Академический Документы

Профессиональный Документы

Культура Документы

Remoulding Test Specimen

Загружено:

Dr Wong Kim YuenАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Remoulding Test Specimen

Загружено:

Dr Wong Kim YuenАвторское право:

Доступные форматы

SOILPRO TECHNICAL SERVICES SDN BHD

METHOD

STATEMENT

7/7/3

1.0

BS 1377: 1990 - British Standard Methods of test for Soils for

civil engineering purposes

BS1377: 1990, Part 1, Method 7.7 - Preparation of test specimens of

compacted soil, under Method 7.3 - Compaction criteria

Method 7.7.3(a) - Compactive effort or

Method 7.7.3(b) - Dry density.

Test Requirement

The degree of compaction to be applied to the soil and the method of forming the test specimens

shall be specified. Before testing, the test requirements for specific applications shall be

addressed as follows:

(a)

Size of test specimens;

(b)

Undisturbed specimens and orientation of undisturbed specimens relative to the plane of

shear;

(c)

Remoulded (re-constituted) specimens moisture content and density;

(d)

1.1

Normal shear pressures range (eg. , and 2) to be applied for each of 3 specimens;

Definitions

Sample

Surface and sub-surface soil extracted or sampled by customers.

Specimen

A portion of a sample on which a test is carried out.

Specimens batch

The portions of a sample prepared for a test. Each specimen is labeled

accordingly with a sequential number after the sample number and separator (-).

e.g. BS1-A, BS1-B and BS1-C.

Sample condition

The disturbed or undisturbed sample condition that is as received for the

specimen(s) tested as such and noted in the test report.

Disturbed sample/

specimens batching

For each disturbed sample, specimens batch is obtained by reconstituting

(remoulding) loose:

a) cohesive soil that is compacted into a square specimen mould (cutter) for

transfer to the shearbox or compacted directly into the shearbox.

b) cohesionless soil that is compacted directly into the shearbox.

1.2

Preparation of test specimens of compacted soils (remoulded)

This procedure is in accordance to BS1377: 1990, Part 1, Method 7.7.3 - Compaction criteria.

1.2.1

Compactive effort The soil is compacted at a specified moisture content into a mould under a

specified compactive effort. In other words, the achieved density is dependant on the standard effort and

predetermined moisture content. The compaction effort is equivalent to that of standard or modified

compaction methods in terms of hammer weight, number of layers, number of blows per layer and height

of hammer drop for a given volume. The specified moisture content can be from any of the following:

a) Insitu density or received density and natural moisture content

b) Optimum moisture content (OMC) from densities versus moisture content relationship

c) Percentage of moisture on the dry side of OMC (e.g. -2% of OMC)

d) Percentage of moisture on the wet side of OMC (e.g. +2% of OMC)

1.2.2

Dry density The soil is compacted at a specified moisture content into a mould to achieve a specified

dry density. In this procedure, the usual manual compactive effort by tamping and the number of blows

per layer shall be determined by trial. The specified dry density could be predetermined from the

densities versus moisture relationship graph, and the moisture content from any of the following:

a) Insitu density or received density and natural moisture content

b) Optimum moisture content (OMC)

c) Percentage of moisture on the dry side of OMC (e.g. -2% of OMC)

d) Percentage of moisture on the wet side of OMC (e.g. +2% of OMC)

Method Statement 7/7/3

1 of 2

SOILPRO TECHNICAL SERVICES SDN BHD

1.3

1.3.1

Normal stress requirement

Purpose

This procedure defines the process for the selection of the desired vertical (normal) stress, . The

relationship of between measured shear stress at failure and normal applied stress is obtained by

carrying out tests on a set of three similar specimens of the same sample under different pressures.

1.3.2

Stress range

For normally consolidated soil, normal stress of v, v and 2v might be appropriate to cover the range

of vertical stress likely to be experienced by the soil insitu.

For soft soil, normal stress of v, v and 1v might be considered.

