Академический Документы

Профессиональный Документы

Культура Документы

Lca Pet

Загружено:

Cesar Alberto Reyna PariОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Lca Pet

Загружено:

Cesar Alberto Reyna PariАвторское право:

Доступные форматы

Int. J. Environment and Waste Management, Vol. 2, Nos.

1/2, 2008

125

Life Cycle Assessment (LCA) of PET bottles

and comparative LCA of three disposal options

in Mauritius

Rajendra Kumar Foolmaun

and Toolseeram Ramjeawon*

Faculty of Engineering,

University of Mauritius, Republic of Mauritius

Fax: + 230 210 5751

Fax: 230-4657144

E-mail: oumeshf@yahoo.com

E-mail: ramjawon@uom.ac.mu

*Corresponding author

Abstract: Disposal of the increasing volume of used Polyethylene

Terephthalate (PET) bottles has been a cause for concern for the Mauritian

Government. To assist Government in decision-making, a study on PET bottles

and its disposal was undertaken using the Life Cycle Assessment (LCA) tool.

Three disposal scenarios, namely (100%) landfilling; (100%) incineration; and

50% landfilling and 50% incineration were compared. Sima Pro 5.1 software

was used to analyse data and Eco-indicator 99 method was used for the impact

assessment. The results showed that about 90% of the total environmental

impact happened during the assembly and use phase of PET bottles. 100%

incineration was found to be the most preferred option.

Keywords: Life Cycle Assessment; LCA; Polyethylene Terephthalate; PET;

PET bottles; plastic bottles; solid wastes.

Reference to this paper should be made as follows: Foolmaun, R.K. and

Ramjeawon, T. (2008) Life Cycle Assessment (LCA) of PET bottles and

comparative LCA of three disposal options in Mauritius, Int. J. Environment

and Waste Management, Vol. 2, Nos. 1/2, pp.125138.

Biographical notes: R.K. Foolmaun is presently working as Environment

Officer in the Ministry of Environment and National Development Unit.

He is a part time Doctoral student at the University of Mauritius and

undergoing a research on the Life Cycle Assessment of Polyethylene

Terephthalate bottles in Mauritius.

Toolseeram Ramjeawon is an Associate Professor of Environmental

Engineering in the Department of Civil Engineering at the University of

Mauritius. He has more than 15 years of relevant experience in the area of

environment policy and management. He is part of the International Life Cycle

Panel of the UNEP-SETAC Life Cycle Initiative and also the coordinator of the

African Life Cycle Assessment Network (ALCANET).

Introduction

The island of Mauritius is 1865 Km2 in land area and lies about 800 Km south east of

Madagascar in the Indian Ocean. It is a relatively densely populated island (population

Copyright 2008 Inderscience Enterprises Ltd.

126

R.K. Foolmaun and T. Ramjeawon

of 1.13 million in 2000). Over the past 20 years Mauritius has achieved an average of 5%

annual economic growth and the per capita income in 2005 was about US$5000, ranking

Mauritius as an upper middle-income country. In parallel to the economic growth, the

volume and nature of wastes has changed significantly. Around 1200 tons of municipal

solid wastes are generated daily. Most of the solid wastes are compacted in five transfer

stations before being sent to the sole sanitary landfill on the island. The latter is presently

filled to around 60% of its total capacity and is expected to be saturated in 2008 if the

present waste trend continues. GoM (2000) and Bro (2003) have recommended that

landfilling be continued as a viable option for disposal of Municipal Solid Waste (MSW)

for the short and medium term while the option of incineration be incorporated along

with landfilling from the year 2013. In September 2006, the Board of Investment in

Mauritius gave a letter of intent to a private company to incinerate 300,000 T of MSW

annually from the year 2009 and to generate 20 MW of energy which would be sold to

the national grid. As it is projected that the amount of solid waste generated will increase

to 466,000 T in the year 2013 (GoM, 2005), it means that both the incinerator plant and a

new landfill will have to be operated in the near future.

PET containers form part of our daily life and the rising consumption has resulted in

the disposal of about 70 millions of used PET bottles annually in Mauritius. In the

absence of other disposal alternatives, used PET bottles are disposed of, co-mingled with

domestic waste at the sole sanitary landfill. Used PET bottles occupy a relatively large

volume in the landfill, whilst constituting an eyesore in the form of litter in the

environmental landscape.

