Академический Документы

Профессиональный Документы

Культура Документы

1985 - Design and Optimization of Solar Steam Systems - Baer

Загружено:

hakeemniyasОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1985 - Design and Optimization of Solar Steam Systems - Baer

Загружено:

hakeemniyasАвторское право:

Доступные форматы

Solar Energy Vol. 35, No. 2, pp.

137-151, 1985

Printed in the U.S.A.

0038-092X/85 $3.00 + ,00

1985 Pergamon Press Ltd.

DESIGN A N D OPTIMIZATION OF SOLAR STEAM

SYSTEMS FOR C O N S T A N T LOAD APPLICATIONS

D . B A E R , J. M. GORDON and Y. ZARMI+

Applied Solar Calculations Unit, Blaustein Institute for Desert Research. Ben-Gurion University of

the Negev, Sede Boqer Campus. Israel 84990

(Received 29 November 1983; revision received 29 June 1984: accepted 9 Januao' 1985)

method is developed for the design and optimization of solar steam systems for constant

load applications. Analytic formulae are derived for yearly collectible energy and collector operating

time in terms of all important system variables and for all principal solar collector types. Examples

are presented to illustrate the simplicity and applicability of the method in sensitivity studies.

Abstract--A

periods without load, e.g. idle weekends, holidays

or shutdown for maintenance, then the yearly colMany industrial steam loads have a constant daylectible energy is simply reduced proportionally.

time load year round and hence may permit optimal

utilization of solar energy. Most steam loads are

furthermore in a temperature range (100-300C) for

2. BASIC DESIGNS

which a developed solar technology already exists.

Solar steam systems can be connected in parallel

The technical feasibility of solar steam production

or in series with backup. Parallel connection refers

has been demonstrated in a number of pilot proto a system in which the collector pump is not acjects[l].

tivated until some steam can be produced (and is

As there are both cost and performance penalties

turned off when steam can no longer be produced).

associated with the storage of (high-temperature)

Steam is delivered to the load at a variable rate (deheat, the first type of solar industrial process steam

pending on radiation) in parallel with the backup

systems to become cost effective will be systems

steam boiler. With a series connection, as soon as

without storage. Indeed, almost every pilot plant

the radiation is sufficiently high so that the solar

built to date is a no-storage system. These demsystem can deliver preheated return condensate (or

onstration projects have, however, been custommakeup water, as the case may be), the collector

designed, one-of-a-kind projects, and the design

pump is activated. The constant flow of return concost was a significant fraction of the total cost.

densate is passed through the collector field (via a

Large-scale computer simulations which require

heat exchanger, if necessary). Then preheated reextensive computer time and detailed meteorologturn condensate is fed directly to the backup boiler;

ical data have commonly been employed.

steam is delivered directly to the load.

Constant-load solar industrial process steam

The series connection has the advantage of

systems without storage have enough factors in

higher yearly collectible energy because collectors

common to permit the formulation of general design

can deliver preheated water even when radiation

principles[l]. The purpose of this paper is to conmay be insufficient to produce steam. Nonetheless,

sider the five basic designs for solar steam producnonthermal factors may dictate a parallel connection without storage, and for each one derive antion, e.g. greater ease in monitoring useful energy

alytic formulae for the yearly useful energy

delivered by solar, simpler controls and interface

delivered as a function of climate and all important

with backup steam boiler, greater safety factor, etc.

system variables: collector area; collector characAccordingly, our analysis below handles both parteristics; load characteristics; heat exchanger charallel and series connections.

acteristics (when applicable); piping; flow rates;

There are five basic modes of solar steam proand collector coolant properties. These analytic reduction without storage:

sults will not only make fundamental functional re!. Direct (in situ) steam production in the colleclationships evident, but will enable the designer to

tors, with parallel backup (Fig. 1);

perform rapid and inexpensive sensitivity and op2. Direct steam production in the collectors, with

timization studies. The analysis of this paper is

series backup (Fig. 2);

based on a load of 7 days/week. If there are daylight

3. Flash boiler (backup in parallel) (Fig. 3);

4. Steam production via a heat exchanger (unfired

t and Department of Physics, Ben-Gurion University

boiler), with parallel backup (Fig. 4); and

of the Negev, Beersheva, Israel

5.

Steam production via a heat exchanger, with

Research funded by the Belfer Foundation for Energy

series backup (Fig. 5).

Research, Ramat Aviv, Israel.

1.

INTRODUCTION

137

138

D. BAEr~et al.

COLLECTORS

LOAD

MM

-"

Fig. 1. Direct (in situ) steam production in collectors with parallel backup.

In Figs. 1-5, Tin is the temperature of return condensate or makeup water (assumed to be near constant); Tp is the temperature at which saturated

steam is to be delivered from the solar system into

the plant steam header (typically a few degrees

above the process steam temperature); rhp is the

constant process steam flow rate; rhc is the flow rate

in the collector loop; Tc and Th are the collector

inlet (cold) and outlet (hot) temperatures, respectively, when a heat exchanger is employed; and Ac

is the collector area.

When solar and backup are in series (Figs. 2 and

5), the collector flow rate is equal to the process

flow rate rhp. When solar and backup are in parallel,

however, a variable flow rate per collector area is

required, with the quantity of steam produced by

solar varying with radiation (and ambient conditions). The words "per collector area" are stressed

here because the heat balance equations governing

collector performance (see Sections 3-8) depend on

inc/Ac and not on rh or Ac only. There are, therefore,

two ways to achieve variable thc/Ac. One way is to

require that steam be produced on but one pass

through the collectors, and vary the flow rate (e.g.

by a variable speed pump controlled by sensors/

microprocessor) according to the radiation level.

That is, vary rhc at fixed A,.. A second way is to

circulate fluid through the collectors at a constant

flow rate (via a simple one-speed pump) as many

times as is necessary to produce steam. That is, for

STEAM

ICO''ECTO.SII

BYPASS

I

""

mp

I

T

i{

t'~

LOAD

.

1 n

Fig. 2. Direct steam production in collectors with series backup.

Design and optimization of solar steam systems

139

TP

-~COL

L E CT ORS

FLASH

TANK

VALVE

LOAD

Tin

<

MM

<

Fig. 3. Flash boiler (parallel backup).

Th

T

COLLECTORS

I

m

HEAT

EXCHANGER

Tc

ILOAD

Tin

Fig. 4. Steam production via heat exchanger (unfired boiler) with parallel backup.

ST EArl

COLLECTORS

HEAT

XCHANGER

BYPASS

XJ

ILOAD

T

Fig. 5. Steam production via heat exchanger with series backup.

140

D. BAER et al.

a given moment of steam production, the fluid element " s e e s " an effective collector area equal to the

actual collector area times the number of passes

required to produce steam. This is an example of

rh< at variable A , . To a first approximation, collector thermal performance cannot distinguish between the two flow strategies.

Of the five modes noted above, direct (in s i t u )

steam production with backup in series must have

the greatest yearly collectible energy (for fixed A<,

location, load, etc.), because the collectors are operated at the lowest temperature possible, and

credit is given for preheating. Without detailed

knowledge of system and load characteristics, one

cannot predict the relative ranking of the other four

modes. Since secondary considerations, such as

pumping energy requirements, often render a superficially optimal design nonoptimal[2] (as can be

the case for direct steam production where pumping

energy can become very large relative to other

modes), our analyses below include analytic

expressions for both yearly collectible energy and

yearly collector operating time.