1.4

Effective vertical stress

Effective vertical stress due to self-weight of soil is obtained by:

'v

= v u

where,

= (sat - w) x z

= ' x z

= sat x z

= w x z

sat

w

1.5

= saturated unit

= water unit weight, 9.81

= depth

'

= buoyant unit weight of the soil

Total vertical (normal) stress

In the absence of data on ground water level or reliable water table, the in-situ pore water pressure, u is

often not taken into consideration.

Therefore, total vertical (normal) stress, v = sat x z

Example

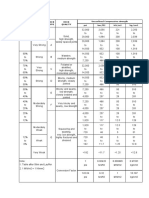

Specimen size: 60 x 60 mm x 20 mm height ( volume = 72 cm 3 )

at depth 3.0 metres, with a wet weight of 135 gm

Bulk density, =

Mass

Volume

135

72

1.875 Mg/m3

Unit weight of soil in kN/m3

is obtained by:

sat =

=

=

where,

g = acceleration due to gravity = 9.81m/sec2

1.875 x 9.81

18.39 kN/m3

Total vertical (normal) stress, v

= sat x z

= 18.39 kN/m3 x 3.0 m

= 55.17 kN/m2

Use v = 60 kN/m2

Therefore the stress range for v, v and 2v is 30, 60 and 120 kN/m2

NOTE:

Selection of stress range might be subjected to the following:

1. Engineer's design requirement for specified stress.

2. For normal slopes, a stress range of 50, 100 and 200 kN/m2 is usually appropriate.

1.6

Example Procedure for specified density to Method 7.7.3(b) - Dry density

Size of test specimen: Diameter 50mm x 100mm height (Ratio-1:2)

Received density or 90% to 95% of dry density as compared to received density

Natural moisture content

Metal Split-mould of test specimen size with collar end and cutter end to hold mould in place

Suitable tampling rod (Diameter 10mm by 200mm length)

Number of compaction layers - 5

Number of blows per layer - 30

[A procedure by trial(s) is done to determine the number of blows for the operator's compactive

effort by tamping to achieve a specified density consistently for the required number of test

specimens]. Note: In the trials, the number of blows per layer shall be changed accordingly

where required.

Method Statement 7/7/3

2 of 2

Вам также может понравиться

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportОт EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportОценок пока нет

- Remoulding Test Specimen MethodДокумент2 страницыRemoulding Test Specimen MethodDr Wong Kim YuenОценок пока нет

- Soilpro Technical Services SDN BHD # Method Statement BS 1377: 1990 - British Standard Methods of Test For Soils For Civil Engineering PurposesДокумент2 страницыSoilpro Technical Services SDN BHD # Method Statement BS 1377: 1990 - British Standard Methods of Test For Soils For Civil Engineering PurposesDr Wong Kim YuenОценок пока нет

- Reservoir Engineering in Modern Oilfields: Vertical, Deviated, Horizontal and Multilateral Well SystemsОт EverandReservoir Engineering in Modern Oilfields: Vertical, Deviated, Horizontal and Multilateral Well SystemsОценок пока нет

- Soil Tests-Brief Method StatementДокумент7 страницSoil Tests-Brief Method StatementDr Wong Kim YuenОценок пока нет

- Exp 7 CompactionTestДокумент9 страницExp 7 CompactionTestKelvin NgugiОценок пока нет

- Laboratory Soil Tests MethodДокумент6 страницLaboratory Soil Tests MethodDr Wong Kim YuenОценок пока нет

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsОт EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechОценок пока нет

- Lecture 02 PDFДокумент51 страницаLecture 02 PDFحسامОценок пока нет

- 3 Compaction - S21Документ3 страницы3 Compaction - S21hassanОценок пока нет

- Astm D 5333 - 03Документ4 страницыAstm D 5333 - 03Manuel100% (1)

- The Fabrication of Materials: Materials TechnologyОт EverandThe Fabrication of Materials: Materials TechnologyРейтинг: 5 из 5 звезд5/5 (1)

- Frost Park 2003Документ14 страницFrost Park 2003akshayОценок пока нет

- Unconfined Compression Test (UC TestДокумент15 страницUnconfined Compression Test (UC TestTeo Peng Keat79% (14)

