Академический Документы

Профессиональный Документы

Культура Документы

Civil - Ijcseierd-Feasibility Study of Grey Water For Mixing Cement and Mortar-Rajesh T. Peche

Загружено:

TJPRC PublicationsОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Civil - Ijcseierd-Feasibility Study of Grey Water For Mixing Cement and Mortar-Rajesh T. Peche

Загружено:

TJPRC PublicationsАвторское право:

Доступные форматы

International Journal of Civil, Structural,

Environmental and Infrastructure Engineering

Research and Development (IJCSEIERD)

ISSN(P): 2249-6866; ISSN(E): 2249-7978

Vol. 5, Issue 5, Oct 2015, 89-98

TJPRC Pvt. Ltd.

FEASIBILITY STUDY OF GREY WATER FOR MIXING CEMENT AND MORTAR

RAJESH T. PECHE1, SANJAY S. JAMKAR2 & PARAG A. SADGIR3

1

Research Scholar, Department of Applied Mechanics, Government College of Engineering, Aurangabad,

Maharashtra, India

Associate Professor, Department of Applied Mechanics, Government College of Engineering, Aurangabad,

Maharashtra, India

3

Associate Professor, Department of Civil Engineering, Government College of Engineering, Aurangabad,

Maharashtra, India

ABSTRACT

In India fresh and potable water is becoming scarce. Water is an integral part of all kinds of development.

Construction industry is among the most water demanding industries. In order to cope up with the water demand of

construction industry, the feasibility of grey water for mixing cement and mortar is assessed in this paper. In this study, two

different equalized grey water samples were taken for bio-chemical analysis. Their qualities were compared with the

quality requirements intended for mixing water. Both the grey water samples and Tap Water (TW) supplied by the

municipal corporation were used for mixing cement and mortar. Standard consistency, initial and final setting times,

soundness and compressive strengths of cement were determined by using both TW and GW for mixing. Results were used

for comparison purpose. In the end, the elemental reports are derived which justifies the usage of grey water as mixing

cement and mortar.

KEYWORDS: Cement, Grey Water, Mixing Water, Mortar, Tap Water

INTRODUCTION

Water is one of the most important elements in human life and construction. According to official statement of

Government of India Ministry of Water Resources (2012), India has more than 17 % of the worlds population, but has

only 4% of worlds renewable water resources. In India utilizable water availability is already under strain and there is

possibility of expanding of water conflicts. As per all codes of concrete, the water used for mixing and curing should

possibly be the potable water. Constructional activities play a major role in infrastructural development. Water has

undisputed important place in civil construction and so far no alternative to water is available. It is seen that the use of

potable water is further causing scarcity of water and that too in highly urbanized and populated areas, as these areas have

the potential and need to expand. Almost all codes of concrete and mixing water indicate that constructional activities not

essentially need fresh or potable water.

In this alarming situation, many Governments like Govt. of Queensland, institutions like WHO and NEERI and

researchers has been focusing on the potential to use all types of wastewater. Duff A. Abrams (1924) studied and tested

almost 68 different non-potable water samples including sea, alkali, mine, mineral and bog waters and highly polluted

sewerage and industrial wastes on mortar and concrete specimens. Harold H. Steinour (1960) also tested various water

samples for their suitability for mixing concrete. Joo-Hwa Tay et al.(1987) studied the use of reclaimed wastewater in

www.tjprc.org

editor@tjprc.org

90

Rajesh T. Peche, Sanjay S. Jamkar & Parag A. Sadgir

concrete. Franco Sandrolini (2000) investigated the effects of ready-mix concrete sludge water on concrete. Ooi Soon Lee

et al. 2001, examined the effects of treated effluent on concrete. B. Chatveera et al. (2006), Marcia Silva et al (2010)

studied the recycled sewage treatment plant water for the use in concrete. Mohd. Shekarchi et al. (2012) investigated

effects of biologically treated domestic waste water in concrete. Almost all results of parametric study suggest the

feasibility of using treated domestic waste water as mixing and/or curing water.

Construction industry is one of the most water demanding industry. It has flexibility to consume non-potable

water for its need but then on acceptance attitude of people and health issues are the challenges to the complete utilization

of wastewater. On this background, investigations on all possible uses of all types of waste water in construction industry,

is the need of the hour. Present study has been conducted to investigate the influences of use of grey water for mixing

cement and mortar.

Physico-Chemical Requirements of Water to be Used for Mixing

Water fit for drinking is fit for all constructional activities like mixing cement, mortar, concrete and curing.

That is potable water is always first choice of all codes of practices related with concrete. When sources other than potable

water, water without any previous record or any questionable water are used, the water has to be qualified by tests. In case

of doubt about the water available for constructional use, the suitability of water for making concrete shall be

ascertained by the compressive strength and initial setting time specified in almost all concrete standards. Table 1 gives

the Main criteria for the assessment of mixing water.