If one can derive an expression for instantaneous

collector performance for no-storage systems, then

an integration of the instantaneous performance

equation over the cumulative frequency of occurrence of radiation values on the collector aperture

represents the solution for yearly collectible energy. The correct result is obtained without computer simulation by evaluating one integral, as will

be shown below in Sections 3-8. Hence the analytic

formulae derived below are as valid as the approximations made in deriving instantaneous performance.

collector inlet temperature, Ti.:

n = F R [ ~ o -- ( U I I ) ( T i ,

T,)]

(3.2)

with

FR = ~

1 - exp

rh~C J J '

(3.3)

where C is the specific heat of collector coolant

fluid. F o r cases in which C has a temperature dependence, we approximate C by its average value

over the operating range of interest.

The collector turn-on/turn-off threshold X is

either

X~n = ( U l ~ o ) ( T i ,

7"<,)

(3.4)

for series backup (Ti, = return condensate temperature), or

x,, =

(Ul'qo)(Tp

T,)

(3.5)

for parallel backup, where Xi, and X R are to be

based on the yearly average daytime ambient temperature. Seasonal or diurnal variations of the instantaneous threshold about its average have a negligible effect[6].

In all of our analyses, the effect of transients is

treated as negligible.

If the instantaneous rate of energy delivery from

the collector field is denoted by q, then the yearly

collectible energy Q for a system that never produces excess energy ( " d u m p e d " energy) is:

Q =

q.

(3.6)

all time

with I > X

3. BASIC C O N C E P T S AND A P P R O X I M A T I O N S

The calculation of system performance requires

as input the instantaneous efficiency curve of the

solar collector:

,q = F ' [ ' q o -

(UII)(T -

To)],

For constant X, the sum over time of eqn (3.6) can

be replaced by an integral over the (dimensionless)

cumulative frequency of occurrence of radiation

values on the collector aperture, f(I):

(3.1)

where ~1 is collector efficiency; "% is collector optical efficiency; U is collector heat loss coefficient;

is the average collector fluid temperature; T~ is

ambient temperature; I is solar irradiance in W/m 2

of aperture; and F ' is a factor to account for the

temperature difference between absorber and fluid.

If-q is nonlinear in 1" - Ta, one needs to approximate

-q by a straight line which gives the best agreement

at anticipated operating temperatures[5]. Since F '

is typically close to unity for collectors used in

steam-producing systems, the very small increase

in F ' when steam is produced directly in the collector will be neglected here. The small change in

collector U value due to steam production in the

collector will also be neglected.

Efficiency is alternatively expressed in terms of

Q = tmax

ff

q df

(3.7)

where/max is the number of seconds of daylight per

year (1.578 107); and f x = f ( I = X ) , given by

f(I)

= 1 + d~b/d(I/I)

(3.8)

with 7 denoting the long-term average radiation on

the collector aperture, and ~b denoting the utilizability function, defined as +(I) = Q ( I ) / Q ( O ) . Utilizability curves are commonly available for the

principal solar collector types in a wide range of

locations[7,8].

If instantaneous collector output exceeds the

load L, then some of the energy delivered by the

collectors is not utilizable ( " d u m p e d " energy). The

Design and optimization of solar steam systems

largest value of Ac for which no energy dumping

occurs, A d u m p , c a n be calculated from the instantaneous heat balance equation evaluated at peak

radiation, I .... :

q(I = I . . . .

Ac = Adump) =

L.

(3.9)

Furthermore, if A , > A d u m p then the value of radiation at which energy dumping begins (dump

threshold) la is determined from:

(3.10)

q(I = L~,A~.) = L.

Once Ia is known (for a given value of A,. > Adump),

one calculates the net yearly useful energy delivered by the collectors Qnet as:

[r

Q n e t = tmax _ _ _

kJYx

q ( I , A , . ) d f + L(1 - fa)

where f e = f ( 1 = Ia), and the L(1 - fd) term in

eqn (3.11) arises from the fact that for I > ld the

net useful instantaneous energy delivery from solar

is simply L.

In Sections 4-8, we will derive expressions for

q(l, Ac) for the five principal modes of solar steam

production, from which calculation of Qnet is

straightforward.

The yearly collector operating time, top, is simply[9]:

top/tr, a = 1 -- f x .

(3.12)

An exact treatment of cooldown heat losses is

complex and will not be attempted here. Rather,

since cooldown losses should be of the order of a

few percent of the yearly collectible energy in

properly designed systems, an approximate treatment should be satisfactory[10]. Cooldown losses,

Qcool, are estimated by:

Qcool =

~,

(MC)i(Tfinal- T~)

BACKUP

This system design is presented in Fig. I. Computer simulation studies of the performance and feasibility of in situ steam production were recently

presented in Refs, [2-4]. During collector operation, the collector inlet and outlet temperatures ai'e

constant at Tin and Tp, respectively, and in,./A, is

variable. The total length of the collector is divided

into two parts. Along the first part, a fraction y of

the total length, sensible heat only is delivered.

Along the remainder, a fraction 1 - y of the total

length, latent heat is delivered at constant temperature Tp.

Water temperature at a fractional distance y

along the collectors is[1 i]

= T~. + [ ( l ' q o / U )

+ Ta -

Tin]

[1 - e x p [ - F ' U A , . y / ( / n c C ) ] ] .

(4.1)

First, let us assume that the collectors never deliver

more energy than the instantaneous load, i.e. no

superheating occurs. The value ofy at which boiling

starts is determined by T(y) = Tp. Equation (4.1)

yields:

I

Xin]

y = [rh,.C/(F'UA~)] In [ / _ - - - ~ j

(4.2)

The latent heat of vaporization, H, is delivered at

constant temperature Tp along the remainder of the

collector, 1 - y. The corresponding heat balance

equation is:

/ n , H = F"qoAc(l - y ) ( l - Xp).

(4.3)

Now & c / A , can be eliminated from eqns (4.2)-(4.3),

yielding for y:

y = B/(1 + B) where B

system

components i

X [I - e x p [ - ( t y e a r - top)/(365"ri)]],

4. D I R E C T (IN SITU) S T E A M P R O D U C T I O N - - P A R A L L E L

T(y)

(3.11)

141

C'q,,

(3.13)

where i denotes components from which cooldown

losses occur (e.g. piping, collectors, flex hoses,

etc.); (MC)i is the thermal capacitance of each component i; "ri -- ( M C ) ( ( U A ) i (in s) is the response

time of each component i; (UA)s is the heat loss

coefficient from the component to ambient (in W/

K); tyca, is the number of seconds in a year (3.1536

107); top is expressed in s/yr; T2 is the average

nighttime ambient temperature; and Tn,aj is the collector fluid temperature at collector turnoff: either

Tfinal =

Tp for systems with backup in parallel, or

Tfinal =

Tin

for systems with backup in series.

= HU(I-

r I - Xin]

XpJ "

Xp) ln l_I _

(4.4)

Over the collector region where sensible heat is delivered, the average fluid temperature T is:

= (l/y) fo ~' T(y') dy'

which with eqn (4.1) yields

(4.5)

= (l~qo/U) + T, +

kt

142

D. BAERet al.

The yearly collector operating time, based on the

threshold Xp, is [eqn (3.12)]:

This corresponds to a threshold X of

= (u/~,,)(~-

L,)

r

=I+

Xp-Xi,

-?)--Z

top/trnax = I -- fp.

"

(4.6)

"

(4.13)

The calculation of piping losses is also straightforward since the collector inlet and outlet temperatures are constant (Tin and Tp, respectively).