- Soil CompactionДокумент18 страницSoil CompactionLiza SyafitriОценок пока нет

- Consolidation TestДокумент6 страницConsolidation TestManish AryaОценок пока нет

- VL2021220102506 Ast09Документ6 страницVL2021220102506 Ast09ty juОценок пока нет

- Notes 1 - Soil CompactionДокумент50 страницNotes 1 - Soil CompactionTang Ching Pang100% (1)

- Compaction Oct2010Документ23 страницыCompaction Oct2010Akshthagowda848_1952Оценок пока нет

- 191-47-234 Geo-7Документ7 страниц191-47-234 Geo-7Tanvir Rajib 191-47-234Оценок пока нет

- Astm D4254 PDFДокумент9 страницAstm D4254 PDFRuddy EspejoОценок пока нет

- Astm D 1558-99 - AtençãoДокумент3 страницыAstm D 1558-99 - Atençãomarco.valentimОценок пока нет

- Analysis of Soil Compaction Using Proctor StandardДокумент7 страницAnalysis of Soil Compaction Using Proctor StandardحسامОценок пока нет

- Geotechnical Laboratory TestsДокумент18 страницGeotechnical Laboratory TestsDavid HongОценок пока нет

- Density determination procedure for disturbed soil samplesДокумент1 страницаDensity determination procedure for disturbed soil samplesDr Wong Kim YuenОценок пока нет

- Rapid Determination of Percent Compaction: Standard Test Method ForДокумент8 страницRapid Determination of Percent Compaction: Standard Test Method ForjjaavenidoОценок пока нет

- Chapter 4 (Week 11) - DrRAДокумент38 страницChapter 4 (Week 11) - DrRAMUHAMMAD ZUHAIR NORAZLIОценок пока нет

- Chapter 4Документ93 страницыChapter 4naqibkamarozamanОценок пока нет

- FE Lec 3Документ13 страницFE Lec 3Paul Justin MangatОценок пока нет

- CE3410 EXP7 PartA 2023 Manual VFДокумент8 страницCE3410 EXP7 PartA 2023 Manual VFAddandi AshrithОценок пока нет

- Soil Compaction & ConsistencyДокумент35 страницSoil Compaction & ConsistencyShekh Muhsen Uddin AhmedОценок пока нет

- Lab Manual For Soil TestingДокумент60 страницLab Manual For Soil TestingVM2009100% (2)

- Soil Lab. ManualДокумент32 страницыSoil Lab. Manualishaq kazeemОценок пока нет

- Field Density TestДокумент11 страницField Density TestNimish Madanan100% (1)

- CompactionДокумент3 страницыCompactionスルタンリスクОценок пока нет

- CBR TEST PARAMETERSДокумент13 страницCBR TEST PARAMETERSsmart.engineerОценок пока нет

- Astm D1558Документ3 страницыAstm D1558johan lopez100% (1)

- Determination of Maximum Dry Unit Weight and Water Content Range For Effective Compaction of Granular Soils Using A Vibrating HammerДокумент11 страницDetermination of Maximum Dry Unit Weight and Water Content Range For Effective Compaction of Granular Soils Using A Vibrating HammerJesús Luis Arce Guillermo50% (2)

- ASTM StandardsДокумент4 страницыASTM StandardsRandel Boris de Ocampo100% (1)

- CONSOLIDATION TEST PARAMETERSДокумент3 страницыCONSOLIDATION TEST PARAMETERSAnuradha GunawardhanaОценок пока нет

- Direct Shear TestДокумент13 страницDirect Shear Testskyxiaochen0% (2)

- TNZ T23_Estimation of the Density of Compacted Aggregate Layers by Direct TransmissionДокумент4 страницыTNZ T23_Estimation of the Density of Compacted Aggregate Layers by Direct Transmissiondan.cumingОценок пока нет

- Astm D5333Документ3 страницыAstm D5333dghadiaОценок пока нет

- Astm d4254Документ9 страницAstm d4254setiajirОценок пока нет

- Job # 8: Consolidation Test - (Oedometer Test) : TheoryДокумент6 страницJob # 8: Consolidation Test - (Oedometer Test) : Theorysimply greenОценок пока нет