Table 1: Main Criteria Given By IS 456, EN 1008, ASTM C94, ASTM C1602 and AS 1379

(Cement Concrete & Aggregates Australia, 2007) For the Assessment of Mixing Water

Parameter

IS 456

Time of set

Initial set 30min

and final set 10

h

Compressive

strength

min 90 % of

control at 28 days

BS EN 1008

Initial set 1 h and final set

12 h with both not differ

by more than 25% from

control.

min 90 % of control at 7&

28 days

ASTM C94/ASTM

C 1602

From 1:00 early to

1:30 later than

control

min 90 % of control

at 7 days

AS 1379

Initial set from 60 min

earlier to 90 min later

than control sample

time.

min 90 % of control at

7& 28 days

It has been observed that many chemicals in mixing water may create harm to concrete if present in excess

amount. The impurities in mixing water harmful to concrete are compiled from various codes like ASTM C 1602/C

1602M-04, ASTM C94, BS EN 1008:2002, IS 456, AS1379-2007. These are Color, Odor, total solids, Chlorides,

Sulphates, Acids, Alkali, phosphates, nitrates, lead, zinc, Oils and fats, Detergents, etc.

The critical limits presented by various concrete standards can be summarized as,

As per EN 1008:2002 the color of mixing water shall be assessed as pale yellow or paler, there should be no smell

or except the odour allowed for potable water. Any foam in the mixing water should disappear within 2 minutes.

Concrete mixing water should have phosphate, lead, zinc and sugar concentration within the permissible limit of

100mg/lit. The nitrate concentration limit is 500mg/lit.

pH: The pH of the water used for mixing should not be less than 4 as per EN-1008, 5 as per AS-1379 and 6 as per

IS-456. According to Neville no significant effect observed within 6.08.0.

Impact Factor (JCC): 5.9234

NAAS Rating: 3.01

Feasibility Study of Grey Water for Mixing Cement and Mortar

91

Total Solids: Total Solids concentration should not exceed the maximum permissible limit of 50,000 mg/lit. as

per ASTM C94 and ASTM C1602 and according to IS 456 it should be less than 2000mg/lit. & also less than 1%

of total aggregates.

Oil and Grease: The oil and grease concentration in the mixing water should not exceed the permissible limit of

50mg/lit. as per AS1379 or there should not be any visible traces of the same as per EN1008

Chlorides: The chloride concentration as Cl should not exceed limit of 500mg/lit given by EN1008, ASTM C94,

ASTM C1602 & IS 456.

Sulphate: As per EN 1008, the sulfate concentration in the mixing water should not exceed the value of

2000mg/lit & according to ASTM C94 and ASTM C1602, 3000mg/lit. Prescribed values of to AS1379 & IS 456

are 500mg/lit and 400mg/lit respectively.

Total Alkalinity: The total alkalinity in mixing water should be within the permissible limit of 1500mg/lit,

600mg/lit, 600mg/lit as per EN 1008, ASTM C94, ASTM C1602 respectively.

No comment has been made on presence of micro-organisms by either of the standards. According to A.M.

Neville (2005) concrete is generally resistant to microbiological attacks because its high pH does not encourage

actions harmful to concrete.

Considering chances of health issues related to the safe handling of objectionable water must be considered.

Biological treatment and pathogen reduction are used to ensure safety in handling reclaimed water. Disinfection methods

can be adopted before use (Cement Concrete & Aggregates Australia, 2007).

EXPERIMENTAL PROGRAM

In this study, the grey water collection system was installed at two different locations. Grey water was first

equalized for 24 hours and then samples were taken for bio-chemical analysis. Same grey water was used for mixing

purpose.

The grey water samples (GW) from two different sources were used for mixing. For comparison municipal

corporation supplied tap water (TW) was used to prepare control specimens. Standard consistency, initial and final setting

times, soundness and compressive strengths of cement were determined by using both TW and GW for mixing. Two

different mortar mixes H-1 and M-1 (SP 20, 1991) of two different consistencies were made by using grey water for

mixing. Curing of these mortar cubes was done by the same grey water.

Test Procedures

Equalized grey water samples were sampled and analyzed for potential pollutants of concrete by procedures given

in different parts of IS3025.

Standard consistency test was performed as per procedures given in IS4031part 4-1988.

Initial and final setting time tests were carried out as per procedures in IS4031 part 5-1988.

Soundness test was conducted in accordance with IS4031 part 3-1988 to ascertain the presence of free lime and

magnesia by measuring the expansion of cement.

www.tjprc.org

editor@tjprc.org

92

Rajesh T. Peche, Sanjay S. Jamkar & Parag A. Sadgir

Test of Compressive strength of cement was carried out according to IS4031 part 6-1988.