The instantaneous energy delivery q is then

S. DIRECT STEAM PRODUCTION--BACKUP IN SERIES

In this mode of operation, illustrated in Fig. 2,

the collector flowrate is equal to the process flowrate, /n~, = rhp. The collector inlet temperature is

constant at Tin while the collector outlet temperature may vary with radiation. Two ranges of radia-

q(I, A,.) = AcF',qo[y(l - X)

+ (1 - y)(I - Xp)]

(4.7)

which with eqn (4.4) yields

"A,.F'.q,,(I - Xp)[l + (Xp - X~,)[Oqo/(UH)][

q(l, A,,) =

1 + (I

(4.8)

"I "

Xp)[C'qo/(UH)] In [ / - - ~ p [

Use of eqns (3.7) and (4.8) then yields the yearly collectible energy Q:

[I + (Xp - Xm)[C,qo/(UH)](l(f) - Xp) ]

'

(4.9)

---2Tin-

where I(f) is the inverse function of f(I); and fp = f ( l = Xp). Provided there is no energy dumping,

eqn (4.9) is the desired result for Q.

Next, the value of Adump is calculated with eqns (3.9) and (4.8) as

Aaumo = (L/F"q,,)

]-/max

.1 + (C'qo/(Un))(Imax

- Xi.]]

- Xp) In [/~ax = Z ]

(4.lO)

For A, > mdump, the dump threshold/,t is the solution to the transcendental equation obtained from

eqns (3.10) and (4.8):

(4.1 l)

and the net yearly useful energy Q,et is obtained from eqns (3.11) and (4.8) as

Q.o,

tm~x A,,F'.% fsi"

[.

(I(f__)) - Xp)[._...~I+ (Xp - X,,)[C'qo/(UH)] ]

x--[~7)-Zo]/df

1 + [C'qo/(UH)](l(f) - p)In [ / ~ 7 X-pp]J

}

+ L ( 1 - S~) ,

(4.12)

where fa = f ( l = la). Equation (4.12), which will

typically be evaluated numerically, is the desired

analytic result for arbitrary collector area and system and load characteristics.

tion values are of interest here:

1. I > Xi,, but I still insufficient to produce steam;

and

2. I high enough to produce steam.

143

Design and optimization of solar sleam systems

L e t Imin denote the minimum radiation value at eqns (3.9)and (5.5)as

which the collectors begin to deliver latent heat at

temperature Tp, in addition to supplying all the sen- Qlatem = tm~xAcF%%

sible heat needed to reach Tp. /min is determined

from eqn (4.1) by requiring that y = 1 at I = lmi~

" rl(f)-X'"l](I(f)-X.)df

(where now inJA,, is a known constant):

xfz'm,,~[1-F--S--u~l

j m p CnL/-~_Xp

x.-x,.

lmin = Xp + [exp(F'UA,/(rh<.C)) - 1

(5.6)

"

(5.1)

For I > lmin, the fraction of collector length that

delivers sensible heat, y, is given by eqn (4.2) (while

the rest of the collector, a fraction 1 - y, delivers

latent heat), and the sensible heat delivered is simply m p C ( T . -- Tin). Hence the instantaneous sensible heat delivered by the collectors, q~e,sibl~, is:

q . . . . ible = A,.FR'qo(I - X,,)

/min ~" I > Xin

and Q is given by

Q = Qsensible + Qlatent

= t .... {a,Ftcqo [Id)(Xin) - Id)(lmi.)]

P

+ A,.F "qo ram

1 --

X,o]]

x~J J

[l(f)-

x In LT(f]

F' UAc

(I(f)

x,,)

(5.7)

dS}

(5.2)

q . . . . ible = #:rlpC(Tp -

Tin )

1 > Imin

If no energy is dumped, then the yearly collectible

energy delivered as sensible heat, Q .... ible, is obtained with eqns (3.9) and (5.2) as

Since neither Adump n o r Id depend on whether

backup is connected in parallel or in series, eqns

(4.10)-(4.11) give Adump and Id for this case as well.

The expression for Qnet(Ac > Adump) is then:

Qnet = /max (AcFR'qo[-Idi(Xin)

Q .... ible = tmax[A,.FRxloff~mi"(I(f) - Xi,) d f

+ #:npH(1 - fd) + AcF'xlo

X ~'~in '

+ t : n p C ( T p - T , n ) f/m, d f ]

= tmax [acFR'qo [ f f l n ( I ( f ) - gin) d f

- Id)(Imin)]

(I(f)

thpC In [ l ( f ) F'UAc

Ll--~)

Xp) d r }

x l]

(5.8)

(5.3)

The yearly collector operating time, based on the

turn-on threshold X~,, is [eqn (3.12)]

+ trl.C(Z. - Tin)(1 - fmin) 1

top/tma = 1 - fi,.

= tmaxAcFR"qo[l~b(X,n) - I~b(Imin)]

Piping losses can again be estimated in a straightforward manner as follows. For Im~n > I, the collectors function as preheaters (sensible heating)

only, and the formalism presented in Refs. [1] and

[12] is appropriate, in which one simply renormalizes "qo and U. F o r I > Imin, both collector inlet and

outlet temperatures are fixed (Tin and T,, respectively), and the calculation of line losses is relatively simple. Since one also knows the yearly collector operating time with Ira,. > I, namely, top(Imin

> I) = tmax(1 -- fmin), these two calculations for

piping losses can be correctly time weighted.

fin

where

= f ( I = Xi.), fmin = f ( l = Imin), and

the two integrals in eqn (5.3) are over the periods

of time during which radiation is insufficient and

sufficient to produce steam, respectively.

The instantaneous heat balance equation for latent heat delivery, qlatent, is:

qlatent ---- A,F"qo(l - Xp)(l - y)

(5.4)

which, with eqn (4.2), can be expressed as

qlatent =

A,.F"qo(I -- Xp)

x

F'UA,.

(5.9)

6. FLASH BOILER

II - x.J

"

(5.5)

If no energy is dumped, then the yearly collectible

energy delivered as latent heat, Qlatent, is given by

The instantaneous heat collected for the flash

boiler configuration drawn in Fig. 3 has been derived in Ref. [1]:

q - A,.FyFn-qo(l - X,),

(6.1)

144

D. BAER e t al.

where

Ff

7. STEAM PRODUCTION VIA HEAT EXCHANGER

(UNFIRED BOILER)--BACKUP IN PARALLEL

A,.FRU(Tp

Tin)

-'

Lknf(-CT~-- ~.) {- ~,.H]]

= [1 - [

In this configuration, shown in Fig. 4, steam can

be produced by varying the flowrate in either the

collector loop or the heat exchanger loop, while the

other is held constant (for convenience). In order

to model this system, the heat exchanger is divided

into sensible and latent sections (see Fig. 6)[1]. The

five governing heat balance equations are:

(6.2)

is a correction factor which accounts for the effect

of the flash boiler on collector performance. If no

energy is dumped, Q is given by [eqn (3.9)]:

Q = tm,A,.FfFR'qo

ff

( I ( f ) - Xt,) d f

(6.3)

(t:rlC)c( Th -- Ti) =

= tmaxacFfFR'qj+(Xp).

Adump is determined from eqns (3.3), (6.1) and

(6.2) as

(UA),(Th - T,)

[ T h - - Tp]

In [Ti _ TpJ

Boiler

(7.1)

gUH

Adump

t h c C In

F'U

/max -- Xp

-1

(thC),.(Th - Ti) = inwH

vloC

Im~ -- Xp - g(Xp - Xi,)

ffnC)c(T,- Tc) =

where L = inp(C(Tp - Ti,) + H) has been assumed, and g = rnp/inc. For A,. > Aoump, the dump

threshold Ia is given by [eqn (3.10)]:

(6.5)

AcFR[I~o-

~ ( I ( f ) - Xp) d f

(6.6)

top/tmax = 1 -- fp.

