Академический Документы

Профессиональный Документы

Культура Документы

Assab MM40 140331

Загружено:

underscore1992Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Assab MM40 140331

Загружено:

underscore1992Авторское право:

Доступные форматы

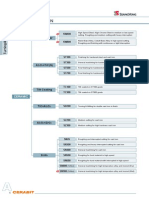

ASSAB MM40

ASSAB MM40

REFERENCE STANDARD

ASSAB DF-2

ARNE

ASSAB DF-3

AISI

WNr.

JIS

O1

(1.2510)

(SKS 3)

O1

(1.2510)

(SKS 3)

D6 (D3)

(1.2436)

(SKD 2)

RIGOR

A2

1.2363

SKD 12

SVERKER 21

D2

1.2379

SKD 11

D2

1.2379

SKD 11

ASSAB XW-5

SVERKER 3

ASSAB XW-10

ASSAB XW-41

ASSAB XW-42

CARMO

CARMO

1.2358

CALMAX

CALMAX

1.2358

CALDIE

CALDIE

ASSAB 88

SLEIPNER

ASSAB PM 23 SUPERCLEAN

VANADIS 23 SUPERCLEAN

(M3:2)

ASSAB PM 30 SUPERCLEAN

VANADIS 30 SUPERCLEAN

(M3:2 + Co)

ASSAB PM 60 SUPERCLEAN

VANADIS 60 SUPERCLEAN

VANADIS 4 EXTRA SUPERCLEAN

VANADIS 4 EXTRA SUPERCLEAN

VANADIS 6 SUPERCLEAN

VANADIS 6 SUPERCLEAN

VANADIS 10 SUPERCLEAN

VANADIS 10 SUPERCLEAN

VANCRON 40 SUPERCLEAN

VANCRON 40 SUPERCLEAN

ELMAX SUPERCLEAN

ELMAX SUPERCLEAN

1.3395

SKH 53

1.3294

SKH 40

(1.3292)

ASSAB 518

P20

1.2311

ASSAB 618

P20 Mod.

1.2738

ASSAB 618 HH

P20 Mod.

1.2738

ASSAB 618 T

P20 Mod.

1.2738 Mod.

ASSAB 718 SUPREME

IMPAX SUPREME

P20 Mod.

1.2738

ASSAB 718 HH

IMPAX HH

P20 Mod.

1.2738

NIMAX

NIMAX

MIRRAX 40

MIRRAX 40

VIDAR 1 ESR

VIDAR 1 ESR

UNIMAX

UNIMAX

CORRAX

CORRAX

ASSAB 2083

420 Mod.

H11

1.2343

SKD 6

420

1.2083

SUS 420J2

1.2083 ESR

SUS 420J2

1.2714

SKT 4

STAVAX ESR

STAVAX ESR

420 Mod.

MIRRAX ESR

MIRRAX ESR

420 Mod.

POLMAX

POLMAX

RAMAX HH

RAMAX HH

ROYALLOY

ROYALLOY

420 F Mod.

PRODAX

ASSAB MM40

ALVAR 14

ALVAR 14

ASSAB 2714

1.2714

SKT 4

H13

1.2344

SKD 61

H13 Premium

1.2344 ESR

SKD 61

4340

1.6582

SNCM8

ASSAB 709

4140

1.7225

SCM4

ASSAB 760

1050

1.1730

S50C

ASSAB 8407 2M

ORVAR 2M

ASSAB 8407 SUPREME

ORVAR SUPREME

DIEVAR

DIEVAR

HOTVAR

HOTVAR

QRO 90 SUPREME

QRO 90 SUPREME

ASSAB 705

ASSAB is a trademark of ASSAB Pacific Pte Ltd.

The information contained herein is based on our present state of knowledge and is intended to provide general notes on our products and their uses.

It should not therefore be construed as a warranty of specific properties of the products described or a warranty for fitness for a particular purpose.

Each user of ASSAB products is responsible for making its own determination as to the suitability of ASSAB products and services.

Edition 140331

ASSAB MM40

General

Properties

ASSAB MM40 is a high-strength beryllium

copper used for plastics moulding applications.