LCA is a decision support tool that facilitates the comparison of alternative

products and services that perform the same function from an environmental perspective.

The methodology also allows analysis of services, such as waste management

(Finnveden, 1999). A literature review showed that studies have been conducted on,

either, part of the life cycle of PET bottle (Boustead, 1995), or on the whole life cycle

(Person et al., 1998). Boustead (1995) performed an eco-profile of bottle grade PET

polymers starting from raw materials extraction and up to the production of the polymer

resins (i.e., cradle to gate analysis). The eco-profile essentially presented quantified

results for inputs in terms of raw materials used, the energy requirements and outputs in

terms of air, water and solid waste emissions. Person et al. (1998) on the other hand,

carried out a LCA of disposable PET bottle as part of a study on LCA of packaging

systems which aimed at comparing the potential environmental impacts associated

with different packaging systems for beer and soft drinks filled and sold in Denmark.

These two researchers used the EDIP method for the impact assessment and found

out that disposable PET bottles contributed mostly to the following five impact

categories:

ecotoxicity, terrestrial

human toxicity

Photochemical Ozone Formation (POCP)

Global warming (GWP)

acidification.

Life Cycle Assessment (LCA) of PET bottles and comparative LCA

127

Disposal of used PET bottles is an important phase of the PET life cycle and has been the

subject of several studies (Craighill and Powell, 1996; Denison, 1996; Ayalon et al.,

2000; Grant et al., 2001; Von Krogh et al., 2001; Mlgaard, 1995; Reid Lea, 1996; Song

and Hyun, 1999; Perugini et al., 2004). Out of the nine studies reviewed, seven

studies (Mlgaard, 1995; Denison, 1996; Reid Lea, 1996; Ayalon et al., 2000; Grant

et al., 2001; Von Krogh et al., 2001; Perugini et al., 2004) showed a general preference

for recycling as a disposal option for PET bottles. However, the review also showed

that the most appropriate disposal method of PET bottles depends on a number

of local factors. White et al. (1999) stated that there was no optimal system for waste

management due to the geographic differences in waste characteristics, energy sources,

availability of some disposal options, and size of markets for products derived from waste

management. Mendes et al. (2004) further reported that the optimal system for any given

region should be determined locally so as to reduce the environmental impact.

The aim of this study was to compare the environmental effects during the whole life

cycle (from manufacture to waste management) of the usage of PET plastic material for

bottling applications on the island of Mauritius using the LCA methodology, and to use

the LCA tool to compare three alternative disposal methods for the used PET bottles,

namely:

disposal of used PET bottles by landfilling-the plastic bottles that are generated in

households are collected together with residual waste and deposited in a landfill

disposal of used PET bottles by incineration with energy recovery-the plastic bottles

that are generated in households are collected with the source sorted plastic

packaging and sent to an incinerator

disposal of 50% of the used PET bottles by landfilling and 50% by incineration.

The results of the study are meant to be employed at the industrial level in order to select

the most environment friendly plastic material for bottling, and for waste management

authorities to select the most appropriate disposal method. The waste management

options have been selected based on the future development of this sector in Mauritius

and the future implementation of a municipal incinerator in 2009.

Methodology

This study has been based upon the LCA methodology, as described in the

ISO Standards 1404014043 (1997, 1998, 2000). The method chosen, due to the

relevance of the impact factors for the study, is Eco-Indicator 99 end-point method.

In this method, normalisation and weighting are performed at three different damage

category levels:

HH: Human Health (unit DALY = Disability Adjusted Life Years).

EQ: Ecosystem Quality (unit: PDF*m2yr; PDF = Potentially Disappeared Fraction of

plant species).

R:

Resources (unit: MJ surplus energy; Additional energy requirement to compensate

lower future ore grade).

128

R.K. Foolmaun and T. Ramjeawon

2.1 Scope definition

For the system function of beverage bottles made of PET during their whole lifetime, the

functional unit was defined as the production, use and disposal of 1000 packs of 1.5 L

PET bottles, used for the packaging of 9000 litres of beverage. One pack contains six

1.5 L PET bottles enclosed by a plastic film made up of LDPE.

For the assessment and comparison of the disposal scenarios, the functional unit

chosen was the disposal of 1 tonne of used PET bottles. Caps amount to around 5% of the

total weight and the labels amount to around 1% of the total weight.