- Determination of In-Situ Density by Core Cutter Method: Experiment No 5 DATEДокумент5 страницDetermination of In-Situ Density by Core Cutter Method: Experiment No 5 DATE11520035100% (1)

- Lab Manual For Soil TestingДокумент58 страницLab Manual For Soil TestingSanjay MuthekarОценок пока нет

- AGTE-1 Degrevised2Документ51 страницаAGTE-1 Degrevised2Vaishali PawarОценок пока нет

- D 6758 - 02 - Rdy3ntgДокумент5 страницD 6758 - 02 - Rdy3ntgAntonio Harry PonceОценок пока нет

- CE 3A03 - Geotechnical Engineering I: Lab Instructions Lab 1: Compaction Test 1. ObjectiveДокумент4 страницыCE 3A03 - Geotechnical Engineering I: Lab Instructions Lab 1: Compaction Test 1. ObjectivefostbarrОценок пока нет

- Part 1 Introduction To Triaxial TestingДокумент4 страницыPart 1 Introduction To Triaxial TestingFernando CachúОценок пока нет

- Direct Shear TestДокумент11 страницDirect Shear Testshahrolhazrien91% (34)

- Concrete Mix Design, Is StandardДокумент12 страницConcrete Mix Design, Is StandardKumaresvaranОценок пока нет

- Test 5: Compaction (Moisture-Density Relationship) TestДокумент8 страницTest 5: Compaction (Moisture-Density Relationship) TestazizОценок пока нет

- SpeedyMoistureTester InstructionДокумент9 страницSpeedyMoistureTester InstructionDr Wong Kim YuenОценок пока нет

- Remoulding Test SpecimenДокумент2 страницыRemoulding Test SpecimenDr Wong Kim YuenОценок пока нет

- Density determination procedure for disturbed soil samplesДокумент1 страницаDensity determination procedure for disturbed soil samplesDr Wong Kim YuenОценок пока нет

- MS28-1985 - Water For ConcretingДокумент2 страницыMS28-1985 - Water For ConcretingDr Wong Kim Yuen100% (1)

- Soil testing methods guideДокумент2 страницыSoil testing methods guideDr Wong Kim YuenОценок пока нет

- MethodStatement CUTriaxial SaturationДокумент2 страницыMethodStatement CUTriaxial SaturationDr Wong Kim YuenОценок пока нет

- C 0) C' and ' C' and ' C' ' C C' Effective Undrained Cohesion C' Undrained Angle of Friction ' Effective Undrained Angle of Friction 'Документ6 страницC 0) C' and ' C' and ' C' ' C C' Effective Undrained Cohesion C' Undrained Angle of Friction ' Effective Undrained Angle of Friction 'Dr Wong Kim YuenОценок пока нет

- Mackintosh ProbeДокумент2 страницыMackintosh ProbeDr Wong Kim Yuen100% (4)

- Rock StrengthДокумент1 страницаRock StrengthDr Wong Kim YuenОценок пока нет

- Consolidation StressДокумент3 страницыConsolidation StressDr Wong Kim YuenОценок пока нет

- Dynamic Probing Devices ComparisonДокумент1 страницаDynamic Probing Devices ComparisonDr Wong Kim YuenОценок пока нет

- Emersion ClassДокумент3 страницыEmersion ClassDr Wong Kim YuenОценок пока нет

- Field Density MethodДокумент1 страницаField Density MethodDr Wong Kim YuenОценок пока нет

- Saturation For Triaxial TestsДокумент1 страницаSaturation For Triaxial TestsDr Wong Kim YuenОценок пока нет

- Z Z Z U Z: Example: Dia. 72mm X 144mm Length Sample (Volume 586.29 CMДокумент1 страницаZ Z Z U Z: Example: Dia. 72mm X 144mm Length Sample (Volume 586.29 CMDr Wong Kim YuenОценок пока нет

