Академический Документы

Профессиональный Документы

Культура Документы

OSP50-E - 1a - 400 Nov2013 - 1 PDF

Загружено:

Guillermo RamirezИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

OSP50-E - 1a - 400 Nov2013 - 1 PDF

Загружено:

Guillermo RamirezАвторское право:

Доступные форматы

50 years in pursuit of the ideal of Single Source for Machine & Control

The miracle of OSP evolution

Okuma Sampling Path control

Why has Okuma continued to create OSP for a full half-century?

Over the half century from the development of OSP in 1963, Okuma has continued creating to provide the

assurance of Single Source for Machine & Control and Only One functions that exceed customers expectations.

Our development concept has always been total responsibility from design to maintenance and repair,

conceived from shop floor situations.

How will OSP continue to evolve from now into the future?

Integration of technologies for machine, electric, information, and knowledge has promoted

knowledge creation on the shop floor, and continues to create a tide of technology.

Fusion of machine & control & Information

OSP-P200

2004

Fusion of

machine and control

CNC (microprocessor)

Fusion of machine &

control & Information &

Knowledge creation

CNC (soft-wired)

OSP-E100

Birth of

electronic control

OSP7000

NC (hard-wired)

1993

OSP5000

1981

1999

OSP-P300

2012

OSP3000

1979

2012

OSP2000

1972

2010

OSP

1963

2004

2001

1994 CNC control ATC

Machining Navi Worlds first

Collision Avoidance System Worlds first

Thermo-Friendly Concept Worlds first

Worlds first

1991 CNC for turret rotation control

1989

1987

1982

5-Axis Auto Tuning System Worlds first

Pioneering a new era with Single

Source for Machine and Control, an

Okuma Only One Technology

Easy-to-use 19" touchscreen

2013

Completely automatic process decision programming function

One-Touch IGF

Development of high-speed NC control technology that

became the foundation of Super-NURBS

Brushless servo motor (digital servo control)

1981 IGF (Interactive Graphic Function)-L

1971

Lathe auto programming (LAP)

OkumaYour Single Source for

Machine & Control

However, commercial-use semiconductor memory

products were not available at that time, so absolute

position feedback with current position memory even if the

power was cut off was still a mere dream. Okuma, a

company constantly in pursuit of the highest ideals in

machine tools, achieved this dream thanks to its willpower

and pride as an organization that had been keeping a

watchful eye on the manufacturing industry.

An NC machine (OSP ) utilizing an absolute position

feedback system was developed in 1963, marking Okumas

debut as Japans only mechanical-electronic manufacturer

producing both machine tools and NC devices.

The absolute position

feedback system

Flexible software

Okuma-Built Controls, Motors,

Drives and Encoders

In 1972 we developed the OSP2000 series of NCs with

built-in minicomputersthe worlds first commercial

computerized NCs (CNCs).

In 1970 NCs were hard-wired NCs with circuits

designed, wired, and assembled specifically for the

machine to be controlled. This meant that changing

specifications or adding options took a huge amount of

time. Replacing these circuits with software made it easy to

change specifications or add optional functions.

Flexible software was planned with the expectation that

customers operating methods and machining techniques

would change over the years they used a machine tool.

This was a very forward-looking way of thinking in the days

when these CNCs were developed.

The technical combination of these Okuma-built

components, creates the foundation of accuracy that all

computer numerical control (CNC) machines require. The

harmonious communication between these units not only

allows Okuma machine tools to have some of the highest

metal removal rates, but also gives positioning repeatability

in the single digit micrometer range. Day in and day out,

even in the most unpredictable environments, Okuma's

complete drive system package delivers perpetual strength

and accuracy.

The absolute position feedback system, which is capable of

sequence return (upon restart of machining that has been

stopped partway through) so zero return setting is not

required, was an essential and fundamental feature from

the customers point of view.

