified transformer population,

and train personnel in analyzing the softwares results.

Transformer dry-out. Using the method preferred by

the participant, EPRI will demonstrate optimal dry-out

procedures on a specified transformer while monitoring

the moisture content of the oil. The dry-out procedure

used will include measurement of the amount of water

removed from the transformer, enabling a comparison

with the assessment derived by the TMM software.

BENEFITS OF PARTICIPATION The extent of benefits

depends on the participants level of involvement.

Depending on their level of participation, participants

may be able to use their acquired knowledge to avoid

transformer failures, which can minimize labor and

equipment costs for repair and/or replacement, reduce

maintenance costs, and decrease the likelihood of

unscheduled outages. Implementing the techniques

described in this project may also extend the life of

participants power transformers. In addition, participants

may avoid additional consulting costs to learn new testing,

monitoring, and dry-out methods.

Participants that choose online monitoring or dry-out

will retain the monitoring hardware after completion of

the project, enabling continued monitoring. Verification

data obtained from the project will be used to improve

the diagnostic engine of the TMM software, enabling

its application to various types, sizes, and manufacturers

of transformers.

The price of the project for each

participant depends on which deliverables are chosen, as

well as other company-specific factors such as the size of

the population of transformers to be ranked, the number of

transformers to be dried, and the method and resources used

for dry-out. The expected range is $40,000 to 200,000

cofunding, or $20,000 to $100,000 tailored collaboration.

PRICE OF PROJECT

PROJECT STATUS AND SCHEDULE The project schedule

depends on the level of participation. Seminars, sampling,

testing, ranking, monitoring, and/or dry-outs can begin at

the convenience of the participating companies.

The project will benefit transformer

owner/operators with concerns regarding, or who have

experienced, failures related to moisture content in

transformers, and those considering transformer dry-out

in the near future.

WHO SHOULD JOIN

CONTACT INFORMATION For more information, contact

the EPRI Customer Assistance Center (EPRICAC) at

800.313.3774 or Barry H. Ward at 650.855.2717,

baward@epri.com

2003 Electric Power Research Institute (EPRI), Inc. All rights reserved.

Electric Power Research Institute and EPRI are registered service marks of

the Electric Power Research Institute, Inc. EPRI. ELECTRIFY THE WORLD

is a service mark of the Electric Power Research Institute, Inc.

Printed on recycled paper in the United States of America

1009099

EPRI 3412 Hillview Avenue, Palo Alto, California 94304 PO Box 10412, Palo Alto, California 94303 USA

800.313.3774 650.855.2121 askepri@epri.com www.epri.com

Вам также может понравиться

- Insulation Resistance Test and Oil Test of Distribution TransformerДокумент6 страницInsulation Resistance Test and Oil Test of Distribution TransformerBash MatОценок пока нет

- TRFR Test FormatДокумент8 страницTRFR Test FormatdilipelineОценок пока нет

- Oil Tan Delta and Resistivity Test - OTDДокумент5 страницOil Tan Delta and Resistivity Test - OTDAnand MandalОценок пока нет

- Power Transformers: Overview Factors On Assessing Insulation LifeДокумент8 страницPower Transformers: Overview Factors On Assessing Insulation LifeДенис ЛяпуновОценок пока нет

- Advanced Methods For Insulation Diagnostics On Power Transformers ENUДокумент7 страницAdvanced Methods For Insulation Diagnostics On Power Transformers ENUMichael Angelo VidalОценок пока нет

- POWERGRID Experience On Life Assessment of EHV Current TransformersДокумент7 страницPOWERGRID Experience On Life Assessment of EHV Current TransformersOm BhaskarОценок пока нет

- Tan-Delta TestДокумент2 страницыTan-Delta TestRakesh BabuОценок пока нет

- Turn To Turn Insulation FaultДокумент7 страницTurn To Turn Insulation Faultzarchiwin05Оценок пока нет