- ReboundHammer FDTmethodsДокумент4 страницыReboundHammer FDTmethodsDr Wong Kim YuenОценок пока нет

- Constant Head PermeabilityДокумент1 страницаConstant Head PermeabilityDr Wong Kim YuenОценок пока нет

- Rebound Hammer Method PDFДокумент1 страницаRebound Hammer Method PDFDr Wong Kim YuenОценок пока нет

- Shearbox Test Assembly DiagramДокумент1 страницаShearbox Test Assembly DiagramDr Wong Kim YuenОценок пока нет

- BS Sieve Analysis Methods for Soil and Aggregate ParticlesДокумент1 страницаBS Sieve Analysis Methods for Soil and Aggregate ParticlesDr Wong Kim YuenОценок пока нет

- Point Load Lump MethodДокумент1 страницаPoint Load Lump MethodDr Wong Kim YuenОценок пока нет

- BS Sieve Analysis Methods for Soil and Aggregate ParticlesДокумент1 страницаBS Sieve Analysis Methods for Soil and Aggregate ParticlesDr Wong Kim YuenОценок пока нет

- Standard Compaction Method 4.3.3Документ1 страницаStandard Compaction Method 4.3.3Dr Wong Kim YuenОценок пока нет

- Shearbox Test Assembly DiagramДокумент1 страницаShearbox Test Assembly DiagramDr Wong Kim YuenОценок пока нет

- Collapse Potential ASTMD5333Документ1 страницаCollapse Potential ASTMD5333Dr Wong Kim YuenОценок пока нет

- Osram 2010 Luminare CatalogДокумент180 страницOsram 2010 Luminare CatalogLenzy Andre FamelaОценок пока нет

- Windows Anzure GuiaДокумент478 страницWindows Anzure GuiaGuillermo Luna Angeles100% (2)

- M2LT Project Manual & SpecificationsДокумент418 страницM2LT Project Manual & SpecificationsfastreturnОценок пока нет

- Assignment of Information Technology of MbaДокумент11 страницAssignment of Information Technology of MbaMohit Bhardwaj0% (1)

- Arch Required FlowchartДокумент1 страницаArch Required FlowchartgullipalliОценок пока нет

- Urban Planning With GisДокумент9 страницUrban Planning With GisMostaque AhmedОценок пока нет

- Family Entertainment CentersДокумент4 страницыFamily Entertainment CentersAnusha PalakurthyОценок пока нет

- D9 MG GensetДокумент4 страницыD9 MG GensetAji HandokoОценок пока нет

- Charger WIND POWER PDFДокумент17 страницCharger WIND POWER PDFHassan TalhaОценок пока нет

- AVS Sevice Desk and Desk Side Support SOOДокумент28 страницAVS Sevice Desk and Desk Side Support SOOCuong Duong DinhОценок пока нет

- CRM TemplateДокумент17 страницCRM TemplateAli MohamedОценок пока нет

- Strategic Management g9 Elon Musk BetsДокумент5 страницStrategic Management g9 Elon Musk BetsJaya Neelanshi SethОценок пока нет

- Internship - BajajДокумент27 страницInternship - BajajRoyal ProjectsОценок пока нет

- TFG A 020Документ81 страницаTFG A 020Sergio FontechaОценок пока нет

- Logistics Section 01 IntroductionДокумент40 страницLogistics Section 01 IntroductionNgọc Nhung Vũ100% (2)

- Tda8359 PDFДокумент20 страницTda8359 PDFsiliboyОценок пока нет

- MBA 6011 Partial Mod 19 2013Документ11 страницMBA 6011 Partial Mod 19 2013sumithaps66469Оценок пока нет

- Euskron Profile ENGДокумент14 страницEuskron Profile ENGEuskron Cutting ToolsОценок пока нет

- Industrial Apron FeedersДокумент5 страницIndustrial Apron FeederstonyОценок пока нет

- Hero Honda Motorcycle ProjectДокумент93 страницыHero Honda Motorcycle ProjectSharath HegdeОценок пока нет

- An Integrated Lean Approach To Process Failure ModДокумент12 страницAn Integrated Lean Approach To Process Failure ModLeoo Cotrina FranciaОценок пока нет