2.2 System boundary

The process tree is illustrated in Figure 1. We are taking into account the entire life-cycle

of the bottles, from the raw material (oil) to the moment they lose, totally, their value

(landfilling). The system boundary, therefore, includes extraction of raw materials and

manufacture of PET pellets; importation of PET pellets from South Africa; conversion of

PET pellets to PET preforms at a local industry in Mauritius; blowing of PET preforms

into PET bottles (prior to bottling) at another local industry; distribution, use and

disposal. Productions of materials for secondary packaging and cap inserts made from

polypropylene are included in the LCA. Since most used PET bottles are disposed of

commingled with municipal solid waste, it is assumed that all used PET bottles were

disposed of by landfilling.

2.3 Main assumptions and data gaps

Consumers disposed their used PET bottles after use without any washing.

Electricity was generated from oil only.

For comparison of the disposal scenarios, it was assumed that the incineration

facility is situated close to the landfilling plant.

Within Mauritius, 16 T trucks that run on diesel as fuel, are used for distribution of

bottled water and for collection of used PET bottles. Average transport distances

used for calculations were as follows:

average car distance travelled by consumers cars to shopping centre: 5 Km

average distance covered by 16 T truck for transportation of PET preforms to

PET bottling plant: 18 Km

average distance covered for distribution of bottled water to the retail outlets:

20 Km

average distance travelled by 16 T trucks for disposal at landfill: 25 Km.

Life Cycle Assessment (LCA) of PET bottles and comparative LCA

Figure 1

129

Flow chart of LCA of PET bottles

2.4 Sensitivity analysis

A Sensitivity analysis was also conducted to investigate the influence on the results by

altering the source of electricity generation from oil to electricity generation from coal, as

it is anticipated that there will be a greater share of electricity generation from coal in the

electricity mix in the future.

Inventory analysis

3.1 Data collection

Data were collected during visits to the two local industries (one industry

which transforms PET pellets to PET preforms and another industry which blows

130

R.K. Foolmaun and T. Ramjeawon

the PET preforms into PET bottles prior to filling and bottling) and from the following

sources: technical reports, Central Statistics Office reports of the Republic of Mauritius.

In the absence of relevant data in Mauritius, the data gaps were filled in using

data from Sima Pro software databases, particularly the Swiss BUWAL 2000

database, on the assumptions that the conditions under which these data apply in

Europe are similar to Mauritius. Data collected were processed and analysed using the

SimaPro 5.1 software.

3.2 Inventory analysis

3.2.1 Inventory analysis results for PET life cycle

The results show that 177 kgs of crude oil were used as feedstock and 6410 MJ of

energy was required to produce 6000 PET bottles of 1.5 L volume. This production

emitted 2420 Kg of carbon dioxide, 23.4 Kg of SOx, 8.87 Kg of NOx and 31.7 Kg of

methane. The result of the inventory analysis is summarised and presented in Table 1.

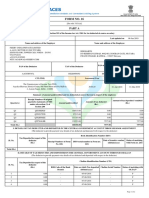

Table 1

Summary of inventory analysis result for PET life cycle

Input

Raw materials

Substance

Energy input

Unit

Amount

Crude oil (feedstock)

Biomass

Natural gas (feedstock)

Rock salt

Limestone

Manure

Process and cooling water

Process water

Water (cooling)

Kg

g

M3

Kg

Kg

g

M3

L

Kg

177

210

84

1.44

1.46

860

4.2

3.09

680

Wood

Kg

6.57

Wood (feedstock)

Kg

4.52

Substance

Unit

Amount

Natural gas (Vol)

Crude oil ETH

Coal ETH

Lignite ETH

Natural gas ETH

Pot. energy hydropower

Steam from waste

incineration

M

Kg

Kg

Kg

M3

Mj

Mj

110

593

37.7

36.6

24.9

201

954

Energy input from electricity

Mj

6410

Output

Airborne emissions Amount Waterborne emissions

Substance

(Kg)

CO

4.43

Amount Solid waste emissions Amount

Substance

(Kg)

10.4

CO2

Anorg. dissolved

substance

2420 BOD

CxHy

Dust

Methane

Non-methane VOC

NOx (as NO2)

SOx (as SO2)

1.93

1.63

31.7

12.2

8.87

23.4

Chlorate ions

Chloride ions

COD

Suspended subst.