Its main properties include:

Physical properties

High thermal conductivity

Good corrosion resistance

Good polishability

Good wear resistance

Good resistance to galling

High strength and hardness

Good machinability

Excellent weldability

Be

1.9

Typical analysis %

Co + Ni

0.25

Delivery condition

Aged to ~40 HRC

Colour code

Black / Gold

Cu

Bal.

ASSAB MM40 is widely used for injection

moulding tools or as cores and inserts in steel

moulds. When used in steel mould, it effectively

cools hot spots, reducing or eliminating the need

for cooling channels. It is available in rounds,

plates, and welding wire.

ASSAB MM40's high thermal conductivity

(3 to 5 times better than steel) ensures uniform,

rapid heat removal leading to advantages such as:

Delivery condition.

Temperature

20C

200C

300C

Density

kg/m3

8 350

Modulus of elasticity

MPa

131 000

124 100

103 400

Coefficient of

thermal expansion

per C from 20C

17.5 x 10 -6

17.8 x 10 -6

Thermal

conductivity

W/m C

105

145

155

Specific heat

J/kg C

380

480

535

Mechanical Properties

Approximate values.

Hardness

40 HRC

Tensile strength, R m

1 280 N/mm2

Yield strength, Rp0.2

1 070 N/mm2

Elongation, A 5

6%

Reduced cycle time

Minimised part distortion / warpage

Reduced scrap rate

Applications

Blow moulds: pinch offs, neck rings and

handle inserts

Injection moulds: moulds, cores and inserts

Injection nozzles and manifolds for hot

runner systems

Comparison of different mould materials

thermal conductivity vs hardness

Positions are approximate and shown for

comparison only.

Thermal conductivity, W/mC

210

175

PRODAX

140

ASSAB MM30

105

ASSAB MM40

70

35

ASSAB 718 SUPREME

ASSAB 8407 SUPREME

STAVAX ESR

0

ASSAB MM40 neck parts of an extrusion blow mould.

10

20

30

40

Hardness, HRC

50

60

ASSAB MM40

Machining recommendations

ASSAB MM40 has a good machinability and can

be machined with conventional cutting tools. The

cutting data below are to be considered as guiding

values and as starting points for developing your own

best practice.

Condition: Delivery condition

Turning

Cutting data

parameters

Turning with carbide

Turning

with HSS

DRILLING

High-speed steel twist drill

Drill diameter

mm

Cutting speed (vc)

m/min

Feed (f)

mm/r

30 - 40

0.03 - 0.08

5 - 10

30 - 40

0.08 - 0.15

10 - 15

30 - 40

0.15 - 0.20

15 - 20

30 - 40

0.20 - 0.25

Rough

turning

Fine

turning

Fine

turning

Cutting speed

(vc)

m/min

270 - 300

300 - 370

60 - 90

Feed (f)

mm/r

0.3 - 0.6

0.3

0.3

Depth of cut (ap)

mm

2-6

Standard high-speed drills can be used but for best

performance the tip should be altered to a brass

point according to the figure below.

Carbide

designation

ISO

K20

K20

St'd.

When drilling holes deeper than 1 x drill diameter, use Peckdrilling

and retract the drill after each 5 mm drilled depth.

Reduce web

to produce

5 helix angle

Use tools with generous positive rake angles.

High-speed steel

Milling

Face and square shoulder milling

Cutting data

parameters

Milling with carbide

Milling

with HSS

Rough

milling

Fine

milling

Fine

milling

Cutting speed

(vc)

m/min

100 - 150

150 - 200

45 - 60

Feed (f z)

mm/tooth

0.2 - 0.4

0.1 - 0.2

0.1

Depth of cut (ap)

mm

2-5

Carbide

designation

ISO

K20

K20

5 helix angle

Plain

point

Brass

point

Threading

When tapping ASSAB MM40, use taps with straight

flutes. Use same kind of taps when tapping blind holes.

Use tools with positive rake angles when milling.

Standard

helix angle

High-speed steel

Suitable cutting speed 6 - 8 m/min.

End milling

Use cutting compound or cutting oil.

Type of end mill

Cutting data

parameters

Solid

carbide

Carbide

indexable

insert

High-speed

steel

80 - 100

150 - 200

45 - 601

Feed (f z)

mm/tooth

0.01 - 0.10 2

0.08 - 0.20 2

0.05 - 0.352

Carbide

designation

ISO

K20

Cutting speed

(vc)

m/min

1 For coated HSS end mill, an increased cutting speed of ~30% can

be used.