- 4l80e Teardown Rebuild and InstallationДокумент146 страниц4l80e Teardown Rebuild and Installationobx4ever50% (2)

- Embedded Linux SlidesДокумент540 страницEmbedded Linux SlidesIngeniero JesusОценок пока нет

- MachinaДокумент14 страницMachinaHSY79Оценок пока нет

- Tugas Enterprise Resource Planning: Kelas AДокумент4 страницыTugas Enterprise Resource Planning: Kelas ARizka HadiwiyantiОценок пока нет

- IBIS Hotel Key Design and Construction CriteriaДокумент2 страницыIBIS Hotel Key Design and Construction Criteriachien100% (1)

- How To Create Simple CDC in Oracle ODI 11GДокумент10 страницHow To Create Simple CDC in Oracle ODI 11GAlina MamayevОценок пока нет

- TechTopics58 - E-Rated Vs R Rated FusesДокумент2 страницыTechTopics58 - E-Rated Vs R Rated FusesBigBaby JulianОценок пока нет

- FactoryTalk® Batch Software SuiteДокумент8 страницFactoryTalk® Batch Software SuiteVÕ QUỐC HIỆUОценок пока нет

- 4.7 Conveyor Belt Operating ProcedureДокумент3 страницы4.7 Conveyor Belt Operating Procedurejohnson OlubiОценок пока нет

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОт EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОценок пока нет

- Industrial Piping and Equipment Estimating ManualОт EverandIndustrial Piping and Equipment Estimating ManualРейтинг: 5 из 5 звезд5/5 (7)

- Guidelines for Siting and Layout of FacilitiesОт EverandGuidelines for Siting and Layout of FacilitiesОценок пока нет

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksОт EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksРейтинг: 5 из 5 звезд5/5 (1)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationОт EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationОценок пока нет

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationОт EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationРейтинг: 4 из 5 звезд4/5 (18)

- Nuclear Energy in the 21st Century: World Nuclear University PressОт EverandNuclear Energy in the 21st Century: World Nuclear University PressРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Asset Integrity Management for Offshore and Onshore StructuresОт EverandAsset Integrity Management for Offshore and Onshore StructuresОценок пока нет

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentОт EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentОценок пока нет

- Guidelines for Chemical Process Quantitative Risk AnalysisОт EverandGuidelines for Chemical Process Quantitative Risk AnalysisРейтинг: 5 из 5 звезд5/5 (1)

- Pocket Guide to Flanges, Fittings, and Piping DataОт EverandPocket Guide to Flanges, Fittings, and Piping DataРейтинг: 3.5 из 5 звезд3.5/5 (22)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideОт EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideРейтинг: 2 из 5 звезд2/5 (1)

- An Applied Guide to Water and Effluent Treatment Plant DesignОт EverandAn Applied Guide to Water and Effluent Treatment Plant DesignРейтинг: 5 из 5 звезд5/5 (4)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesОт EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertРейтинг: 3 из 5 звезд3/5 (2)

- Well Control for Completions and InterventionsОт EverandWell Control for Completions and InterventionsРейтинг: 4 из 5 звезд4/5 (10)

- Guidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisОт EverandGuidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisОценок пока нет

- Guidelines for Engineering Design for Process SafetyОт EverandGuidelines for Engineering Design for Process SafetyОценок пока нет

- Guidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsОт EverandGuidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsОценок пока нет

- Pipeline Integrity: Management and Risk EvaluationОт EverandPipeline Integrity: Management and Risk EvaluationРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionОт EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionРейтинг: 4.5 из 5 звезд4.5/5 (16)

- Robotics: Designing the Mechanisms for Automated MachineryОт EverandRobotics: Designing the Mechanisms for Automated MachineryРейтинг: 4.5 из 5 звезд4.5/5 (8)

- Guidelines for the Management of Change for Process SafetyОт EverandGuidelines for the Management of Change for Process SafetyОценок пока нет

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesОт EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesОценок пока нет