TOC

Waste water (Vol) (m3)

Substance

(Kg)

Mineral waste

7.14

(mining)

0.25

Waste bioactive

3.69

landfill

7.38 E03 Waste in inert landfill 0.058

18.1

Emissions to soil

0.96

Substance

(mg)

1.61

Pb

369

3.05

Cd

90.8

460

Hg

23.7

Life Cycle Assessment (LCA) of PET bottles and comparative LCA

131

The inventory analysis results of the PET life cycle were compared with that of the study

conducted by Person et al. (1998) in Table 2. The deviations are due to the following

reasons:

Different waste disposal scenarios. The present study considered landfilling as a

disposal method for used PET bottles while Person et al., considered recycling (90%)

and incineration with energy recovery (10%) as disposal alternatives. Their study

assumed that the recycled PET replaced equal amounts of virgin PET and PET

recycled from other products. Recycling implies fewer raw materials were utilised

and thus lower air and water emissions. Incineration with energy recovery on the

other hand, implied avoided energy and emissions

Person et al. expanded their system boundaries so as to include parts of other life

cycles affected by the outflow of recycled PET bottles and parts of other life cycles

that were affected by energy recovery from waste incineration.

In the present study electricity was produced from heavy oil which has higher air

emissions as compared to a mixture of light fuel oil, hydropower, coal and

alternative sources such as peat as used in study by Person et al.

Transport distances used in the present study are smaller, since Mauritius is a small

island state, compared to distances used in Denmark by Person et al.

Table 2

Comparison of results of this study with Person et al. (1998) (for a functional unit of

9000 litres of packaged beverage)

Parameter

Unit

Present study

Person et al. (1998)

Mass of unit PET bottle

34

42

Crude oil (feedstock)

kg

177

218

Bauxite

77.8

86.22

Methane

Kg

31.7

21.78

CO

Kg

4.43

6.32

Carbon dioxide

Kg

2420

1755

Dust

Kg

1.63

1.64

NMVOC

Kg

12.2

0.5

NOx

Kg

8.87

9.9

H2S

mg

340

2709

SO2

Kg

23.4

11.79

HCl

105

126

BOD

250

255.6

COD

961

1386

Oil

29.4

65.7

Hg

mg

54.5

28.62

3.09

1.26

Kg

18.1

4.27

AOX

Chloride

132

R.K. Foolmaun and T. Ramjeawon

3.2.2 Inventory analysis results for the disposal scenarios

Table 3 provides a summary of emissions occurring for disposal Scenarios 13, and the

following can be observed:

Scenarios 2 and 3-incorporating incineration had higher emissions of Carbon

dioxide compared to Scenario 1

Scenarios 1 and 3 had higher emissions of methane with respect to Scenario 2, due to

the anaerobic decomposition of paper labels in the landfill

with the exception of carbon dioxide and carbon monoxide, all emissions of

Scenario 2 bear negative values due to avoided emissions from energy recovery.

Table 3

Summary of emissions for Scenarios 13

Scenario 1:

Scenario 2: incin.

Scenario 350%

Substances

Unit landfill (100%) 100%with energy recovery landfill and 50% incin.

Air emissions

CO

g

413

120

267

CO2

Kg

381

4.54E3

2.46E3

Dust

Kg

0.0828

1.48

0.697

Methane

Kg

38.7

4.53

17.1

NM-Voc

Kg

0.47

8.76

4.15

Nox (as NO2)

Kg

1.13

5.42

2.15

Sox (as SO2)

Kg

1.22

39.2

19

Water emissions

Anorg. dissolved subs. Kg

0.492

19.4

9.45

BOD

g

0.101

2.48

1.19

Chloride ions

Kg

4.9

26.6

10.8

COD

g

3.29

42.9

19.8

Oil

g

25

18.5

21.7

Sulphate

Kg

3.04

0.95

1.05

Suspended solids

Kg

0.0665

3.3

1.62

TOC

Kg

2.94

0.0681

1.44

Emissions to soil

Carbon

Kg

Nil

0.999

Cd

mg

93.9

Nil

47

Hg

mg

25

Nil

12.5

120

Nil

59.9

3.99

Nil

mg

66.9

Nil

33.5

N-tot

P-tot

Pb

Impact assessment

Since normalisation and weighting were performed by the Eco-indicator 99 method

the interpretation of results is mainly based on single score and characterisation.