- Guest Editorial - Understanding Dissolved Gas Analysis (DGA) Techniques and InterpretationsДокумент10 страницGuest Editorial - Understanding Dissolved Gas Analysis (DGA) Techniques and InterpretationsAlpesh PatelОценок пока нет

- Operation & Maintenance of Capacitor Voltage TransformerДокумент9 страницOperation & Maintenance of Capacitor Voltage TransformerrpshvjuОценок пока нет

- Transformer Refurbishment Policy at Rte Conditioned by The Residual Lifetime AssessmentДокумент10 страницTransformer Refurbishment Policy at Rte Conditioned by The Residual Lifetime AssessmentPit SamprasОценок пока нет

- New Frontiers of DGA Interpretation For Power TFs and Their AccessoriesДокумент8 страницNew Frontiers of DGA Interpretation For Power TFs and Their Accessoriesdes1982Оценок пока нет

- On Line Processing of Xmer OilДокумент16 страницOn Line Processing of Xmer OilrajfabОценок пока нет

- Power Transformer Loss EvaluationДокумент3 страницыPower Transformer Loss Evaluationziebarthj100% (1)

- Transformer TestingДокумент4 страницыTransformer TestingNarendra DuvediОценок пока нет

- Monitor Lightning Arresters OnlineДокумент5 страницMonitor Lightning Arresters OnlineJoshi DhvanitОценок пока нет

- Approved - Type Test Validity Guidelines PDFДокумент12 страницApproved - Type Test Validity Guidelines PDFKiran VittalraoОценок пока нет

- Partial Discharge Diagnostic System PDFДокумент2 страницыPartial Discharge Diagnostic System PDFSellappan MuthusamyОценок пока нет

- Product: Complete Diagnostic SolutionsДокумент8 страницProduct: Complete Diagnostic SolutionsbhpОценок пока нет

- Field Experience with Sweep Frequency Response AnalysisДокумент8 страницField Experience with Sweep Frequency Response AnalysisThien Nguyen VanОценок пока нет

- Transformer BushingДокумент11 страницTransformer BushingNunna BaskarОценок пока нет

- Typical Limiting Values of SubStation Equipments.Документ10 страницTypical Limiting Values of SubStation Equipments.Jeya KannanОценок пока нет

- Application of Duval Triangles To DGA in LTCs (IEEE WG C57.139) 13mar12 PDFДокумент32 страницыApplication of Duval Triangles To DGA in LTCs (IEEE WG C57.139) 13mar12 PDFdes1982Оценок пока нет

- Transformer Testing SafetyДокумент8 страницTransformer Testing SafetyAvoor KhanОценок пока нет

- 1LAB000113 Test Book Intro Table Contents 2010Документ16 страниц1LAB000113 Test Book Intro Table Contents 2010jayaprasadviОценок пока нет

- Micom P341Документ425 страницMicom P341Vel MuruganОценок пока нет

- TRX Oil Test PropertiesДокумент48 страницTRX Oil Test PropertiesbibhooОценок пока нет

- Test ProcedureДокумент21 страницаTest Procedurerehansadiq1100% (1)

- Transformer OilДокумент48 страницTransformer OilusefiОценок пока нет

- DGA Oil SamplingДокумент6 страницDGA Oil Samplinghino_kaguОценок пока нет

- DGA of CT OilДокумент13 страницDGA of CT Oilraza239Оценок пока нет

- Insulation Resistance of Power TransformerДокумент16 страницInsulation Resistance of Power TransformerMELVIN100% (3)

- Testing NotesДокумент12 страницTesting NotesJigar TakoliaОценок пока нет

- Power Quality TechniquesДокумент9 страницPower Quality TechniquesS Bharadwaj ReddyОценок пока нет

- Svsprasad Engineer (Design), Switchgear Products Division, Vijai Electricals LimitedДокумент52 страницыSvsprasad Engineer (Design), Switchgear Products Division, Vijai Electricals Limitedkrmrps0% (1)