(6.7)

Piping losses can be evaluated with the procedure

described in Refs. [1] and [12], in which -% and U

are simply renormalized according to piping and

system parameters.

(Tl+ Tp-Tw)[(--~--~[I~Io-U(T,.-

ZF-Rs

Tp - T w ) ~

[1"% - U ( T , . -

(7.3)

Preheater

(7.4)

Collector

(7.5)

T,,)]

where Ti is the outlet fluid temperature from the

boiler section on the collector side; (UA)I and

(UA)2 are the effective heat exchange UA products

for the preheating and boiling sections, respectively; and subscripts c and w denote collector and

water (heat exchanger or load) loop, respectively.

We approximate the U values of the sensible and

latent heating sections as equal (since the dominant

resistance to heat transfer occurs on the collector

side, this should be a good approximation), and assume a knowledge of the total heat exchanger UA

value, (UA)Hx: ( U A ) n x = (UA)I + (UA)2.

Equations (7.1)-(7.5), five equations in five unknowns ( ( U A h or (UA)2; Th; 7",.; Ti; and rh,. or rh,,),

can be reduced to one equation in one unknown,

To:

ff

Since the turn-on threshold is X;, the yearly collector operating time is

----

U(Tc-

= (~nC),.(Th - To)

= tmaxAcFyFR"qo[I~b(Xp) - l~b(Ia)].

T,,))

(mC)c(Ti - To) = ffnC)w(Tp - T,,)

+ L(1 - fa)]

0 = In

(UA)2(Ti - Tp - ( T , . [ T, - Tp ]

In L T,, - Tw]

Preheater

Qnet is then [eqn (3.11)]:

Qnet = tmax A,.FyFR'qo

(7.2)

'

(6.4)

Id = Xp + L/(AcFfFs~qo).

Boiler

T , ) ] + T , . - Tp]

.

T.)] + ( L - -

Tp)(T, + Tp - Tw)

+

1 -

I AcFR . . . . . . .

L(--~ [ I x l o - U(T~- Ta) ]

(~,,- T~)A~FR

x

In[

(-rh--~

- ( UA)ttx/(inC),.,

[hol-U(Tc-Ta)]+(Tc-Tp)(T-S_

+

, Tp-Tw

-T'~)TT[

)]_(T[

+ Tp -- -T-~)

(7.6)

145

Design and optimization of solar steam systems

where T~ -- H/Cw; and we have taken thc as constant and known (this is the more common case in

actual practicet. Hence for every value of I > X,,

one can solve eqn (7.6) for T,. = T,(1). Then with

a knowledge of T,(I), q is given by:

q = A, F R ( I ~ , , - U[T,.(1) - T,,)]

(7.7)

so that if no energy is dumped, Q is given by [eqn

(3.7)]

Q = A,.F~no

f/

t,

[l(f) - XAIIf))I df

(7.8)

where X,. ~ ( U/~qo)(L. - T~). The procedure is then

to solve eqn (7.6) numerically for Tc(l) (Xc(1)), and

then perform numerically the integration in eqn

(7.8).

Adump is determined from eqns (3.3), (3.9) and

(7.7):

ffnC ),

Adump

An approximate but closed-form expression for

q (for the case of the unfired boiler with parallel

backup) has been derived in Ref. [1], wherein the

collectors are considered as suppliers of latent heat

only:

q = A,.FBFR"qo(I - Xt,)

where

FB=[ 1 [

A,.FtcU

]

+ [(rhC),.[exp((UA)t~x/(&C),,) - 1]]

'

(7.13)

For this approximate treatment, we can easily calculate Q:

l

Q = t,~A,.FBFRrlo

F' U

ff (l(f)

p

- Xp) df

= tmaxAcFBFR'qj~b(Xp).

ln [ 1 -

(7.12)

(7.14)

[ (thC)~[ImaxVlo -U~(T,.(lm~) - Ta)]] ]

(7.9)

adumo -

(&C), In

F'~

1 +

Setting q = L in eqn (7.12), we calculate Adumpas:

1

exp((UA)tc~g(~nC),.) - 1

(mC)c'qo(lm~ - Xp)

UL

(7.15)

and ld as

(7.16)

lj = Xp + L/(A,FBFR'qo).

Qnet is then:

Q.~t = tmax [ AcFRF#qo ~ Y~d ( I ( f ) -- Xp) df + L(I - fd)]

(7.17)

= tm,xa,.FBFR'qo[l+(Xp) - Iqb(ld)].

A solar steam system with backup in parallel produces steam during its entire operating time, and a

very large fraction of collector area delivers the latent heat of vaporization (as opposed to the sensible

as

heat part of steam production). Hence the approxla = L/(AFn'qo) + (U/,qo)(T,(ld) - T,) (7.10) imation of eqn (7.12) and the resulting calculations

[eqns (7.14)-(7.17)] turn out to be within a few perTc = T , ( I d )

cent of the exact treatment above [eqns (7.7)where eqns (7.10) must be solved simultaneously (7.11)] for typical solar steam system parameters.

and numerically for Id. Once Id, and hence fd, is

The yearly collector operating time is

known, Qnet is calculated from [eqn (3.11)]:

which is a transcendental equation for Adump because T,.(Ima) depends on Adu,w. The dump threshold, ld, is obtained from eqns (3.3), (3.10) and (7.7)

top/tmax =

Q,~t = tma[a,.Fn~.~a[I(f)'qo

- U(T,(I(f)) - 7",)] d f + L(I -

fa)]/

(7.11)

1 -- f p .

(7.18)

Piping losses can be estimated as described above

for the flash boiler case[l, 12].

146

D. BAER et al.

8. STEAMPRODUCTIONVIA HEAT EXCHANGER-BACKUP tem (in analogy to the analysis of Section 7, in

IN SERIES

which the heat exchanger is divided up into sensible

and latent heating sections):

For the system illustrated in Fig. 5, the flow rates

in both the collector and heat exchanger loops are

( U A ) j ( T h - T~)

constant, the latter being equal to &p. With series

(&C),(L,

- L) =

backup (as noted above in Section 5), there will be

a radiation value, I m i n , below which sensible heatIn LT.

_~.j

ing only can be delivered by the collectors. The

instantaneous heat balance equation for a solar colBoiler (8.6)

lector delivering sensible heat only at constant flow

rate and via a heat exchanger can be expressed

( U A ) 2 [ T i - Tp - ( T o - T.,)]

(rhC)c(L- T,)=

as[l 1]

_

In [ L

q = A,K~FR'qo(I - Xi.)

(8.1)

Preheater

where

F~ = [1

,,FRU

+ A(mC),-[ [ lmCl,

(8.7)

(&C).(Ti - L ) = (&C),,(T. - T,,.)

Preheater

(8.8)

(8.2)

where ( F ~ / C ) m i n = MIN((rhC),, rht,C,,.); and ~ is the

heat exchanger effectiveness.

For I > Imm, solar provides all the sensible heating, which is &pC(Tp - Tin), so that I ~ . can be

obtained from solving the instantaneous heat balance equation:

AcF.~FR~q,,(lmi.

Xin)

&pC,,,(Tp

A,.Fn[l'qo-

FRUA, [111,,

. . . . . . /--U -+

(&C), L

T.-

7",.] + T ~ . - TpJ

......

+T,.-Tp

(8.3)

The instantaneous sensible heat delivery, q .... ib~,

is then

, ]

(&C),.