Mortars were prepared according to SP 20 (1991) handbook on masonry design and construction--part 2.

MSaterials Used

Cement: 53 Grade Ordinary Portland cement confirming to IS12269.

Mixing water: Tap water (TW) confirming to IS10500 and grey water (GW) obtained from residential apartment

and boys hostel building was used in this study.

Fine aggregates for compressive strength of cement: Standard sand obtained from Ennore, Tamil Nadu specified

by IS650 was procured for compressive strength test of cement.

Fine aggregates for Mortar: Locally available sand confirming to IS 383 was procured.

Various properties of the materials used are tabularised in Table 2.

Table 2: Properties of Materials Used in Experimentation

Cement

Ultratech OPC 53 GR.

Standard sand

Fine

Aggregates

Mixing

water

Local Sand

Screened Grey water (GW)

Tap water (TW)

Specific Gravity: 3.15Confirming

To IS-12269

Obtained from Ennore, Tamil Nadu

specified by IS650

Specific Gravity: 2.52, Fineness

Modulus : 2.49, confirming to

Zone-III grading as per IS

383Water Absorption: 0. 62% ,

Moisture content: Nil

Boys hostel, residential apartments

Confirming to IS-10500

Grey Water Collection

A set up as shown in Figure 1 was installed for the collection of grey water samples from boys hostel of

Government College of Engineering and also from residential apartments of State Government employees. Initially grey

water was passed through two screens in first barrel to screen-out floating and suspended materials. In second barrel the

water passed through 20 to 10mm coarse aggregates and then again through 10 to 4.75mm coarse aggregates for further

filtration. Sludge valve is provided in every barrel for the periodic backwashing.

RESULTS AND DISCUSSIONS

Critical Elemental Analysis of Grey Water Used for Concrete Mixing

Color: As per EN 1008:2002 the color shall be assessed qualitatively as pale yellow or paler. The samples of grey

water (GW1, GW2) used for mixing were light milky in color which is within the permissible limit.

Odour: According to EN-1008, no smell except the odour is allowed for the potable water along with a slight

smell of cement and if the blast furnace slag is present in the water, a slight smell of hydrogen sulphide is also acceptable.

Practically, no smell was noticed for both the grey water samples.

Impact Factor (JCC): 5.9234

NAAS Rating: 3.01

93

Feasibility Study of Grey Water for Mixing Cement and Mortar

Figure 1: Schematic of Grey Water Screening Tank and Set up of Grey Water Screening Tank

PH: The pH of the water used for mixing should not be less than 4 as per EN-1008, 5 as per AS-1379 & 6 as per

IS-456. According to Neville no significant effect observed within 6.08.0. The pH of the GW1 used for concrete mixing

was 7.9 & that of GW2 was 7.8, hence are within the stipulated standards as mentioned above.

Detergent: According to EN-1008, any foam in the mixing water should disappear within 2 minutes and for both

the samples of grey water used for concrete mixing the foam disappeared within a minute.

Total Solids: The Total Solids concentration was 170mg/lit. and 166mg/lit. for GW1 & GW2 resp. Total Solids

concentration should not exceed the maximum permissible limit of 50,000 mg/lit. as per ASTM C94, it should be less than

2000mg/lit. as per IS 456 & also less than 1% of total aggregates. Therefore the used samples were under the mentioned

specifications.

Oil and Grease: The oil and grease concentration in the mixing water should not exceed the permissible limit of

50mg/lit. as per AS1379 or there should not be any visible traces of the same as per EN1008. No visible traces have been

observed in the both samples of grey water used for concrete mixing.

Chlorides: The chloride concentration as Cl for the GW1 & GW2 samples were 26mg/lit and 34mg/lit which are

less than limit of 500mg/lit given by EN1008, ASTM C94 & IS 456.

Nitrate: The nitrate concentration of both samples was in the range of 0.071mg/lit. & 1.85 mg/lit. respectively, which is

less than the limit of 500mg/lit. as per EN 1008.

Sulphate: As per EN1008 and ASTM C94 the sulfate concentration in the mixing water should not exceed the

value of 2000mg/lit & 3000mg/lit respectively. It should also be less than 500mg/lit.& 400mg/lit according to AS1379 &

IS 456 respectively. The sulphate concentration in GW1 and GW2 was found to be 1.4mg/lit. & 2.8 mg/lit resp. which is

within the specified values.

Total Alkalinity: The total alkalinity in the grey water samples GW1 and GW2 was found as 104mg/lit. and 100

mg/lit. which is within the permissible limit of 1500mg/lit. and 600mg/lit. as per EN 1008 & ASTM C94 respectively.