Single Source for Machine & Controlthe

and knowledge creation. This has been

foundation for machine, control, information,

Okumas unchanging philosophy towards OSP

History of OSP development

Birth of electronic

control

Birth of electronic

control

Fusion of machine

and control

NC (hard-wired)

CNC (soft-wired)

CNC (microprocessor)

1963

OSP

1971

OSP Numerical Control

(Okumas 1st)

LAP (lathe auto

programming for roughing)

Okuma began researching NC

machine tools in 1960, and

successfully developed an absolute

position detector during the

development of the OSP III. Use of

an absolute detection system that

does not lose the current position

even when the power is shut off is a

basic concept for the reliability of

Okuma CNCs that has been

continued to today.

With final shape inputs; rough

copying, round bar turning, and

grooving could be done

automatically. It drew

considerable attention for being

easy to use and effectively

shortening time requirements.

Nicknamed the Okuma cycle,

LAP was soon adapted in other

major NC systems throughout

the world.

1972

OSP2000

1981

OSP5000

OSP2000 CNC

OSP5000

The OSP2000 series was the worlds

first practical computerized NC

(CNC), equipped with a dedicated

NC minicomputer. Complex,

high-level machine control with

software was achieved using the

concept of advanced flexible

software. This was an NC that could

respond flexibly to changing needs.

The OSP5000 series were high

performance CNCs equipped with a

multiprocessor system. A multitask

function was standard, and tape

operation was stopped with the

standard specifications of tape

storage operation and manual data

input (MDI).

Fusion of machine &

control & Information

1981

1989

IGF (Interactive Graphic Function)L

One-Touch IGF (Complete process auto-decision programming)

An interactive graphic function

(IGF) was developed that

automatically created NC

programs when the operator

pushed keys according to

instructions on the screen. NCs

entered a new era with

revolutionary software that

enabled data input with human

and NC interaction.

The 10-year dream of having

the NC make completely

automated decisions for all

machining processes, cutting

conditions, and tools after input

of the material and machined

shapes was realized. Since

then versions have been

repeatedly upgraded, earning a

reputation among

inexperienced users as an NC

that is simple to operate and

among veterans as an NC that

reflects user know-how.

2004

OSP-P200

Collision Avoidance System

Fusion of machine &

control & Information &

Knowledge creation

2012

OSP-P300

OSP-P200

OSP-P300

This was the worlds first practical

open CNC to combine machine

control and PC technology.

User-friendly functions were added

with a large color liquid crystal

display and touch panel operation.

Machine Control and Windows

Collaboration:

Innovative new functions (Collision

Avoidance System, etc.) provided

only by Okuma with Single Source

for Machine & Control using

Okumas own NC software.

As a machine & control builder,

Okuma makes further strides in

machine tool manufacturing with

this superb control featuring "Easy

Operation." Okuma took a close

look at the way machinists actually

operate machine tools, to help them

create smoother and more effective

ways of producing parts. Novice

operators as well as professional

machinists get complete control

and satisfaction.

Pursuing the ideal CNC

The trajectory of OSP

OSPbringing further improvements to

accuracy, reliability, and operability based

on a user first philosophy

For OSP, the zero point is to

improve ease of use

When Okuma developed its own CNC as a machine tool

manufacturer in the 1960s, we were told that this was both

reckless and went against industry conventions. Incremental systems were the mainstream at the time, but Okuma

engineers confronted this challenge head on and developed

OSP with absolute position feedback, which could

accurately reproduce the tool position when a machine was

restarted. Customers were freed from bothersome zero

return operations, dramatically improving the

user-friendliness and reliability of CNCs.

This user-first philosophy and spirit of unflinchingly

taking on the challenges of an unknown technology have

been passed on to successive generations of Okuma

engineers, and the company has developed it own

hardware and software as well as core units such as

encoders and servo motors. In our pursuit of CNCs that let

customers enjoy the performance of Okuma machines to

the fullest, we have left a trail of innovation that has

rewritten the history of control technology.