In /

(--~)~---

ible

tnpCw(Tp - Tin)

I > Imin

I > Xin

tmax AcK~Fn'q,,

(8.10)

(8.4)

and, if no energy is dumped, the yearly collectible

energy delivered as sensible energy, Q .... ~b~, is

O .... ible

+]

T,-

-- ( O A ) H x / ( t ~ t C ) c

q ....

(8.9)

These four equations in four unknowns (T,. ; Th; Ti;

and A~ or A2) can be reduced to one equation in

one unknown, T,.:

0 = In

Imin >

Collector

= (&C),.(Th - L )

or

q .... ible = A,.I~FRxh,(I - Xi,)

T.)]

Tin)

U(T,.-

The solution for T,. as a function of I must be performed numerically. The instantaneous latent delivery, Oatcnt, is:

fffmin

i. ( l ( f ) - X i n ) d f

qlatent

+ I:npCw(Tp

--

Tin)

A,.FR(ITIo - U ( T , . -

rain df

T.))

Cn.C,,(T.

L.)

(8.11)

and the yearly collectible energy delivered as latent

heat, Qlatc,,, is

which, in analogy to eqn (5.3), yields

Q .... ible = tmaxA,F~FR'qo[ld~(Xin) -- Icb(Imin)].

(8.5)

When I > lmin (i.e. when latent heat is delivered),

there are four energy balance equations for the sys-

[ ['

Ql. . . . t = tmax AcFR

m,, [ l ( f ) ' q o -

U(T,(I(f))

- L,)I d f - CnpC,,.(T~ - Ti,)(1 - fmi,)]

(8.12)

Design and optimization of solar steam systems

147

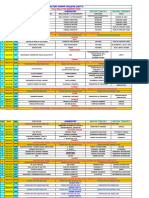

Table 1. Load, location and collector characteristics for examples of section 9

L a t i t u d e : 350

Location:

T a = 15C

y e a r l y average normal beam i r r a d i a n c e

T = 354 W/m2

p = 0.255 = f r a c t i o n

max

of d a y l i g h t

= 450 W/m2

= 936 W/m 2

hours during which c o l l e c t o r s

see no (beam) r a d i a t i o n

Load:

Tp = 200C

Tin = 90C

H = 1.96 x 106 J/kg

Collectors:

concentrators

tracking

The total Q for no-dump systems is then

ible

+ A,.FR

f;

-- Iqb(Imin)]

u(L.(I(f)tint, C , , ( T p -

ff

thpC.,(Tp

(I(f)n,,-

( a t 200C)

(8.15)

and piping losses can be evaluated as for the case

of the system with a heat exchanger with parallel

backup (see Section 7).

T~n)(1 - f m i . ) l

3

l~b(Imin)]

U(T,,(I(f))-

T,,))df

rain

axis

tov/t ..... = 1 - fi,

Q,ct = t .... [A~,F~FR,qo[7+(Xi,)

fd

F'n o = 0.70

horizontal

T,)] d f

The values of Aa,,np and I d a r e the same as for

the heat exchanger system with parallel backup

[eqns (7.9) and (7.10)] since Aaump and ld cannot

depend on the mode of backup operation. Q.~, is:

+ A,,FR

365 d a y s / y r

(8.13)

[l(f)n,,

rain

= I kg/s

where a very large fraction of collector operating

time (and area) is spent delivering latent heat, this

approximate treatment will again be accurate to

within a few percent of the treatment derived immediately above.

The yearly collector operating time is

+ Qi,t~,t

= tmax[AcFxFR'qo[]~b(Xin)

about n o r t h - s o u t h

F'U = 0.40 W/(m2-K)

Q = Q....

Cw = 4300 J / ( k g - K )

9. ILLUSTRATIVEEXAMPLES

We consider a constant load solar industrial process steam system for which the load, location and

collector characteristics are summarized in Table

1. The average solar radiation on the collector aperture, I, can be obtained for all the principal solar

collector types from the correlations of Ref. [6].

The utilizability function + used in our calculations

is the analytic formula of Refs. [7, 8]:

Ti.) + L(I - f d ) ] (8.14)

(9.1)

The accuracy of applying the approximate treatment of Ref. [1], eqns (7.12)-(7.17), directly to this where p is the fraction of daylight hours during

case of series backup will depend on collector area which the collectors see no radiation. For the val(and system characteristics). At small collector ues cited in Table 1, eqn (9.1) is:

areas, where a significant fraction of collector operating time is spent delivering sensible heat (pre=

(9.2)

heating) only, this approximate treatment is poor

and should not be employed. At large collector

areas (of the order of Adump and larger), however, The cumulative frequency distribution function,

148

D. BAER et al.

Table 2. Yearly collectible energy per collector area, Q/Ac, for direct steam production with

backup in series and in parallel

Ac (m2)

Q/Ac series (Gd/(m2-yr))

Q/Ac parallel (Gd/(m2-yr))

500

3.483

3.126

1000

3.405

3.126

1500

3.346

3.126

2500

3.276

3.126

4000

3.244

3.126

or

f(I), is then obtained from eqn (3.8) as

f(i)= 1-(l-p)

= 8.54 hr/day

while for backup in parallel,

1 - 9-~j

top/tmax = 1 -- f ( X p )

Based on a knowledge of f ( I )

thresholds

and the two

top = 1.045 107 s/yr

= 7.96 hr/day

and

Xp = (Uhqo)(Tp

- T,) = 106 W / m z,

= 0.712

FRO~I

Th

COLLECTORS

(Sections 5-7).

We now consider the relative thermal advantage

of series over parallel backup as a function of collector area for the case of direct steam production

(Sections 4, 5). For Ac < Adump with parallel

backup, Q is linear in Ac [eqn (4.9)], while with

series backup, Q increases less than linearly with

A,. [eqn (5.8)]. Adump = 4158 m 2 [eqn (4.10)] independent of parallel or series backup. Table 2 sum-

we can immediately calculate the yearly collector

operating time [eqn (3.12)]. For backup in series,

f(Xi,)

= 0.663

or

gin = (U/Xlo)(Tin - Ta) = 43 W/m 2

top/tmax = 1 -

(Sections 4 and 8),

(9.3)

I ]o.97

= 1 - 0.745

top = 1.123 x 107 s/yr

/ ~ a x f 'rex" - p ' / ' - J

1-

TO

LOAD

I

BOILER

(UA) 1

Ti I

I o

EATER

(UA) 2

mc

Tc

<

[.Tin

mw

<

Fig. 6. Boiling and preheating sections of heat exchanger (when latent is delivered). Thermal power

/n~H and (inC)w(Tp - Tin)are delivered across the heat exchanger to the load loop in the boiling and

preheating sections, respectively.

Design and optimization of solar steam systems

149

1.00

f

t.)

,

v

c,

0.50

u

0.00

10

15

kg/s

Fig. 7. Dependence of yearly collectible energy on collector flow rate rh,. for flash boiler.

Q(~hc)/Q(th,, --* ~) is plotted vs. rhc for fixed A, = 1000 m 2. System parameters as in Table 1.

20000

S-

10000

0

0

5000

A c

m 2

000

Fig. 8. Dependence of net yearly collectible energy Qnet on collector area Ac for flash boiler, hl,./A,

is fixed at 0.005 kg/(s-mZ). System parameters as in Table 1. Adump = 4210 m 2.

150

D. BAER et al.

1.00

0

II

0.50

0.00

1

F'U

( W/m2K

Fig. 9. Dependence of yearly collectible energy on collector F'U value for flash boiler.