The following impact categories were considered in the model: Carcinogens,

Life Cycle Assessment (LCA) of PET bottles and comparative LCA

133

Respiratory organics, Respiratory inorganics, Climate change, Ecotoxicity, Ozone layer,

Acidification/Eutrophication, Mineral and Fossil fuel.

4.1 Impact assessment of PET life cycle

The results of impact assessment were reported for two separate phases: assembly

and use phase and the disposal phase. The assembly and use phase included the

extraction of raw materials (i.e., PET, PP, LDPE); polymerisation of PET, PP and LDPE;

manufacture of paper; shipping of these materials to Mauritius; transformation of the

PET pellets to preforms and PET bottles; and distribution of the bottled water.

The disposal phase reflected the waste management method for the disposal of used

PET bottles.

The results indicated that the highest environmental impacts occurred during the

assembly and use phase (Figure 2), more specifically under the damage category

Resources (Figure 3) owing to the relatively high utilisation of fuel and minerals.

The data show that during the production of PET resin, besides oil, a substantial amount

of minerals is used (Fe, Limestone, KCl, Bauxite, Sulphur, NaCl).

Two processes, namely electricity generation from oil in Mauritius and industrial

manufacture of PET pellets in South Africa, contributed to around 90% of the total

environmental impacts (Figure 4). The process contribution results also reveal that

transport contributes very little (0.01%) to the total environmental loads while the

disposal phase contributes to only 5% of the total environmental impact. A break down of

the disposal phase indicated that landfilling of paper labels causes the highest

environmental impacts as shown in Figure 5, while disposal of PET plastic contribute to

only 5.4% of the total environmental impacts. This is explained by the fact that landfilled

paper labels decompose readily in the anaerobic landfill environment to release methane

while PET bottles, like other plastics, do not degrade readily in landfills.

Figure 2

Single score LCIA result of 1000 packs of PET bottles

134

R.K. Foolmaun and T. Ramjeawon

Figure 3

Weighted result of LCIA of 1000 packs of PET bottles

Figure 4

Results of process contribution analysis

Figure 5

Percentage environmental impacts of processes within the waste disposal phase

Life Cycle Assessment (LCA) of PET bottles and comparative LCA

135

4.2 Impact assessment of Scenarios 13

The results are illustrated in Figure 6, which shows that the scenarios incorporating

incineration had negative values for the impact assessments owing to avoided emissions.

Between the two scenarios incorporating incineration, Scenario 2 had higher negative

values (258 pt) as compared to Scenario 3 (121 pt).

Figure 6

Impact assessment results for comparative scenarios

4.3 Sensitivity analysis

Since electricity generation caused the highest environmental impact in the life cycle of

PET bottles, the influence of altering the source of electricity generation on the present

results was investigated. For this purpose, electricity generation in the LCA of PET

bottles was altered to electricity generation using coal instead of oil. The sensitivity

analysis showed that altering electricity generation from oil to coal had a relatively

significant effect on the damage category, Resources (decrease by 48%) (Table 4).

This highlights the importance of developing the environmental impact for the electricity

mix in the country to improve the accuracy of the results.

Table 4

Sensitivity analysis of LCIA results (weighted)

Impact indicators

Unit

Electricity generated

with oil

Electricity generated

with coal

90.4

Human health

Pt

83.1

Ecosystem quality

Pt

12.1

Resources

Pt

139

Total

Pt

234

9.74

72.4

173

Difference (%)

8.07

19.5

47.92

21.37

136

R.K. Foolmaun and T. Ramjeawon

Interpretation

The impact assessment results show that the highest environmental impact occurred

during the assembly and use phase, more particularly under the damage category,

Resources. The process contribution results reveal that during the life cycle of PET

bottles in Mauritius, the highest environmental impacts can be attributed to the electricity

generation from oil for consumption in two processes: the transformation of PET

pellets into PET preforms (1422.5 KWh) and the blowing of preforms to PET bottles

(359.15 KWh). The highest environmental impacts in Mauritius, therefore, occurred at

the transformation process of PET pellets into PET preforms. The process contribution

results also indicated that the disposal method has a much lower environmental impact

compared to the assembly and use phase.