NC Operation Panel

NC Panel Computer

Servo Drive Unit

DD Encoder

Abso Scale

Machining technology developed

with methods that cannot be

imitated by other companies

Absolute Position Encoder

High-level machining and simple operation with NC control. This was the ideal we were pursuing when the

Okuma cycle (lathe auto-programming; LAP) was

developed in 1971. Since that time, we have continued to

produce pioneering support technologies, such as practical

application of interactivity in which NC programs are

automatically created by pressing keys following screen

instructions.

More than anything else, it was the birth of One-Touch

IGF in 1989 that marked a major new epoch. This was a

revolutionary technology by which the NC determined the

machining process, cutting conditions, and tools

completely automatically based solely on input of the blank

shape and machined shape. Achieving this, however,

required analysis of procedures, tools, and cutting

conditions for each type of machining, design of algorithms,

and creation of programs. It was going to be an enormous

investment of time and work. Okuma therefore brought

veteran machining employees and the software

development team together in the same room to lay down a

Users Voice

Spindle PREX Motor

BL Servo Motor

system in which refined techniques would be visualized

with drawings and numerical values. Trial programs were

tested one at a time amid heated debate, and the nearly

overwhelming tasks of assessment and revision were gone

through repeatedly.

The One-Touch IGF that came into being in this way

greatly reduced the number of inputs and time. This

completely changed the image of CNCs that had prevailed

to that time, such as by enabling confirmation of tools up to

the cutting of blanks with the use of animation. The

completely automatic operation decision function that was

born from the development system of literal Single Source

for Machine & Control became a core Okuma technology,

and as it was expanded to other series and machine

models, and evolved to become Advanced One-Touch

IGF. Today OSP has a firmly established position as a

control that not only automatically creates NC programs but

also easily carries out machining preparations including

zero setting and tool compensation.

Looking at the evolution of successive

OSPs, you can see Okumas approach

of uncovering users hidden needs

and reflecting them in improved

performance and operability, as well

as their pride in their products.

Keiso Kogyo Co., Ltd.

Our employees high regard for OSP

comes from its user-centered design

concept and operability. This is

exemplified by the ease of use in

program editing and macro creation

and the ease with which parameter

changes can be understood.

Unicraft Nagura Corporation

In-house development of core

technologies that make it possible

to do what could not be done

problems are.

Issues that needed to be addressed included thermal

deformation of machines due to changing temperatures, the

occurrence of machining chatter, interference and collisions

due to operation errors, and tuning to obtain machining

accuracy. These things can cause production efficiency to

drop especially at sites where 5-axis machining with high

machining quality and complex machine movements is

done. It used to be that thermal deformation was viewed as

a machine characteristic and the search for cutting

conditions and collision prevention checks as operator

skill. These things were understood to be one part of the

technical proficiency and machining know-how of the

machine shop. At Okuma, however, we consider these

matters to belong to the technical field of machining

infrastructure (foundation) that we should provide to

customers, and it was our challenge to achieve ways to

deal with them as Only-One technologies.

Following the Thermo-Friendly Concept to control

thermal deformation developed in 2001, we introduced the

Collision Avoidance System to prevent interference and

collisions even when operation error occurs and Machining

Navi to visualize machining status and identify the optimum

cutting conditions without chatter. The 5-Axis Auto Tuning

System to automatically tune for geometric error in 5-axis

machining, in which achieving accuracy is difficult, and

dramatically raise the reliability of slope machining and

free-form machining was introduced in 2012.

These technologies have become synonymous with

Okuma as Intelligent Technology. When commanded to

do what people want to do, the NC makes decisions as if it

had intelligence of its own and carries out the optimum

machining together with the machine. This has been made

possible by the trinity of machine technology built up over

more than a century, electronic and electrical technology

refined over half a century, and control and information

technology that is finely meshed with the other two to the

highest degree. This is Okumas key technology to help

customers bring out the highest levels of accuracy and

productivity intrinsic to machine tools on their shop floors.

Okuma has a tradition of in-house development of whatever

is necessary if it does not already exist. Examples are

development of an optical AbsoScale, considered to be

essential for highly accurate position detection, invention of

a brushless motor that is maintenance-free, development

of a high-speed calculation board for dies/molds, being the

first to make NC turrets and ATCsthe list goes on and

on.