Q(F' U)/Q(F' U = 0) is plotted vs. F ' U for fixed Ac = 1000 m z. System parameters as in Table 1.

marizes these results, in which we see a thermal

advantage (in Q) of 9% at Ac = 500 m 2, which decreases as A , is increased, to 3% at Ac = 4000 m 2.

Next we consider the dependence of Q on collector flow rate th,. for the flash boiler configuration

(Section 6). Q depends on rh,, via both the FR [eqn

(3.3)] and Fs [eqn (6.2)] factors in eqn (6.3) and, if

A,, > Adump, via the rh,, dependence of the dump

threshold [eqn (6.5)] as well [see eqn (6.6)]. Figure

7 presents a plot of Q vs rh,, at fixed Ac = 1000 m E

(well below Aaump). Further sensitivity studies, illustrated in Figs. 8 and 9, include the dependence

of Q on Ac (at fixed thc/A,.) and of Q on the collector

F ' U value, respectively.

10. SUMMARY

In this paper we have derived analytic results

which make solar steam system design, sensitivity

and optimization studies readily calculable and conceptually clear. Fundamental functional relationships emerge along with an understanding of the

basic physics of the problem. The formalism developed herein is applicable to all collector types

provided the utilizability function (or cumulative

frequency distribution) is available. The power of

the analytic results derived above is that they enable one to calculate accurately yearly collectible

energy, pumping energy and piping losses on a programmable hand calculator and without necessitating extensive hourly meteorological data and computer time.

The calculational step of going from instantaneous to yearly performance for no-storage systems

is exact (barring the effect of transients). The two

primary sources of inaccuracy in the calculation of

yearly energy delivery are: (a) the inaccuracy of

curve fits to utilizability functions; and (b) simplifying assumptions made in deriving the instantaneous heat balance equations.

REFERENCES

1. C. F. Kutscher, R. L. Davenport, D. A. Dougherty,

R. C. Gee, P. M. Masterson and E. K. May, Design

approaches for solar industrial process heat systems.

Solar Energy Research Institute Report SER1/TR-2531356, Golden, CO (1982).

2. L. M. Murphy and E. K. May, Steam generation in

line-focus solar collectors: A comparative assessment

of thermal performance, operating stability, and cost

issues. Solar Energy Research Institute Report SERf/

TR-632-1311, Golden, CO (1982).

3. R. J. Pederson and E. K. May, Flow instability during

direct steam generation in a line-focus solar collector

system. Solar Energy Research Institute Report

SERI/TR-632-1354, Golden, CO (1982).

4. J, Vresk, Direct solar steam generating system. 3rd

International C.I.B. Symposium on Energy Conservation in the Built Environment, Dublin, Ireland

(1983).

5. P. I. Cooper and R. V. Dunkle, A nonlinear flat-plate

collector model. Solar Energy 26, 133 (1981).

6. A. Rabl, Yearly average performance of the principal

solar collector types. Solar Energy 27, 215 (1981).

7. J. M. Gordon and Y. Zarmi, The utilizabilityfunction:

1. Theoretical development of a new approach. Solar

Energy 31, 529 (1983).

8. J. M. Gordon and Y. Zarmi, The utilizabilityfunction:

2. Validation of theory against data-based correlations. Solar Energy 31, 537 (1983).

9. J. C. Mitchell, J. C. Theilacker and S. A. Klein, Calculation of monthly average collector operating time

and parasitic energy requirements. Solar Energy 26,

Design and optimization of solar steam systems

555 (1981); and J. M. Gordon and A. Rabl, Design,

analysis and optimization of solar industrial process

heat plants without storage. Solar Energy 28, 519

(1982).

10. R. Gee, A simple energy calculation method for solar

industrial process heat systems. Solar Energy Re-

151

search Institute Report SERI/TP-253-1871, Golden,

CO (1983).

11. J. A. Duffle and W. A. Beckman, Solar Engineering

of Thermal Processes. Wiley, New York (1980).

12. W. A. Beckman, Duct and pipe losses in solar energy

systems. Solar Energy 21,531 (1978).

Вам также может понравиться

- An Electrical Analog of A Flat-Plate Solar Water Heating SystemДокумент4 страницыAn Electrical Analog of A Flat-Plate Solar Water Heating SystemChih-yuan WengОценок пока нет

- Thermodynamic Analysis of Combined Open-Cycle-Twin-Shaft Gas Turbine (Brayton Cycle) and Exhaust Gas Operated Absorption Refrigeration UnitДокумент10 страницThermodynamic Analysis of Combined Open-Cycle-Twin-Shaft Gas Turbine (Brayton Cycle) and Exhaust Gas Operated Absorption Refrigeration Unitmce10Оценок пока нет

- Solar Power Plant Using Parabolic Trough by Model Predic Control Controlling Outlet TemperatureДокумент11 страницSolar Power Plant Using Parabolic Trough by Model Predic Control Controlling Outlet TemperatureirinmichaelОценок пока нет

- Pergamon Pii:: Energy Convers. MGMTДокумент11 страницPergamon Pii:: Energy Convers. MGMTJessica SilvaОценок пока нет

- Design of A Solar Organic Rankine Cycle Prototype For 1 KW Power OutputДокумент11 страницDesign of A Solar Organic Rankine Cycle Prototype For 1 KW Power Outputshilpi duttaОценок пока нет

- 06 Exergy Analysis GSДокумент41 страница06 Exergy Analysis GSAlexander ArboledaОценок пока нет

- Applied Energy: Ci. Ambrosone, A. Andretta, F. Bloisi, B. Coluzzi, S. de Stefano, GДокумент13 страницApplied Energy: Ci. Ambrosone, A. Andretta, F. Bloisi, B. Coluzzi, S. de Stefano, GResearcherzОценок пока нет

- 2002-Cervantes-Experiments On A Solar-Assisted Heat Pump and An Exergy Analysis of TheДокумент9 страниц2002-Cervantes-Experiments On A Solar-Assisted Heat Pump and An Exergy Analysis of TheJessica SilvaОценок пока нет

- F Chart Method Klein Duffie BeckmanДокумент10 страницF Chart Method Klein Duffie BeckmansergioОценок пока нет

- Performance of A Multi-Functional Direct-Expansion Solar Assisted Heat Pump SystemДокумент9 страницPerformance of A Multi-Functional Direct-Expansion Solar Assisted Heat Pump SystemAnonymous 4yqrYm3Оценок пока нет

- PB2Документ8 страницPB2Thor L. LemmingerОценок пока нет

- Analysis of The Dynamic Characteristics of A Single-Pressure Combined-Cycle Power PlantДокумент10 страницAnalysis of The Dynamic Characteristics of A Single-Pressure Combined-Cycle Power PlantIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- (2005) A. SencanДокумент13 страниц(2005) A. SencanHusnain AliОценок пока нет

- Thermal Performances of Stirling Engine Solar DrivenДокумент10 страницThermal Performances of Stirling Engine Solar DrivenHotzizleОценок пока нет

- Exergetic Optimization of Solar Flat Plate CollectorsДокумент6 страницExergetic Optimization of Solar Flat Plate Collectorslewist57Оценок пока нет

- A05060105 PDFДокумент5 страницA05060105 PDFinventionjournalsОценок пока нет

- Dynamics Model of Fire Tube Shell BoilerДокумент10 страницDynamics Model of Fire Tube Shell BoilerViro AkahanОценок пока нет

- Entropy 19 00394 With CoverДокумент9 страницEntropy 19 00394 With Coverarun rajaramОценок пока нет

- Modeling Simulation and Performance Evaluation of Parabolic TroughДокумент9 страницModeling Simulation and Performance Evaluation of Parabolic TroughVikas PatelОценок пока нет