The investigation of the three disposal scenarios for used PET bottles show that

scenarios incorporating incineration had lower environmental impacts compared to the

scenario of landfilling. This finding is in agreement with some of the earlier studies

reviewed, such as Lea (1996) and Denison (1999), which found incineration to be better

than landfilling. Other studies comparing disposal alternatives and conducted by Chung

and Poon (1996), Arena et al. (2003) and Mendes et al. (2004) on municipal solid waste

showed similar findings.

Conclusions

During the life cycle of PET bottles, the highest environmental impacts occurred

within the assembly and use phase and were attributed to only two processes:

electricity generation from oil and production of PET pellets. On the island, the

highest environmental impacts occurred during electricity production from oil.

Transport contributed very little to the total environmental loads.

Comparison of the three disposal scenarios indicated that energy recovery gave a net

environmental benefit for most of the impact categories. Landfilling gave the highest

environmental burdens when compared to energy recovery.

References

Arena, U., Mastellone, M.L. and Perugini, F. (2003) The environmental performance of alternative

solid waste management options: a life cycle assessment study, Chemical Engineering

Journal, Vol. 96, pp.207222.

Ayalon, O., Avnimelech, Y. and Shechter, M. (2000) Application of a comparative

multi-dimensional LCA in solid waste management policy: the case of soft drink containers,

In Journal of Environmental Science and Policy, Vol. 3, Nos. 23, April, pp.135144.

Boustead, I. (1995) Eco-Profiles of the European Plastics Industry, Report 8: Polyethylene

Terephthalate (PET), Association of Plastic Manufacturers in Europe Technical and

environmental Centre, Brussels.

Bro, C. (2003) Environmental Solid Waste Management Project, Feasibility Report, Ministry of

Local Government. Government of Mauritius. Port-Louis.

Life Cycle Assessment (LCA) of PET bottles and comparative LCA

137

Chung, S.S. and Poon, C.S. (1996) Evaluating waste management alternatives by the multiple

criteria approach, Resources, Conservation and Recycling, Vol. 17, pp.189210.

Craighill A.L. and Powell, J.C. (1996) Life cycle assessment and economic evaluation of

recycling: a case study, Resource Conservation and Recycling, Vol. 17, pp.7596.

Denison, R.A. (1996) Environmental lifecycle comparisons of recycling, landfilling, and

incineration: a review of recent studies, Annual Review of Energy and the Environment,

Vol. 21, p.191237.

Finnveden, G. (1999) Methodological aspects of life cycle assessment of integrated solid waste

management systems, Resour. Conserv. Recy., Vol. 26, No. 314, pp.173187.

GoM (2005) Government of the Republic of Mauritius. Report of the Ministry of Environment &

NDU, Mauritius Staking out the Future, Chapter 9, Port Louis, Republic of Mauritius,

pp.143159.

Grant, T., James, K.L., Lundie, S. and Sonneveld, K. (2001) Life Cycle Assessment for Paper and

Packaging Waste Management Scenarios in Victoria, Final report of Stage 2.

ISO 14040 (1997) Environmental Management Life Cycle Assessment Principles and

Framework, International Organisation for Standardisation, Geneva.

ISO 14041 (1998) Environmental Management Life Cycle Assessment Goal and Scope

Definition and Inventory Analysis, International Organisation for Standardisation, Geneva.

ISO 14042 (2000) Environmental Management Life Cycle Assessment Life Cycle Impact

Assessment, International Organisation for Standardisation, Geneva.

ISO 14043 (2000) Environmental Management Life Cycle Assessment Life Cycle

Interpretation, International Organisation for Standardisation, Geneva.

Lea, R.W. (1996) Plastic incineration versus recycling: a comparison of energy and landfill cost

savings, Journal of Hazardous Materials, Vol. 47, pp.295302.

Mendes, M.R. Amaraki, T. and Hanaki, K. (2004) Comparison of the environmental impact of

incineration and landfilling in Sao Paulo city as determined by LCA, Resources,

Conservation and Recycling, Vol. 41, No. 4, pp.4763.