High-speed, high-accuracy machining of dies and molds

is based on technology that symbolizes the balance

between mechanics and control. High-speed, high-quality

machining of free-form surfaces requires that program

commands be faithfully reproduced, and that collaboration

with the machine be pursued to the utmost. Prime

examples are feed axis drive system bending

compensation, circular quadrant projection compensation,

high-speed contouring typified by Super-NURBS, and

CAD/CAM systems, all of which have reached the level of

practical application since the late 1980s. These

technologies have allowed us to provide customers the joy

doing what could not be done, and have received great

support in areas such as press die machining.

Improving machining infrastructure

so customers can make maximum

use of machine capacity

The daily life of Okuma developers differs from the image of

quietly carrying out research in an experimental laboratory.

New development themes are discovered not only from

handling technical inquiries that come from sales personnel,

but also from the three actuals (actual place, actual thing,

actual facts) in going to customer sites to see and hear

directly how they use their machines and what their

Collision Avoidance System

Machining Navi

Advanced One-Touch IGF

Custom Application Program Interface

M/E/I

M/E/I/K

5-Axis Auto Tuning System

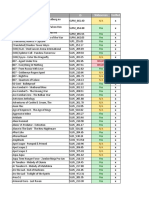

NC Basics

Servo Navi

M/E

DD encoder

Easy Operation

PREX motor

Thermal deformation compensation

(Thermo-Friendly Concept)

Hi-Cut Pro

Safety, Ecology, Energy-Saving

Super-NURBS

Safety, eco, energy-saving

As required for NC controls

NC basics

As required for NC controls

M/E

Innovations from

Mechanics/Electronics

M/E/I

Innovations from

Mechanics/Electronics/Information

tech

M/E/I/K

Innovations from

Mechanics/Electronics/IT/Knowledge

creation

Control with OSP enables program

editing and compensation tasks to be

done during machining, facilitating

work. We find the user task function to

be particularly useful, as it helps to

prevent repeat machining and reduce

unforeseen defects in axial grinding.

You can feel the user-oriented design

concept of OSP in the ease of

program editing and search and

implementation of the fixed cycle from

an early point. That user-oriented

approach is also seen in the speed

with which Okuma handles repairs

and troubles.

Chushin, Inc.

Koretsune Seiko, Ltd.

, OGUCHI-CHO, NIWA-GUN, AICHI 480-0193, JAPAN TEL (0587) 95-7825 FAX (0587) 95-6074

Pub No.OSP50-E-(1a)-400 (Nov 2013)

This product is subject to the

Japanese government Foreign

Exchange and Foreign Trade

Control Act with regard to security

controlled items; whereby Okuma

Corporation should be notified

prior to its shipment to another

country.

The miracle of OSP evolution

Total solutions that respond to a wide range of customer needs

50 years in pursuit of the ideal of Single Source for

Machine & Control

Machine, control, information,

and knowledge creation

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- AS400 RPG400 BasicsДокумент148 страницAS400 RPG400 Basicscharaviz84100% (1)

- 04pC Operations Manual PDFДокумент62 страницы04pC Operations Manual PDFGuillermo RamirezОценок пока нет

- 04pC Operations Manual PDFДокумент62 страницы04pC Operations Manual PDFGuillermo RamirezОценок пока нет

- 6000 Most Common Korean Words - For All TOPIK Levels PDFДокумент232 страницы6000 Most Common Korean Words - For All TOPIK Levels PDFZac67% (3)

- MCV 510 - 1250B Operation and Maintenance Manual V2 - 2 PDFДокумент346 страницMCV 510 - 1250B Operation and Maintenance Manual V2 - 2 PDFGuillermo Ramirez100% (4)

- MCV 510 - 1250B Operation and Maintenance Manual V2 - 2 PDFДокумент346 страницMCV 510 - 1250B Operation and Maintenance Manual V2 - 2 PDFGuillermo Ramirez100% (4)