2 Depending on radial depth of cut and cutter diameter.

Grinding

Conventional grinding wheels can be used when

grinding ASSAB MM40.

Surface grinding, use A 54 LV-type of wheels.

Cylindrical grinding, use A 60 LV-type of wheels.

All grinding should be done wet to avoid breathing

metal dust.

ASSAB MM40

Heat treatment

Welding

ASSAB MM40 is delivered in the heat-treated

condition. ASSAB MM40 is intended for use in the

delivery condition, no further heat treatment is

generally required.

ASSAB MM40 can easily be welded if good

care is taken and good welding practices are

followed. The area to be welded should be

thoroughly cleaned with a degreasing solvent.

The always present oxidised layer should be

removed using aggressive brushing, sand blasting

or acid pickling immediately prior to the

welding.

Surface treatment

To enhance the surface properties of ASSAB MM40,

standard treatments can be applied.

Type of treatment

Benefits

Hard chrome

Wear resistance, corrosion

resistance, hardness

Electroless (chemical)

Nickel

Hardness, wear resistance,

surface release, corrosion

resistance

Electroless Nickel

with Teflon

Hardness, wear resistance,

surface release

PVD:

Titanium Nitride

Chromium Nitride

Superior wear resistance,

surface release

For best results TIG (GTAW) or MIG (GMAW) is

recommended. Suitable welding consumables are

available for welding ASSAB MM40. The preheating

temperature for welding is approx. 200C.

The weld and the surrounding area will show a lower

hardness. In order to bring the hardness of the weld

section into a similar hardness as the original base

material, the piece should be heat treated for

3 hours at 315C after welding.

Welding operations should be carried out using

properly designed local exhaust ventilation to

draw all fumes away from the operator and

through an appropriate filter before venting

outside of the work area.

Note: Treatment temperature should not exceed 320C.

Electrical discharge machining

While ASSAB MM40's high thermal conductivity

makes it slower to EDM than mould steel,

EDM'ing presents no significant problem.

Proper ventilation with an effective exhaust system is

essential to prevent fumes in the air.

Extrusion blow mould with ASSAB MM40 inserts.

ASSAB MM40

Polishing

Safe handling

ASSAB MM40 has very good polishability and

highly glossy surfaces are readily achievable.

ASSAB MM40 is a copper-alloy with a content

of ~2% Beryllium.

The following steps can serve as guidelines:

During the machining of ASSAB MM40, make sure

to avoid breathing metal dust, fume or mist. It

is recommended to perform machining, grinding

and polishing wet. If dry operation is needed, use

ventilation to capture the dust.

1. After grinding, pre-polish using successively

finer grit stones ending with a 600 grit.

2. Polish with diamond paste grade 15 to

obtain a dull satin looking surface.

Further information can be found in our

Material Safety Data Sheets.

3. Polish with a grade 6 diamond paste.

4. Polish with a grade 3 diamond paste.

5. If necessary, hand finish with a #1 grade

diamond paste.

As in all polishing, work thoroughness and

cleanliness are of utmost importance. In order

to avoid overpolishing, or orange peel effect,

do not polish longer than necessary to achieve

an even looking surface.

Further information

For further information, i.e., steel selection, heat

treatment, application and availability, please

contact our ASSAB office nearest to you.

ASSAB MM40

Ningbo

ASSAB Tooling Technology

(Ningbo) Co., Ltd.

Tel : +86 574 8680 7188

Fax: +86 574 8680 7166

info.ningbo@assab.com

Cikarang*

PT. ASSAB Steels Indonesia

Tel : +62 21 461 1314

Fax: +62 21 461 1306/

+62 21 461 1309

info.cikarang@assab.com

MALAYSIA

Kuala Lumpur - Head Office

ASSAB Steels (Malaysia) Sdn. Bhd.

Tel : +60 3 6189 0022

Fax: +60 3 6189 0044/55

info.kualalumpur@assab.com

Jiangxi*

ASSAB Tooling (Dong Guan)

Co, Ltd., Jiangxi Branch

Tel : +86 769 2289 7888

Fax : +86 769 2289 9312

info.jiangxi@assab.com

Choosing the right steel is of vital importance. ASSAB engineers

and metallurgists are always ready to assist you in your choice of

the optimum steel grade and the best treatment for each application.