Phosphates: GW1 & GW2 the samples used for concrete mixing had phosphate, lead and zinc concentration of

0.21, 0.17 & 0.9 and 1.2, 0.06 & 0.08 mg/lit respectively which is within the permissible limit of 100mg/lit as specified in

EN 1008.

B.O.D. and C.O.D.: B.O.D. of the grey water samples, GW1 and GW2, used for concrete mixing were found to

be 18 and 56 mg/lit., whereas C.O.D. values were 29 and 153mg/lit respectively. The C.O.D. to B.O.D ratios are 1.61 and

2.73. The COD/BOD ratio is a good indicator of greywater biodegradability. A COD/BOD ratio below 22.5 indicates

easily degradable wastewater, While greywater is generally considered easily biodegradable (B. Jefferson et. al, 2004).

Different studies indicate low greywater biodegradability with COD/BOD ratios of 2.93.6 (Peter Ridderstolpe, 2004).

www.tjprc.org

editor@tjprc.org

94

Rajesh T. Peche, Sanjay S. Jamkar & Parag A. Sadgir

This is attributed to the fact that biodegradability of greywater depends primarily on the type of synthetic surfactants used

in detergents and on the amount of oil and fat present.

Total and Fecal Coliform: The total coliform concentration in the samples GW1 and GW2 of grey water used

for concrete mixing was found to be 10MPN/100ml & 6.1 MPN/100ml whereas Fecal Coliform concentration was found

to be 3.7MPN/100ml & 1.8MPN/100ml respectively. According to A.M. Neville (2005), concrete is generally resistant to

microbiological attacks because its high pH does not encourage such actions.Nevertheless, under certain, fortunately rare,

tropical conditions, some algae, fungi and bacteria can use atmospheric nitrogen to form nitric acid which attack concrete.

The proportion of pathogens in greywater is generally low. Pathogens are primarily added to wastewater with the

faeces. The risk of infection is the function of thefaecal contamination of the water. As greywater does not contain faeces,

it is normally regarded as rather harmless (Peter Ridderstolpe, 2004). Presence of fecal coliform indicate that greywater

could create a health risk if it came into contact with humans Results of chemical analysis of Grey Water samples show

that the presence of chemicals harmful to concrete are within the standard permissible limits mentioned in various codes.

But due to presence of fecal coliforms in grey water it should be disinfected before use.

Results of Standard Consistency, Setting Time, Soundness and Compressive Strength of Cement

All these tests were carried out as per respective parts of IS: 4031. Three test samples each mixed by using TW,

GW1 and GW2 were tested to determine standard consistency. Whereas six samples each were prepared and tested for

determination of Setting time, soundness and compressive strength of cement. The relative values of test results are

presented in Table 3.

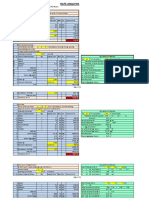

Table 3: Relative Results of Standard Consistency, Setting Time, Soundness

and Compressive Strength Tests of Cement

Mixing Water

TW

GW1

GW2

Standard

Consistency

100

98.7

97.41

Relative Result %

Set Time

Soundness

Initial

Final

100

103.57

105.37

100

100.97

105.88

100

94.32

106.38

Compressive

Strength, 28th

Day

100

100.55

101.86

Results of standard consistency show that the amount of water required for Standard Consistency of cement is

almost same in case of both TW and GW samples. In this case no significant difference in behaviour of TW and both

samples of GW were noticed. With respect to the tap water, grey water mixes indicate slight increase in both initial and

final setting time of cement. The increased values are also within the prescribed values given in IS 12269-1987.

For 53 grade cement, maximum expansion should be less than 10 mm when tested by the Le-Chatelier method

(IS: 12269, 2013). Grey water mixed cement pastes show expansions almost same to that of the tap water cement paste.

Both soundness test results are well within the prescribed limit given in IS 12269-1987.

It was found that grey water tends to increase the compressive strength of cement.

Impact Factor (JCC): 5.9234

NAAS Rating: 3.01

95

Feasibility Study of Grey Water for Mixing Cement and Mortar

Figure 2: Comparison of Results of Standard Consistency, Setting Time, Soundness

and Compressive Strength Tests of Cement by Using Tap and Grey Water for Mixing

Results shows that the compressive strength of cement mixed with Grey water is higher than that of tap water

mixed cement. Figure 2 presents the comparison of results of standard consistency, Setting time, soundness and

compressive strength tests of cement by using tap and grey water for mixing.

Results of Compressive Strengths of Mortar Cubes

Mortar cubes of 1:3 proportion i.e. H-1 mortar and 1:5 proportions i.e. M-1 mortar (SP 20, 1991) were casted

using TW, GW1 and GW2. Two water cement ratios were used for different consistencies. Six cubes per mix were tested

for compressive strength. Average 28th day strength test results are presented in table 4.