- CNC Turning Center Programming ManualДокумент198 страницCNC Turning Center Programming Manualpagnic50% (2)

- CNC Turning Center Programming ManualДокумент198 страницCNC Turning Center Programming Manualpagnic50% (2)

- Manual Centro Mecanizado DoosanДокумент106 страницManual Centro Mecanizado DoosanFray Alonso Triana OlayaОценок пока нет

- Fanuc Oi PDFДокумент16 страницFanuc Oi PDFGuillermo Ramirez100% (1)

- A-65623EN Manual Setting of Parameters Related To FSSB - TMN11062E - 02 PDFДокумент15 страницA-65623EN Manual Setting of Parameters Related To FSSB - TMN11062E - 02 PDFGuillermo Ramirez100% (1)

- Contractor Hse Management ProgramДокумент12 страницContractor Hse Management ProgramAhmed IbrahimОценок пока нет

- EMCO WinNC For Sinumerik Operate Mill EN 1848 C 02 PDFДокумент486 страницEMCO WinNC For Sinumerik Operate Mill EN 1848 C 02 PDFGuillermo RamirezОценок пока нет

- Doosan Puma MX Series PDFДокумент68 страницDoosan Puma MX Series PDFGuillermo RamirezОценок пока нет

- 04 - Fanuc - PLC - EN PDFДокумент45 страниц04 - Fanuc - PLC - EN PDFGuillermo RamirezОценок пока нет

- MILACRON OPERATING MANUAL (Rexonavn - Com)Документ405 страницMILACRON OPERATING MANUAL (Rexonavn - Com)Cempeireng Iyalah100% (3)

- Welcome To Mastercam Mastercam CAD CAMДокумент40 страницWelcome To Mastercam Mastercam CAD CAMDao PhuОценок пока нет

- Blockchain Disruption in The Forex Trading MarketДокумент64 страницыBlockchain Disruption in The Forex Trading MarketVijayKhareОценок пока нет

- 1466054527911-SKF Tbu PDFДокумент175 страниц1466054527911-SKF Tbu PDFGuillermo RamirezОценок пока нет

- 1466054527911-SKF Tbu PDFДокумент175 страниц1466054527911-SKF Tbu PDFGuillermo RamirezОценок пока нет

- In - PUMA V400 Series (0409) PDFДокумент100 страницIn - PUMA V400 Series (0409) PDFGuillermo RamirezОценок пока нет

- A20 PDFДокумент8 страницA20 PDFGuillermo Ramirez100% (2)

- PEPS Referenciák PDFДокумент12 страницPEPS Referenciák PDFGuillermo RamirezОценок пока нет

- b087z Chucks Part1 PDFДокумент48 страницb087z Chucks Part1 PDFGuillermo RamirezОценок пока нет

- L Series Cincom L20-VIII: CNC Sliding Head LathesДокумент14 страницL Series Cincom L20-VIII: CNC Sliding Head LathesGuillermo RamirezОценок пока нет

- Smed International PaperДокумент60 страницSmed International PaperyulindaОценок пока нет

- Union e PDFДокумент33 страницыUnion e PDFGuillermo RamirezОценок пока нет

- Anilam 4200t CNC Programming and Operations ManualДокумент355 страницAnilam 4200t CNC Programming and Operations ManualAlexandru PrecupОценок пока нет

- Union e PDFДокумент33 страницыUnion e PDFGuillermo RamirezОценок пока нет

- 13 Fault Diagnosis and Maintenance For CNC Machine PDFДокумент5 страниц13 Fault Diagnosis and Maintenance For CNC Machine PDFGuillermo RamirezОценок пока нет

- Anilam 4200t CNC Programming and Operations ManualДокумент355 страницAnilam 4200t CNC Programming and Operations ManualAlexandru PrecupОценок пока нет

- 4143 CNC ProgrammingCH1 PDFДокумент34 страницы4143 CNC ProgrammingCH1 PDFGuillermo RamirezОценок пока нет