ASSAB not only supplies steel products with superior quality, we offer

the state-of-the-art machining, heat treatment and surface treatment

services to enhance steel properties to meet your requirement in

the shortest lead time. Using holistic approach as a one-stop solution

provider, we are more than just another tool steel supplier.

ASSAB and Uddeholm are present on every continent. This ensures

you that high-quality tool steels and local support are available

wherever you are. Together, we secure our position as the world's

leading supplier of tooling materials.

For more information, please visit www.assab.com

Вам также может понравиться

- Assab - XW 10 D20140711Документ8 страницAssab - XW 10 D20140711Orlando CellanОценок пока нет

- Assab - XW 42 150216Документ8 страницAssab - XW 42 150216Rachmadi NorcahyoОценок пока нет

- ABRAuk Creusabro 4800Документ3 страницыABRAuk Creusabro 4800Anonymous 48jYxR1CОценок пока нет

- 701 Armox Workshop RecommendationsДокумент11 страниц701 Armox Workshop RecommendationssudhavelОценок пока нет

- 2205 InfoДокумент6 страниц2205 InfoMave75Оценок пока нет

- Aspac Royalloy enДокумент7 страницAspac Royalloy enNugroho Faris SudrajatОценок пока нет

- BS3100 A2Документ11 страницBS3100 A2AlexОценок пока нет

- Monel K500 PDFДокумент6 страницMonel K500 PDFOZAIRTRADELINKОценок пока нет

- ARTY - Aubert Et Duval - Produits - Longs - GB PDFДокумент6 страницARTY - Aubert Et Duval - Produits - Longs - GB PDFScott_B4UОценок пока нет

- Preheat Ions For A 514 Grade B MaterialДокумент2 страницыPreheat Ions For A 514 Grade B Materialjrod64Оценок пока нет

- Sandvik SAF 2205: Duplex Stainless SteelДокумент8 страницSandvik SAF 2205: Duplex Stainless SteelIuliu HurducaciОценок пока нет

- CRДокумент8 страницCRErfan EffendyОценок пока нет

- Corrax D20140714Документ8 страницCorrax D20140714mj_davis04Оценок пока нет

- DS482Документ3 страницыDS482mariomatoОценок пока нет

- Sumiten 780SДокумент2 страницыSumiten 780Sdiah131Оценок пока нет

- UR45 NPlusДокумент4 страницыUR45 NPlusMaiara Lima PereiraОценок пока нет

- EN24 and EN24T SteelДокумент3 страницыEN24 and EN24T Steelpatrik710Оценок пока нет

- Macsteel VRN - Wear Abrasion Steels - Creusabro 8000Документ4 страницыMacsteel VRN - Wear Abrasion Steels - Creusabro 8000jonodo89Оценок пока нет

- Cast Iron Welding AlloysДокумент4 страницыCast Iron Welding AlloysKhin Aung ShweОценок пока нет

- Technical Data: ApplicationsДокумент3 страницыTechnical Data: ApplicationssushmaxОценок пока нет

- Plates PDFДокумент10 страницPlates PDFkarthiksaadhanaОценок пока нет

- Calmax D20140711 PDFДокумент12 страницCalmax D20140711 PDFSinan YıldızОценок пока нет

- Fundamentals of Fabrication WeldingДокумент22 страницыFundamentals of Fabrication WeldingKevinОценок пока нет

- Basic Steel Selection Based On BS 970 en SeriesДокумент8 страницBasic Steel Selection Based On BS 970 en SeriesAmarendra Pendse100% (1)

- Manganese 12 14%Документ3 страницыManganese 12 14%Sreedhar Rakesh VellankiОценок пока нет

- 2 Grade InformationДокумент17 страниц2 Grade InformationAndres Alejandro RoblesОценок пока нет

- Raex 500Документ4 страницыRaex 500chara459254Оценок пока нет

- 010 - AR200 Product Data Sheet 2012 04 01Документ2 страницы010 - AR200 Product Data Sheet 2012 04 01Baihaki StОценок пока нет