Tap water mortar samples and test samples of grey water mortar show no significant difference in compressive

strength. However grey water mortars give little more strength than control or tap water mortar which can be seen in Figure.

3.

As per SP 20(S&T): 1991, handbook on masonry design and construction--part 2, the minimum compressive

strength of H-1 mortar i.e. mortars of proportion 1:3 should be 10MPa and that of M-1 (1:5 mortars) should be 5 MPa.

Three out of four mixes are satisfying the minimum strength requirement of SP20. Whereas average compressive strength

of M-1 mixes, with 0.65 water cement ratio is less than the prescribed value. Out of eight, average compressive strength

values of grey water mortar, two are less than control mix but the lowest value is 98.57%. The maximum % strength

achieved by grey water mortars is 106.32%. All the values of the strength of grey water mortars satisfy the provisions

given in different codes of concrete.

Table 4: Results of 28th Day Compressive Strengths of Cement Mortar Made by Potable and Grey Water

Mixing

Water

Mortar Type

H-1

TW

M-1

www.tjprc.org

Proportion

of Mix

1:3

1:3

1:5

1:5

W/C

Ratio

0.5

0.6

0.55

0.65

Average 28th Day

Strength M. Pa.

14.233

11.343

6.66

4.193

Relative

Strength %

100

100

100

100

editor@tjprc.org

96

Rajesh T. Peche, Sanjay S. Jamkar & Parag A. Sadgir

1:3

1:3

1:5

1:5

1:3

1:3

1:5

1:5

H-1

GW1

M-1

H-1

GW2

M-1

0.5

0.6

0.55

0.65

0.5

0.6

0.55

0.65

14.353

11.553

6.656

4.333

14.76

12.06

6.93

4.133

100.8

101.85

99.84

103.33

103.7

106.32

104.05

98.57

Figure 3:

Comparison of 28th Day Compressive Strengths of Cement

Mortar Made by Tap Water and Grey Water

CONCLUSIONS

Scarcity of water points towards reuse of non-potable water for all purposes including construction.

Grey water is relatively less polluted non potable source of water.

Investigations by different researchers found that almost all non-potable waters can be used as mixing water.

Analytical results of Grey water samples tested during this study also fulfil the chemical limits of mixing water.

Other than screening, no special treatment is required to be given to grey water before its use for construction.

Presence of faecal coliforms points out the need of disinfection before use for human safety.

Regarding standard consistency of cement no significant difference in behaviour of TW and both samples of GW

were noticed.

With respect to the tap water, grey water mixes indicate slight increase in both initial and final setting time of

cement.

Soundness test results are well within the prescribed limit given in IS 12269-1987.

Compressive strength of cement mixed with Grey water was higher than that of tap water mixed cement.

Grey water mortars show little more compressive strength than control or tap water.

Grey water can be used as mixing water.

Impact Factor (JCC): 5.9234

NAAS Rating: 3.01

97

Feasibility Study of Grey Water for Mixing Cement and Mortar

REFERENCES

1.

A.M. Neville, (2005), Properties of Concrete, Fourth Edition, Pearson Education.

2.

Abrams, Duff A., (1924), Tests of Impure Waters for Mixing Concrete, ,Bulletin 12, Structural Materials

Research Laboratory, Lewis Institute, Chicago.

3.

Antoine Morel et al, (2006), Greywater Management in Low and Middle-Income Countries, Sandec: Department

of Water and Sanitation in Developing Countries.

4.

B. Chatveera , P. Lertwattanaruk et al, (2006), Effect of sludge water from ready-mixed concrete plant on

properties and durability of concrete, Cement & Concrete Composites, 28, 441450.

5.

B. Jefferson et. al, (2004), Grey water characterisation and its impact on the selection and operation of

technologies for urban reuse, Water Science & Technology Vol. 50, no 2, pp 157-164, IWA publishing.

6.

BS EN 1008, (2002), , Mixing water for concrete Specification for sampling, testing and assessing the

suitability of water, including water recovered from processes in the concrete industry, as mixing water for

concrete, British Standards.

7.

Cement Concrete & Aggregates Australia, (2007), Use of Recycled Water in Concrete Production.

8.

Franco Sandrolini et al., (2001), Waste wash water recycling in ready-mixed concrete plants, Cement and

Concrete Research, 31, 485489.

9.

Government of India Ministry of Water Resources, (2012), Draft national water policy, as recommended by

national water board in its 14th meeting held on 7th June 2012.

10. IS: 10500, (2009), Draft Indian Standard, Drinking Water Specification, Second Revision.

11. IS: 12269, (2013), Indian Standard, Ordinary Portland Cement, 53 Grade - Specification,

12. IS: 3025, (1986), Indian Standard Methods of Sampling and Test (Physical and Chemical) for Water and Waste

Water, Bureau of Indian Standards.