Mlgaard, C. (1995) Environmental impacts by disposal of plastic from municipal solid waste,

Resources, Conservation and Recycling, Vol. 15, No. 1, pp.5163.

Person, L., Ekvall, T. and Weidema, B.P. (1998) Life Cycle Assessment of Packaging Systems for

Beer and Soft Drinks, Technical report 6: disposable PET bottles. Ministry of Environment

and Energy, Denmark, Danish Environmental Protection Agency, Miljprojekt No. 405,

p.198.

Perugini, F., Mastellone, M.L. and Umberto, A. (2004) Environmental aspects of mechanical

recycling of PE and PET: a life cycle assessment study, Progress in Rubber, Plastics and

Recycling Technology, Vol. 20 No. 1, pp.6984.

Song, H.S. and Hyun, J.C. (1999) A study on the comparison of the various waste management

scenarios for PET bottles using the life-cycle assessment (LCA) methodology, Resources,

Conservation and Recycling, Vol. 27 pp.267284.

von Krogh, L., Lerche Raadal, H. and Jorgen Hanssen, O. (2001) Life Cycle Assessment of

Different Scenarios for Waste Treatment of as Plastic Bottle Used for Food Packaging,

OR 39.01, Ostfold Research Foundation.

White, P.R., Franke, M. and Hindle, P. (1995) Integrated Solid Waste Mangement- A Life Cycle

Inventory, Gaithersburg, MD, USA, Aspen Publishers Inc., Chapman & Hall, New York.

138

R.K. Foolmaun and T. Ramjeawon

Bibliography

Clift, R., Doig, A. and Finnveden, G.(2000) The application of life cycle assessment to integrated

waste management. Part I. methodology, Trans. IchemE., Vol. 78(B), p.279287.

Consoli, F., Allen, D., Boustead, J., Franklin, W., Jensen, A.A., de Oude, N., Parrish, R.,

Perriman, R., Postlethwaite, D., Quay, B., Seguin, J. and Vignon, B. (Eds.) (1993) Guidelines

for Life Cycle Assessment: a Code of Practice, SETAC, Brussels.

CSO (2005) Government of the Republic of Mauritius. Report of the Central Statistical Office,

Digest of Environment Statistics for the Year 2005, Port Louis, Republic of Mauritius.

GoM (2000) Government of the Republic of Mauritius, Report of the Ministry of Economic

Development, Productivity and Regional Development, Feasibility Study Final Report on

Environmental Solid Waste Management Programme, Mauritius, and prepared by

Fichtner GmBh. for the Republic of Mauritius, Chapter 2, Port Louis, Republic of Mauritius,

pp.2-12-48.

GoM (2002) Government of the Republic of Mauritius. Report of the Ministry of Environment,

Meeting the Challenges of Sustainable Development, Port Louis, Republic of Mauritius, p.169.

McDougall, F.R., White, P., Franke, M. and Hindle, P. (2001) Integrated Solid Waste Management,

A Life Cycle Inventory, 2nd ed., Blackwell Science.

Oodit, D. (2004) A Comparative Life Cycle Assessment of the Roof Construction Materials Used in

the Mauritian Housing Sector, MSc Environmental Engineering dissertation, University of

Mauritius, Reduit, Republic of Mauritius, p.77.

SETAC (1991) A Technical Framework for Life Cycle Assessments, Society for Environmental

Toxicology and Chemistry, Washington DC.

Tan, R.R. and Culaba, A.B. (2002) Environmental Life-Cycle Assessment: A Tool for Public and

Corporate Policy Development, p.12, www.lcacenter.org/library/pdf/PSME2002a.pdf-, date

accessed July 2005.