- Duplex Stainless Steel WeldingДокумент25 страницDuplex Stainless Steel Weldingkdsenipah6667Оценок пока нет

- B Bã-Hler Nibas 70 20-Fd Fcaw 02Документ1 страницаB Bã-Hler Nibas 70 20-Fd Fcaw 02kamals55Оценок пока нет

- Piping FabricationДокумент36 страницPiping FabricationMouchartStéphanieОценок пока нет

- Data SAF2205 04Документ8 страницData SAF2205 04il_yoo_1Оценок пока нет

- Recomandari de Prelucrare A HardoxuluiДокумент8 страницRecomandari de Prelucrare A HardoxuluiEueueueueu12345Оценок пока нет

- Piping FabricationДокумент36 страницPiping Fabricationmurali100% (1)

- Secco Catalogo 1Документ16 страницSecco Catalogo 1emilio_707Оценок пока нет

- A 400 HB Wear Resistant Steel: StandardДокумент4 страницыA 400 HB Wear Resistant Steel: StandardVíctor SandovskyОценок пока нет

- Diamond and CBN English 07Документ26 страницDiamond and CBN English 07Vk PrabakranОценок пока нет

- Esab DublexДокумент8 страницEsab DublexSuphi YükselОценок пока нет

- Asaab 8407 - 2MДокумент11 страницAsaab 8407 - 2MPrabath MadusankaОценок пока нет

- Class: Er410 Aws: A5.9: Request A Quotedata Sheetmaterial Safety Sheetback To Products PageДокумент2 страницыClass: Er410 Aws: A5.9: Request A Quotedata Sheetmaterial Safety Sheetback To Products PageAditya PrajasОценок пока нет

- ASTM A514 GR H Data Sheet 2012 04 02 PDFДокумент2 страницыASTM A514 GR H Data Sheet 2012 04 02 PDFRodolfoMarínОценок пока нет

- 24UTP Railway GBДокумент8 страниц24UTP Railway GBwpsssamsungОценок пока нет

- SAF Welding Cutting GuideДокумент165 страницSAF Welding Cutting GuideSelvem0% (1)

- WC 6000Документ3 страницыWC 6000Sameer KhanОценок пока нет

- 60Si2Mn Spring Steel PDFДокумент4 страницы60Si2Mn Spring Steel PDFShubhamОценок пока нет

- WS Hws Hss Asp CPMДокумент12 страницWS Hws Hss Asp CPMGross Meltiade AlexanderОценок пока нет

- CoatingДокумент25 страницCoatingjayavardhan_99Оценок пока нет

- Astm A240 Uns S32205Документ3 страницыAstm A240 Uns S32205Mintone Sajayah BekabekaОценок пока нет

- Duplex Stainless Steel WeldingДокумент25 страницDuplex Stainless Steel WeldingcfcshakerОценок пока нет

- Cutting Edge BrochureДокумент2 страницыCutting Edge BrochureKen SmithОценок пока нет

- Sumihard 400 (ASM 400)Документ2 страницыSumihard 400 (ASM 400)jose wanderleyОценок пока нет

- S690QLДокумент4 страницыS690QLReginaldo Matias NunesОценок пока нет

- Pipe Steel Pipe CatalogueДокумент16 страницPipe Steel Pipe Cataloguezishanf_1Оценок пока нет

- CHEMICAL ANALYSIS (Max Values) : Hardness Range (Delivery Condition) : 370-430 HBW Heat ResistanceДокумент4 страницыCHEMICAL ANALYSIS (Max Values) : Hardness Range (Delivery Condition) : 370-430 HBW Heat ResistanceFilipe CordeiroОценок пока нет

- Duplex Stainless SteelsДокумент25 страницDuplex Stainless Steelspym1506gmail.comОценок пока нет

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Forging Operations - Machine Forging, Forging Dies and Special Forging OperationsОт EverandForging Operations - Machine Forging, Forging Dies and Special Forging OperationsОценок пока нет

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonОт EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonОценок пока нет

- Drilling Machine Definition, Parts, Operation, TypesДокумент19 страницDrilling Machine Definition, Parts, Operation, TypesMunem Shahriar100% (2)

- Asme B1.11-1958 (2016)Документ12 страницAsme B1.11-1958 (2016)vijay pawarОценок пока нет