- Gethermie ORCДокумент7 страницGethermie ORCSyaiful FuadОценок пока нет

- Modeling Research On A Solar Tower Thermal Collection-Natural Gas Turbine Power Generation SystemДокумент4 страницыModeling Research On A Solar Tower Thermal Collection-Natural Gas Turbine Power Generation SystemBORIS KAPLANОценок пока нет

- Research PaperДокумент9 страницResearch PapercroprobosОценок пока нет

- Thermal Performance of A Direct Expansion Solar-Assisted Heat PumpДокумент8 страницThermal Performance of A Direct Expansion Solar-Assisted Heat PumpJessica SilvaОценок пока нет

- SolarsДокумент11 страницSolars11751175Оценок пока нет

- Coefficient of Performance Under Optimized Figure of Merit in Minimally Nonlinear Irreversible RefrigeratorДокумент7 страницCoefficient of Performance Under Optimized Figure of Merit in Minimally Nonlinear Irreversible RefrigeratoraldoОценок пока нет

- C5008098319 PDFДокумент5 страницC5008098319 PDFRamkishan SahuОценок пока нет

- An Efficient Parabolic Dish Engine Based On Rankine CycleДокумент5 страницAn Efficient Parabolic Dish Engine Based On Rankine CycleAsepta Surya WardhanaОценок пока нет

- Thermoeconomic Evaluation of Combined Cycle Cogeneration Systems - MakaleДокумент8 страницThermoeconomic Evaluation of Combined Cycle Cogeneration Systems - Makaley_durОценок пока нет

- Air Standard Cycles - BasicsДокумент19 страницAir Standard Cycles - Basicsexpressive87Оценок пока нет

- PhysResInt 10 341016Документ10 страницPhysResInt 10 341016kannanmech87Оценок пока нет

- Optimal Chilled Water Delta-TДокумент8 страницOptimal Chilled Water Delta-Tanup_nairОценок пока нет

- A CFD Analysis of The Flow Structure Inside A SteamДокумент10 страницA CFD Analysis of The Flow Structure Inside A SteamvundavilliravindraОценок пока нет

- 07B - Feidt2007Документ11 страниц07B - Feidt2007SUSANA APAZA HUALLPAОценок пока нет

- Open WordДокумент10 страницOpen WordAbdla DoskiОценок пока нет

- PinchДокумент14 страницPinchYounes AgrouazОценок пока нет

- Numerical-Simulation and Experimental-Validation of The Largest Egyptian Solar Process-Heat SystemДокумент18 страницNumerical-Simulation and Experimental-Validation of The Largest Egyptian Solar Process-Heat Systemgazali belhajОценок пока нет

- MTH, +, Q/ + o Ak O.: Heat Recovery Systems Vol. 5. No. 5, Pp. 441Документ4 страницыMTH, +, Q/ + o Ak O.: Heat Recovery Systems Vol. 5. No. 5, Pp. 441Philip ShihОценок пока нет

- RECS Ecos2012 423Документ12 страницRECS Ecos2012 423Santiago Del Rio OliveiraОценок пока нет

- A.zerrouki Et El The Natural Circulation Solar Water Heater ModelДокумент11 страницA.zerrouki Et El The Natural Circulation Solar Water Heater ModelJuan-Pierre HerbothОценок пока нет

- Optimization of Combined Cycle Power Plant ReportДокумент14 страницOptimization of Combined Cycle Power Plant ReportbasharalhawarnaОценок пока нет

- Transient Analysis of A Photovoltaic-Thermal Solar Collector For Co-Generation of Electricity and Hot Air-WaterДокумент6 страницTransient Analysis of A Photovoltaic-Thermal Solar Collector For Co-Generation of Electricity and Hot Air-WaterUmer AbbasОценок пока нет

- Loyola Marymount RankineCyclerДокумент22 страницыLoyola Marymount RankineCyclerKevin LangleyОценок пока нет

- PJST12 1 152Документ9 страницPJST12 1 152Harman Preet SinghОценок пока нет

- Organic Rankine CycleДокумент8 страницOrganic Rankine CycleAytaç ŞanlısoyОценок пока нет

- Optimization of Energy Plants Including Water/lithium Bromide Absorption ChillersДокумент23 страницыOptimization of Energy Plants Including Water/lithium Bromide Absorption ChillersIgor Maciel O. SilvaОценок пока нет

- Energies: Performance Evaluation of Air-Based Heat Rejection SystemsДокумент28 страницEnergies: Performance Evaluation of Air-Based Heat Rejection SystemsLoken RizalОценок пока нет

- T.T. Chow, Z. Lin and C.L. Song City University of Hong Kong Hong Kong SAR, China G.Q. Zhang Hunan University Changsha, ChinaДокумент8 страницT.T. Chow, Z. Lin and C.L. Song City University of Hong Kong Hong Kong SAR, China G.Q. Zhang Hunan University Changsha, ChinaGiuseppeОценок пока нет

- 2015 - O Joneydi Shariatzadeh - Modelingandoptimizationofanovelsolarchimneycogener (Retrieved 2019-10-30)Документ10 страниц2015 - O Joneydi Shariatzadeh - Modelingandoptimizationofanovelsolarchimneycogener (Retrieved 2019-10-30)Min YikaiОценок пока нет

- 2nd Law Analysis of Brayton Rankine CycleДокумент19 страниц2nd Law Analysis of Brayton Rankine CycleJoao MinhoОценок пока нет

- Steam GeneratorДокумент8 страницSteam GeneratorFrancesco CordellaОценок пока нет

- 1 s2.0 1359431196000038 MainДокумент13 страниц1 s2.0 1359431196000038 Mainmeow1989Оценок пока нет

- The Effect of Collector Aspect Ratio On The Collector Efficiency of Flat-Plate Solar Air HeatersДокумент7 страницThe Effect of Collector Aspect Ratio On The Collector Efficiency of Flat-Plate Solar Air Heatersaxel_oscОценок пока нет

- Second Law Analysis If IC EnginesДокумент16 страницSecond Law Analysis If IC Enginesdjermounimohamed100% (1)

- Guidelines For Ethylene Quench Tower Rev 17Документ17 страницGuidelines For Ethylene Quench Tower Rev 17totongop0% (1)

- Finite Physical Dimensions Optimal Thermodynamics 1: FundamentalsОт EverandFinite Physical Dimensions Optimal Thermodynamics 1: FundamentalsОценок пока нет

- Statement of Purpose: I Also Believe I'll Be A Suitable Candidate To Carry Forward Work in This FieldДокумент1 страницаStatement of Purpose: I Also Believe I'll Be A Suitable Candidate To Carry Forward Work in This FieldhakeemniyasОценок пока нет

- Hydrogen Nexus in A Sustainable Energy FutureДокумент8 страницHydrogen Nexus in A Sustainable Energy FuturehakeemniyasОценок пока нет

- 2019 - Role of Porous Metal Foam On The Heat Transfer Enhancement For A TES Tube - YangДокумент15 страниц2019 - Role of Porous Metal Foam On The Heat Transfer Enhancement For A TES Tube - YanghakeemniyasОценок пока нет

- 2015 - Thermal Modeling and Performance Investigation of A Double Stage Metal Hydride Based Heat Transformer - SekharДокумент19 страниц2015 - Thermal Modeling and Performance Investigation of A Double Stage Metal Hydride Based Heat Transformer - SekharhakeemniyasОценок пока нет

- Case Studies in Thermal Engineering: SciencedirectДокумент12 страницCase Studies in Thermal Engineering: SciencedirecthakeemniyasОценок пока нет