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Form16 Fiserv 2018-19Документ8 страницForm16 Fiserv 2018-19SiddharthОценок пока нет

- Broken Needle Policy ProcedureДокумент2 страницыBroken Needle Policy ProcedureSatya TripathiОценок пока нет

- Corporate Crime Project FinalДокумент32 страницыCorporate Crime Project Finalankita100% (1)

- Amazon Dupont Citation and Notice, May 2021Документ9 страницAmazon Dupont Citation and Notice, May 2021GeekWireОценок пока нет

- Marketing: What Are The Goals of Marketing?Документ2 страницыMarketing: What Are The Goals of Marketing?Marlon EllamilОценок пока нет

- Governance of Cybersecurity: 2015 Report: How Boards & Senior Executives Are Managing Cyber RisksДокумент45 страницGovernance of Cybersecurity: 2015 Report: How Boards & Senior Executives Are Managing Cyber Risksleo5880Оценок пока нет

- Competitive Markets: T T T T Multiple Choice QuestionsДокумент12 страницCompetitive Markets: T T T T Multiple Choice QuestionsLance TizonОценок пока нет

- JJM Operational Guidelines PDFДокумент132 страницыJJM Operational Guidelines PDFEE WS100% (3)

- Amena Akter Mim 1620741630 - SCM 320 Individual Assignment 1Документ10 страницAmena Akter Mim 1620741630 - SCM 320 Individual Assignment 1amena aktar MimОценок пока нет

- Introduction To Strategic ManagementДокумент16 страницIntroduction To Strategic ManagementNelsie PinedaОценок пока нет

- Engl 6Документ2 страницыEngl 6JJ JaumОценок пока нет

- MIS Practical FileДокумент27 страницMIS Practical FileSukhdeep SinghОценок пока нет

- Project Element Response: Project Name Today's Date Project Start Date Target Completion DateДокумент2 страницыProject Element Response: Project Name Today's Date Project Start Date Target Completion DatezidisamirОценок пока нет

- English For Business CorrespondenceДокумент7 страницEnglish For Business CorrespondenceNurviana PramestiОценок пока нет

- Od 330390050476522100Документ3 страницыOd 330390050476522100rjvОценок пока нет

- Matching Supply With Demand Solutions To End of Chapter Problems 4Документ6 страницMatching Supply With Demand Solutions To End of Chapter Problems 4Omar Al-azzawi100% (1)

- Startup MCQ 2Документ7 страницStartup MCQ 2bhupesh joshiОценок пока нет

- Hopfloor: Mandate Trade UnionДокумент36 страницHopfloor: Mandate Trade UnionGugutza DoiОценок пока нет

- BI1001268978 - 1800792430MHC12023 - 06062023 - 1421 (1) MaxicareДокумент1 страницаBI1001268978 - 1800792430MHC12023 - 06062023 - 1421 (1) MaxicareJanet CafrancaОценок пока нет

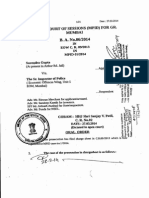

- Surendra Gupta Refuse To Pay NSELДокумент2 страницыSurendra Gupta Refuse To Pay NSELBhoomiPatelОценок пока нет

- BCom - SEM 4 2024 - UДокумент9 страницBCom - SEM 4 2024 - UarunvklplmОценок пока нет

- CTC PICC Catalogue 2022Документ9 страницCTC PICC Catalogue 2022Navaneetha KrishnanОценок пока нет

- Taxation On Real Estate Transactions: A - B S. MДокумент37 страницTaxation On Real Estate Transactions: A - B S. MMcke YapОценок пока нет

- Homework Assignment 1 PDFДокумент2 страницыHomework Assignment 1 PDFDavid RoblesОценок пока нет

- Ms Thesis Last Final FinalДокумент54 страницыMs Thesis Last Final FinalgizaskenОценок пока нет

- Resume - Jatin Kumar NagarДокумент1 страницаResume - Jatin Kumar NagarVinayОценок пока нет

- Aggregations of Manufacturing Based On NACE Rev. 2Документ3 страницыAggregations of Manufacturing Based On NACE Rev. 2xdjqjfrxhiivnpОценок пока нет

- Axel Herrera Douglas Cárcamo: MBA With Emphasis in Technology - Systems Engineer - Degree in EconomicsДокумент2 страницыAxel Herrera Douglas Cárcamo: MBA With Emphasis in Technology - Systems Engineer - Degree in EconomicsAxel Juzto Morza PeraleZzОценок пока нет

- Document From Hassan RazaДокумент14 страницDocument From Hassan RazaAli RazaОценок пока нет

- Module 1 - List of Full PFRSДокумент4 страницыModule 1 - List of Full PFRSLee Suarez100% (1)