13. IS: 383, (1970), Reaffirmed-1997, Indian Standard specification for coarse and fine aggregates fromnatural

sources for concrete, Second Revision, Bureau of Indian Standards.

14. IS: 4031 - Part 3, (1988), Indian Standard Methods of. Physical Tests for Hydraulic Cement, Determination of

Soundness, Bureau of Indian Standards.

15. IS: 4031 - Part 5, (1988), Indian Standard Methods of Physical Tests for Hydraulic Cement, Determination of

Initial and Final Setting Times, Bureau of Indian Standards.

16. IS: 4031 - Part 6, (1988), Indian Standard Methods of Physical Tests for Hydraulic Cement, Determination of

Compressive Strength of Hydraulic Cement other than Masonry Cement,

17. IS: 4031- Part 4, (1988) Indian Standard Methods of Physical Tests for Hydraulic Cement, Determination of

Consistency of Standard Cement Paste, Bureau of Indian Standards.

18. IS: 650, (1991), Indian Standard, Standard Sand for Testing Cement specification, Bureau of Indian Standards.

www.tjprc.org

editor@tjprc.org

98

Rajesh T. Peche, Sanjay S. Jamkar & Parag A. Sadgir

19. IS456, (2000), Indian Standard, Plain and Reinforced Concrete Code of Practice, Fourth Revision, Bureau of

Indian Standards.

20. Joo-Hwa Tay, Woon-Kwong, (1987), Use of reclaimed wastewater for concrete mixing, Journal of Environmental

Eng.,113:1156-1161.

21. Marcia Silva, Tarun R. Naik, (2010), Sustainable Use of Resources Recycling of Sewage Treatment Plant Water

in Concrete, Second international conference on sustainable construction materials and technology, Ancona, Italy.

22. Mohammad Shekarchi et al, (2012), Use of biologically treated domestic waste water in concrete, Kuwait Journal

of Science and Eng.,39(2B), 97-111.

23. National Environmental Engineering Research Institute and United Nations Children's Fund UNICEF, India,

(2007), Greywater Reuse in Rural Schools, Wise Water Management, Guidance manual.

24. Ooi Soon Lee et al., (2001), Reusing treated effluent in concrete technology, Jurnal Teknologi, 34(F) ,1

10,Universiti Teknologi Malaysia.

25. Peter Ridderstolpe, (2004), Introduction to Greywater Management, EcoSan Res Programme, Stockholm

Environment Institute.

26. Queensland Government, (2008), A guide to the use of greywater in Queensland.Effective, Greywater guidelines.

27. SP 20(S&T), (I991), Handbook on masonry design and construction--part 2, First revision, Bureau of Indian

Standards.

28. Steinour, H H, (1970), Concrete mix water--how impure can it be?, Portland Cement Association R & D Lab Bull,

No 119.

29. World Health Organization, (2006), Guidelines for the safe use of wastewater, excreta and greywater , use in

agriculture, Volume IV.

Impact Factor (JCC): 5.9234

NAAS Rating: 3.01

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Rate AnalysisДокумент6 страницRate AnalysisRaj BharathОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Better Bonfire KilnДокумент24 страницыBetter Bonfire Kilnchedica22100% (2)

- Floor Finish: Estimated Unit Rate Amount Quantity (UAE DHS) (UAE DHS) Item Description UnitДокумент10 страницFloor Finish: Estimated Unit Rate Amount Quantity (UAE DHS) (UAE DHS) Item Description UnitThanuja WijesingheОценок пока нет

- P07-F06 Method Statement For External Stone CladdingДокумент7 страницP07-F06 Method Statement For External Stone CladdingJaime Manalili LandinginОценок пока нет

- Baluchari As The Cultural Icon of West Bengal: Reminding The Glorious Heritage of IndiaДокумент14 страницBaluchari As The Cultural Icon of West Bengal: Reminding The Glorious Heritage of IndiaTJPRC PublicationsОценок пока нет

- Comparative Study of Original Paithani & Duplicate Paithani: Shubha MahajanДокумент8 страницComparative Study of Original Paithani & Duplicate Paithani: Shubha MahajanTJPRC PublicationsОценок пока нет

- 2 29 1645708157 2ijtftjun20222Документ8 страниц2 29 1645708157 2ijtftjun20222TJPRC PublicationsОценок пока нет

- Flame Retardant Textiles For Electric Arc Flash Hazards: A ReviewДокумент18 страницFlame Retardant Textiles For Electric Arc Flash Hazards: A ReviewTJPRC PublicationsОценок пока нет

- 2 33 1641272961 1ijsmmrdjun20221Документ16 страниц2 33 1641272961 1ijsmmrdjun20221TJPRC PublicationsОценок пока нет