- Circuit Breaker Ppt2018Документ16 страницCircuit Breaker Ppt2018Subhajit JoydharОценок пока нет

- 8.5mva FINIAL Test ReportДокумент5 страниц8.5mva FINIAL Test ReportRyan JohnОценок пока нет

- HV Testing of TransformerДокумент20 страницHV Testing of TransformerVivek AmbavtaОценок пока нет

- Cable Testing Report By: Neetrac: Presented By: Tapas Ankit KumarДокумент21 страницаCable Testing Report By: Neetrac: Presented By: Tapas Ankit KumartapasОценок пока нет

- Temperature Correction Factors - Power Grid IndiaДокумент6 страницTemperature Correction Factors - Power Grid IndiaAMIT BISWASОценок пока нет

- Dga IsДокумент38 страницDga IsHitesh PantОценок пока нет

- AirRIP® Flex Transformer BushingДокумент29 страницAirRIP® Flex Transformer BushingSandeep BОценок пока нет

- Wall Bushings: STB Series: 40.5 252 KV Combined Wall Bushings With Current Transformer: STB-L Series: 40.5 252kVДокумент4 страницыWall Bushings: STB Series: 40.5 252 KV Combined Wall Bushings With Current Transformer: STB-L Series: 40.5 252kVRamesh PatelОценок пока нет

- Doble Lemke Power Transformer Advanced PD Monitoring UHF 2009Документ21 страницаDoble Lemke Power Transformer Advanced PD Monitoring UHF 2009taufiqishak09Оценок пока нет

- Four Types of High Voltage Current TransformersДокумент3 страницыFour Types of High Voltage Current TransformersSudhakar KethireddyОценок пока нет

- Atlanta Transformer ComponentsДокумент74 страницыAtlanta Transformer Componentsalex696Оценок пока нет

- 13 Ed Gulski PraesentationДокумент45 страниц13 Ed Gulski Praesentationcarlos vidalОценок пока нет

- BHEL Vocational Training Report on TransformersДокумент31 страницаBHEL Vocational Training Report on Transformersrahat100% (1)

- Understanding Offline Testing and Condition Monitoring Results From BushingДокумент51 страницаUnderstanding Offline Testing and Condition Monitoring Results From Bushingcarlos patrick100% (1)

- KT NTPC Power TransformersДокумент63 страницыKT NTPC Power TransformersKaran Tripathi100% (1)

- Distribution Transformer Maintenance and ProtectionДокумент77 страницDistribution Transformer Maintenance and ProtectionAbin PaulОценок пока нет

- Transformer Earth FaultДокумент5 страницTransformer Earth FaultvyroreiОценок пока нет

- SFRA Methods for Transformer Testing & Fault DetectionДокумент9 страницSFRA Methods for Transformer Testing & Fault Detectionafzal47Оценок пока нет

- Power Cables Testing Fault Location - KSAДокумент4 страницыPower Cables Testing Fault Location - KSAcarlos vidal100% (1)

- PDCheck User Manual - Rev08Документ59 страницPDCheck User Manual - Rev08anurag_jay12464100% (1)

- Production Well Testing With Non-Radiactive PDFДокумент4 страницыProduction Well Testing With Non-Radiactive PDFHéctor Ramiro Pérez RodríguezОценок пока нет

- Condition monitoring maximizes vessel availabilityДокумент5 страницCondition monitoring maximizes vessel availabilityRachel Renti CruzОценок пока нет

- SC CalculationsДокумент112 страницSC CalculationsJAY PARIKHОценок пока нет

- GRE Word ThesaurusДокумент137 страницGRE Word ThesaurusPhanidhar GubbalaОценок пока нет

- Company Logo: Cable Size CalculationДокумент7 страницCompany Logo: Cable Size Calculationahmadgce04Оценок пока нет