- TravistheT Rex USTerminologyДокумент8 страницTravistheT Rex USTerminologyHaruka IchikoОценок пока нет

- Yarn Manufacturing McqsДокумент19 страницYarn Manufacturing Mcqssandip kumar mishraОценок пока нет

- Free Pattern: Black LadyДокумент9 страницFree Pattern: Black LadyMarina Assa80% (5)

- Wooden French Curves - Made at Techshop: Food Living Outside Play Technology WorkshopДокумент11 страницWooden French Curves - Made at Techshop: Food Living Outside Play Technology WorkshopRod HyattОценок пока нет

- Clamp Assembly PDFДокумент1 страницаClamp Assembly PDFPhap NguyenОценок пока нет

- Alpharetta Hoodie Vest: Designed by Kristin OmdahlДокумент4 страницыAlpharetta Hoodie Vest: Designed by Kristin OmdahlAnonymous SoUejG9100% (1)

- Short Notes On FabricsДокумент4 страницыShort Notes On Fabricsmaisura nayeemОценок пока нет

- List of Mills in CoimbatoreДокумент15 страницList of Mills in CoimbatoreSaravanan Thiruvalathaan75% (12)

- Thread Tolerances For Screws and NutsДокумент2 страницыThread Tolerances For Screws and NutsBill WhiteОценок пока нет

- Preguntas Cap 25 Manufactura ModernaДокумент7 страницPreguntas Cap 25 Manufactura ModernaJavierОценок пока нет

- LAVÉDRINE, Bertrand - Photographs of The Past. Process and PreservationДокумент368 страницLAVÉDRINE, Bertrand - Photographs of The Past. Process and Preservationgonzaleiton100% (4)

- Deco Square: Skill: Beginner/Intermediate US Terms MaterialsДокумент2 страницыDeco Square: Skill: Beginner/Intermediate US Terms MaterialsLeda María FracchiaОценок пока нет

- 21.01.11 Cowan Windows To GralcoДокумент39 страниц21.01.11 Cowan Windows To GralcomeghadurganОценок пока нет

- Multiple Choice Questions On Manufacturing Process and Production EngineeringДокумент3 страницыMultiple Choice Questions On Manufacturing Process and Production EngineeringrahmaОценок пока нет

- Worksheet Fasteners 360102 eДокумент7 страницWorksheet Fasteners 360102 eAndrew SpringОценок пока нет

- Vanished No More: Giant of Photography Roman Vishniac Finds A Home at The Magnes - Berkeley News 11.20.2018Документ7 страницVanished No More: Giant of Photography Roman Vishniac Finds A Home at The Magnes - Berkeley News 11.20.2018magnesmuseumОценок пока нет

- Lathe Machine Lab ReportДокумент5 страницLathe Machine Lab ReportEdgar ThorpeОценок пока нет

- Sliding Lid BoxesДокумент7 страницSliding Lid Boxesgmand68100% (1)

- Diy Wood StarsДокумент10 страницDiy Wood StarsDavid H. VargasОценок пока нет

- Dinosaurs PatternДокумент8 страницDinosaurs PatternbajarapunteОценок пока нет

- Grinding OperationsДокумент25 страницGrinding OperationsSundaram Jegatheesan100% (2)

- Spin PlanДокумент10 страницSpin PlanhaseebОценок пока нет

- Hes A3003-03 Chamfer of Thread EndДокумент5 страницHes A3003-03 Chamfer of Thread EndPreetam Kumar100% (1)

- Artssum 1 Performance 1Документ3 страницыArtssum 1 Performance 1Kes DimapilisОценок пока нет

- Metalman Product Catalogue PDFДокумент8 страницMetalman Product Catalogue PDFwilly0366Оценок пока нет

- Inel Si Cercei Cu Perle Semi ImbracateДокумент0 страницInel Si Cercei Cu Perle Semi ImbracateCer An83% (6)

- Texture: Launching The Imagina - On: A Comprehensive Guide To Basic DesignДокумент35 страницTexture: Launching The Imagina - On: A Comprehensive Guide To Basic DesignMoncef LazaarОценок пока нет

- Make A KnifeДокумент7 страницMake A KnifeAllan HannaОценок пока нет