- 2 31 1648794068 1ijpptjun20221Документ8 страниц2 31 1648794068 1ijpptjun20221TJPRC PublicationsОценок пока нет

- The Conundrum of India-China Relationship During Modi - Xi Jinping EraДокумент8 страницThe Conundrum of India-China Relationship During Modi - Xi Jinping EraTJPRC PublicationsОценок пока нет

- 2 4 1644229496 Ijrrdjun20221Документ10 страниц2 4 1644229496 Ijrrdjun20221TJPRC PublicationsОценок пока нет

- 2 44 1653632649 1ijprjun20221Документ20 страниц2 44 1653632649 1ijprjun20221TJPRC PublicationsОценок пока нет

- Development and Assessment of Appropriate Safety Playground Apparel For School Age Children in Rivers StateДокумент10 страницDevelopment and Assessment of Appropriate Safety Playground Apparel For School Age Children in Rivers StateTJPRC PublicationsОценок пока нет

- 2 52 1642055366 1ijpslirjun20221Документ4 страницы2 52 1642055366 1ijpslirjun20221TJPRC PublicationsОценок пока нет

- 2 52 1649841354 2ijpslirjun20222Документ12 страниц2 52 1649841354 2ijpslirjun20222TJPRC PublicationsОценок пока нет

- Using Nanoclay To Manufacture Engineered Wood Products-A ReviewДокумент14 страницUsing Nanoclay To Manufacture Engineered Wood Products-A ReviewTJPRC PublicationsОценок пока нет

- Dr. Gollavilli Sirisha, Dr. M. Rajani Cartor & Dr. V. Venkata RamaiahДокумент12 страницDr. Gollavilli Sirisha, Dr. M. Rajani Cartor & Dr. V. Venkata RamaiahTJPRC PublicationsОценок пока нет

- 2 51 1651909513 9ijmpsjun202209Документ8 страниц2 51 1651909513 9ijmpsjun202209TJPRC PublicationsОценок пока нет

- Covid-19: The Indian Healthcare Perspective: Meghna Mishra, Dr. Mamta Bansal & Mandeep NarangДокумент8 страницCovid-19: The Indian Healthcare Perspective: Meghna Mishra, Dr. Mamta Bansal & Mandeep NarangTJPRC PublicationsОценок пока нет

- 2 67 1653022679 1ijmperdjun202201Документ12 страниц2 67 1653022679 1ijmperdjun202201TJPRC PublicationsОценок пока нет

- 2 51 1656420123 1ijmpsdec20221Документ4 страницы2 51 1656420123 1ijmpsdec20221TJPRC PublicationsОценок пока нет

- Effectiveness of Reflexology On Post-Operative Outcomes Among Patients Undergoing Cardiac Surgery: A Systematic ReviewДокумент14 страницEffectiveness of Reflexology On Post-Operative Outcomes Among Patients Undergoing Cardiac Surgery: A Systematic ReviewTJPRC PublicationsОценок пока нет

- 2 51 1647598330 5ijmpsjun202205Документ10 страниц2 51 1647598330 5ijmpsjun202205TJPRC PublicationsОценок пока нет

- An Observational Study On-Management of Anemia in CKD Using Erythropoietin AlphaДокумент10 страницAn Observational Study On-Management of Anemia in CKD Using Erythropoietin AlphaTJPRC PublicationsОценок пока нет

- Analysis of Bolted-Flange Joint Using Finite Element MethodДокумент12 страницAnalysis of Bolted-Flange Joint Using Finite Element MethodTJPRC PublicationsОценок пока нет

- 2 67 1648211383 1ijmperdapr202201Документ8 страниц2 67 1648211383 1ijmperdapr202201TJPRC PublicationsОценок пока нет

- Self-Medication Prevalence and Related Factors Among Baccalaureate Nursing StudentsДокумент8 страницSelf-Medication Prevalence and Related Factors Among Baccalaureate Nursing StudentsTJPRC PublicationsОценок пока нет

- A Review of "Swarna Tantram"-A Textbook On Alchemy (Lohavedha)Документ8 страницA Review of "Swarna Tantram"-A Textbook On Alchemy (Lohavedha)TJPRC PublicationsОценок пока нет

- Effect of Degassing Pressure Casting On Hardness, Density and Tear Strength of Silicone Rubber RTV 497 and RTV 00A With 30% Talc ReinforcementДокумент8 страницEffect of Degassing Pressure Casting On Hardness, Density and Tear Strength of Silicone Rubber RTV 497 and RTV 00A With 30% Talc ReinforcementTJPRC PublicationsОценок пока нет

- Vitamin D & Osteocalcin Levels in Children With Type 1 DM in Thi - Qar Province South of Iraq 2019Документ16 страницVitamin D & Osteocalcin Levels in Children With Type 1 DM in Thi - Qar Province South of Iraq 2019TJPRC PublicationsОценок пока нет