- Hindalco Routine Test Report Page No. 4 & 5Документ2 страницыHindalco Routine Test Report Page No. 4 & 5JAY PARIKHОценок пока нет

- Irr - Pa & Id Fan - Boiler 1Документ14 страницIrr - Pa & Id Fan - Boiler 1Jay Rameshbhai ParikhОценок пока нет

- CEA Battery ManagementДокумент112 страницCEA Battery ManagementJAY PARIKHОценок пока нет

- GRE Word ThesaurusДокумент137 страницGRE Word ThesaurusPhanidhar GubbalaОценок пока нет

- CT Testing at ERDA & HALOLДокумент3 страницыCT Testing at ERDA & HALOLJAY PARIKHОценок пока нет

- Best PracticesДокумент28 страницBest PracticesJAY PARIKHОценок пока нет

- CableInstallation PDFДокумент8 страницCableInstallation PDFJAY PARIKHОценок пока нет

- Keeping SafeДокумент3 страницыKeeping SafeJay Rameshbhai ParikhОценок пока нет

- 3AH1 Operating InstrДокумент29 страниц3AH1 Operating InstrJAY PARIKHОценок пока нет

- CableДокумент2 страницыCableJAY PARIKHОценок пока нет

- CT Testing at ERDA & HALOLДокумент3 страницыCT Testing at ERDA & HALOLJAY PARIKHОценок пока нет

- 3AH3 Circuit Breaker DetailsДокумент28 страниц3AH3 Circuit Breaker Details2003vinayОценок пока нет

- 3AH Catalog PDFДокумент75 страниц3AH Catalog PDFalsilva2014100% (1)

- Boiler DraftДокумент22 страницыBoiler DraftJAY PARIKHОценок пока нет

- Air CompressorsДокумент10 страницAir CompressorsJAY PARIKHОценок пока нет

- Voltage Regulator DECS-100 ManuelДокумент81 страницаVoltage Regulator DECS-100 Manuelctsak100% (1)

- SynchroniserДокумент21 страницаSynchroniserJAY PARIKHОценок пока нет

- Boiler TechnologiesДокумент5 страницBoiler TechnologiesSubhabrata SahaОценок пока нет

- SynchroniserДокумент21 страницаSynchroniserJAY PARIKHОценок пока нет

- WoodwardДокумент4 страницыWoodwardKUNALJAYОценок пока нет

- 011-23340000 / 23344787 / 23344773 / 23345500 / 23345800 or Mail To: Care@irctc - Co.inДокумент1 страница011-23340000 / 23344787 / 23344773 / 23345500 / 23345800 or Mail To: Care@irctc - Co.inJAY PARIKHОценок пока нет

- MX3EG1A Automatic Synchronizer Technical ManualДокумент38 страницMX3EG1A Automatic Synchronizer Technical Manualsgshekar30Оценок пока нет

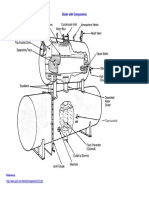

- 0507BoilerwithComponents PDFДокумент1 страница0507BoilerwithComponents PDFJAY PARIKHОценок пока нет

- Boiler Water TreatmentДокумент7 страницBoiler Water TreatmentJAY PARIKH100% (1)

- Statement Showing Cost & Profitability of Power Generated - Cogeneration PlantДокумент19 страницStatement Showing Cost & Profitability of Power Generated - Cogeneration PlantJAY PARIKHОценок пока нет

- Procedure For Calculation of Efficiency-1Документ7 страницProcedure For Calculation of Efficiency-1JAY PARIKHОценок пока нет

- Improve Primary Air Heater EfficiencyДокумент4 страницыImprove Primary Air Heater EfficiencyJAY PARIKHОценок пока нет

- ZXDD01 P1500 Installation GuideДокумент9 страницZXDD01 P1500 Installation GuideJose Samuel Alva Ancón100% (1)