- Numerical Melting Performance Analysis of A Cylindrical Thermal Energy Storage Unit Using Nano-Enhanced PCM and Multiple Horizontal FinsДокумент19 страницNumerical Melting Performance Analysis of A Cylindrical Thermal Energy Storage Unit Using Nano-Enhanced PCM and Multiple Horizontal FinshakeemniyasОценок пока нет

- 2002 - Performance of Annular Fins With Different Profiles - MokheimerДокумент12 страниц2002 - Performance of Annular Fins With Different Profiles - MokheimerhakeemniyasОценок пока нет

- Institute Calendar 2017 18 v2Документ68 страницInstitute Calendar 2017 18 v2hakeemniyasОценок пока нет

- Unit - 2: Lathe - The Turning MachineДокумент73 страницыUnit - 2: Lathe - The Turning MachinehakeemniyasОценок пока нет

- 1989 - Efficiency and Optimized Dimensions of Annular Fins of Different Cross-Section Shapes - UllmannДокумент6 страниц1989 - Efficiency and Optimized Dimensions of Annular Fins of Different Cross-Section Shapes - UllmannhakeemniyasОценок пока нет

- BR1472026470Electricity Systems and Future Scenario Pinakeswar MahantaДокумент2 страницыBR1472026470Electricity Systems and Future Scenario Pinakeswar MahantahakeemniyasОценок пока нет

- 1992 - Heat Transfer Enhancement in The Direct Contact Melting Process - SaitoДокумент11 страниц1992 - Heat Transfer Enhancement in The Direct Contact Melting Process - SaitohakeemniyasОценок пока нет

- Bhavikatti Engineering Mechanics SampleДокумент11 страницBhavikatti Engineering Mechanics SamplehakeemniyasОценок пока нет

- B.Tech ME 2016 v2Документ123 страницыB.Tech ME 2016 v2hakeemniyasОценок пока нет

- For Others: National Institute of Technology Tiruchirappalli - 620 015Документ2 страницыFor Others: National Institute of Technology Tiruchirappalli - 620 015hakeemniyasОценок пока нет

- Fundamentals of Numerical Modelling and Simulation of Multi-Physics and Multi-Domain SystemsДокумент2 страницыFundamentals of Numerical Modelling and Simulation of Multi-Physics and Multi-Domain SystemshakeemniyasОценок пока нет

- Academic Calendar (July Session) B.tech. (III and V) and B.arch. (III)Документ1 страницаAcademic Calendar (July Session) B.tech. (III and V) and B.arch. (III)hakeemniyasОценок пока нет

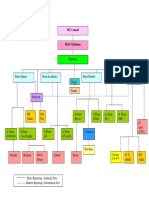

- 583 Nitt Org Chart v5Документ1 страница583 Nitt Org Chart v5hakeemniyasОценок пока нет

- 1987 - Multiphase Isenthalpic and Isentropic Flash Algorithms - MichelsenДокумент15 страниц1987 - Multiphase Isenthalpic and Isentropic Flash Algorithms - MichelsenhakeemniyasОценок пока нет

- Concept of PH and BufferДокумент27 страницConcept of PH and BufferRolling Coast100% (1)

- Principles of SpectrophotometryДокумент2 страницыPrinciples of SpectrophotometryVijay KumarОценок пока нет

- Synthesis of Fly Ash-Based Self-Supported Zeolites Foam Geopolymer Via Saturated Steam TreatmentДокумент14 страницSynthesis of Fly Ash-Based Self-Supported Zeolites Foam Geopolymer Via Saturated Steam TreatmentShabrina RaedyОценок пока нет

- Aspects of The Physical Chemistry of Starch: R. Parker and S. G. RingДокумент17 страницAspects of The Physical Chemistry of Starch: R. Parker and S. G. RingJavier NavarreteОценок пока нет

- PHYSICAL CHEMISTRY-phase Diagram 3 ComponentsДокумент22 страницыPHYSICAL CHEMISTRY-phase Diagram 3 ComponentsMuhammad YanuarОценок пока нет

- Haloalkanes Q BankДокумент7 страницHaloalkanes Q BankVishnuОценок пока нет

- 9 Different Types of Sheet Metal Operations With Diagrams Following Are The 9 Different Types of Sheet Metal OperationsДокумент15 страниц9 Different Types of Sheet Metal Operations With Diagrams Following Are The 9 Different Types of Sheet Metal OperationsAbdulbar kelilОценок пока нет

- 11th Chemistry Chapter 4 PDF Notes - Unlocked - OCRДокумент27 страниц11th Chemistry Chapter 4 PDF Notes - Unlocked - OCRamirbadshahОценок пока нет

- 5.4 - Organic Independat OtesДокумент5 страниц5.4 - Organic Independat Otesvarda9877Оценок пока нет

- Heat Exchanger PerformanceДокумент31 страницаHeat Exchanger PerformanceFA AyОценок пока нет

- Saft MieДокумент93 страницыSaft MiePatrice PariОценок пока нет

- Chapter 4: Absorbers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallДокумент11 страницChapter 4: Absorbers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallBaskar KannaiahОценок пока нет

- Liposomes 181012045701Документ55 страницLiposomes 181012045701Ravi ParasharОценок пока нет

- Heat 4e Chap02 LectureДокумент48 страницHeat 4e Chap02 LectureSubho Samanta100% (4)

- Alternative Cycles Based On Carbon Dioxide For Central Receiver Solar Power PlantsДокумент13 страницAlternative Cycles Based On Carbon Dioxide For Central Receiver Solar Power PlantsfaizaОценок пока нет

- Eamcet Track Sheet (2024)Документ2 страницыEamcet Track Sheet (2024)MAHESWARA RAO ThotaОценок пока нет

- Tutorial 8Документ3 страницыTutorial 8CHANDAN RAJОценок пока нет

- Leak CalcДокумент3 страницыLeak Calckisan singhОценок пока нет

- ElectrochemistryДокумент93 страницыElectrochemistrySrinivasanОценок пока нет

- Solved Multiple Choice Questions IE by NKB - PDF 116788864Документ15 страницSolved Multiple Choice Questions IE by NKB - PDF 116788864Pranav SharmaОценок пока нет

- CH 1002 Test 1 MK AnswersДокумент4 страницыCH 1002 Test 1 MK AnswersGift ChuluОценок пока нет

- Laboratory Manual: Bacis Physical ChemistryДокумент30 страницLaboratory Manual: Bacis Physical ChemistryNurul SafwahОценок пока нет

- Limit Tests (Autosaved)Документ53 страницыLimit Tests (Autosaved)Adithi ukОценок пока нет

- 01 Static ElectricityДокумент31 страница01 Static ElectricitySkyZz CSGOОценок пока нет

- Formulas in Cooling TowerДокумент6 страницFormulas in Cooling TowerGringoОценок пока нет

- Book To SeekДокумент148 страницBook To SeekDeXnt BachaОценок пока нет

- To Determine % Purity of The Given Sample of Mefenamic Acid by Titrimetric Method. Chemicals RequiredДокумент4 страницыTo Determine % Purity of The Given Sample of Mefenamic Acid by Titrimetric Method. Chemicals RequiredjerritОценок пока нет

- Lecture 2-Introducction To Thermal Unit OperationДокумент34 страницыLecture 2-Introducction To Thermal Unit Operationyemane gadaОценок пока нет

- Silica Colloidal Hydrated 0738eДокумент2 страницыSilica Colloidal Hydrated 0738eRoscol8Оценок пока нет

- Report - 1 - 12.12.2011Документ42 страницыReport - 1 - 12.12.2011rosha_friends4ever_noja100% (1)