- 2 67 1645871199 9ijmperdfeb202209Документ8 страниц2 67 1645871199 9ijmperdfeb202209TJPRC PublicationsОценок пока нет

- Numerical Analysis of Intricate Aluminium Tube Al6061T4 Thickness Variation at Different Friction Coefficient and Internal Pressures During BendingДокумент18 страницNumerical Analysis of Intricate Aluminium Tube Al6061T4 Thickness Variation at Different Friction Coefficient and Internal Pressures During BendingTJPRC PublicationsОценок пока нет

- 2 67 1645017386 8ijmperdfeb202208Документ6 страниц2 67 1645017386 8ijmperdfeb202208TJPRC PublicationsОценок пока нет

- Quality AssuranceДокумент9 страницQuality AssuranceAnonymous Of0C4dОценок пока нет

- B.Arch. Estimation SpecificationДокумент2 страницыB.Arch. Estimation SpecificationDivya Varghese KurumuttathuОценок пока нет

- EG Week 12 (1) (Autosaved)Документ36 страницEG Week 12 (1) (Autosaved)Sachi DhanandamОценок пока нет

- Method Statement For Brickworks: Pembinaan Infra E&J SDN BHDДокумент5 страницMethod Statement For Brickworks: Pembinaan Infra E&J SDN BHDChezy629Оценок пока нет

- Material Testing Lab ManualДокумент47 страницMaterial Testing Lab ManualN.Dinesh Kumar reddyОценок пока нет

- Discipline Section Sub Head (DSR Sub Head No.) Non-DSR Sub-Head DSR Item No. BOQ Item NoДокумент154 страницыDiscipline Section Sub Head (DSR Sub Head No.) Non-DSR Sub-Head DSR Item No. BOQ Item NoAssistant EngineerОценок пока нет

- TDS - Emaco R907 PlusДокумент2 страницыTDS - Emaco R907 PlusVenkata RaoОценок пока нет

- Factors and Allowances for Estimating Concrete QuantitiesДокумент57 страницFactors and Allowances for Estimating Concrete QuantitiesGhadahОценок пока нет

- SAIL DSP GTS Vol II.168-399Документ232 страницыSAIL DSP GTS Vol II.168-399Koushik DeyОценок пока нет

- Boq For RCДокумент9 страницBoq For RCamanОценок пока нет

- PAT 254 BUR KaylaДокумент66 страницPAT 254 BUR Kaylaadeliene 25Оценок пока нет

- The Utilization of Agricultural Waste As Agro-Cement in Concrete: A ReviewДокумент16 страницThe Utilization of Agricultural Waste As Agro-Cement in Concrete: A ReviewCivil StructureОценок пока нет

- University of Duhok Materials Technology and Testing Chapter on Mortars, Binders and GypsumДокумент20 страницUniversity of Duhok Materials Technology and Testing Chapter on Mortars, Binders and GypsumZhiwar oramariОценок пока нет

- Dar (Civil) IIДокумент888 страницDar (Civil) IIShyam Kumar100% (1)

- MES Amended Schedule 2009Документ562 страницыMES Amended Schedule 2009Saeed Ahmed0% (1)

- Grouting PDFДокумент22 страницыGrouting PDFSuvajit BisaiОценок пока нет

- PDF JKSR 2020Документ389 страницPDF JKSR 2020Aarush GuptaОценок пока нет

- BOQДокумент9 страницBOQayan3176Оценок пока нет

- SBW-RFAMS-008-Submission of Method Statement For Plastering WorkДокумент24 страницыSBW-RFAMS-008-Submission of Method Statement For Plastering WorkChamux skalОценок пока нет

- Nitotile GTA PDFДокумент2 страницыNitotile GTA PDFvibishnanОценок пока нет

- Method Statement For BlockworksMasonry - WelcomeДокумент1 страницаMethod Statement For BlockworksMasonry - WelcomeChristopher PantojaОценок пока нет

- Overall TestingДокумент20 страницOverall TestingGerald TanОценок пока нет

- E GCOct 2013 NsДокумент0 страницE GCOct 2013 Nsvae2797Оценок пока нет

- MA. P.E. /A2: Ance R/a 2 For M Ason Ryc Eme NTДокумент2 страницыMA. P.E. /A2: Ance R/a 2 For M Ason Ryc Eme NTKlevisSheteliОценок пока нет

- MaterialsДокумент295 страницMaterialshthanhbinh166Оценок пока нет

- Compressive Strength of Hydraulic Cement Mortars (Using 2-In. or (50-mm) Cube Specimens)Документ9 страницCompressive Strength of Hydraulic Cement Mortars (Using 2-In. or (50-mm) Cube Specimens)Jesús Luis Arce GuillermoОценок пока нет