- Newtec NOP1760 MDM6000 High Speed SystemДокумент4 страницыNewtec NOP1760 MDM6000 High Speed SystemmiltonzxОценок пока нет

- KEIL For StellarisДокумент18 страницKEIL For StellarisdAnieLОценок пока нет

- BG1 2006Документ76 страницBG1 2006Abraham JyothimonОценок пока нет

- FPSO Installation Procedures Verified with Marine SimulationsДокумент1 страницаFPSO Installation Procedures Verified with Marine SimulationsRavikumar mahadevОценок пока нет

- Gesture Controlled Animatronic Robotic HandДокумент12 страницGesture Controlled Animatronic Robotic HandRahul GowthamОценок пока нет

- 2021 & Beyond: Prevention Through DesignДокумент9 страниц2021 & Beyond: Prevention Through DesignAgung Ariefat LubisОценок пока нет

- SQL Server 2019 Editions DatasheetДокумент3 страницыSQL Server 2019 Editions DatasheetKeluarga ZulfanОценок пока нет

- Niq Logistics PropozalsДокумент20 страницNiq Logistics PropozalsPelumi Gabriel obafayeОценок пока нет

- Malaysia Rail Industry - A SnapshotДокумент25 страницMalaysia Rail Industry - A SnapshotRushdi Rahim100% (3)

- Smart Watch ManualДокумент9 страницSmart Watch ManualMURALEE VEERAMALAIОценок пока нет

- Design and Construction Standards For Kiosk Type SubstationsДокумент37 страницDesign and Construction Standards For Kiosk Type SubstationsFlo MircaОценок пока нет

- HB2300 ProGrafNT PG - Konfig enДокумент78 страницHB2300 ProGrafNT PG - Konfig enBojan MilovanovicОценок пока нет

- Avh 3850 DVDДокумент27 страницAvh 3850 DVDEnrique DNОценок пока нет

- DKT Phone User ManualДокумент141 страницаDKT Phone User Manualdanniel_sОценок пока нет

- Critical Success Factors For Data Lake Architecture: Checklist ReportДокумент17 страницCritical Success Factors For Data Lake Architecture: Checklist ReportNomanОценок пока нет

- Autonomous Vehicles RRLДокумент8 страницAutonomous Vehicles RRLDominique LopenaОценок пока нет

- MP 4000 RMM+ Remote MonitoringДокумент2 страницыMP 4000 RMM+ Remote Monitoringammonwar1stОценок пока нет

- CT DatasheetДокумент5 страницCT DatasheetGold JoshuaОценок пока нет

- Avid Codecs 2.3.7 Download: Codec PackagesДокумент5 страницAvid Codecs 2.3.7 Download: Codec PackagesjairmrfОценок пока нет

- Why Bridges CollapseДокумент4 страницыWhy Bridges CollapseNataliaОценок пока нет

- DR-ID330CL - Operation Manual - 897N202069 - Z72N100628 - RefДокумент84 страницыDR-ID330CL - Operation Manual - 897N202069 - Z72N100628 - RefFernando ValleОценок пока нет

- Wseries PDFДокумент4 страницыWseries PDFsongreОценок пока нет

- Ree AssignmentДокумент6 страницRee AssignmentAbhishek YadavОценок пока нет

- Syg5283thb 380c-8 Camion ConcretoДокумент378 страницSyg5283thb 380c-8 Camion ConcretoAlex MazaОценок пока нет

- LTK 70 01 001Документ2 страницыLTK 70 01 001Qiang ZhangОценок пока нет

- Online Bike ShowroomДокумент11 страницOnline Bike ShowroomsandipОценок пока нет

- VRPP Technical ManualДокумент16 страницVRPP Technical ManualJegadeshwaran RОценок пока нет

- eWON Cosy - Industrial Remote Access RouterДокумент3 страницыeWON Cosy - Industrial Remote Access RouterGerald OlivierОценок пока нет