- SOL-Logarithm, Surds and IndicesДокумент12 страницSOL-Logarithm, Surds and Indicesdevli falduОценок пока нет

- 3-Storeyed 31-3-2015-Schedule PDFДокумент1 страница3-Storeyed 31-3-2015-Schedule PDFSi Thu AungОценок пока нет

- Animal Defenses TestДокумент3 страницыAnimal Defenses TestNermine MouallemОценок пока нет

- ZTE V4 RNC Commissioning and Integration TrainingДокумент2 страницыZTE V4 RNC Commissioning and Integration TrainingBeena SinghОценок пока нет

- 1.rle Rubrics For Case PresentationДокумент2 страницы1.rle Rubrics For Case PresentationKhristine EstosoОценок пока нет

- Pearson Letter To ParentsДокумент2 страницыPearson Letter To ParentsPatricia WillensОценок пока нет

- Makaut Grade Card Collection Notice 2018-19Документ1 страницаMakaut Grade Card Collection Notice 2018-19Sourav PandaОценок пока нет

- SCM 2011 PDFДокумент4 страницыSCM 2011 PDFAakash KumarОценок пока нет

- Effect of Liquidity Risk On Performance of Deposit Money Banks in NigeriaДокумент6 страницEffect of Liquidity Risk On Performance of Deposit Money Banks in NigeriaEditor IJTSRDОценок пока нет

- Examiners' Report Principal Examiner Feedback January 2018Документ7 страницExaminers' Report Principal Examiner Feedback January 2018WandaОценок пока нет

- WideScreen Code For PS2 GamesДокумент78 страницWideScreen Code For PS2 Gamesmarcus viniciusОценок пока нет

- TM 9-1425-429-12-HR - Stinger - Training - Set - 1983 PDFДокумент34 страницыTM 9-1425-429-12-HR - Stinger - Training - Set - 1983 PDFWurzel1946Оценок пока нет

- Individual Performance Commitment and Review Form (Ipcrf) : Annex EДокумент8 страницIndividual Performance Commitment and Review Form (Ipcrf) : Annex Emenzi magnoОценок пока нет

- Is There Any Way To Download The Whole Package of Asphalt 8 Airborne So That I Can Install It On Any Android Device Without An Internet Connection - QuoraДокумент4 страницыIs There Any Way To Download The Whole Package of Asphalt 8 Airborne So That I Can Install It On Any Android Device Without An Internet Connection - QuoraMounir2105Оценок пока нет

- Solution PDFДокумент20 страницSolution PDFVard FarrellОценок пока нет

- Research 9: Activity 4: Background of The StudyДокумент7 страницResearch 9: Activity 4: Background of The StudyPhilip AmelingОценок пока нет

- ENGLISH TOEFL Structure (3rd Exercise)Документ5 страницENGLISH TOEFL Structure (3rd Exercise)susannnnnnОценок пока нет

- Final FirstpartДокумент11 страницFinal FirstpartLance Johnpaul SyОценок пока нет

- Rule Based ClassificationsДокумент14 страницRule Based ClassificationsAmrusha NaallaОценок пока нет

- UnitPlan (P.E) Grade 6Документ13 страницUnitPlan (P.E) Grade 6Lou At CamellaОценок пока нет

- One Plan Student 1Документ7 страницOne Plan Student 1api-465826207Оценок пока нет

- Validation For A Login PageДокумент2 страницыValidation For A Login PageAmal RajОценок пока нет

- 12.07.20. O&M Manual 41013 - New PLCДокумент41 страница12.07.20. O&M Manual 41013 - New PLCFranco Sebastián GenreОценок пока нет

- Analisa AgriculturalДокумент6 страницAnalisa AgriculturalFEBRINA SARLINDA, STОценок пока нет

- Evs ManualДокумент24 страницыEvs ManualJoseph TuckerОценок пока нет

- SFN ProfileДокумент4 страницыSFN Profiledinesh panchalОценок пока нет